History of umpo and its structure. Ufa motor-building production association

The imposition of sanctions against Russia became an impetus for the introduction of import substitution in the economy, including in the military-industrial complex. It cannot be said that the past year has become simple for the state defense order due to its volume and complexity. Deputy Prime Minister of the Russian Federation Dmitry Rogozin wrote about this at the beginning of last year in his Twitter blog. However, the capabilities of the Russian defense industry have adapted to external conditions due to its history and the support program developed by the government. Thus, the State Armaments Program until 2020 provides for more than 19 trillion rubles.

PJSC "Ufa Motor-Building Production Association" (part of JSC "UEC" of the State Corporation Rostec) has developed a unique test bench to determine the capacity of the nozzles of the VK-2500 helicopter engine, manufactured by the UEC under the import substitution project.

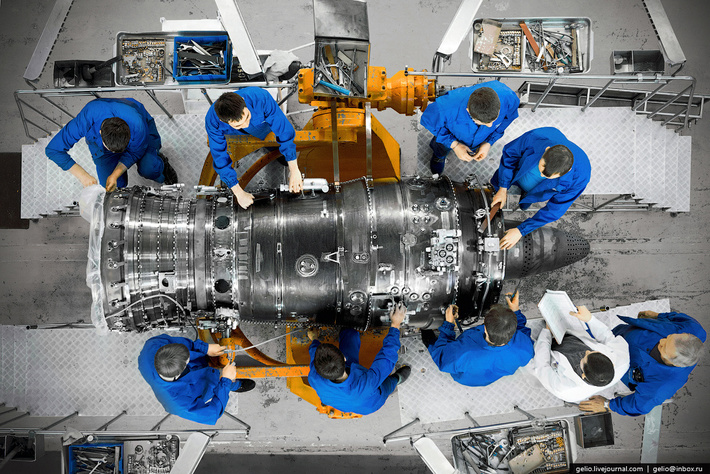

The test facility was fully designed and assembled at UMPO PJSC. The design services, the department of the chief mechanic, the department of automated process control systems, the construction department, production and auxiliary shops took part in the process of its creation. The final certification of the stand took place in December 2015, and since January 2016 it has been fully operational. One operator is enough to control the complex, the process is fully automated.

In the context of unstable supplies from Ukraine, Gazprom transferred orders to Russia and intends to acquire a contractor

After the start of the crisis in Ukraine, Gazprom began curtailing relations with Ukrainian suppliers, in particular, the company stopped buying gas pumping units from them. Now orders have gone to Russian factories, and the monopolist wants to enter the capital of one of them. As President of Bashkiria Rustem Khamitov told Izvestia, Gazprom is negotiating with OAO Ufa Engine Building Production Association”(the largest shareholder is the United Engine Corporation, part of the Rostec Group of Companies) on the creation of a joint venture based on JSC Ufa-AviaGaz (100% subordinate to UMPO).

