DIY sports bench for home. DIY wooden bench for bench press. Do-it-yourself bench press bench: step-by-step operations

In this article you can download simulator drawings bench for bench press. Bench Press Bench- the most popular and widespread sports equipment, especially loved by all athletes. When entering the gym, a novice athlete, like many professionals, runs directly to the bench press bench. Of course, its role in building muscle mass is greatly exaggerated and athletes concentrate too much on it, forgetting about other equally important muscle groups, and in fact, more important ones. Such as the muscles of the legs, back, abs and others. However, the bench press bench is my first machine that I have made by hand.

This is what the bench looks like right now. Adjustable backrest with lock, maximum angle of 90 degrees, that is, perpendicular to the horizontal position. Extendable racks that, when the backrest is raised up, allow them to be used as squat racks. On the Internet you can find many simple, basic simulator drawings, but often its design is already outdated and the drawing contains a minimum of information and data.

At the very beginning, I made a simple version of the Press Bench, without an adjustable back, just with a board upholstered in leatherette and without retractable racks, as well as without bars for push-ups. But later I modified it and improved it.

There are many different types of bench presses. Frankly, I wanted to make a standard bench on four supports with a simple horizontal board, like in many gyms with old, Soviet exercise equipment. Fortunately, there were no problems taking the dimensions of the bench during one of my visits to the gym. In the gym, no one bothers you to redraw simulator drawings. But after comparing with the store version, it became clear that the Bench with four supports is very heavy and bulky. Therefore, for production we chose a bench on three supports: two at the back - the racks for the barbell itself and one in front - under the seat.

Of course, because the simulator is bulky and heavy, it is no worse than a light and compact one. But nevertheless, many elements of such structures are simply superfluous. Also, in most cases, in gyms for angled bench presses, there was always a bench with an inclined board next to it, that is, two separate benches - for two different exercises. This option is well suited for free rooms with a lot of space, but not for a home gym. Therefore, as we have already said, the choice fell on a simpler and more compact modification of the bench press, somewhat similar to this one:

As you can see, the backrest here is adjustable, but the uprights are not retractable. In addition, it is noticeable that the bench is collapsible; it consists of separate profile pipes that are connected to each other with bolts. This is a less strong and less reliable option than a one-piece, welded structure.

Bench Press Bench

So, the frame of the Bench looks like this.

The entire structure is made of 4x4cm profile pipe. The petals of the racks for the bar are made of a metal strip 4 cm wide. Having clamped the plates cut from the strip in a vice, they need to be bent with hammer blows at the desired angle. Then they are simply placed at the top of the profile pipe of the future racks and welded with a welding machine.

In the end, all that remains is to attach narrow plywood (about 30cm wide) or board to the frame of the bench. To do this, you need to drill three holes for bolts with a diameter of 8mm, as shown in the photo above.

Drawing of the bench press machine:

Attention! IN drawings of the simulator an error was made - the distance from the floor to the horizontal surface and the length of the supporting profile pipe were incorrectly indicated. It should be 340mm. Simulator drawings updated.

If you need a bench with an adjustable back and retractable racks, read on.

Incline Bench with Simple Adjustable Backrest

First of all, I would like to note that ultimately the Bench Press was modified by us to install the module: “Attachment for legs”. To do this, we replaced the 4x4cm support profile pipe with the same one, only thicker - 5x5cm, so that the attachment could be installed in it.

For further explanations in the photo, we will use this version of the Bench - with a support profile pipe 5x5cm. You can use the simple design described above if you do not plan to install a foot attachment.

So, to install an adjustable back and seat, you need to weld an oblong metal ring to the frame of the bench, to which the back and seat will be attached, as shown in the photo below.

There is no need to drill three holes in the bench for the board, since the board will be attached to an adjustable metal structure.

Below in the photo is a bench for bench press with a frame skeleton installed in the same metal ring for an adjustable back and seat. This frame is made from a 2x2cm profile pipe.

