Biogas plant diagram for a home with your own hands. Do-it-yourself biogas plant for gasification of the house. Schemes of self-made biogas plants

A do-it-yourself biogas plant can be done without much effort. Its use will significantly save on energy resources, which today are becoming more and more expensive each time. If you decide on your own to build equipment that allows you to get biogas from waste, you can consume cheap energy that will be used for heating your home and other needs.

Beneficial use

If, during the operation of the plant, surpluses of biogas or fertilizers are formed, then there is an opportunity to sell them at a market price, thereby turning what is literally under your feet into profit. If you are a large farmer, then you have the opportunity to purchase a ready-made biogas station. Such installations, produced in the factory, are very expensive, but they have a long lifespan.

A do-it-yourself biogas plant can be made from improvised materials, it will not cost very much, and such equipment will work on the same principle. In this case, you can use the available tools, as well as the details available in the arsenal of the master.

The principle of biogas formation

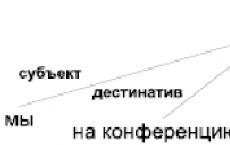

If you set out to make an installation that will run on biogas, then you need to present the technology for generating biogas. So, in a special container, which is called a bioreactor, the process of processing biological mass is carried out, anaerobic bacteria take part in this.

A do-it-yourself biogas plant for a house on quail manure works on the principle of creating conditions that are characterized by the absence of air and fermentation. All this lasts for some time, the duration of which depends on the amount of raw materials used in the process.

Ultimately, a mixture of gases is formed, which contains 60% methane and 35% carbon dioxide. The remaining gaseous components are contained in the mass in an amount of 5%. Among the latter, hydrogen sulfide can be distinguished in a small amount. The gas formed in this way is continuously withdrawn from the reactor, and after it undergoes a purification process, it enters the intended use.

Service features

Waste that has undergone processing becomes high-quality fertilizers, which must be removed from the bioreactor from time to time. They can be laid on the fields. A do-it-yourself biogas plant can be done without much effort if you have access to livestock and agricultural businesses. This indicates that biogas production will only become economically viable if there is a source of manure and other organic waste from livestock production.

Features of self-construction of a bioreactor

In order to understand how to make a biogas plant on your own, you need to figure out what parts it consists of. You can take as a basis the simplest scheme of equipment that can be built on your own. The design does not provide for heating and mixing, but there is one of the main parts - the reactor, which is also known as a methane tank. This component is required for the implementation of manure processing. In addition, there is a bunker through which raw materials are loaded. It is necessary to provide the structure with an entrance hatch, as well as a water seal. But in order to be able to unload the waste raw materials, a pipe will be needed. A similar element will be required in order to realize the possibility of removing biogas.

This is what a biogas plant looks like. It is not difficult to make such a design with your own hands. In order to receive free biofuel, you should choose a place on the site where you can build a reinforced tank, which will be based on concrete. This vessel will act as a bioreactor. At its base, it is necessary to provide for the presence of a hole through which raw materials that have been worked out will be removed. This hole must be made in such a way that it is possible to close it well. This is due to the fact that the functioning of the system is possible only in sealed conditions.

The dimensions of the concrete compartment can be determined taking into account the amount of organic waste used at a time. It is necessary to find out how much raw material will appear every day in a farm or a private courtyard. But you should not save money, since it will be possible to ensure the full operation of the bioreactor only if the tank is filled to 2/3 of the available volume. If you make a biogas plant with your own hands from a barrel, then it will work according to the following principle: as soon as organic waste enters the well-closed capacity of the bioreactor, which is located at a depth in the soil, they begin to ferment, which leads to the release of biogas.

Features of the manufacture of containers

A do-it-yourself biogas plant can be made taking into account the daily use of a small amount of waste. In this case, it is permissible to replace the reinforced concrete tank with a steel container, which can even be a barrel. If you decide to resort to just such a solution, then it is necessary to choose a metal vessel, guided by some rules.

First of all, you need to pay attention to the welds, which must be strong enough and tight. When using a small container, you should not count on the fact that it will be possible to obtain a significant amount of biogas. The output will depend on the mass of organic waste that is simultaneously processed in the reactor. Thus, in order to form 100 m 3 of biogas, it is necessary to process a ton of waste.

Reactor heating equipment

A do-it-yourself biogas plant for the home can be made in such a way that during its operation it will be possible to obtain greater efficiency. This is provided by heating. Such manipulations will speed up the process of fermentation of the biological mass. If the equipment is installed in the southern regions, then this need does not arise. The ambient temperature provides a natural activation of fermentation. However, if the plant operates in regions with a cold climate, then in winter, heating acts as a necessary condition for the operation of biogas production equipment. It must be remembered that the fermentation process begins at a temperature that exceeds 38 ° C.

Methods for equipping a biogas plant with heating

A do-it-yourself biogas plant for the home can be equipped with heating in several ways. The first involves the need to connect the unit to the heating system as a coil. It must be mounted under the reactor. The second method involves the installation of an electric heating element in the base of the tank. The third method is characterized by the provision of direct heating of the tank by using electric heating systems. gas equipment. The activation of the production of biological gas at home can be supplemented by the function of mixing the mass in the compartment. To do this, design a device that resembles a household mixer. It will be driven by a shaft through a hole in the lid, alternatively it can be placed in the walls of the tank.

Installation equipment output system

A do-it-yourself mini-biogas plant cannot work without a gas exhaust system. To do this, the installation must have a special hole that must be mounted in the upper part of the cover, the latter must close the tank well. To exclude the possibility of mixing gas with air, it is necessary to ensure its removal through the hydraulic seal.

Required required materials:

- two containers;

- connecting pipes;

- valves;

- gas filter;

- means of ensuring tightness (glue, resin, sealant, etc.);

Desirable:

- stirrer with electric motor;

- temperature sensor;

- pressure meter;

The following sequence is suitable for the southern regions. For performance in any conditions, it is necessary to add a reactor heating system, which will provide heating of the vessel to 40 degrees Celsius and increase thermal insulation, for example, enclose the structure with a greenhouse. It is desirable to cover the greenhouse with a black film. It is also desirable to add a condensate outlet to the pipeline.

Building a simple biogas plant:

- Create a storage tank. We select a tank where the resulting biogas will be stored. The tank is fixed with a valve and equipped with a pressure gauge. If gas consumption is constant, then there is no need for a gas tank.

- Insulate the structure inside the pit.

- Install pipes. Lay pipes in the pit for loading raw materials and unloading compost humus. An inlet and an outlet are made in the reactor vessel. The reactor is placed in a pit. Pipes are connected to the holes. The pipes are tightly fixed with glue or other suitable means. Pipe diameters less than 30 cm will contribute to clogging. The loading place should be chosen on the sunny side.

- Install sunroof. The rector, equipped with a hatch, makes repair and maintenance work more convenient. The hatch and the reactor vessel should be glued with rubber. Temperature, pressure and raw material level sensors can also be installed.

- Choose a container for the bioreactor. The selected container must be durable - since a large amount of energy is released during fermentation; have good thermal insulation; be air and waterproof. Egg-shaped vessels are best suited. If it is problematic to build such a reactor, then a cylindrical vessel with rounded edges would be a good alternative. Square-shaped containers are less efficient because hardened biomass will accumulate in the corners, making fermentation difficult.

- Prepare a pit.

- Choose a place for mounting the future installation. It is advisable to choose a place far enough from the house and so that you can dig a hole. Placement inside the pit allows you to significantly save on thermal insulation, using cheap materials like clay for this.

- Check the tightness of the resulting structure.

- Start system.