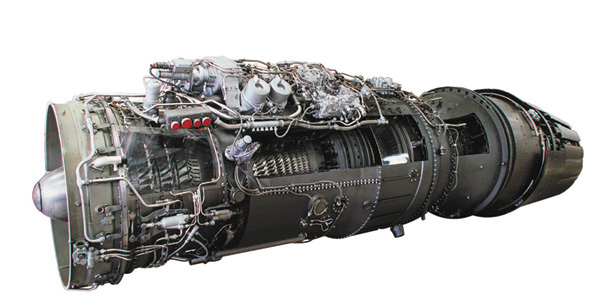

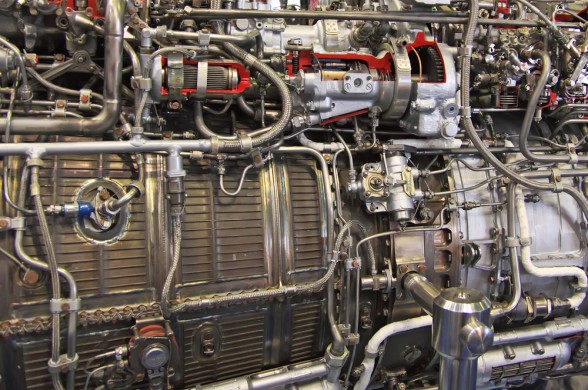

OAO Ufa Motor-Building Production Association is the largest developer and manufacturer of aircraft engines in Russia. More than 20 thousand people work here. UMPO is part of the United Engine Corporation. The main activities of the enterprise are the development, production, maintenance and repair of turbojet aircraft engines, the production and repair of helicopter components, and the production of equipment for the oil and gas industry. UMPO serially produces AL-41F-1S turbojet engines for Su-35S aircraft, AL-31F and AL-31FP engines for Su-27 and Su-30 families, separate components for Ka and Mi helicopters, AL- 31ST for gas pumping stations of OAO Gazprom. Under the leadership of the association, a promising engine is being developed for the fifth-generation fighter PAK FA (promising aviation complex of front-line aviation, T-50). UMPO participates in cooperation in the production of the PD-14 engine for the latest Russian passenger aircraft MS-21, in the program for the production of VK-2500 helicopter engines, in the reconfiguration of the production of RD-type engines for MiG aircraft.

OAO Ufa Motor-Building Production Association is the largest developer and manufacturer of aircraft engines in Russia. More than 20 thousand people work here. UMPO is part of the United Engine Corporation. The main activities of the enterprise are the development, production, maintenance and repair of turbojet aircraft engines, the production and repair of helicopter components, and the production of equipment for the oil and gas industry. UMPO serially produces AL-41F-1S turbojet engines for Su-35S aircraft, AL-31F and AL-31FP engines for Su-27 and Su-30 families, separate components for Ka and Mi helicopters, AL- 31ST for gas pumping stations of OAO Gazprom. Under the leadership of the association, a promising engine is being developed for the fifth-generation fighter PAK FA (promising aviation complex of front-line aviation, T-50). UMPO participates in cooperation in the production of the PD-14 engine for the latest Russian passenger aircraft MS-21, in the program for the production of VK-2500 helicopter engines, in the reconfiguration of the production of RD-type engines for MiG aircraft.

OAO "Ufa Motor-Building Production Association" (the parent company of the division "Engines for combat aviation" of the United Engine Corporation) together with the National Research technological university MISiS successfully conducted the first experience in the history of Russian engine building in manufacturing a high-precision large-sized thin-walled titanium alloy part.

At the site of titanium casting of UMPO JSC, castings of the rack and the central part of the separation case of a promising engine for civil aircraft PD-14 were made.

The technology developed by the MISiS team under the guidance of the head of the Department of Technology of Foundry Processes, Professor, Doctor of Technical Sciences Vladimir Belov and tested on UMPO equipment has no analogues in the world. Unlike, for example, the technology of large-sized thin-wall investment casting, patented in France, here casting into graphite rods is used. The material used in the work is Russian, produced in Chelyabinsk.

The head enterprise of the UEC division (part of the Rostec Group of Companies) "Engines for combat aviation" Ufa engine-building production association together with the Ufa State Aviation technical university produced the first gas turbine engine blades made of heat-resistant aluminum.

In 2013, we managed to obtain the first samples of parts from a new alloy, this year full-size compressor blades were produced from it, the press service of the enterprise reports. The next step - welding them to the disk using linear friction welding - will be done after machining. All studies are carried out jointly by UMPO and USATU with the participation of another representative of the DBA division - NPP Motor. The technology is planned to be tested on the GTP-953 gas turbine drive developed at Motor and, in case of successful tests, to be offered for implementation in the production of gas turbine engines for military aviation., which is part of Rostec) in January-June increased net profit by 39.4% compared to the same period of last year. OAO "Ufa Motor-Building Production Association" (UMPO) and its branch OKB im. A. Lyulki completed the technical design of the engine of the second stage for the fifth generation fighter T-50.

