Vehicle axle load indicator system. Door opening sensor, temperature control sensor, built-in motion sensor, vehicle axle load, rotation sensor, hour meter, kan module

The development of the market entails the expansion of trade routes and an increase in the number of freight carriers. In the conditions of mass competition, transport companies are forced to reduce tariffs, and in order to compensate for losses - to increase the efficiency of each vehicle and the fleet as a whole.

In an effort to transport as much cargo as possible in one trip, the norms of permissible axial loads are often exceeded and, as a result, wear of the roadway. To combat such violations, many countries have introduced weight control and severe penalties. For example, in the Russian Federation, the fine for reloading reaches 400,000 rubles, and it is planned to increase it to 1,000,000.

It is paradoxical that the car often carries less cargo than the carrying capacity allows, but the axle loads are exceeded. The reason is the incorrect distribution of cargo on board.

In addition to transport companies, trucks are massively operated by enterprises for the regional movement of goods or their delivery to retail outlets, warehouses, etc. In the interests of such enterprises - accounting for shipped products, rational use of rolling stock in order to save fuel and lubricants, as well as the fight against "left" flights.

How to determine that the car is loaded "to the eyeballs"? How to correctly measure and distribute the load on the axle and not get a fine? Does the driver make unauthorized loading and unloading?

To solve these problems, special truck scales are used. However, given the size, cost and features of their operation, they are not widely used.

An alternative to such scales is the development of our partners - the ALM system, which allows you to receive detailed information about the axle loads of the vehicle and the weight of the cargo on board.

How does the system work?

At the heart of the entire ALM system is a weighing computer located in the driver's cab. Special axle load sensors are connected to it, which are mounted in the suspension elements of the car.

At the heart of the entire ALM system is a weighing computer located in the driver's cab. Special axle load sensors are connected to it, which are mounted in the suspension elements of the car.

Sensors monitor the impact of the load on the vehicle suspension and transmit all the necessary data to the weighing computer with a measurement accuracy of up to 98%:

- load per axle (from 2 to 6 axles),

- net weight of cargo,

- the total weight of the vehicle.

These data are applicable in the accounting of shipped products, and also allow you to control the shipper for compliance of the documented weight of the cargo with the real one.

A feature of the ALM system is that, regardless of the total number of axles per vehicle only two axle load sensors are installed. The device uses its own algorithms to calculate the load on all axles of the car and trailer using two sensors installed on the front and rear axles of the tractor.

In this case, the weighing computer displays the load on each axle of the machine in the same way as if the sensors were installed in each axle. This reduces the cost of purchasing a large number expensive sensors and make the cost of the ALM system acceptable as a whole.

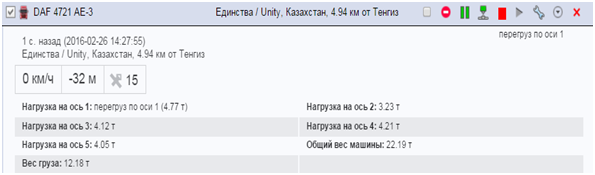

In addition to displaying data for the driver, the ALM system is capable of transmitting data on the weight of the load to any GPS trackers that have a digital RS-485 interface. This allows you to integrate information about the loading of each vehicle into the Wialon system and view actual sensor values in real time.