In an inclined position, the back of the bench rests on a transverse metal beam with a diameter of 20-22mm, which is inserted into pre-drilled holes in the bench posts (photo above). There are 4 such holes in one rack, their diameter is 24mm. To ensure exact alignment of the holes, they must be drilled separately on each side, and not through each other. As a result, you will end up with 4 holes in one rack, 8 on both sides, and the same number in the second, together - 16.

You can drill such holes with a regular drill if you do not have a drilling machine. To do this, you need to buy a 24mm metal crown like this. Inside the crown itself there is a regular 6 or 8 mm drill. First, this drill enters the metal, then the crown removes the chips.

Simulator drawings The Incline Press Bench is the same as the Horizontal Bench (see above), except for the length of the racks, in this case it is 105cm instead of 87cm. The distance between the holes for the cross beam is 12cm. The distance from the horizontal plane of the bench to the first hole is 8 cm.

Why did we call this adjustable backrest simple? Since with this design it has only five positions: lower and four inclined, and the maximum angle of inclination with this design is only 45 degrees. It is no longer possible to raise the back of the bench any higher, since there will be nothing to support it with, and even more so, it is impossible to secure it in a vertically level position, at an angle of 90 degrees.

This problem can be solved by another design for fixing the backrest in an inclined position.

Incline Bench with adjustable backrest and racks

In order for the backrest to rise to a vertically level position, it is necessary to attach an additional structure to its middle, which will rest against the bottom of the bench. There is no longer any need to drill through holes in the racks, as can be seen in the photo below.

The rod rack holders themselves can be cut down. If you are making a bench from scratch - then just don't weld them to the posts.

Next is the top view. The fastening mechanism is clearly visible.

The additional design contains significantly more holes. Using the fixing pin, you can select the desired angle of inclination. The support can also be moved closer to the base of the backrest, thus increasing the angle of inclination. To keep the support in this position and not move back, you need to drill a hole in the side of the frame itself, into which the pin will go through and fix the support in the desired position.

Drawings of the incline bench press machine:

Attention! IN drawings of the simulator an error was made - the distance from the floor to the horizontal surface and the length of the supporting profile pipe were incorrectly indicated. It should be 330mm for a 50x50mm profile pipe and 340mm for a 40x40mm profile pipe. Simulator drawings updated.

Simple reclining back design

As you can see in the photo below, the structure for a simple inclined bench is connected with a pin, and closed or regular nuts are screwed onto its sides.

Between the large and small frames, thick washers are strung onto the pin on both sides; you need to make them yourself.

Recline frame with support structure, dimensions

This element is added to the standard back frame, also fixed on a pin, and clamped with nuts on the sides.

The disassembled structure of the back and support looks like this.

Drawings of the machine: Bench press, backrest frame:

1. Two wide washers, handmade, outer diameter:

20mm, inner: 11mm, thickness: 10mm.

2. Six closed 10mm nuts, simple ones possible.

3. Two pins. Cut from a metal circle with a diameter of 10mm, a length of 180mm, threads on both sides of approximately 15mm.

4. Small pin, made in the same way, length: 100mm.

5. A piece of profile pipe 2x2cm, length: 40mm.

Retractable racks

It should be noted that the use of such a design for tilting the backrest is a necessity for retractable racks, which will be discussed further. If you use the previous scheme, then it will not be possible to install retractable racks, since the transverse beam will interfere with them.

The racks are made from a 3x3cm profile pipe; its size must be selected so that it can fit into the supporting structure of the bench. That is, if your bench is made of 5x5cm pipe, then the racks will need to be made of 4x4cm.

In order for them not to wobble, it is advisable to buy prof. pipe 3.5x3.5cm. But metal of such intermediate sizes is not always available at the metal warehouse. The rack holders are made of metal strip according to the same principle as described above for the horizontal bench. The length of the stands is 82cm. The distance between the holes is 15cm, but you can make it smaller, for example 7cm each. The diameter of the holes is 10.5-11mm, for a pin with a diameter of 10mm.

