Recommendations for improving the economic efficiency of the commercial activities of the State Enterprise “Region. Development of measures to improve the efficiency of the company Development of a program to improve the efficiency of the enterprise

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Similar Documents

Features, essence and methods of analysis of commercial activity. Analysis of the commercial activities of IP Bezdolnaya T.I. "Handicraft". Measures to improve the efficiency of the commercial activities of the enterprise, their economic efficiency.

thesis, added 06/11/2010

Theoretical and methodological foundations for evaluating the effectiveness of the commercial activities of a trading enterprise. General characteristics of the activities of IP Adamenkov M.I. in the regional market. Proposals for improving the efficiency of management decisions of the enterprise.

test, added 10/09/2014

The essence and laws of commercial activity, the role of planning in it. Conducting an analysis of the financial stability of the enterprise in the market and the sources of information necessary for it. Development of measures to improve the efficiency of the enterprise.

thesis, added 09/04/2009

The role of transport support for commercial activities in the conditions of the development of market relations. Technical and operational indicators of the enterprise. Registration of the contract and application for transportation. Measures to improve business activities.

term paper, added 04/25/2015

Efficiency of entrepreneurial activity and its subjects. Economic and financial performance of the enterprise. Reserves for the improvement and use of fixed assets. Analysis of the range and structure of products. Evaluation of marketing activities.

thesis, added 10/14/2011

Essence, principles and main functions of commercial activity. Indicators of the effectiveness of the commercial activity of the enterprise. Analysis and planning of retail turnover, dynamics of the composition of distribution costs, labor support of the enterprise.

thesis, added 09/29/2012

Methods for evaluating the effectiveness of commercial activities and the process of supplying goods to an enterprise, which consists in organizing, bringing goods from manufacturers to a retail network in the quantity and assortment corresponding to the demand of the population.

thesis, added 04/26/2010

Assessment of the current state and trends in the formation of an economic analysis of the financial and economic activities of the enterprise. General analysis of financial and economic activities and development of measures to improve the efficiency of CJSC "SKB SM".

term paper, added 08/27/2011

Based on the analysis of the financial results of an industrial enterprise, the reserves for profit growth and profitability at the enterprise, in this section of the thesis, we can draw some conclusions that an industrial enterprise may have the following reserves for increasing profits, and therefore the level of profitability:

Increasing the volume of production and sales of manufactured products, by increasing profits and new investments;

Reducing the cost of manufactured products, through the introduction of some, more advanced production methods (non-waste production, recycling of raw materials, use of waste for other industrial and non-production purposes);

Search for more profitable suppliers, assessing their remoteness or proximity to the enterprise, the availability of high-quality equipment for the storage and transportation of raw materials and materials, the prices for their services, the frequency of delivery of raw materials, conscientiousness;

Improving the quality of products, by reducing the cost of production.

Of course, these innovations will entail an increase in costs, but in the end they will pay off and will bring real profit.

It is also possible to make a number of proposals to improve the financial results of NZZHBI-NK LLC, which can be applied both in the short and medium term, and in the long term:

Improve enterprise management, thereby reducing the cost of management personnel;

Carry out timely markdown of products that have lost their original quality;

Implement an effective pricing policy, differentiated in relation to certain categories of buyers, that is, develop a system of discounts, for example, for regular customers, firms involved in the establishment and further sale of products;

Carry out systematic monitoring of the operation of equipment and make its timely adjustment in order to prevent a decrease in quality and the release of defective products;

When commissioning new equipment, pay enough attention to training personnel, improving their qualifications (at the expense of the enterprise or with large discounts, but with the subsequent provision of relevant documents) for the effective use of equipment and preventing its breakdown due to low qualifications;

Raising the qualifications of employees;

Opportunity for workers to make proposals for a more rational use of equipment, storage and transportation of raw materials, production methods, and then their appropriate moral and material encouragement;

Develop and introduce an effective system of material incentives for personnel, closely linked to the main results of the enterprise's economic activity and saving resources;

Use systems for de-bonding employees in case of violation of either labor or technological discipline;

Develop and implement measures aimed at improving the material climate in the team (rest rooms, unloading and discharge rooms, health rooms, etc.), which will ultimately affect the increase in labor productivity;

It is useful to use the hours of the greatest working capacity of workers, and vice versa, the hours of the least activity;

Systematically conduct sociological surveys in order to find out the wishes and preferences of employees, which in the future will be accompanied by an increase in productivity;

At the expense of the profit remaining at the disposal of the enterprise after the payment of all taxes, organize the payment of the thirteenth wage to employees;

Make discounts for certain categories of workers on the purchase of travel tickets, partial payment for tourist vouchers, vouchers for rest homes, sanatoriums, health institutions, vouchers for pioneer summer camps, and more;

For putting forward a rational proposal, to provide the employee with the right to participate in the management of the enterprise;

to constantly monitor the conditions of storage and transportation of raw materials and finished products.

In the current activities of the enterprise, quite often there is a need to implement relatively small-scale, relatively low-capital-intensive and quickly paid back organizational and technical measures. The main purpose of such activities is to improve the efficiency of production.

Each enterprise makes a decision on a large set of issues: determining the range of manufactured and sold products; which market or its segment to enter with this product; what technologies to use for the production and sale of goods; what structure of resources is needed and how to allocate labor, material and financial resources; what indicators should the company achieve over a certain period, especially in terms of the quality and technical characteristics of the goods, in terms of production and marketing efficiency, etc.

The volume of production and the volume of sales of products are interrelated indicators. In conditions of limited production possibilities and unlimited demand, priority is given to the volume of production, which determines the volume of sales. But as the market saturates and competition intensifies, it is not production that determines the volume of sales, but, on the contrary, the possible volume of sales is the basis for developing a production program. The enterprise should produce only those goods and in such volume that it can sell.