- Add raw materials. We are waiting for about two weeks until all the necessary processes take place. A necessary condition for gas combustion is to get rid of carbon dioxide. For this, a regular filter from a hardware store is suitable. A homemade filter is made from a 30 cm long piece of gas pipe filled with dry wood and metal shavings.

Composition and types

Biogas is a gas obtained as a result of a three-phase biochemical process over biomass, taking place under sealed conditions.

The process of biomass decomposition is sequential: first it is exposed to hydrolytic bacteria, then acid-forming and finally methane-forming. The material for microorganisms at each stage is the product of the activity of the previous stage.

At the output, the approximate composition of biogas looks like this:

- methane (from 50 to 70%);

- carbon dioxide (from 30 to 40%);

- hydrogen sulfide (~2%);

- hydrogen (~1%);

- ammonia (~1%);

The accuracy of the proportions is affected by the raw materials used and the gas production technology. Methane has the potential for combustion, the higher its percentage, the better.

Ancient cultures dating back more than three thousand years (India, Persia or Assyria) have experience in the use of combustible swamp gas. The scientific justification was formed much later. The chemical formula of methane CH 4 was discovered by the scientist John Dalton, the occurrence of methane in the swamp gas was discovered by Humphrey Davy. A major role in the development of the alternative energy industry was played by the Second World War, which requires the warring parties to have a huge need for energy resources.

The USSR's possession of vast reserves of oil and natural gas led to the lack of demand for other technologies for generating energy, the study of biogas was mainly the subject of interest of academic science. At the moment, the situation has changed so much that, in addition to the industrial production of various types of fuel, any person can create a biogas plant for their own purposes.

Installation device

Installation device - a set of equipment designed to produce biogas from organic raw materials.

According to the type of raw material supply, the following types of biogas plants are distinguished:

- with portion feed;

- with continuous supply;

Biogas plants with a constant supply of raw materials are more efficient.

By type of processing of raw materials:

- Without automatic mixing raw materials and maintaining the required temperature - complexes with a minimum configuration, suitable for small farms (scheme 1).

- With automatic mixing, but without maintaining the required temperature - also serves small farms, more efficiently than the previous type.

- Maintaining the desired temperature, but without automatic mixing.

- With automatic mixing of raw materials and temperature support.

Principle of operation

The process of converting organic raw materials into biogas is called fermentation. The feedstock is loaded into a special container that provides reliable protection of biomass from oxygen access. An event that occurs without the intervention of oxygen is called anaerobic.

Under the influence of special bacteria in an anaerobic environment, fermentation begins to occur. As fermentation develops, the raw material becomes covered with a crust, which must be regularly destroyed. Destruction is done by thorough mixing.

Stirring the contents is required at least twice a day, without violating the tightness of the process. In addition to removing the crust, stirring allows you to evenly distribute the acidity and temperature within the organic mass. As a result of these manipulations, biogas is produced.

The resulting gas is collected in a gas tank, from there it is delivered to the consumer through pipes. Biofertilizers obtained after the processing of raw materials can be used as a food supplement for animals or added to the soil. This fertilizer is called compost humus.

The biogas plant includes the following elements:

- homogenization tank;

- reactor;

- agitators;

- storage tank (gas-holder);

- heating and water mixing complex;

- gas complex;

- complex of pumps;

- separator;

- control sensors;

- I&C with visualization;

- safety system;

An example of an industrial type biogas plant is shown in Scheme 2.

Raw materials used

The decomposition of any animal or plant residues releases flammable gas to varying degrees. Mixtures of various compositions are well suited for raw materials: manure, straw, grass, various waste, etc. The chemical reaction requires a humidity of 70%, so the raw material must be diluted with water.

The decomposition of any animal or plant residues releases flammable gas to varying degrees. Mixtures of various compositions are well suited for raw materials: manure, straw, grass, various waste, etc. The chemical reaction requires a humidity of 70%, so the raw material must be diluted with water.

The presence of cleaning agents, chlorine, washing powders in organic biomass is unacceptable, as they interfere with chemical reactions and can damage the reactor. Also not suitable for the reactor is raw material with sawdust from coniferous trees (containing resins), with a high proportion of lignin and exceeding the moisture threshold of 94%.

Vegetable. Vegetable raw materials are excellent for biogas production. Fresh grass gives the maximum fuel yield - about 250 m 3 of gas with a methane share of 70% is obtained from a ton of raw materials. Corn silage is slightly smaller - 220 m 3 . Tops from beets - 180 m 3.

Almost any plant, hay or algae can be used as biomass. The disadvantage of the application lies in the duration of the production cycle. The biogas production process takes up to two months. The raw material must be finely ground.

Animal. Waste from processing, dairy, slaughterhouses, etc. suitable for biogas plant. Animal fats give the maximum fuel yield - 1500 m 3 of biogas with a methane share of 87%. The main drawback is scarcity. Animal raw materials must also be crushed.

Excrement. The main advantage of manure is its low cost and easy accessibility. The disadvantage is that the quantity and quality of biogas is lower than from other types of raw materials. Horse and cow dung can be recycled immediately. The production run will take approximately two weeks and will yield a 60 m 3 output with 60% methane content.

Chicken manure and pig manure cannot be used directly because they are toxic. To start the fermentation process, they must be mixed with silage. A human waste product can also be used, but sewage will not work, as the feces content is low.

Work schemes

Scheme 1 - biogas plant without automatic mixing of raw materials:

Scheme 2 - biogas plant of industrial type:

Obtaining biogas (methane) is important for owners of livestock and poultry farms. On farms with poultry and large livestock, the issue of waste disposal is always acute. In order to get rid of litter and manure, it is necessary to take care of the collection, removal, disinfection and processing. All these procedures require certain material costs, time and effort.

In order for the process of manure utilization to begin to bring profit, and not losses, it is advisable to think about processing manure into biogas. Domestic biogas from bird and animal droppings is 50-80% methane. This is the same gas that burns in boilers, stoves and is used for cars. Methane is emitted from manure randomly, on its own. If left to rot in the sun for a year, the manure will ferment and release biogas. You only need to optimize this process to increase the amount of methane produced and speed up the production time.

To increase the efficiency of biogas production, it is necessary to accelerate the process of decomposition and fermentation of raw materials. To do this, you need to create the most favorable conditions for the reproduction of the necessary bacteria. To do this, you will need to place manure in a special container - a reactor. At the same time, the container must be closed - in such conditions, bacteria will multiply more actively. Already in the reactor, the manure is crushed, and then mixed with water. Water must be clean. Otherwise, foreign microbes will get into the substrate, which can slow down the fermentation process.

In industrial conditions, it is equipped with a reactor heating system, an acidity controller and special blades for mixing the substrate. Stirring manure allows you to get rid of the formation of a hard crust, which blocks the flow of oxygen from the outside and the exit of methane from the inside. The term for obtaining methane in industrial conditions is at least fifteen days. During this time, manure can decompose up to 25%. The maximum outflow of methane occurs at a degree of decomposition of 33%.

It should be noted that rotten sludge forms on the bottom of the reactor. It is removed using a special tube, which takes it to a separate tank for sludge. Subsequently, the sludge is cleaned and removed. The methane rising up the tank is cleaned in a steam bath, and then sent to the gas collector.

Industrial production of methane involves the daily injection of fresh substrate, which is mixed with what has already begun to ferment. For a day, you can add 5% fresh manure instead of 5% waste. The manure removed from the reactor can be used as soil fertilizer. So you will have a waste-free production, where you can get both biogas and fertilizers.