In the photo above, handles are attached to the racks, which replace push-up bars. They are made from a circle with a diameter of 30mm and a length of 14cm (more is possible). Shallow holes of 2-3 cm with a diameter of 8 mm are drilled in the cut beams. A 10mm thread is cut into them using a tap. In the racks themselves at the top you need to drill a hole for the bolt, as shown in the photo. All that remains is to take a 10mm bolt 4-5cm long, a washer for it, insert it into the drilled hole and screw the handle onto it.

Back upholstery

All that remains is to cut out the plywood and cover it with leatherette. Plywood thickness 8-12mm. In the photo below, the plywood is coated with paint on the underside. If you want to make a regular horizontal bench without an adjustable back, then the plywood in this case should be solid from one rectangle.

In principle, at first, even an unnecessary door to the bathroom left after renovation will do. The author, when making his first bench press bench, did just that, until a full-fledged backrest was made from plywood - he really wanted to quickly test the machine in practice.

Four holes with a diameter of 8 mm are drilled in small and large plywood. From the top side, special nuts with teeth for wood are driven into them, as in the photo below. In total you need to buy eight pairs: a bolt + a nut, the length of the bolt is 30mm, the diameter of the bolt and nut is 8mm.

Drawings of the exercise machine Press bench, board:

Next, we cut out leatherette or thin carpet fabric with scissors, preferably, of course, ordinary leatherette, which, for example, is used to sheathe metal armored doors. For small plywood you need to cut a piece measuring 44x32cm, for large plywood the length is 92cm, width on the narrow side: 29cm, on the wide side: 33cm.

Next, using a knife-blade, we cut out the foam rubber according to the size of the plywood, the height of the foam rubber is 2 cm, you can buy it at a hardware store or at the market.

We hammer nuts with teeth into the holes, lubricate the plywood with Moment glue around the perimeter and in the center (optional) so that the foam does not move out when upholstered with fabric.

We put foam rubber on top and leatherette on top (fabric is shown here in the photo, since the last time the back was re-upholstered with fabric instead of leatherette).

The most difficult thing here is to sheathe the corners. Although in reality the process is simple, first we wrap one side of the corner - we punch it, then the other.

Large and small plywood sheathed around the perimeter. Time spent: 5 min.

As a result, we get these two soft backs.

All that remains is to place the trimmed back and seat on the metal structure that we described above and secure with bolts

This is what the structure looks like from below, with the seat raised. There is a felt square in the middle to get rid of metallic knocking when lowering the bench to a horizontal position.

The main thing is that the holes in the board coincide with the holes in the metal frame of the bench. If you did everything according to our drawings, then there will be no difficulties with this. The same applies to the back of the exercise machine; it is secured with four bolts.

From the very beginning, for the Home Gym we wanted to make a machine like this with safety nets on the sides. In this case, you can perform the exercises yourself, with heavy weights, without outside help. At the same time, you feel more confident, because you know that the bar will not fall below the side bars.

But after we made the Power Frame, the need for such a machine was no longer necessary, since the Power Frame allows you to achieve the same result if you slide a regular bench press inside.

Today, many people seriously care about their health and make a lot of efforts to have a really fit and slender figure, for which they regularly work out in the gym. Any set of exercises necessarily includes a bench press, for which an appropriate bench is required. Those who do not have the opportunity to constantly visit a fitness club and want to train at home do not necessarily have to buy such a bench, spending a lot of money. In this case, a do-it-yourself bench press will be an excellent assistant; a person can actually make such a device on his own. As a result, everyone will have the opportunity to exercise at home at a time convenient for themselves, without adjusting to the gym schedule.

Necessary qualities of a bench designed for bench press

The dimensions of such a simulator must have specific properties; it must correspond to the established parameters. The backrest of the bench must be adjustable without any effort, have fasteners with the greatest strength, and the angle cannot exceed 90 degrees.

There are many methods for developing such a bench, but most of them can now be considered outdated. It is worth paying attention to the simplest option for making a home exercise machine, in which the drawings of a bench for bench press with your own hands will provide considerable assistance. You can make a standard bench that includes 4 supports with an ordinary board that is in a horizontal state; similar training devices are now present in many fitness clubs.

While in the gym, anyone who wants to make a bench with their own hands can immediately take measurements from the sample. But this option will be quite bulky, and the bench will weigh a lot.