The rate of growth in the volume of production and sales of products, improving its quality directly affect the amount of costs, profit and profitability of the enterprise, i.e., the economic efficiency of the economic activity of the enterprise.

In the course of its functioning, the enterprise often has to solve problems for the development of production. The main goal of such development is always to increase the volume of sales of manufactured products, meet the market demand for it and receive an additional amount of profit. To implement such measures, it is necessary to study the market for this type of product, to determine the real possibilities of acquiring the necessary resources.

To form the sales volume, NZZHBI-NK LLC annually concludes contracts directly with consumers for the supply of products. At the same time, determining for each participant in market relations the required volumes, terms, schedules for the delivery (receipt) of products, raw materials, services, their quality, technical and economic characteristics, as well as price. Decisions on carrying out the necessary measures are taken at scheduled meetings, where there are: management, chief engineer, chief technologist, chief mechanic, economist, engineer of the quality department, engineer of the supply department.

As the analysis of the technical and economic indicators of NZZHBI-NK LLC showed, the sales department works according to the old, traditional scheme, that is, with those consumers of products with whom contact has been established for a long time.

To increase the efficiency of the sales staff, it is necessary to have initiative and internal discipline, since he himself will have to develop an action program for himself and carry it out. He must know his range of goods well, be able to communicate and easily assimilate the information received. It is also important that he imagines the production problems of consumers and the possibilities of using the goods or services of his company to solve them. He must continuously collect information and accumulate ideas that are useful to his clientele, regardless of the possibility of obtaining a commercial effect in exchange for this information, and also constantly be interested in new types of services for his clients.

Measures to improve the efficiency of the distribution channel can be represented in the study of the sales market (in the search for and obtaining information about consumers). To do this, it is necessary to take part in industry-specific exhibitions-fairs, where there is the greatest concentration of buyers who could become regular customers of the plant. Participants of the exhibition-fair have the opportunity to get to know the products offered by the plant, to determine for themselves all the advantages and disadvantages of the goods. After the exhibitions, as a rule, the number of proposals increases, the results of which are the conclusion of contracts and further cooperation.

Summing up, we can definitely say that participation in exhibitions and fairs is of great importance for improving the performance of the enterprise.

Currently, there are new modern approaches to the organization of marketing activities. This approach can be the use of the global computer network "Internet", which has great potential. Through the Internet, a much larger number of potential buyers could learn about the activities of LLC NZZHBI-NK. By creating a website and also opening an online store, the company will shorten the order-payment cycle. At the same time, it is obvious that the shorter this cycle, the less expensive it is, the satisfaction of the client increases and the profit of the enterprise increases.

These activities will help increase the activity of the sales channel, but this requires retraining of sales specialists and advanced training.

Retraining of specialists can be carried out off-the-job (formal training method, or classroom method) and on-the-job. Since the sales staff of the enterprise is small, it is impractical to conduct on-the-job training.

In order to strengthen the material interest of employees of the sales department in fulfilling plans and contractual obligations, increasing production efficiency and quality of work, organizations have been delegated the right to introduce bonus systems for employees. Incentive instruments can be bonuses to wages or a bonus based on the results of work for the year (from one to three monthly salaries). You can also offer for marketers who have achieved success in their work, tourist trips.

At present, innovative developments are a powerful means of economic efficiency. Often, the growth of an enterprise is associated with some kind of changes that improve and update the range and technology of manufacturing products, improve the quality of products, improve processes, and so on.

Our state pays more and more attention to the development of innovations in all areas of activity, including the manufacture of reinforced concrete products. The main element of the concrete mixture is cement. At the moment, plasticizers have been developed for cement with the help of chemical additives.

Until recently, in our country, various types of industrial waste were used as plasticizing additives. As a rule, the effect of such additives was low, their chemical composition is often not stable. The domestic industry, especially for concretes, began to produce an effective plasticizing additive - superplasticizer C-3, which in its action is not inferior to the best foreign samples of a similar class, and is 5-6 times cheaper in cost. When this additive is introduced into concrete, up to 20% of cement can be saved (with the same plasticity of the concrete mixture). Without reducing the consumption of cement and without increasing the plasticity of the concrete mixture, but by reducing its water-cement ratio, it is possible to increase the strength of concrete by 20-25%.

As measures aimed at the efficiency of the organization of the production process can be: reconstruction and re-equipment of the plant, shop; development of a new type of product; the need to eliminate bottlenecks. It is possible to increase the volume of production by increasing the degree of use of installed equipment over time, by increasing the intensity of loading this equipment and by increasing production capacity.

These activities will help increase productivity. Labor productivity growth can be achieved by:

increase in output due to a more complete use of the production capacity of the enterprise, since with an increase in production volumes at the available capacity, only the variable part of the cost of working time increases, and the constant remains unchanged. As a result, the time spent on producing a unit of output is reduced;

reducing labor costs for its production by intensifying production, introducing integrated mechanization and automation, more advanced equipment and production technology, reducing losses of working time by improving the organization of labor, logistics and other factors in accordance with the plan of organizational, technical and innovative measures .

The efficiency of the economic activity of the enterprise is determined by the results obtained (in the course of this activity), which reflect the achievement of development goals (increase in market share in the form of the achieved volume of sales or profit as an effect, etc.). Competitive success in the market is expressed in the quality of products and the price at which it became possible to sell, in the volume of products sold or effect, and correlated with the value of the total, applied and consumed resources.

The efficiency of economic activities of LLC "NZZHBI-NK" consists of a variety of activities: in the search for suppliers; in the purchase of raw materials and materials; in increasing the volume of production and sales of products; improvement of the production and technological process, etc.