Setting up a manure biogas plant at home

To construct a plant for the processing of manure into biogas, you will need:

- hermetically closing container (made of metal, concrete, plastic) with a volume of at least one cubic meter;

- cover for the reactor with a sealed passage for the stirrer handle;

- material for thermal insulation of the bottom (plays the role of a heating system);

- hand mixer from improvised materials (you can use a shovel or screw auger);

- branch pipes for supply/extraction of the substrate and for biogas output.

During the construction process, you may need additional materials: pipes, filters, valves. All this can be found in the hardware store. The design is quite simple, and you can improve it as you build it.

As an experiment, you can try to make an installation from an ordinary plastic barrel. They are produced in volumes from 100 to 200 liters. The barrel will serve as a reactor. Make two holes in it for the inlet and outlet of the pipes. The inlet is made closer to the bottom, and the outlet is made from above. The diameter of the holes depends on the diameter of the nozzles used. Plastic pipes can be bought at a hardware store. We insert them into the holes and isolate them securely. An inlet pipe with a bend (with a connector) is suitable, and a short straight pipe is suitable for the outlet.

The role of the reservoir for the resulting biogas is given to a smaller capacity. For example, you can take a bucket with a volume of 20 liters. The bucket is fixed with a plumbing valve. From it we take the tube to a metal holder with a valve, from where the gas will be released.

Do not forget about the thermal insulation of the barrel. It can be wrapped with mineral wool, polyethylene foam or any other material. It is best to put the barrel in the sun to increase the temperature inside the reactor. We fall asleep inside the raw materials in the ratio of 0.7 liters of water per 1 kg of manure. We put any suitable container for removing sludge, put a bucket on top and wait for fermentation. We are waiting for about three weeks for the first batch of our home biogas. Remember that methane must be cleaned of carbon dioxide before use. A special filter, which is sold in the store as a "filter for cleaning compressed air, carbon dioxide and steam", will cope with this task.

Do-it-yourself biogas from manure: building an underground plant

Another easy way to build your own manure-to-biogas plant is to build an underground system. First you need to dig a hole with a volume of at least one cubic meter. Its walls and bottom are filled with expanded clay concrete. From opposite walls, one pipe is output for supplying biomass and removing sludge. The outlet pipe should be located closer to the bottom, and the inlet pipe should be 50 cm above the bottom. The end of the outlet pipe is brought to the waste container. The end of the inlet pipe should be located in such a way that it is convenient for you to pump new raw materials through it.

The upper part of this "bunker" is a domed or cone-shaped gas holder. It is easiest to make it from metal sheets or brickwork. At the top of the gas tank, a sealed hatch and a gas pipe with a water seal are mounted. We advise you to provide for the presence of such an important part as a pressure relief valve. It will ensure safety when working with the installation and will maintain optimal pressure inside the reactor.

The mixing of the substrate in such an installation occurs according to the principle of bubbling. To do this, take a few plastic pipes and make as many holes in them as possible. Then fix the pipes inside the reactor in a vertical position. When the gas rises, it will emit bubbles, which at the exit will begin to boil in the substrate, thereby mixing it.

Biogas from manure - a profitable investment

For those who are not ready to make such a camera, there is always another way out - you can buy a ready-made one. The construction of the installation will still require a small investment from you. If you are not confident in your abilities or do not have all the materials, it is advisable to simply buy a PVC installation. As a result, you still organize your home production for manure processing and biogas production.

The constant increase in the cost of traditional energy carriers is pushing home craftsmen to create home-made equipment that allows you to get biogas from waste with your own hands. With this approach to farming, it is possible not only to obtain cheap energy for heating the house and other needs, but also to organize the process of recycling organic waste and obtaining free fertilizers for subsequent application to the soil.

Excess produced biogas, as well as fertilizers, can be sold at market value to interested consumers, turning into money what is literally “lying underfoot”. Large farmers can afford to buy pre-fabricated biogas plants. The cost of such equipment is quite high. However, the return on its operation corresponds to the investments made. Less powerful installations operating on the same principle can be assembled on their own from available materials and parts.

What is biogas and how is it produced?

As a result of biomass processing, biogas is obtained

Biogas is classified as an environmentally friendly fuel. In terms of its characteristics, biog is in many ways similar to natural gas produced on an industrial scale. The biogas production technology can be represented as follows:

- in a special container called a bioreactor, the process of biomass processing takes place with the participation of anaerobic bacteria under conditions of airless fermentation for a certain period, the duration of which depends on the volume of loaded raw materials;

- as a result, a mixture of gases is released, consisting of 60% of methane, 35% of carbon dioxide, 5% of other gaseous substances, among which there is hydrogen sulfide in a small amount;

- the resulting gas is constantly withdrawn from the bioreactor and, after cleaning, is sent for its intended use;

- processed waste, which has become high-quality fertilizer, is periodically removed from the bioreactor and taken to the fields.

Visual diagram of the biofuel production process

In order to establish continuous production of biogas at home, one must own or have access to agricultural and livestock enterprises. It is economically profitable to engage in biogas production only if there is a source of free supply of manure and other organic animal waste.

Gas heating is still the most reliable heating method. You can learn more about autonomous gasification in the following material:

Types of bioreactors

Plants for the production of biogas differ in the type of loading of raw materials, the collection of the resulting gas, the placement of the reactor relative to the surface of the earth, and the material of manufacture. Concrete, brick and steel are the most suitable materials for building bioreactors.

According to the type of loading, bioinstallations are distinguished, into which a given portion of raw materials is loaded and goes through a processing cycle, and then is completely unloaded. Gas production in these units is unstable, but any kind of raw material can be loaded into them. As a rule, they have a vertical arrangement and take up little space.

A portion of organic waste is loaded daily into the system of the second type and a portion of ready-made fermented fertilizers equal to it in volume is unloaded. The working mixture always remains in the reactor. The so-called continuous loading plant consistently produces more biogas and is very popular with farmers. Basically, these reactors are located horizontally and are convenient if there is free space on the site.

The selected type of biogas collection determines the design features of the reactor.

- balloon systems consist of a rubber or plastic heat-resistant cylinder in which a reactor and a gas holder are combined. The advantages of this type of reactors are simplicity of design, loading and unloading of raw materials, ease of cleaning and transportation, and low cost. The disadvantages include a short service life, 2-5 years, the possibility of damage as a result of external influences. Tank reactors also include channel-type plants, which are widely used in Europe for the processing of liquid waste and sewage. Such a rubber top is effective at high ambient temperatures and there is no risk of damage to the cylinder. The fixed dome design has a fully enclosed reactor and a make-up tank for slurry discharge. The gas accumulates in the dome, when loading the next portion of the raw material, the processed mass is pushed into the compensation tank.

- Floating dome biosystems consist of a monolithic bioreactor located underground and a movable gas holder that floats in a special water pocket or directly in the feedstock and rises under the action of gas pressure. The advantage of a floating dome is the ease of operation and the ability to determine the gas pressure by the height of the dome. This is a great solution for a large farm.

- When choosing an underground or above-ground installation, it is necessary to take into account the slope of the relief, which facilitates the loading and unloading of raw materials, enhanced thermal insulation of underground structures, which protects the biomass from daily temperature fluctuations and makes the fermentation process more stable.

The design can be equipped with additional devices for heating and mixing raw materials.

Is it profitable to make a reactor and use biogas

The construction of a biogas plant has the following objectives:

- production of cheap energy;

- production of easily digestible fertilizers;

- savings on connection to expensive sewerage;

- processing of household waste;

- possible profit from the sale of gas;

- reducing the intensity of unpleasant odors and improving the environmental situation in the territory.