The technical design of the advanced engine (PD) of the second stage for the fifth generation fighter PAK FA (T-50) was successfully accepted by the commission of customers (the Ministry of Defense of the Russian Federation and the Sukhoi company). The design of the product was created in cooperation with the design services of the enterprises of the "Engines for combat aviation" division, headed by the branch of JSC "UMPO" - OKB im. A. Lyulki. Thus, development work on the product goes to a new level.

The next steps in the creation of the T-50 engine will be the development, manufacture and testing of demonstrators and the presentation of the product to the interdepartmental commission. In particular, the production of experimental gas generators and demonstrators is planned to begin in the first half of 2014.

At the Ufa Motor-Building Production Association (UMPO), a reconstructed stand was opened, where serial products of the enterprise will be tested. “At the moment, the stand is designed for testing AL-41F-1S and AL-31FP engines,” said Alexander Artyukhov, head of the DBA division, managing director of UMPO. “However, in the future it can be re-equipped for testing AL-31F products and new engines.”

In the division of the United Engine Corporation "Engines for Combat Aviation", headed by OJSC "Ufa Engine-Building Production Association", development work continues on the engine of the second stage for the fifth generation fighter T-50 (promising complex of front-line aviation, PAK FA), which should be completed after 2015.

At the Ufa Motor-Building Production Association, in an experimental mode, blades were welded onto a unicycle for a promising PD-14 engine.

According to Vladimir Ivanov, Deputy Managing Director for Innovations and Advanced Programs, linear friction welding was used in the work, which is one of the critical technologies, without which it is impossible to create a new generation of aircraft engines.

“The technology has high productivity, ensures maintainability, and, which is unique, allows welding of a monowheel, the disk and blades of which are made of different materials,” Vladimir Ivanov explained.

OAO "Ufa motor-building production association" begins delivery of 920 AL-31FP engines to India via Rosoboronexport. This is the largest single contract with a foreign customer in post-Soviet history.

Back in 2000, under the terms of the general contract for the organization of licensed production of Su-30MKI aircraft and AL-31FP engines, the Indian side was granted the right in the form of an option to purchase an additional number of AL-31FP technological kits for various phases.

In October 2012, an agreement was signed with India to exercise this option. Deliveries of AL-31FP will last for ten years, and the first batch of ten sets will be shipped before the end of the first quarter of this year.

OAO "Ufa Motor-Building Production Association" is one of the largest aircraft engine manufacturers in Russia. The company was founded in 1925. The company employs about 16 thousand people. In 2012, sales revenue amounted to 25,425 million rubles compared to 20,734 million rubles in 2011. 72 percent of production is exported.

The main areas of activity of OJSC UMPO are pilot production, development, repair and maintenance of aircraft turbojet engines, repair and production of helicopter units, production of equipment for the oil and gas industry. JSC "UMPO" serially produces turbojet engines: 117 C (for aircraft of the Su-35S class), AL-31F (for aircraft of the Su-27 class), AL-31F and AL-31FP (for aircraft of the Su-30 class), R95Sh and P195 (for Su-25 class aircraft), equipment units for Mi and Ka helicopters.

JSC "UMPO" put into operation and developed a quality control system based on the requirements of GOST R ISO 9001, ISO 9001, OST 1 02773, GOST RV 0015-002, AS / EN 9100 implemented at all stages of the product life cycle. This is confirmed by the certificates of two QMS certification bodies: Bureau Veritas Rus and ANO InIS VVT in Moscow. The representative of the top management for quality is the quality director, deputy managing director, Vadim Veniaminovich Korznikov.

The association is the main enterprise of the Engines for Combat Aviation organization - a new industry association with a high level of external, internal and international specialization, cooperation, implementation of an international quality management system, and lean manufacturing principles. As the only manufacturer and developer of engines for military aviation in Russia, this division is the basis of the industry and supplies its dynamic development.

JSC UMPO is a member of the United Engine Corporation, a 100% subsidiary of JSC OPK Oboronprom, which specializes in managing engine building assets.