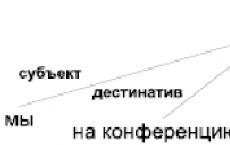

But all activities depend on the specific conditions prevailing at the enterprise for a given period of time. And in turn, they all affect labor productivity. The main directions of increasing the economic efficiency of the economic activity of the enterprise are shown in Figure 3.1.

Figure 3.1 - The main directions for improving the efficiency of the economic activity of the enterprise NZZHBI-NK LLC

Figure 3.2 - Development of marketing policy measures

These transformations and innovations will help the company to improve the results of performance, increase the level of profitability, and consequently increase the profit of the enterprise.

Any organization sooner or later faces the problem of increasing production efficiency. And it is not always about the economic component.

What methods to prefer when organizing such work is decided by the management of the enterprise. Based on the knowledge of the internal and external environment, the features of production processes, it is possible to develop a plan that will lead to the achievement of the intended goal.

What is meant by performance efficiency?

Enterprise efficiency is an economic category. This concept means the performance of the company, which can be expressed in:

- growth in production rates;

- reducing costs, tax burden;

- reducing the amount of emissions into the environment;

- increasing labor productivity, etc.

There are also scientific works that define the effectiveness of an organization as the effectiveness of an operation or project, in which the resulting product or new action brings more money than was spent. Or these manipulations save a certain amount of resources, which also exceeds the costs of the work associated with their implementation.

Efficiency Conditions

In most cases, in an effort to improve the efficiency of the organization, management expects to get a certain financial result. But this does not always reflect the strategic future of production. Therefore, it is believed that it is more correct to achieve growth rates. We can say that it was possible to achieve economic efficiency of production if:

- the resulting financial result is higher than that of competitors;

- the organization allocates sufficient resources to carry out production or management changes;

- growth rates of financial indicators will be higher in the short term than those of competitors.

This approach constantly motivates the search for solutions that increase the competitiveness of production. This is important in order to carry out work aimed at strategic development.

It is also important that each structural unit of the organization should be concerned about finding ways to increase its economic efficiency. After all, if one of them does not work well, the organization will not be able to improve its performance as a whole.

Tools for increasing efficiency

Ways to improve the efficiency of the enterprise are very diverse. The main ways to increase the profit of the organization are as follows:

- cost reduction, which can be achieved by reducing the price conditions for purchases, optimizing production, reducing staff or wage levels;

- modernization of processes or the entire production, which allows to achieve an increase in labor productivity, a decrease in the volume of processed raw materials, waste, automation of most operations;

- changes in the organizational system that can affect the management structure, principles of customer service, communication, etc.;

- strengthening marketing communications, when the task is to maximize the growth of sales of goods, changing attitudes towards the organization, finding new opportunities for production.

Each of these areas can be detailed and has its own methods of work. The entire management system in the company must be set up so that at any level, employees take the initiative, leading to increased economic efficiency.

Often, a set of measures that should increase the efficiency of work affects all blocks of activity at once. Such a systematic approach allows you to use a synergistic effect.

Factors Affecting Efficiency

If the management of the enterprise is interested in achieving improved results, it must analyze information about the state of the external and internal environment. Then it will be clear which of the existing factors should be used for the benefit of future strategic development. These include:

- Minimum resource usage. The less technology, equipment, personnel are used while maintaining the volume of output, the more effective the organization.

- Increasing the efficiency of personnel by optimizing the structure, improving qualifications and training, searching for more competent personnel, changing the motivation system.

- Increasing the efficiency of personnel by improving their health and improving working conditions. Measures aimed at solving these problems lead to a reduction in the number of sick days (savings in the employer's funds), increased productivity and employee loyalty.

- Strengthening socio-psychological factors. The use of decentralization tools in management can be a good impetus for development.

- Application of the results of scientific and technological progress. Ignoring modern technologies or excuses from their implementation due to the need for investment leads to a decrease in competitiveness and possible liquidation later. Fearing an unfavorable economic situation in the current period, companies often block their way to development in the future.

- The use of diversification, cooperation and other strategies that allow the use of existing resources in different projects.

- Attraction of investment capital and other mechanisms of third-party financing. Even privatization can open up ways to improve the efficiency of an enterprise.

All these factors lead not only to the growth of economic, but also managerial efficiency. In order to track the effectiveness of the work being done, it is necessary to outline the timing of the control and the indicators that will be checked.

Separately, we will dwell on the factor of improving the health of employees - for the reason that few employers have so far paid due attention to this. Meanwhile, taking care of the team directly affects the company's profits. For example, according to a study conducted as part of the HR Lab. – Laboratory of HR Innovations”, a smoking employee spends 330 working (!) hours per year on smoke breaks. If his salary is 50,000 rubles a month, then it turns out that in a year the company loses up to 100,000 rubles in wages, plus about 40,000 rubles in taxes and social contributions; plus the cost of sick leave, which smokers, according to statistics, take more often. And if the employee's salary is higher, then the costs are even higher. And if there are dozens, hundreds of such employees in the company?

In order to eliminate this extra cost item and increase the efficiency of smoking workers, companies can be advised. (At the link you will find a calculator with which you can calculate how much your company will save if employees stop smoking.)

Where to start?

To understand what work needs to be done to improve production efficiency, a thorough analysis should be carried out. The head of the company must have a rationale for future management decisions, therefore, it is required:

- collect statistics for previous years on product output, its sales, the number of employees in the state, the wage fund, profitability, etc.;

- find out industry averages or competitors' performance;

- to compare the economic performance of the enterprise and other market participants;

- depending on which indicator is more behind, analyze the factors that led to such a result;

- identify responsible persons for the development of measures that should change the situation, and the time frame for achieving new indicators.

It is possible that management will have to make many decisions about itself. For example, to transform the functions and style of management, the distribution of responsibilities, the amount of delegated authority, the methods of working with personnel and the transfer of information within the company.