Graph of the profitability of the production and use of biogas

To assess the benefits of building a bioreactor, a prudent owner should consider the following aspects:

- the cost of the bio-installation is a long-term investment;

- home-made biogas equipment and installation of a reactor without the involvement of third-party specialists will cost much less, but its efficiency is lower than that of an expensive factory one;

- to maintain stable gas pressure, the farmer must have access to animal waste in sufficient quantities and for a long time. In the case of high prices for electricity and natural gas or the lack of the possibility of gasification, the use of the installation becomes not only profitable, but also necessary;

- for large farms with their own raw material base, a profitable solution would be to include a bioreactor in the system of greenhouses and cattle farms;

- for small farms, efficiency can be increased by installing several small reactors and loading raw materials at different intervals. This will help avoid interruptions in gas supply due to a lack of feedstock.

How to build a bioreactor on your own

The decision on construction has been made, now it is necessary to design the installation and calculate the necessary materials, tools and equipment.

Important! Resistance to aggressive acidic and alkaline media is the main requirement for the bioreactor material.

If a metal tank is available, it can be used provided that it has a protective coating against corrosion. When choosing a container made of metal, pay attention to the presence of welds and their strength.

A durable and convenient option - a polymer container. This material will not rot or rust. A barrel with thick rigid walls or reinforced will perfectly withstand the load.

The cheapest way is to lay out a container of brick or stone, concrete blocks. To increase the strength, the walls are reinforced and coated inside and out with a multi-layer waterproofing and gas-tight coating. The plaster must contain additives that provide the desired properties. The best shape that will withstand all pressure loads is oval or cylindrical.

At the base of this container, an opening is provided through which the waste material will be removed. This hole must be tightly closed, because the system works effectively only in sealed conditions.

Calculation of the necessary tools and materials

For laying out a brick container and arranging the entire system, you will need the following tools and materials:

- container for mixing cement mortar or concrete mixer;

- drill with mixer nozzle;

- crushed stone and sand for the device of a drainage pillow;

- shovel, tape measure, trowel, spatula;

- brick, cement, water, fine sand, rebar, plasticizer and other necessary additives;

- welding machine and fasteners for mounting metal pipes and components;

- water filter and a container with metal shavings for gas purification;

- tire cylinders or standard propane gas storage tanks.

The size of a concrete tank is determined from the amount of organic waste that appears daily in a private courtyard or farm. Full-fledged operation of the bioreactor is possible if it is filled to two-thirds of the available volume.

Let us determine the volume of the reactor for a small private farm: if there are 5 cows, 10 pigs and 40 chickens, then per day of their life a litter of 5 x 55 kg + 10 x 4.5 kg + 40 x 0.17 kg = 275 kg + 45 kg + 6.8 kg = 326.8 kg. To bring chicken manure to the required moisture content of 85%, add 5 liters of water. Total weight = 331.8 kg. For processing in 20 days it is necessary: 331.8 kg x 20 \u003d 6636 kg - about 7 cubes only for the substrate. This is two-thirds of the required volume. To get the result, you need 7x1.5 \u003d 10.5 cubic meters. The resulting value is the required volume of the bioreactor.

Remember that it will not work to produce a large amount of biogas in small containers. The output directly depends on the mass of organic waste processed in the reactor. So, to get 100 cubic meters of biogas, you need to process a ton of organic waste.

Preparing a site for a bioreactor device

The organic mixture loaded into the reactor should not contain antiseptics, detergents, chemicals that are harmful to the life of bacteria and slow down the production of biogas.

Important! Biogas is flammable and explosive.

For the correct operation of the bioreactor, it is necessary to follow the same rules as for any gas installations. If the equipment is airtight, biogas is discharged to the gas tank in a timely manner, then there will be no problems.

If the gas pressure exceeds the norm or will poison if the tightness is broken, there is a risk of an explosion, therefore it is recommended to install temperature and pressure sensors in the reactor. Inhaling biogas is also hazardous to human health.

How to ensure biomass activity

You can speed up the fermentation process of biomass by heating it. As a rule, in the southern regions such a problem does not arise. The ambient temperature is enough for the natural activation of fermentation processes. In regions with harsh climatic conditions in winter, without heating, it is generally impossible to operate a biogas plant. After all, the fermentation process starts at a temperature exceeding 38 degrees Celsius.

There are several ways to organize the heating of a biomass tank:

- connect a coil located under the reactor to the heating system;

- install electric heating elements at the base of the tank;

- provide direct heating of the tank by using electric heaters.

Bacteria that affect the production of methane are dormant in the raw material itself. Their activity increases at a certain temperature level. The installation of an automated heating system will ensure the normal course of the process. Automation will turn on the heating equipment when the next cold batch enters the bioreactor, and then turn it off when the biomass warms up to a predetermined temperature level.

Similar temperature control systems are installed in hot water boilers, so they can be purchased at stores specializing in the sale of gas equipment.

The diagram shows the entire cycle, starting from loading solid and liquid raw materials, and ending with the removal of biogas to consumers

It is important to note that you can activate the production of biogas at home by mixing the biomass in the reactor. For this, a device is made that is structurally similar to a household mixer. The device can be set in motion by a shaft, which is led out through a hole located in the lid or walls of the tank.

What special permits are required for the installation and use of biogas

In order to build and operate a bioreactor, as well as to use the resulting gas, it is necessary to take care of obtaining the necessary permits at the design stage. Coordination must be passed with the gas service, firefighters and Rostekhnadzor. In general, the rules for installation and operation are similar to the rules for using conventional gas equipment. Construction must be carried out strictly according to SNIPs, all pipelines must be yellow and have the appropriate markings. Ready-made systems manufactured at the factory are several times more expensive, but they have all the accompanying documents and meet all technical requirements. Manufacturers provide warranties for equipment and service and repair their products.

A self-made biogas plant can save on energy costs, which occupy a large share in determining the cost of agricultural products. A decrease in production costs will affect the increase in the profitability of a farm or a private farmstead. Now that you know how to get biogas from existing waste, it remains only to put the idea into practice. Many farmers have long since learned to make money from manure.

Owners of private houses located in regions with limited access to traditional fuels should definitely pay attention to modern biogas plants. Such units make it possible to obtain biogas from a variety of organic waste and use it for personal needs, including heating residential premises.

Gas can be obtained from almost any biomass - waste from the livestock industry, food production, agriculture, foliage, etc. At the same time, you can build such an installation yourself.

The mechanism of action of biogas plants

Both homogeneous raw materials and mixtures of different biomass are suitable for biogas production. A biogas plant is a volumetric sealed structure equipped with devices for supplying raw materials, heating biomass, mixing components, diverting the resulting biogas into a gas collector and, of course, protecting the structure.

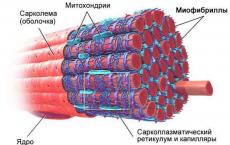

In the reactor, under the influence of anaerobic bacteria, the biomass is rapidly decomposed. During the fermentation of organic raw materials, biogas is released. Approximately 70% of the composition of such a gas is methane, the rest is carbon dioxide.

Biogas is characterized by excellent calorific value, it has no pronounced odor and color. In terms of its properties, biogas is practically in no way inferior to the more traditional natural gas.

In developed countries, additional installations are used to clean biogas from carbon dioxide. If you wish, you can buy the same installation and get pure biomethane.

Biogas plants on a silo. 1 Silos. 2 Biomass loading system. 3 Reactor. 4 Fermentation reactor. 5 Substrater. 6 Heating system. 7 Power plant. 8 Automation and control system. 9 Gas pipeline system

On average, one cow or other animal weighing half a ton is capable of producing enough manure per day to produce about 1.5 m3 of biogas. The daily manure of one average pig can be processed into 0.2 m3 of biogas, and a rabbit or chicken - into 0.01-0.02 m3 of fuel.