A good alternative in this situation would be a do-it-yourself press bench consisting of 3 supports. It is best to make a simulator yourself from two supports in the rear component and one located in the front. In clubs for bench presses performed at an angle, a bench installed nearby is offered, equipped with a special inclined board, but for home this option is not the most suitable, since it will take up quite a lot of space. To carry out training in the conditions of a standard city apartment, it is desirable to produce the most lightweight and at the same time optimally reliable device for regular training.

Using drawings in the production of a bench press

To competently carry out the necessary work related to the manufacture of a bench for performing bench presses, it is necessary, first of all, to understand in detail the existing drawing. First of all, it is worth paying attention to the frame design, made from the appropriate profile pipe. It should measure 4 x 4 centimeters. The components of the barbell stands are made from a metal strip; its best width is also 4 centimeters.

In the future, a do-it-yourself bench press bench is created as follows. The plates are clamped from a strip of metal, then they are bent as carefully as possible using a hammer. After this, they are installed in the upper section of the profile pipe related to the racks and secured by welding. At the final stage, you only need to attach fairly narrow plywood; its width should not exceed 30 centimeters.

There are other options for similar training devices for training at home. There is a type of inclined bench that has an adjustable backrest and stands. In order for the backrest to ultimately have maximum functionality, a special structure should be installed in the middle; it can rest against the lower component of the finished bench. Holes through and through will not be required in this case. A separate design has a larger number of holes. The selection of a suitable angle of inclination can be done using a pin. The support may not remain in the same position all the time; it can change, due to which the angle of inclination will increase.

Sheathing the plywood will take very little time. The result will be comfortable and soft backrests. If you correctly apply the drawings of a bench press with your own hands, you will definitely create an excellent device that will really help you train at home in comfort and quickly achieve fairly good results, even for a person who has not previously played sports at all.

Daily performance of a special set of exercises, which certainly includes the bench press, will lead to significant progress in a short time; a person himself will not be able to help but notice positive changes in his state of health and level of physical fitness. Soon he will be able to easily perform those actions that previously seemed absolutely impossible to him.

Details Published 08/07/2012 22:55Many basic exercises with dumbbells are performed using an athletic (sports) bench. It is simply necessary for those who use dumbbells not only for exercise, but also for more serious activities, to build muscle mass, strength, and an athletic figure. This equipment is in great demand and not a single gym can do without it. A more or less decent bench for bodybuilding, or as it is fashionable to call it today, bodybuilding, has an impressive price in the sports equipment retail chain. Therefore, Russian craftsmen often make this projectile on their own. And indeed many designs and technologies for its manufacture have been invented. You will get acquainted with one of them that is quite simple to build, without the use of a welding machine, and at the same time very functional and aesthetically attractive, by reading this article.

The design of a wooden training bench consists of a base made of solid timber, a backrest with a seat and movable supports for changing the angle of the backrest position.

For the load-bearing base of the bench, a 15x15cm beam is used, but you can take an even thicker one.

To connect the posts with the legs and the cross beam, a groove is made in the cross beam and the legs.

To do this, after marking the groove with a pencil, longitudinal cuts are made, after which the excess material is removed using a chisel.

The legs and crossbar are secured to the posts using studs, washers and nuts.

Next, as shown in the diagram above, it is necessary to make movable supports. These parts should be made from durable types of wood, beech, hornbeam, oak, or hard varieties of pine. You can find out more about hardwoods.

To fix the back of the bench, the supports are fixed in grooves on the cross beam, and in places where the groove runs next to the nut, it is advisable to make a metal stop from a corner.

That's all you need to do to get a wonderful athletic bench.

Happy assembly everyone, and productive activities!

Let's talk about how, having ready-made drawings, you can make a bench press bench with your own hands. Why a bench press bench? Yes, because this is one of the most popular and sought-after exercise machines, with which you can effectively train at home at any convenient time!