What can hinder efficiency gains?

Even if the management sees the point in the changes that should lead to an increase in the efficiency of the company, the results may not be. Oddly enough, the problems lie in the psychological perception of managerial changes, as well as in their legal support.

For example, the introduction of new technologies and the installation of equipment almost always results in a reduction in staff. Naturally, the employees of the enterprise do not want to be left without work. Their task is to delay such changes as much as possible. They can also resort to economic arguments, saying that the reinstallation of equipment for some time will require the cessation of work.

From the point of view of legislation, the process of dismissal of employees is strictly regulated. If procedures are violated, the enterprise is doomed to incur additional costs, which reduces economic performance.

In order to overcome all these resistances, it is necessary to think over a system for notifying employees about changes, demonstrating the positive aspects of implementing changes.

Additional difficulties may be related to:

- with a lack of funding or the inability to access investment sources;

- with the lack of competencies among the employees of the enterprise, which does not allow the implementation of the plans;

- with the lack of a strategic planning system in the organization and analytics for previous years of work.

To achieve economic efficiency, systematic and large-scale work will be required. We cannot exclude the need to involve third-party specialists who can save time on implementing changes.

In general, with a competent approach and the use of reasonable measures, it is possible to increase the efficiency of each enterprise, regardless of the situation and at what stage of its development it is.

Based on the enterprise developed by VISION and the marketing analysis carried out, measures to improve the efficiency of the technical service of the Seiho-Motors company will be as follows:

1. Introduction of an additional night shift for car maintenance. It is proposed to introduce an additional shift of car maintenance workers. The duration of the shift will be 12 hours (from 21:00 to 9:00). The duration of the shift will not differ from the duration of the day shift.

The introduction of a car maintenance shift is due to the fact that at the moment the queue for maintenance takes from 2 to 7 days.

After the introduction of an additional night shift, clients will be redistributed and some of the clients who will be conveniently served from 21 to 9 (this is approximately 21% according to marketing research) will be served at night. There will also be maintenance of cars, the repair of which was not completed on the day shift.

2. Opening of a painting and body shop on the basis of a service station. The most important and significant event to improve the company's efficiency. It can be seen that competing companies have painting and body shops and the situation is such that many of our potential customers apply for such services not to an official dealer, but to competing companies.

3. Increasing the motivation of employees in order to prevent the leakage of qualified personnel from the enterprise by increasing wages

4. Provision of high-quality services not only to customers who purchased cars in the Seiho Motors auto center, but also to owners of cars of other brands (diversification of car service), that is, the use of universal posts for servicing various foreign car brands, which affects the financial and economic policy, stimulates the search for additional external and internal reserves, in order to ensure a competitive position.

Development of a plan for the painting and bodywork area

Marketing plan.

The elements of a marketing strategy are:

Carrying out events for clients in order to obtain feedback, timely identification of emerging needs;

Determining the degree of customer satisfaction from service stations;

Collection of information about competitors, methods of work, their strengths and weaknesses, development plans;

Marketing activities related to the opening of MKU will be carried out in 2 stages:

1. Presentation of the ICU for media representatives

Presentation of MKU on the basis of Seiho-Motors LLC for specially invited media. It is possible to demonstrate the performance of painting and bodywork for customers and the media. First of all, the media will be represented by regional TV channels, radio stations, as well as specialized newspapers and magazines, and possibly websites.

This is, first of all, advertising on previously defined media (radio, television, press, Internet); personal informing clients of Seiho Motors LLC (who have already purchased cars of the Chevrolet, Opel, Cadillac, Hummer range) about the opening of MKU in the form of sending SMS messages, as well as in the published Seiho Motors News magazine, which is sent to all customers of the company ; special offers for the first 1500 MKU clients.

It is also necessary to develop the main provisions on the trade policy of the paint and body shop:

Customers pay for the services of the technical center upon completion of work, i.e. after they are completed, and corporate clients - legal entities make an advance payment for the declared work.

In the spare parts warehouse, the necessary level of stock of original spare parts necessary for the smooth operation of the MCU must be maintained.

The increase in profits is planned to be achieved through high-quality after-sales service and the introduction of new types of services that were not previously available in Seiho-Motors.

The pricing policy is relevant for the technical center, MKU and the sale of spare parts. Here the dealer can independently set prices and conduct price promotions. Basic moments:

Providing customers of the technical center with discounts under the discount program;

Special prices for service maintenance of cars older than three years;

Carrying out seasonal promotions;

The workload of the paint and body shop is seasonal, and is determined by the floating demand for this type of service.

The production capacity is expected to be reached within 12 months from the start of production.

Service Sales Forecast

The revenue of the dealership is formed by three components:

Car sales;

Service center services;

Sale of spare parts.

Revenue from the sale of painting and body repair services consists of the following indicators:

Table 26 - Revenue from the sale of services

Consider the services of a car service, or rather the MKU. In the first month after the opening, we cannot guarantee a hundred percent load. Full loading of 100% will occur only in the 9th month after the opening of the MKU and the revenue will be 11.669.492 rubles.

Property plan of the painting and body shop. This subsection reveals the structure of the MCU, describes the equipment necessary for uninterrupted operation.

Table 27 - MCU loading plan

| Name | Normal hours at full load | Planning period | |||||||

| 11.2012 | 12.2012 | 01.2013 | 02.2013 | ||||||

| Standard hours for sale | 5 400 | - | 20% | 30% | 40% | 50% | |||

| Revenue | 1 458 | 1 944 | 2 430 | ||||||

| Standard hours for sale | 5 400 | 3 240 | - | 60% | 70% | 85% | 100% | ||

| Revenue | 2 916 000 | 3 402 000 | 12 393 000 | 14 580 000 |

The structure of the painting and body shop

The basis of the paint and body shop includes 3 main sections:

1. Body repair area.

There are all devices, tools and mechanisms necessary for body repair, including slipways, tilters, hydraulic cranes and pipe benders.