For comparison: 1 m3 of biogas from manure gives about the same amount of thermal energy as 3.5 kg of firewood, 1-2 kg of coal, 9-10 kWh of electricity.

The simplest biogas mixture recipe includes the following components:

- cow dung - about 1500 kg;

- rotted leaves or other organic waste - 3500 kg;

- water - 65-75% of the total mass of the previous components. Pre-heat the water to about 35 degrees.

This amount of biomass will be enough to produce biogas for half a year of operation with moderate consumption. On average, biogas begins to be released within 1.5-2 weeks after loading the mixture into the plant.

Gas can be used to heat the house and a variety of household and household buildings.

Construction of a typical biogas plant

biogas plant

The main components of a complete biogas system are:

- reactor;

- humus supply system;

- agitators;

- biomass;

- gasholder;

- separator;

- protective part.

A domestic installation will have a somewhat simplified design, however, for completeness of perception, you are invited to read the description of all the listed elements.

Biogas plants

Reactor

This part of the installation is usually assembled from stainless steel or concrete. Externally, the reactor looks like a large hermetic container, on top of which a dome is installed, usually having a spherical shape.

Currently, the most popular are the collapsible design reactors made using innovative technologies. Such a reactor can be easily assembled with your own hands with minimal time. If necessary, it is just as easy to disassemble and transport to another place.

Steel is convenient in that you can easily create holes in it for connecting other elements of the system. Concrete is superior to steel in terms of strength and durability.

Biomass Feeding System

This part of the installation includes a waste receiving bin, a water inlet pipe and a screw pump designed to send the humus to the reactor.

A front loader is used to load the dry component into the bunker. At home, this task can be done without a loader, using various improvised means, for example, shovels.

In the bunker, the mixture is moistened to a semi-liquid state. After reaching the desired level of moisture, the screw transfers the semi-liquid mass to the lower compartment of the reactor.

Agitators

Fermentation of humus in the reactor should occur evenly. This is one of the most important conditions for ensuring intensive release of biogas from the mixture. It is in order to achieve the most uniform fermentation process of the mixture that the design of a typical biogas plant includes agitators with electric drives.

There are submersible and inclined type mixers. Submersible mechanisms can be lowered into the biomass to the required depth to ensure intensive and uniform mixing of the substrate. Usually such mixers are placed on a mast.

Inclined mixers are mounted on the side surfaces of the reactor. An electric motor is responsible for the rotation of the screw in the fermenter.

Automated heating system

For successful production of biogas, the temperature inside the system must be maintained at +35-+40 degrees. To do this, automated heating systems are included in the design.

The source of heat in this case is a hot water boiler, in some situations electric heating units are used.

gas holder

gas holder

Biogas is collected in this structural element. Most often, the gas holder is placed on the roof of the reactor.

The production of modern gas tanks is usually carried out using polyvinyl chloride - a material that is resistant to sunlight and a variety of adverse natural phenomena.

gas holder

In some situations, instead of a conventional gas tank, special bags are used. Also, these devices allow you to temporarily increase the amount of biogas produced.

For the manufacture of gas-bags, special polyvinyl chloride with elastic properties is used, which can inflate as the volume of biogas increases.

Separator

Separator

This part of the system is responsible for drying the spent humus and obtaining, if necessary, high-quality fertilizers.

The simplest separator consists of a screw and a separator chamber. The chamber is made in the form of a sieve. This allows the biomass to be separated into a solid component and a liquid part.

Press screw separator

The drained humus is sent to the shipping compartment. The system sends the liquid part back to the receiving chamber. Here, the liquid is applied to moisten the new feedstock.

The simplest do-it-yourself biogas plant

Biogas plant for home

A domestic biogas plant will have a somewhat simplified design, but its manufacture should be approached with the utmost responsibility.

First step. Dig a hole. At its core, a biogas plant is a large pit with a special finish. The most important and at the same time the most difficult part of the manufacture of the system under consideration is the correct preparation of the walls of the bioreactor and its base.

The pit must be sealed. Strengthen the base and walls with plastic or concrete. Instead, you can purchase ready-made solid-bottomed polymer rings. Such devices provide the necessary tightness of the system. The material will retain its original characteristics for many years, and if necessary, you can easily replace the old ring with a new one.

Second step. Equip a gas drainage system. This saves you the hassle of buying and installing agitators, which saves time and money on assembling the plant.

The simplest version of the gas drainage system is vertically fixed PVC sewer pipes with many holes in the body.

Choose pipes of such length that their upper edges rise slightly above the upper level of the loaded humus.

Third step. Cover the outer layer of the substrate with foil insulation. Thanks to the film, conditions will be created for the accumulation of biogas under the dome under conditions of slight overpressure.

Fourth step. Install the dome and mount the exhaust pipe at its highest point.

Gas consumption should be regular. Otherwise, the dome over the biomass tank may simply explode. In summer, gas is formed more intensively than in winter. To solve the last problem, buy and install suitable heaters.

Procedure and conditions for the successful use of a biogas plant

Average specific yield of biogas

Thus, it is not difficult to assemble a simple biogas plant on your own. However, for its successful operation, you must remember and follow a few simple rules.

One of the most important requirements is that the loaded organic mass should not contain any substances that can have a negative impact on the vital activity of anaerobic microorganisms. Prohibited inclusions include various kinds of solvents, antibacterial drugs and other similar substances.

A number of inorganic substances can also lead to a deterioration in the vital activity of bacteria. In view of this, it is forbidden, for example, to dilute humus with water left after washing clothes or washing a car.

Remember: a biogas plant is a potentially explosive unit, so follow all safety regulations relevant to the operation of any gas equipment.

Thus, even manure and, in principle, almost everything that you previously tried to get rid of with all your might can be useful on the farm. You just need to properly build a home biogas plant, and very soon your house will be warm. Follow the recommendations received, and you will no longer have to spend huge amounts on heating.

Successful work!

Read also on our website an article - do-it-yourself hydroponic installation.

Video - DIY biogas plant

svoimi-rykami.ru

Biogas plant on your own

The article on biogas production presented the theoretical foundations for the production of methane gas from biomass by anaerobic digestion.

The article on biogas production presented the theoretical foundations for the production of methane gas from biomass by anaerobic digestion.

The role of bacteria in the step-by-step transformation of organic substances was explained, with a description of the necessary conditions for the most intensive production of biogas. In this article, practical implementations of biogas plants will be given, with a description of some improvised designs.

As energy prices are rising and many livestock and small farm owners have problems with waste disposal, biogas industrial complexes and small biogas plants for a private home have come on the market. Using search engines, the Internet user can easily find an affordable turnkey solution to meet the needs of the biogas plant and its price, get in touch with equipment suppliers and agree on the construction of a biogas generator at home or on the farm.

Biogas industrial complex

Bioreactor - the basis of a biogas plant

The container in which the anaerobic decomposition of biomass takes place is called a bioreactor, fermenter, or methane tank. Bioreactors are fully sealed, with a fixed or floating dome, with a diving bell design. Bell psychrophilic (not requiring heating) bioreactors have the form of an open reservoir with liquid biomass, in which a container in the form of a cylinder or bell is immersed, where biogas is collected.

The collected biogas exerts pressure on the cylinder, causing it to rise above the tank. Thus, the bell also performs the function of a gas tank - a temporary storage of the resulting gas.