Where can I get plans for making a bench press bench? There are quite a lot of them on the Internet, and there are various drawings for making a bench: with and without a backrest, with clamps and the most primitive options. If you are a beginner athlete and cannot yet boast of outstanding results in the field of strength training without a coach, then an ordinary simple bench without a back is quite suitable for you in the initial stages, especially since it is the easiest to do, and no drawings are required for this. It will be enough to watch several videos on the topic in order to understand what is what.

Such a bench will consist of ordinary boards on a frame, covered with leatherette or leather, without any racks or special bars for push-ups. Over time, as the exercises become more complex, you can improve the bench to suit you.

If you want to make a bench for doing the bench press, then there should be no obstacles to this. Study the drawings on the Internet, and if necessary, take measurements from the finished exercise machine in the gym. The heaviest bench is on four supports, it is also considered the most cumbersome and uncomfortable. Therefore, let's talk about how to make a bench with your own hands on three supports from three racks.

How does its bulkiness affect the functionality of a bench? No, it doesn’t make sense to simply use extra structures to make it.

How to make a bench for bench press - the easiest option

The design of the bench press is made on the basis of a profile pipe. The optimal dimensions for it are 4 x 4 cm. For the petals of the racks, you can use a metal strip of small width - no more than 4 cm. To give them the desired shape, it will be enough to bend them with a hammer, and then install them in the upper part of the profile pipe using a welding tool apparatus.

Finally, you will need to attach the board or plywood to the frame using pre-drilled bolt holes. It will be a little more difficult to make a bench with a back that can be adjusted to different angles and special racks. Read below how to do this. You can get a better look at the bench manufacturing process with the help of a video.

How to make an inclined bench with a back?

To begin with, we note that the most convenient option for a bench press machine at home is a bench with an additional attachment for the legs. To make it, you will need to replace the support pipe with a thicker one that can support your legs. If the foot attachment seems like an unnecessary pleasure to you, then you can do without it, using support pipes with dimensions of 4 x 4 cm, as for a simple bench.

To attach the adjustable backrest, you will need to weld an oblong ring, again made of metal, to the frame. There is no need to make special holes in the bench, because the board will be fixed to an adjustable structure. The frame for the adjustable backrest can be made from a profile pipe (dimensions 2 x 2 cm).

Each rack must have 4 holes. It is important to drill them separately on each side using a regular drill. The backrest in this case is called simple because it can have only five positions. Tilt angle: maximum possible - 45 degrees.

If the goal is an inclined bench, then its length should be approximately 18-20 cm longer. Watch thematic videos to understand what the process looks like in practice.

Bench with back and uprights

Bench press frame diagram

In order for the backrest to be installed at a right angle, it will be necessary to attach an auxiliary structure to it, which will rest against the bottom of the bench. In this case, stand holders will not be needed.

The auxiliary structure has many holes, and the use of a pin for fixation will allow you to select the optimal backrest angle. In order for the support to hold securely and not move, you need to make a hole in the side of the frame for the pin - in this case it will act as a lock for the support in the correct position. A video on making a bench with a back and a stand is also available for viewing.

How to make racks?

Retractable racks can be made only if an auxiliary structure is used. For their manufacture, profile pipes (dimensions 3 x 3 cm) are suitable if supports with dimensions 4 x 4 cm were used for the bench. If the bench was made of pipes with dimensions 5 x 5 cm, then for the racks you will need a pipe with dimensions 4 x 4 cm.

To make the racks stable, look for a profile pipe with intermediate dimensions, for example, 3.5 x 3.5 cm. To make rack holders you will need a metal strip; they will need to be made in the same way as in the case of holders for the simplest horizontal bench, described above. A post length of 82 cm and a distance between holes of 15 cm will be sufficient.

If you want to improve the bench press bench and expand its functionality with your own hands, then additionally you can fix the handles in the racks - they will act as parallel bars. Check out the videos that clearly show how to make a bench with racks with your own hands.

Finish line - what to cover the bench with?

The upholstery of a bench press can be made of leatherette

The finishing touch will be plywood as the base of the bench and finishing material for it - for example, leatherette. Plywood must have a thickness of at least 12 mm. By the way, to make a bench with your own hands, you can use an ordinary interior door, at least until the plywood back is made.