Body repair of the car will be carried out on modern equipment using the best consumables;

2. Plot coloring.

Includes a preparation section, a polishing section, a painting and drying chamber. The site is planned to be equipped with the most modern equipment for high-quality selection of color and painting. The site will be equipped with a painting and drying chamber.

The MCC will be equipped with a color matching laboratory, which will make it possible to obtain any color shades of paints;

Figure 7 - Property plan of the painting and body shop

1. Painting and drying chamber.

2. Sites of preparation.

3. Finishing/polishing area.

4. The painter's room.

5. Laboratory.

6. Technical room (compressor room).

7. Areas of body repair (building berth, floor system, lift).

8. Assembly / disassembly areas.

9. Warehouse of spare parts, LMB (located outside the site).

10. Technical room (storage of mobile equipment, tools, etc.) (located outside the site).

Equipment of the painting and body shop.

The project is planned to use modern equipment selected on the basis of a study of commercial offers from various suppliers.

Table 28 - Main suppliers by proposed equipment

| Name | Manufacturer |

| Painting and drying booths | Belgium |

| Gun Flushing Equipment | Drester, Germany |

| IR drying | IRT, Sweden |

| Equipment for the receiving area | France |

| Welders | Migatronic, Denmark |

| Compressor | Atlas Copco, Sweden |

| Equipment and tools for painters | Sata, Germany 3M, USA |

| Equipment and materials for the laboratory | Sata, Germany EtMan, Russia |

| Mobile place of the preparer, power tool | Festo, Germany |

| Tools and accessories for preparers | 3M USA |

| Devices for fixing workpieces and masking materials | Colad, Netherlands INP, Holland |

| Low and Medium Lifts | Hercules, Germany |

| Leveling equipment | chief, USA |

Production plan.

This section of the business plan provides a brief description of the features of the technological process for the provision of services for painting and body work. The production plan is formed on the basis of the marketing plan for manufactured products and the projected production capacities of the enterprise. The necessary staff of the working personnel of the painting and body shop is determined, and the wages of workers are also calculated.

MKU operating mode

The duration of the work shift is 12 hours;

Duration of the working week - 7 days a week;

Average number of working days per month (KRD) - 30 days;

The coefficient of effective use of working time (KEIRV) - 75%.

The number of jobs MCU.

The total number of jobs provided for in the project is 59.

Payroll and composition, the number of production personnel is presented in table 30.

Calculation of the wage fund for production personnel.

From Table 29, the following calculations can be made.

The total salary for production workers per month is 1305500. The Ural coefficient of 15% is calculated on the basis of wages.

UK \u003d 1305500 * 0.15 \u003d 195825 rubles.

ESN \u003d 0.26 * (ZPosn. + UK).

Table 29 - Staffing

So, UST per month \u003d 0.26 * (1305500 + 195825) \u003d 390344 rubles.

The total wage bill for production workers is

FZP \u003d ZPosn + UK + ESN.

Salary payroll = 1305500 + 195825 + 390344 = 1,715,369 rubles. per month.

The cost structure of a standard hour is shown in Table 30.

Table 30 - The cost structure of the standard hour

| Index | Costs per year, rub. without VAT | Costs for 1 standard hour, rub. without VAT | Costs for 1 standard hour, rub. VAT included |

| Variable costs, including: Production staff salaries | 18 000 000 | ||

| UST | 4 680 000 | ||

| Fixed costs, including: Equipment depreciation | 2 198 544 | 40,1 | |

| Other fixed costs, including: Expenses for non-production personnel | 1 800 000 | ||

| UST | 468 000 | ||

| Travel allowances | 53 000 | 1,2 | |

| Clothes for workers | 290 000 | 4,5 | 5,3 |

| Repair and service | 630 000 | 9,8 | 11,6 |

| Inexpensive equipment | |||

| Advertising | 2.5 | 1,9 | |

| Representation expenses | 200 000 | 3,2 | 3,8 |

| Marriage, alterations | 370 000 | 5,7 | 6,7 |

| Communal payments | 390 000 | 6,1 | 7,2 |

| Repair and service | 60 000 | 1,0 | 1,2 |

| Own transport | 160 000 | 2,5 | 2,9 |

| Product delivery | 160 000 | 2,5 | 2,9 |

| Connection | 290 000 | 4,5 | 5,3 |

| TOTAL | 30 586 544 | 473,3 | 486,1 |

Calculation of the production capacity of the painting and body shop

We calculate the production capacity (N) of the paint and body shop based on the total number of posts (based on the layout) (14), the duration of the shift (12 hours), the number of working days per year (365), the efficiency ratio (shows the ratio of hours sold to actual time works) (0.9) and the productivity coefficient of employees (the ratio of the total time of work on the order to the time the mechanic was at the workplace) (0.75) and we get for 22 posts per year:

N \u003d 22 x 12 x 365 x 0.9 x 0.75 \u003d 64,800 standard hours per year.

5400 standard hours per month.

Investment plan. Based on the data obtained, it is possible to draw up a schedule for the implementation of the project.

Table 31 - Schedule of the project implementation, thousand rubles

| Ready stage | Total cost, rub. VAT included | |

| Design | 1 740 000 | |

| SMR | 25 247 330 | |

| Supply and installation of equipment | 11 733 299 | |

| Total, rub. VAT included | 38 720 629 | |

| Own funds, rub. | 11 228 982 | |

| Borrowed funds, rub. | 27 491 647 |

This section outlines the stages and amounts of investments required to open a paint and body shop, a project implementation schedule is drawn up, which describes in detail the stages of project readiness and shows what financial investments are needed and in what period. It also reflects the amount of own funds and borrowed funds necessary for the implementation of this project.