Floating Dome Bioreactor

The disadvantage of the bell design of a biogas reactor is the impossibility of mixing the substrate and heating it during the cold periods of the year. Also a negative factor is a strong smell, and unsanitary conditions due to the open surface of part of the substrate.

In addition, part of the resulting gas will escape into the atmosphere, polluting the environment. Therefore, these bioreactors are used only in artisanal biogas plants in poor countries with a hot climate.

Another example of a floating dome bioreactor

In order to prevent environmental pollution and eliminate unpleasant odors, the reactors of biogas plants for home and large industries have a fixed dome design. The shape of the structure in the process of gas formation does not matter much, but when using a cylinder with a dome-shaped roof, significant savings in building materials are achieved. Bioreactors with a fixed dome are equipped with nozzles for adding new portions of biomass and removing the spent substrate.

A variation of the fixed dome bioreactor

Main types of biogas plants

Since the fixed dome design is the most acceptable, most ready-made bioreactor solutions are of this type. Depending on the loading method, bioreactors have a different design and are divided into:

- Portion, with a single load of the entire biomass, and with subsequent full unloading after the processing of raw materials. The main disadvantage of this type of bioreactors is the uneven release of gas during the processing of the substrate;

- continuous loading and unloading of raw materials, due to which a uniform release of biogas is achieved. Due to the design of the bioreactor, during loading and unloading, biogas production does not stop and there are no leaks, since the nozzles through which the addition and removal of biomass is carried out are made in the form of a water seal that prevents gas from escaping.

Batch bioreactor example

Batch biogas reactors can be of any design that prevents gas leakage. So, for example, at one time in Australia, channel methanetanks with an elastic inflatable roof were popular, where a slight overpressure inside the bioreactor inflated a bubble of durable polypropylene. Upon reaching a certain level of pressure inside the bioreactor, the compressor was turned on, pumping out the generated biogas.

Channel bioreactors with flexible gas holder

The type of fermentation in this biogas plant can be mesophilic (with weak heating). Due to the large area of the inflating dome, channel bioreactors can only be installed in heated rooms, or in regions with a hot climate. The advantage of the design is the absence of the need for an intermediate receiver, but the big disadvantage is the vulnerability of the elastic dome to mechanical damage.

Large channel bioreactor with flexible gas tank

Recently, batch bioreactors with dry fermentation of manure without adding water to the substrate are gaining popularity. Since manure has its own moisture, it will be enough for the life of organisms, although the intensity of reactions will decrease.

Dry-type bioreactors look like a sealed garage with tightly closing doors. The biomass is loaded into the reactor using a front loader and remains in this state until the completion of the complete gas generation cycle (about half a year), without the need to add the substrate and mix it.

Batch bioreactor loaded through a hermetically sealed door

DIY biogas plant

It should be noted that in most bioreactors, as a rule, only the gas generation zone is sealed, and the liquid biomass at the inlet and outlet is under atmospheric pressure. Excessive pressure inside the bioreactor displaces part of the liquid substrate into the nozzles, due to which the level of biomass in them is somewhat higher than inside the tank.

The red lines in the diagram indicate the difference in levels in the bioreactor and nozzles

These designs of home-made bioreactors are popular among folk craftsmen who independently make biogas plants with their own hands for the home, allowing reusable manual loading and unloading of the substrate. In the manufacture of bioreactors with their own hands, many craftsmen experiment with completely sealed containers, using several rubber chambers from the tires of the wheels of large vehicles as a gas holder.

Drawing of a gas tank made from tractor chambers

In the video below, an enthusiast of homemade biogas production, using the example of barrels filled with bird droppings, proves the possibility of actually obtaining combustible gas at home, processing poultry waste into useful fertilizer. The only thing that can be added to the design described in this video is that you need to put a pressure gauge and a safety valve on a homemade bioreactor.

Bioreactor Productivity Calculations

The amount of biogas is determined by the mass and quality of the raw materials used. On the Internet, you can find tables that indicate the amount of waste produced by various animals, but the owners, who have to remove manure every day, do not need this theory, because they know the amount and mass of the future substrate through their own practice. Based on the availability of raw materials renewable every day, it is possible to calculate the required volume of the bioreactor and the daily production of biogas.

Table of obtaining the amount of manure from some animals with an approximate calculation of the biogas yield

After the calculations have been made and the design of the bioreactor has been approved, you can proceed to its construction. The material can be a reinforced concrete container, poured into the ground, or brickwork, sealed with a special coating that is used to treat pools.

It is also possible to build the main tank of the home biogas plant from iron coated with anti-corrosion material. Small industrial bioreactors are often made from large volume, chemically resistant plastic tanks.

Construction of a masonry bioreactor

In industrial biogas plants, electronic control systems and various reagents are used to correct the chemical composition of the substrate and its acidity level, and special substances are added to the biomass - enzymes and vitamins that stimulate the reproduction and vital activity of microorganisms inside the bioreactor. In the process of development of microbiology, more and more resistant and effective strains of bacteria methanogens are being created, which can be purchased from companies involved in the production of biogas.

The graph shows that with the use of enzymes, the maximum biogas yield occurs twice as fast.

The need for pumping and cleaning biogas

The constant production of gas in a bioreactor of any design leads to the need to pump out biogas. Some primitive biogas plants can burn the resulting gas directly in a burner installed nearby, but the instability of the overpressure in the bioreactor can lead to the extinction of the flame, followed by the release of poisonous gas. The use of such a primitive biogas plant connected to a stove is categorically unacceptable because of the possibility of poisoning with toxic components of raw biogas.

The burner flame when burning biogas must be clean, even and stable

Therefore, almost any scheme of a biogas plant includes gas storage tanks and a gas purification system. As a homemade cleaning complex, you can use a water filter and a homemade container filled with metal shavings, or purchase professional filtration systems. The tank for temporary storage of biogas can be made of chambers from tires, from which the gas is pumped out from time to time by a compressor into standard propane cylinders for storage and subsequent use.

In some African countries, inflatable gas holders in the form of a pillow are used to store and transport biogas.

As an alternative to the mandatory use of a gas tank, an improved floating dome bioreactor can be perceived. The improvement consists in the addition of a concentric baffle which forms a water pocket that acts like a water seal and prevents the biomass from coming into contact with air. The pressure inside the floating dome will depend on its weight. By passing the gas through the purification system and reducer, it can be used in a household stove, periodically bled from the bioreactor.

Bioreactor with floating dome and water pocket

Grinding and mixing of the substrate in the bioreactor

Agitation of the biomass is an important part of the biogas formation process, providing bacteria with access to nutrients that can clump at the bottom of the bioreactor. In order for the biomass particles to be better mixed in the bioreactor, they must be crushed mechanically or manually before being loaded into the methane tank. Currently, in industrial and home-made biogas plants, three methods of mixing the substrate are used:

- mechanical agitators driven by an electric motor or manually;

- circulating mixing with a pump or propeller pumping the substrate inside the bioreactor;

- bubbling mixing by blowing the already existing biogas into the liquid biomass. The disadvantage of this method is the formation of foam on the surface of the substrate.

The arrow indicates the mixing circulation screw in a homemade bioreactor

Mechanical mixing of the substrate inside the bioreactor can be carried out manually or automatically by turning on the electric motor using an electronic timer. Water-jet or bubbling mixing of biomass can only be carried out using electric motors controlled manually or using a software algorithm.

This bioreactor has a mechanical agitator

Substrate heating in mesophilic and thermophilic biogas plants

The optimal temperature for gas formation is the temperature of the substrate in the range of 35-50ºC. To maintain this temperature, various heating systems can be installed in the bioreactor - water, steam, electric. Temperature control should be carried out using a thermal switch or thermocouples connected to the actuator that regulates the heating of the bioreactor.