As for the upholstery, in addition to leatherette, you will have to use a sheet of foam rubber to make it more comfortable to exercise on the bench press machine. To prevent the foam from moving, you will need to lubricate it with glue. The final touch is to attach the upholstery using a simple staple gun.

As you can see, there is nothing difficult in making a bench press bench with your own hands, especially when you have access to the Internet and thematic videos with detailed instructions. The main thing is patience and the desire to make a convenient and practical exercise machine for regular training, and drawings can always be found ready-made or created independently, using a bench in the gym as a sample.

Developed shoulders and textured pectoral muscles have always been considered advantages of the male figure. But athleticism is simply at the peak of popularity today. And crowded gyms are the best proof of this.

The beauty of the Hellenic heroes inspires or with such forms it is easier to conquer a woman’s heart - everyone has their own motivations for building muscles. But, without a doubt, strong muscles inspire respect and increase self-esteem.

In addition to physical perfection, it also means strength and endurance, and most importantly, health. And it’s not at all necessary to work out in a gym. The main men's exercise - the bench press - can be performed without crossing the threshold of your own apartment. You just need to purchase a weight bench. The effect of home exercises is comparable to training in the most prestigious gym.

Purpose and benefits of use

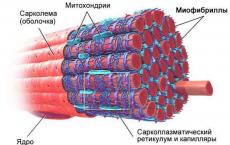

bench press allows you to specifically strengthen the pectoral musclesThe full name of the machine is “bench press”. This exercise is included in the basis of strength training in powerlifting and bodybuilding. It is also basic for beginner athletes; it is performed with free weights - dumbbells or a barbell. Bench presses develop, pump, and both deltas.

The choice is difficult, but the result is worth it

An athletic bench for performing bench press is a horizontal bench-bed, equipped with devices for installing additional sports equipment.

The models differ in their functional content and set of adjustments; the same parameters determine the price.

The range of sports benches is varied. When choosing sports equipment for your home, you need to proceed from the conditions of three maximums:

- maximum capabilities of the simulator;

- maximum benefit and positivity from classes;

- maximum security;

When using at home, for reasons of ease of storage and transportation, it is better to purchase folding structures.

Bench selection criteria

only if you choose a good bench can you competently perform standing presses and deadlifts

only if you choose a good bench can you competently perform standing presses and deadlifts Key parameters to pay attention to:

width and length: the bench primarily supports the spine and head, it should not be wider than 32 and narrower than 25 cm, longer than 1.25 and shorter than 1.20 m, you need to focus on your own feelings of stability of the position of the body and head;

backrest tilt: to load more muscles, it is rational to purchase a bench with a movable back (adjustable tilt down and up) - from -20 to +40 degrees, then the height of the stand for the barbell must be adjustable;

height: are based on the distance between the ankle and knee joints, the length of the lower leg usually fits into the standard bench height of 40-45 cm.

The seat should be at knee level, and your feet should rest firmly on the floor for safety in case the barbell moves to the side.

your own weight plus the planned weight for the bench press multiplied by 1.5 or 2 - this is the number that they focus on when looking at the characteristics of the equipment.weight: lightweight benches are usually unstable.

upholstery: The medium hardness of the filler is the most gentle on the spine when lifting weights; the wear-resistant coating lasts longer.

Bench equipment

the effectiveness of training directly depends on the design features of the bench press

the effectiveness of training directly depends on the design features of the bench press

Stores sell benches both as a separate item and combined with stands. When bench pressing dumbbells, a rack is not needed; for a barbell, a rack is required.

Barbell stand.

It is a technical device consisting of two connected vertical supports. Necessary for working with heavy weights, Serves as a bar holder when changing discs.

The design may include simple hooks for a barbell or steps with fixation of several height positions. On some models, bars are provided for and relaxing the spine after deadlifting.

An important detail is the presence of safety stops that prevent the iron from falling onto the chest.

This is the key to the safety of an athlete training alone. If you plan to perform exercises with weights under the supervision of a belayer, you can buy a rack without these elements. The adjustable height of the stops and the rack itself add variety to the training - it becomes possible to press with a limited range of motion.