As can be seen from the table, there is not enough own funds for the implementation of the project, so borrowed funds in the amount of 27.5 million rubles will be taken.

Financial plan. Revenue from the sale of products consists of two main parameters: the number of standard hours for sale and the sale of spare parts. Both indicators depend on the total workload of the workshop. For the purpose of comparing the cash flows of the current and future periods, the calculations include a discount factor that is made up of the accepted discount rate and an adjustment for project risk.

The discount factor taking into account the percentage of risk of the investment project in the calculations is taken equal to 15%.

Table 32 - Economic efficiency indicators

| Index | Unit rev. | Discounted values | Undiscounted values |

| Discount rate | % | ||

| planning horizon | years | 5,17 | 5,17 |

| Discounted sales proceeds | Rub. | 420 461 341 | 581 628 926 |

| Net operating profit, NOP | Rub. | 186 581 058 | 257 720 619 |

| Discounted DP | Rub. | 162 144 091 | 230 328 972 |

| Net income, NPV | Rub. | 147 145 215 | 218 284 775 |

| Investments in the project, of which: | Rub. | 37 835 564 | 39 435 843 |

| - Equity, including: | Rub. | 11 460 597 | 11 944 197 |

| - To cover the payment deficit | Rub. | 687 724 | 715 215 |

| - Borrowed capital | Rub. | 26 374 967 | 27 491 647 |

| Return on investment from the beginning of the project | years | 1,79 | 1,69 |

| Return on investment from commissioning | years | 1,13 | 1,03 |

| Return on equity from the start of the project | years | 1,19 | 1,17 |

| Payback of own funds after loan repayment | years | 0,32 | 0,22 |

| Loan repayment period from the beginning of the project | years | 1,47 | 1,47 |

| Loan repayment period from receipt of the first tranche | years | 1,47 | 1,47 |

| ROI | % | 37,13 | 53,52 |

| Return on equity | % | 42,11 | 57,71 |

Measures to introduce a night shift at service stations.

As was seen earlier from marketing research, another significant drawback of the service station is the 12-hour work shift. An analysis of the service station capacity showed that the number of service requests is 48 cars per day, and in fact the service station serves 32 cars, therefore 16 cars are not serviced on the day the application is received - some customers wait in line (from 2 to 7 days), the rest go to be serviced to competitors.

Also, 21% of respondents noticed that a convenient time for visiting a car service center is at night.

In this chapter, personnel measures will be taken to organize the work of service stations at night.

Since the service station area was not previously used during the night shift, there will be no cost for new areas.

The acquisition and investment in new equipment is also not required. Since the existing equipment will be used.

The work schedule is planned to be introduced 2 working days, 2 days off. The duration of the work shift is 12 hours.

To enter an additional shift, it is planned to hire additional employees:

Auto mechanic - 16 people;

Autoelectrodiagnostic - 2 persons;

Wheel alignment specialist - 2 people;

Car wash - 4 people;

It is supposed to have 2 brigades for car maintenance. Each team includes the following professionals:

Auto mechanic - 8 people;

Autoelectrodiagnostic - 1 person;

Wheel alignment specialist - 1 person;

Car wash - 2 people;

The form of remuneration is based on a contract basis. Salary is the basis for payroll. Depending on the results of activities (quality of work, customer ratings), fulfillment of the plan, fulfillment of General Motors standards, fulfillment of orders of the enterprise, a bonus is accrued. The amount of the bonus depends on the position held.

Also, according to the Labor Code for work at night (from 22:00 to 6:00), an additional payment to the tariff rate in the amount of 20% of the tariff is required. Recalculation of wages was made for all employees of the company. Since not only new employees will work on the night shift, but also old ones. Therefore, it is necessary to recalculate all salaries of employees. The table shows labor costs including the unified social tax for each type of profession.

Total for the month, the cost of wages will amount to 31,750 rubles for each position.

Total for the year for all employees introduced, wage costs will amount to 2,448,306 rubles.

It is also necessary to take into account the fact that the wages of former employees will increase as they will work at night.

The cost of wages per year, taking into account allowances for night work of former employees, will be.

It is also necessary to provide for the following costs:

Training costs amount to 290,000 rubles. in year;

The cost of clothing for employees is 190,000 rubles. in year;

Therefore, the total costs will amount to 3,035,406 rubles. in year.

In order to calculate the efficiency from the introduction of additional employees, how many cars can be serviced by a car service at night. For the calculation, statistical data for previous periods were taken. About 960 vehicles are serviced at the technical service station monthly. That is 32 cars a day. Consequently, the service will be able to service 2 times more cars. Please note that not all customers will be ready to leave their car at the service at the specified time, so it should be borne in mind that the number of customers will be less. But at the same time, cars remain overnight that require longer repairs, for example, 1-2 days. Therefore, the number of cars in service will decrease by about 35%, the number of cars in service will be 21 units. per shift, 630 vehicles per month.

Table 33 - Calculation of wages for each type of profession, rub.

| Job title | Ok lad | Number of hours at the usual rate per month | Number of hours at the rate + 20% surcharge for night time | Tariff rate per hour at regular tariff | Tariff rate according to the tariff + 20% for night time | Amount at regular rate | Amount at the rate +20% for the night | Total |

| Workshop foreman | ||||||||

| Auto Mechanic | ||||||||

| Autoelectrodiagnostician | ||||||||

| Wheel alignment specialist | ||||||||

| Car washers | ||||||||

| Total | - | - |

Table 34 - The total cost of wages per year, rub.