You also need to remember that an open flame will overheat the walls of the bioreactor, and inside its biomass will burn. The burnt substrate will reduce heat transfer and the quality of heating, and the hot wall of the bioreactor will quickly collapse. One of the best options is water heating from the return pipe of the home heating system. It is necessary to install a system of electric valves to be able to turn off the heating of the bioreactor or connect the heating of the substrate directly from the boiler if it is too cold.

Electric and water heating system of the bioreactor

Heating the substrate in the bioreactor with the help of heating elements will be beneficial only if there is alternative electricity obtained from a wind generator or solar panels. In this case, the heating elements can be connected directly to the generator or battery, which will exclude expensive voltage converters from the circuit. To reduce heat loss and reduce the cost of heating the substrate in the bioreactor, it is necessary to insulate it as much as possible using various heaters.

Insulation of the bioreactor with thermal insulation material

Practical experiences that are inevitable when building biogas plants with your own hands

No matter how much literature a novice enthusiast of independent biogas production reads, and no matter how many videos he watches, in practice you will have to learn a lot yourself, and the results, as a rule, will be far from the calculated ones.

Therefore, many novice masters follow the path of independent experiments in obtaining biogas, starting with small containers, determining how much gas from the available raw materials is produced by their small experimental biogas plant. Component prices, methane output and the future costs of building a complete working biogas plant will determine its viability and feasibility.

In the video above, the master demonstrates the capabilities of his biogas plant, noting how much biogas will be produced in one day. In his case, when pumping eight atmospheres into the compressor receiver, the volume of the resulting gas after recalculations, taking into account the volume of the tank 24 l, will be about 0.2 m².

This amount of biogas obtained from a 200 liter barrel is not significant, but, as shown in the following video of this wizard, this amount of gas is enough for an hour of burning one stove burner (15 minutes multiplied by four atmospheres of a cylinder, which is twice the size of the receiver).

In another video below, the master talks about obtaining biogas and biologically pure fertilizers by processing organic waste in a biogas plant. It must be borne in mind that the value of organic fertilizers may exceed the cost of the resulting gas, and then biogas will become a useful by-product of the process of making quality fertilizers. Another useful property of organic raw materials is the ability to store them for a certain period for use at the right time.

infoelectric.ru

Do-it-yourself biogas: technology for obtaining alternative fuel from biological waste

Worried about the impending energy crisis, humanity is actively trying to develop renewable energy sources.

Along with solar and wind power plants, installations have appeared for obtaining gaseous fuels called biogas from organic waste.

A remarkable feature of this technology is its simplicity: anyone can implement it on a small scale. So, do-it-yourself biogas - that's what the conversation will be about.

If we owe the appearance of solar panels and wind turbines to the discoveries of scientists, then in the case of biogas, they did not have to invent anything - nature did everything itself. This type of fuel is a product of the vital activity of special bacteria, which are collectively called hydrolytic, acid-forming and methane-forming.

As the name suggests, the main component of biogas is methane, which is also found in natural gas. In biogas, it accounts for 60% of the total volume. About a third (35%) is carbon dioxide, the remaining 5% is other gases, for example, hydrogen sulfide.

Schematic diagram of a biogas plant

Where do these wonderful microorganisms come from? They are a natural microflora that lives in the intestines of cattle and decomposes its contents. These bacteria are carried outside with manure, which is used to fuel the new gas generating plant.

When microbes are settled in a new place of residence, their "menu" can be diversified with other waste. Any organic matter will do: excrement of other animals and birds, plants and sawdust, food industry waste. All this is subjected to fermentation with the formation of biogas. At the same time, the raw material turns into the most valuable fertilizer.

A prerequisite for the life of methanogens and other bacteria is the absence of air access (such microorganisms are called anaerobic).

Factors affecting biogas production

The volume of biogas produced by a friendly team of microbes under different conditions can vary and depends on a number of factors.

Type of raw material

Most biogas can be obtained from food industry waste containing sugar pulp and a large amount of fat. The least profitable type of raw material is cattle manure.

Manure - raw material for biogas

Temperature

With increasing temperature, the productivity of bacteria increases. According to the temperature regime, gas generators are divided into three types.

Psychrophilic

These are installations without heating, in which the temperature is maintained in the range from 18 to 25 degrees. At the moment, they are almost never used.

mesophilic

Thanks to heating, the temperature regime is maintained in the range from 25 to 40 degrees.

Thanks to heating, the temperature regime is maintained in the range from 25 to 40 degrees.

Advantages:

- low energy consumption;

- the amino acid composition of fertilizers is the most useful.

Flaws:

- relatively low biogas productivity;

- lack of a disinfecting effect (the raw materials contain pathogenic bacteria that should be disposed of).

thermophilic

Intensive heating is applied, the temperature exceeds 40 degrees.

Advantages:

- high performance;

- pathogenic bacteria die.

Flaws:

- high energy costs;

- low quality fertilizers.

Thermophilic bioreactor on manure

For each type of raw material there is an optimal temperature regime. Why can't you just heat up the reactor to the highest possible temperature? For two reasons:

- due to the increase in energy costs, the profitability of the installation will decrease;

- as the temperature rises, the amount of free ammonia also increases.

The latter dependence leads to inhibition of gas generation (this gas is toxic to bacteria).

Metabolism and freedom of movement

The raw material must be sufficiently liquefied so that microbes and gas bubbles can move in it. To do this, hot water is added to the installation, bringing the load humidity to 85% in winter and up to 92% in summer.

In order for metabolic processes to take place in the reactor better, its contents must be stirred from time to time (approximately every 4 to 6 hours).

Fermentation time

If the raw materials are unloaded ahead of schedule, the bacteria will not have time to compensate for the loss in numbers and the productivity of their colonies will drop.

With excessively long exposure, productivity is also reduced due to a lack of nutrients.

With excessively long exposure, productivity is also reduced due to a lack of nutrients.

On average, the optimal fermentation time is:

- for psychrophilic regimen: 30-40 days or more;

- for mesophilic: 10 - 20 days;

- for thermophilic: 5 - 10 days.

Acid-base balance

The highest productivity is observed at pH values from 6.5 to 8.5 (depending on the raw material).

Carbon to nitrogen ratio

The optimal value again depends on the raw material. Carbon should be 10 to 20 times more than nitrogen.

Comparison of biogas with more traditional fuels

The strengths of this technology include:

- The raw material used to produce biogas is an inexhaustible resource and is free of charge.

- Biogas energy is not tied to a specific place - raw materials for installation can be found in any region.

- Wide range of applications: biogas can act as a source of heat, electricity and motor fuel.

In terms of construction costs (3-4 thousand euros for each kW of power), biogas plants are between nuclear (5 thousand euros per 1 kW) and coal (2 thousand euros per 1 kW) stations.

Biogas plant

In practice, it has been proven that the greater the power of the installation, the cheaper the energy generated with its help. Also, profitability depends on the type of raw materials used.

Scheme of organizing the production of biogas at home

When constructing a gas generator with a capacity of more than 10 MW, operating on food waste, it will be necessary to spend about 2 thousand euros for each kW of power; at the same time, a plant with a capacity of up to 1 MW, using cow dung as a raw material, will cost 7 thousand euros per 1 kW.

The unit consists of several technological units.

Reactor

Represents the integral reinforced concrete capacity upholstered with thermal insulation with several technological openings. The reactor must be hermetically sealed to prevent air from entering its interior.

Biomass Feeding System

To load raw materials, the plant is equipped with a bunker. Waste is fed here manually or with the help of a conveyor.