Within the framework of the division of the United Engine Corporation DBA (Engines for Combat Aviation), in the summer of 2013, final measures were taken to establish branches of the Design Bureau named after A.I. A. Lyulki, OJSC Ufa Motor-Building Production Association and Lytkarinsky Machine-Building Plant. Also, employees of the branches were transferred to UMPO from OAO NPO Saturn. As a result, the number of employees of the Ufa enterprise increased by almost one and a half thousand people. According to the data for the first half of 2013, 19,041 employees work in the association.

Also in the summer of 2013, work was completed on a comprehensive action plan in connection with the transfer of management functions of the research and production enterprise Motor to UMPO OJSC, the main company of the Combat Aviation Engines division. As a result, JSC UMPO assumed one hundred percent the functions of legal, financial, personnel, corporate and accounting management, as well as the supply of Motor. The work carried out in this plan became the basis for a business plan to include similar functions for all other enterprises of the DBA division and can be noted along with such processes as the creation of a unified design bureau and a unified budget of the division.

According to information received from the press service of the United Engine Corporation, by order from the owner of the UEC - Oboronprom, dated August 21, 2013, it is planned to rename the Ufa Engine Building Production Association. According to the recommendation, the new name should contain the location of the enterprise and the name of the incoming structure (ODC) and. Thus, the preliminary name: UEC-Ufa.

JSC "UMPO" is located on two production sites in the city of Ufa, Republic of Bashkortostan, it includes 2 specialized production - aviation and instrumental, which employs about 15 thousand workers, specialists and employees.

The main task of the enterprise was and remains the production of modern high-quality aviation equipment. During its existence, the enterprise has produced more than 50 basic and modified aircraft engines, which were installed on 170 types and modifications of aircraft. More than 25 models and modifications of liquid-propellant rocket engines have been produced for missiles of various classes. More than 100 world aviation records have been set on planes with Ufa engines.

Currently, UMPO produces AL-31F and AL-31FP turbojet engines for Su-27, Su-30 aircraft with all their modifications, R95Sh and R195 for the Su-25 family of aircraft, rotor columns for Ka-27, Ka-28 helicopters , Ka-32, transmissions for Mi-26 helicopters. Since 2010, the association began to supply the Sukhoi Company OJSC plant in Komsomolsk-on-Amur with AL-41F-1S engines (product 117C) for the Su-35S, a 4 ++ generation fighter that uses fifth generation technologies.

OJSC "UMPO" first entered the foreign market with its products in 1952. 49 countries of the world operate equipment manufactured by UMPO; The main trading partner is India, for which the company also manufactures AL-55I engines installed on HJT-36 training aircraft. The association actively supports foreign partners by organizing licensed production of engines, providing their repair and training specialists from these countries.

JSC "UMPO" has a full technological cycle for the production of aircraft engines. Mastered technological processes, incl. unique, a set of equipment, staff qualifications allow the association to produce the most modern science-intensive products. UMPO provides a full range of technical support services for its products: after-sales warranty service, repair of modules, assemblies and engines with the restoration of all operational characteristics, personnel training, and modernization of previously manufactured equipment.

Along with aviation, the association produces gas turbine engines for ground-based industrial applications. On the basis of AL-31F, the production of the AL-31ST gas turbine drive was mastered, which is used as part of gas compressor units with a capacity of 16 MW and AL-31STE for block-modular power plants of 20 MW. UMPO can offer potential customers a whole range of products in various configurations, including turnkey delivery of entire stations.

The current quality management system complies with the requirements of international standards of the ISO-9001-2001 series, which is confirmed by the certificate of conformity NBP 02.112.0495-2004 in the Military Register voluntary certification system. In 2010, the association received a certificate of compliance of the quality management system with the aerospace standard AS 9100. The AS 9100 certificate increases the competitiveness of UMPO OJSC when working with Russian customers and indicates the creation of conditions for the production of high-quality products in the association.

OJSC "UMPO" has a package of licenses and certificates both for the production and repair of aviation equipment, and for the design and manufacture of gas power and oil equipment.

JSC "UMPO" is part of the "United Engine Corporation" - a 100% specialized subsidiary of JSC OPK "Oboronprom" for managing engine building assets.