According to statistics, the approximate cost of servicing one car is 2500 rubles. Consequently, the monthly revenue from servicing cars during the night shift will be 1,575,000 rubles. Revenue for the year will amount to 18,900,000 rubles, if we take into account the costs of newly introduced personnel in the amount of 3,035,406 rubles. per year, then the revenue will be 15,864,594 rubles. in year.

In this chapter, the necessary policies were described and carried out in 2 stages developed in special policies: the opening of MKU and the increase in the work shift at the service station. Calculations were made and an analysis of measures was made, which showed that the planned period for repaying the principal amount of the loan due to the operating activities of the MCU is 1.53 years.

Ways to improve the efficiency of production and economic activities-is a set of specific measures to increase the efficiency of production in the given directions. In cases where the improvement of product quality, the introduction of new technology, advanced experience, technical re-equipment and reconstruction, the introduction of a new economic mechanism have an impact on the final results of the work of enterprises, it should be both in planning, evaluating and stimulating the activities of labor collectives, and in economic analysis fully identify and take into account the full effect obtained due to such factors. (10, p. 135).

When substantiating and analyzing all indicators of economic efficiency, factors of increasing production efficiency in the main areas of development and improvement of production are taken into account. These areas cover a set of technical, organizational and socio-economic measures, on the basis of which the economy of living labor, costs and resources is achieved, as well as improving the quality and competitiveness of products. The most important factors for increasing production efficiency here are:

- - acceleration of scientific and technological progress, raising the technical level of production, manufactured and mastered products (improving its quality), innovation policy;

- - structural restructuring of the economy, its orientation towards the production of consumer goods, the conversion of defense enterprises and industries, the improvement of the reproductive structure of capital investments (the priority is the reconstruction and technical re-equipment of existing enterprises), the accelerated development of science-intensive, high-tech industries;

- - improvement of the development of diversification, specialization and cooperation, combination and territorial organization of production, improvement of the organization of production and labor at enterprises and associations;

- - denationalization and privatization of the economy, improvement of state regulation, economic accounting and the system of motivation for work;

- - strengthening of socio-psychological factors, activation of the human factor on the basis of democratization and decentralization of management, increasing the responsibility and creative initiative of employees, comprehensive development of the individual, strengthening the social orientation in the development of production (improving the general educational and professional level of employees, improving working conditions and safety, increasing culture of production, improvement of ecology). (19, p. 325).

Among all the factors for increasing efficiency and strengthening the intensification of production, a decisive place belongs to the denationalization and privatization of the economy, scientific and technological progress and the revitalization of human activity, strengthening the personal factor (communications, cooperation, coordination, commitment), increasing the role of people in the production process. All other factors are interdependent on these decisive factors.

Depending on the place and scope of implementation, ways to increase efficiency are divided into national (state), sectoral, territorial and intra-production. In the economic science of countries with developed market relations, these paths are divided into two groups: intra-production and external or factors affecting the change in profits and controlled by the company and uncontrollable factors to which the company can only adapt.

The second group of factors is specific market conditions, prices for products, raw materials, energy, exchange rates, bank interest, the system of state orders, taxation, tax incentives, etc. (22, p. 25).

The most diverse group of intra-production factors on the scale of an enterprise, association, firm. Their number and content are specific to each enterprise, depending on its specialization, structure, operating time, current and future tasks. They cannot be unified and uniform for all enterprises.

A quantitative assessment of internal production factors is given in terms of technical and organizational improvement of production - reducing labor intensity and increasing labor productivity, reducing material consumption and saving material resources, savings from reducing production costs and increasing profits and profitability, increasing production capacity and output, economic effect from the implementation of measures , as well as the specific amounts of capital costs and the timing of the implementation of activities.

The most important preliminary condition for the creation of a coherent and effective economic mechanism, the adaptation of enterprises to the conditions of a regulated market is the further development of a set of theoretical and methodological issues in planning and accounting. In this regard, there is a need to specify the directions of action and use the main internal and external factors to improve the efficiency of business entities. (27, p. 231).

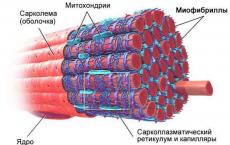

Technology. Technological innovations, especially modern forms of automation and information technology, have the most significant impact on the level and dynamics of the efficiency of production (provision of services). According to the principle of a chain reaction, they cause significant (often radical) changes in the technical level and productivity of technological equipment, methods and forms of organizing labor processes, training and qualifications of personnel, and the like.

The equipment has a leading place in the program for improving efficiency, primarily in production, as well as other activities of business entities. The performance of existing equipment depends not only on its technical level, but also on the proper organization of repair and maintenance, optimal service life, shift work, load over time, and the like.

Materials and energy have a positive effect on the level of performance efficiency if the problems of resource conservation, reduction of material consumption and energy intensity of products (services) are solved, management of stocks of material resources and sources of supply is rationalized.

Products. The products of labor themselves, their quality and appearance (design) are also important factors in the efficiency of business entities. The level of the latter should correspond to the useful value, that is, the price that the buyer is willing to pay for a product of the appropriate quality. However, in order to achieve high efficiency in managing the economy, the usefulness of the goods alone is not enough. The works offered by the enterprise (organization) for sale must appear on the market in the right place, at the right time and at a well-considered price. In this regard, the subject of activity must ensure that there are no organizational and economic obstacles between the production of products (the provision of services) and the individual stages of marketing research.

Workers. The main source and determining factor in the growth of performance efficiency are employees - managers, managers, specialists, workers. The business qualities of employees, the increase in their labor productivity are largely determined by an effective motivational mechanism at the enterprise (in the organization), the support of a favorable social microclimate in the workforce. (13, p. 195).

Organization and systems. The unity of the workforce, rational delegation of responsibility, proper management standards characterize the good organization of the activities of the enterprise (institution), which provides the necessary specialization and coordination of management processes, and, consequently, the highest level of efficiency (productivity) of any complex production and economic system.