Also, a pipe with hot water is supplied to the reactor.

Agitators

The mixing blades are mounted on a vertical shaft, the shank of which goes out through a sealed hole in the reactor lid.

The mixing blades are mounted on a vertical shaft, the shank of which goes out through a sealed hole in the reactor lid.

The device is driven by an electric motor through a gear reducer.

The motor can be turned on manually or automatically.

Automated heating system

Heating is installed at the bottom of the reactor. The heat carrier can be water or electricity. The heating elements are switched on by a thermostat set to a certain temperature.

gas holder

This is a container into which the biogas generated in the reactor enters.

Separator

As mentioned above, biogas is a mixture of various gases. The separator allows you to separate methane from impurities for subsequent supply to the consumer.

The simplest do-it-yourself biogas plant for home

A self-made biogas generator, of course, is inferior in performance to expensive factory-made plants, but it will require significantly lower initial costs.

For its construction you will need:

For its construction you will need:

- reinforced concrete rings;

- steel bunker;

- a massive lid made of steel or reinforced concrete (there is a known case when a heavy bell was used as a lid);

- pipelines for water supply and discharge of the finished product.

The volume of the reactor should exceed the volume of the load by 1.5 times.

Installation scheme

In the simplest version, the gas generator is not equipped with heating and mixing device. Works on the construction of the installation are carried out in the following sequence:

- A pit of sufficient size is dug, the bottom of which is concreted.

- Several reinforced concrete rings are lowered into the pit one after the other, forming a cylindrical tank from them. All joints should be sealed with bituminous mastic.

- The concrete container is pasted over with thermal insulation and waterproofing, after which they proceed to backfill the pit.

- A lid with a tightly closed loading hatch is placed on top of the reactor. During the fermentation of raw materials in the reactor, high pressure is formed, so the lid can be secured with cables for reliability. It will not be superfluous to install a safety valve in it with a counterweight in the form of a weight.

- It is necessary to attach the bunker to the loading hatch.

- It remains to connect pipelines to the reactor. At the same time, a water seal must be installed on the line of discharge of the finished product.

Biomass is prepared as follows:

- You should take 3 parts of cow dung and 7 parts of rotten plant residues - vegetable tops, leaves, peelings, etc.

- The resulting mixture must be diluted with water, thereby raising its moisture content to 60% - 70%.

In order to increase productivity, a more advanced installation scheme can be applied, including water heating. A hot water boiler operating on the fuel produced by the plant will act as a heat generator.

DIY biogas plant - drawing

When loading raw materials, it is enough to warm up to 35 degrees, after which its temperature as a result of fermentation will rise to 70 degrees.

As practice has shown, a 5-ton load of biomass allows for 6 months to receive an average of about 40 cubic meters per day. m of gaseous fuel.

Related video

No comments yet

microclimat.pro

Do-it-yourself biogas plant for a private house: recommendations for the device and an example of homemade arrangement

A prudent owner dreams of cheap energy resources, efficient waste disposal and obtaining fertilizers. A do-it-yourself home biogas plant is an inexpensive way to make dreams come true. Self-assembly of such equipment will cost reasonable money, and the gas produced will be a good help in the household: it can be used for cooking, heating the house and other needs.

What do you need to get biogas

Biogas is formed as a result of the fermentation of a biological substrate. It is decomposed by hydrolytic, acid- and methane-forming bacteria. The mixture of gases produced by bacteria turns out to be combustible, because. contains a large percentage of methane.

By its properties, it practically does not differ from natural gas, which is used for industrial and domestic needs.

If desired, each homeowner can purchase an industrial biogas plant, but it is expensive, and the investment pays off within 7-10 years. Therefore, it makes sense to make an effort and make a bioreactor with your own hands.

If desired, each homeowner can purchase an industrial biogas plant, but it is expensive, and the investment pays off within 7-10 years. Therefore, it makes sense to make an effort and make a bioreactor with your own hands. Biogas is an environmentally friendly fuel, and the technology for its production does not have a particular impact on the environment. Moreover, as a raw material for biogas, waste products that need to be disposed of are used. They are placed in a bioreactor where processing takes place:

- For some time, the biomass is exposed to bacteria. The fermentation period depends on the volume of raw materials.

- As a result of the activity of anaerobic bacteria, a combustible mixture of gases is released, which includes methane (60%), carbon dioxide (35%) and some other gases (5%). Also, during fermentation, potentially dangerous hydrogen sulfide is released in small quantities. It is poisonous, so it is highly undesirable for people to be exposed to it.

- The mixture of gases from the bioreactor is cleaned and enters the gas tank, where it is stored until it is used for its intended purpose.

- Gas from a gas tank can be used in the same way as natural gas. It goes to household appliances - gas stoves, heating boilers, etc.

- Decomposed biomass must be regularly removed from the fermenter. This is an additional effort, but the effort pays off. After fermentation, the raw material turns into high-quality fertilizer, which is used in fields and gardens.

A biogas plant is beneficial for the owner of a private house only if he has constant access to waste from livestock farms. On average, out of 1 cubic meter. substrate can be obtained 70-80 cubic meters. biogas, but gas production is uneven and depends on many factors, incl. biomass temperature. This complicates the calculations.

Biogas plants are ideal for farms. Animal waste can provide enough gas to fully heat residential premises and outbuildings

Biogas plants are ideal for farms. Animal waste can provide enough gas to fully heat residential premises and outbuildings In order for the gas production process to be stable and continuous, it is best to build several biogas plants, and put the substrate into the fermenters with a time difference. Such installations operate in parallel, and the raw materials are loaded into them sequentially. This guarantees a constant production of gas, so that it can be continuously supplied to household appliances.

Ideally, the bioreactor should be heated. Every 10 degrees of heat doubles the production of gas. Although the arrangement of heating requires investment, it pays off with greater design efficiency.

Ideally, the bioreactor should be heated. Every 10 degrees of heat doubles the production of gas. Although the arrangement of heating requires investment, it pays off with greater design efficiency. Homemade biogas equipment, assembled from improvised materials, is much cheaper than industrial production plants. Its efficiency is lower, but it fully corresponds to the invested funds. If you have access to manure and the desire to make your own efforts to assemble and maintain the structure, this is very beneficial.

Advantages and disadvantages of the system

Biogas plants have many advantages, but there are also enough disadvantages, so before starting design and construction, you should weigh everything:

- Recycling. Thanks to a biogas plant, you can get the most out of the garbage that you would have to get rid of anyway. This disposal is less hazardous to the environment than landfill.

- Renewability of raw materials. Biomass is not coal or natural gas, the extraction of which depletes resources. In agriculture, raw materials appear constantly.

- Relative small amount of CO2. When gas is produced, the environment is not polluted, but when it is used, a small amount of carbon dioxide is released into the atmosphere. It is not dangerous and is not capable of critically changing the environment, because. it is absorbed by plants during growth.

- Moderate sulfur emission. When biogas is burned, a small amount of sulfur is released into the atmosphere. This is a negative phenomenon, but its scale is known in comparison: when natural gas is burned, environmental pollution with sulfur oxides is much greater.

- Stable work. Biogas production is more stable than solar panels or windmills. If solar and wind power cannot be controlled, then biogas plants depend on human activity.

- You can use multiple settings. Gas is always a risk. To reduce potential damage in the event of an accident, several biogas plants can be dispersed around the site. If correctly designed and assembled, a system of several fermenters will work more stable than one large bioreactor.

- Benefits for agriculture. Some types of plants are planted to obtain biomass. You can choose those that improve the condition of the soil. For example, sorghum reduces soil erosion and improves its quality.