A useful option is the variable size of the rack horizontally, so you can squeeze the barbell with a grip of different widths.

Leg flexion-extension block. A useful additional device for shaping the gluteal muscles and calves.

Butterfly block. A questionable device that interferes with the full performance of bench presses.

Emphasis for the partner. A soft safety stop will prevent you from falling forward when assisting in the bench press.

Which is better: collapsible or monolithic design

The bench press bench is available in two versions:

Monolithic. This is a single welded frame on which the bench and stand are attached. Use at home is inconvenient. But if space allows, for the comfort of performing exercises, it is advisable to choose options where the distance between the rack supports is greater.

Collapsible. The ability to detach the bench from the rack allows you to expand the boundaries of the use of sports equipment. Squats with a barbell and dumbbell rows will become available. Again, disassembled storage will save useful space in the room. After training, you can always lean the exercise machine against the wall or put it on the balcony. Rigid bolts connecting the individual parts ensure easy assembly and disassembly of the structure. In expensive models, the racks are retractable (telescopic).

It is believed that the simpler the simulator is, the more reliable it is. You shouldn’t fall for Chinese inventions like “ten in one”. Such versatility will not provide the required reliability and quality of work on the simulator. Extra elements will only increase the risk of all kinds of breakdowns.

A rational option might be to purchase a bench and stand separately.

The main thing is that the locking mechanisms are simple and durable.

About the care and maintenance of the simulator

do not overload the simulator

do not overload the simulator With careful handling and compliance with operating conditions, the simulator can last a long time. Even with round-the-clock operation, the period will be more than 10 years.

But the service rules must be followed:

Transportation in original packaging for protection from precipitation and mechanical loads.

Storage at a positive temperature of 10-35 ° C, humidity 50-75%.

After being in a cold or damp room with the formation of condensation on metal surfaces, you need to keep it at room conditions for 2.5-4 hours, after which you can start assembling or directly training.

Installation on a non-slip, flat surface, leaving half a meter of space around.

Use of rubber mats to reduce vibration.

Do not overload the machine. The maximum load capacity is indicated in the instructions in the specifications. Otherwise, the fastening assembly parts will not hold up, and the welds will separate. The person will inevitably be seriously injured.

Powder coating of metal parts prevents corrosion more reliably than an enamel layer.

Popular samples for home use

Officially registered manufacturers of sports equipment are guaranteed to produce high-quality and reliable products. You can trust them with your health and safety.

| Manufacturers |

Name | Equipment | Price |

| M. B. Barbell Russia |

MV 2.06 Bench-rack | 3 positions for the bar, steps for the partner, rubber thrust bearings, without stops; | 18000-21500 |

| Rekord | Rk-02 Bench-rack Rk-01 Bench-rack 1.5 year warranty |

3 levels of position for the bar, without stops, max load 270 kg, weight 25 kg; 3 levels of position for the bar, adjustable stops, max load 270 kg, weight 35 kg |

6990 |

| Carbon Germany/China |

Carbon MB-50, bench with stand, 1 year warranty |

Adjustable stand, backrest angle, 2 additional blocks, max load 140, weight 17 kg | 13990 |

| Oxygen, Germany/China | Oxygen Boston Ш bench with rack; 1 year warranty |

Multifunctional: barbell, butterfly, leg and abdominal training, max load 210 kg, weight 28 kg | 15890 |

A note to the homemade master

Making a simulator yourself is not very difficult. Having a drawing, a standard assortment (pipes, angles), a welding machine and several bolts to stop the moving part of the racks, it is easy to mount a reliable frame for the future projectile.

For a sun lounger, ordinary plywood is suitable. It is upholstered with strong artificial leather, having previously placed a softening layer. It is advisable to reinforce the foam rubber with a layer of padding polyester, otherwise it will quickly wash out.

How to make a bench press with your own hands (video instructions):

The male torso in the form of an inverted triangle looks attractive, but it is also an indicator of a powerful immune system. Representatives of the fair sex do not need such body geometry, but training on a bench press will benefit them too. Developed pectoral muscles will add expressiveness to the female form.