Working methods. With the predominance of labor-intensive processes, more advanced methods of work become quite promising to ensure the growth of the efficiency of the enterprise (organization). Continuous improvement of labor methods provides for a systematic analysis of the state of workplaces and their certification, advanced training of personnel, generalization and use of positive experience accumulated at other enterprises (firms).

The management style, which combines professional competence, efficiency and high ethics of relationships between people, practically affects all areas of the enterprise (organization). It depends on the extent to which external factors of growth in the efficiency of activities at the enterprise (in the organization) will be taken into account. (19, p. 155).

Infrastructure. An important prerequisite for increasing the efficiency of enterprises (organizations) is a sufficient level of development of a network of various institutions of market and production and economic infrastructure. Currently, all business structures use the services of innovation funds and commercial banks, exchanges (commodity, stock, labor) and other institutions of market infrastructure. The proper development of the production infrastructure (communications, specialized information systems, transport, trade, etc.) has a direct impact on the performance of enterprises (organizations). Of decisive importance for the effective development of all structural elements of the economy is the presence of a wide network of social infrastructure institutions.

Structural changes in society also affect performance indicators at different levels of management. The most important are structural changes of an economic and social nature. The main ones occur in the following areas: technology, research and development, accompanied by revolutionary breakthroughs in many branches of knowledge (proportion of imported and domestic technologies); composition and technical level of fixed assets (fixed capital); the scale of production and activities (mainly due to deconcentration through the formation of small and medium-sized enterprises and organizations); models of employment of the population in various industrial and non-industrial sectors; staff composition by gender, education, etc. (10, p. 283).

Implementation of the achievements of modern scientific and technological progress and, first of all, waste-free, low-waste, resource-saving technologies and equipment for their implementation. This increases the yield of products from the same volume of processed raw materials, and hence the return on capital. Replacement of existing obsolete equipment with new, more productive and economical. With a normally functioning economy under the conditions of aggregate concentration, with a doubling of the capacity of machines, the price will increase only one and a half times.

Scientific and technological progress has been and remains the most important factor in increasing the efficiency of social production and ensuring its high efficiency. Until recently, scientific and technical progress proceeded evolutionarily. The advantage was given to the improvement of existing technologies, partial modernization of machinery and equipment. Such measures gave a certain, but insignificant return. There were insufficient incentives for the development and implementation of measures for new technology. Under the current conditions of the formation of market relations, revolutionary, qualitative changes are needed, a transition to fundamentally new technologies, to the technology of subsequent generations - a radical re-equipment of all sectors of the national economy based on the latest achievements of science and technology. The most important directions of scientific and technical progress:

- - wide development of progressive technologies;

- - production automation;

- - creation of the use of new types of materials.

The main ways to improve the efficiency of production and economic activities can be represented as a diagram

In the context of the transition to a market economy, its initial stage, scientific and technical measures are very important. The collectives of enterprises and their leaders pay the main attention to the material stimulation of labor. Most of the after-tax profits go to the consumption fund. This situation is not normal. Obviously, as market relations develop, enterprises will begin to pay due attention to the development of production in the future and will allocate the necessary funds for new equipment, the renewal of production, for the development and production of new products. (16, p. 217).

The development and implementation of measures for new technology were not sufficiently stimulated. In modern conditions, the formation of market relations requires revolutionary, qualitative changes, the transition to fundamentally new technologies, technology of subsequent generations, it is necessary to radically re-equip the enterprise based on the latest achievements of science and technology.

The problem of financing scientific and technological progress, the re-equipment of industry enterprises, the introduction of new modern competitive technologies, the integrated mechanization and automation of the production process and management, the use of progressive forms of organization of production and labor, everything that appears in order to increase competitiveness and is the most relevant, important and just necessary. At the present stage of the economy, the most scarce resource is finance. Financial resources are scarce at any level of the national economy. Therefore, the problem of financing scientific and technological progress in the industry must be addressed in a multifaceted and multichannel way.

In general, in the economy, the sources of financing scientific and technological progress within the framework of the development of its industries are well known, but the problem lies in their reality - opportunities, attractiveness for external investors, guarantees, etc.

The sources of financing the scientific and technological progress of industrial production are as follows.

- o own funds of enterprises and, above all, the profit remaining at their disposal;

- o funds of higher organizations (for state and municipal unitary enterprises), associations, concerns, financial and industrial groups (for joint-stock, corporate enterprises, business entities);

- o domestic investors;

- o foreign investors.

Currently, enterprises in many industries are in financial difficulty. Therefore, financing of scientific and technological progress from own funds is limited. However, enterprises in a number of industries operate profitably. The art in using the profits remaining at their disposal lies in their optimal distribution for accumulation and consumption. No matter how hard it is, profitable industrial enterprises should first of all direct profits and other financial resources to technical re-equipment, innovation and other relevant areas of scientific and technological progress. With the overcoming of the existing difficulties in the domestic industry, the further dynamic development of its industrial enterprises will act in this way. (6, p. 83).

Investors, both domestic and foreign, should become an important source of financing the scientific and technological progress of industrial enterprises. A number of industries are just attractive objects. However, credit is still expensive, guarantees are insufficient, and the risk is significant. Even more attractive conditions should be created for foreign investors. The economic development trend favors the inflow of foreign investments, as well as domestic ones from a number of financially specific regions - Moscow and St. Petersburg. Regional redistribution of investments is inevitable and effective.

From an economic point of view, investments in scientific and technological progress are generally attractive. Everything that is invested in scientific and technological progress, as a rule, returns several times faster than in other areas.

Only the skillful use of the entire system of these factors can ensure the appropriate growth rates of the efficiency of production and economic activity. (18, p. 314).