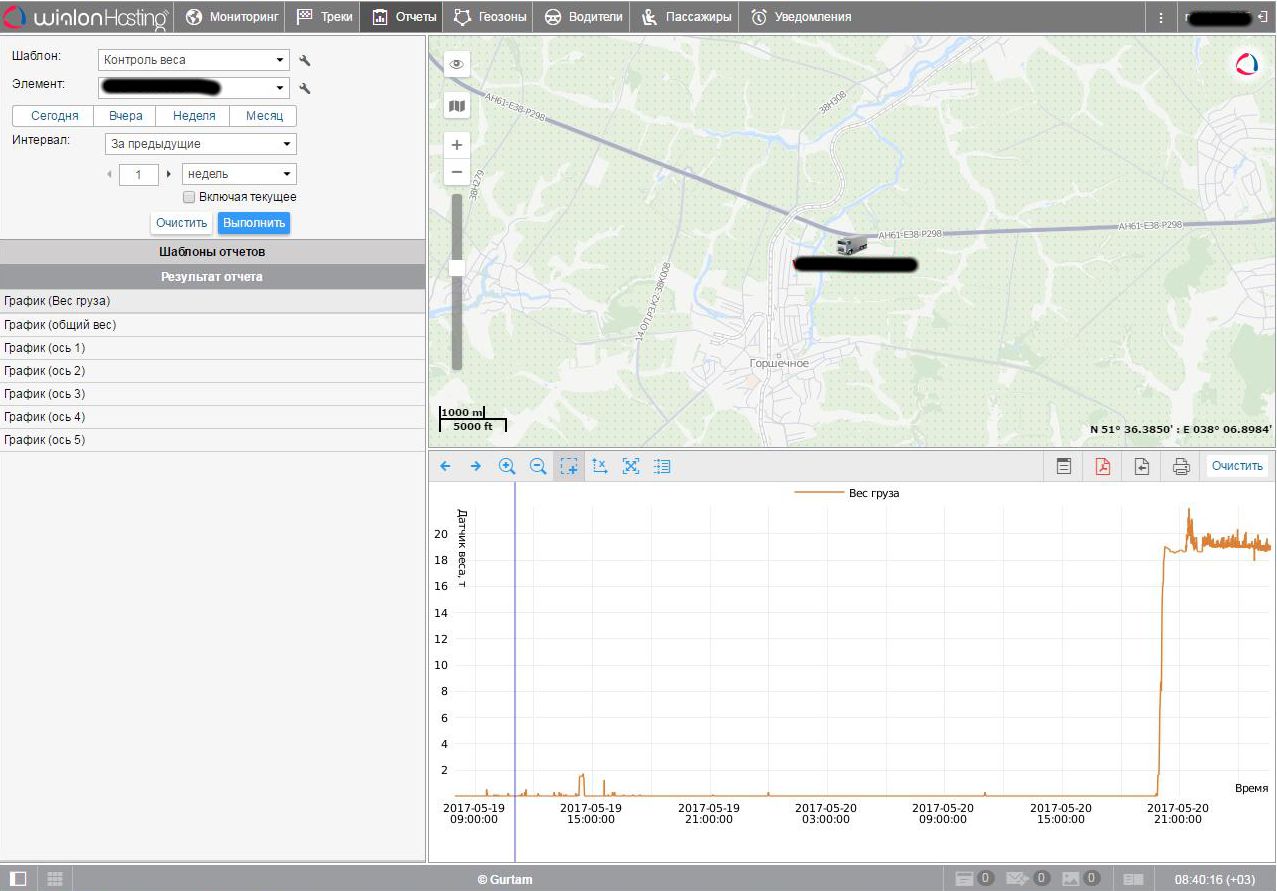

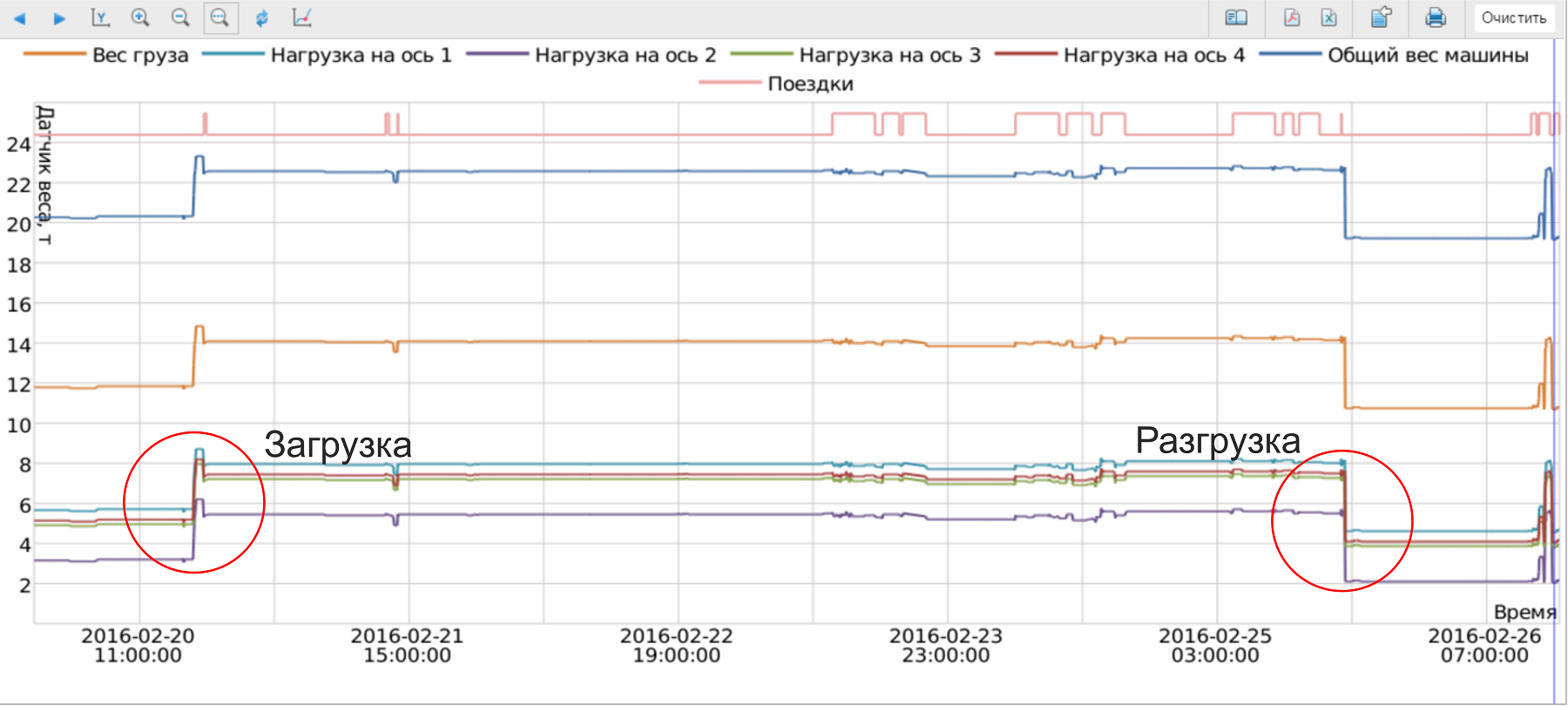

In order to see all changes in the load level on each of the axles for a certain period of time, Wialon can generate detailed report.

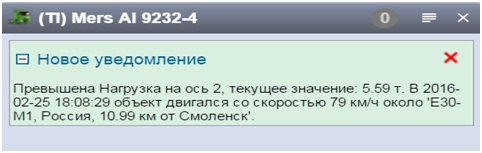

Additionally, you can control the fact of loading and unloading the car, as well as exceeding the axle load by setting up the sending of operational online, sms and email notifications.

Thus, the ALM system helps to perform 2 main functions:

1) Assist the driver with loading.

With the help of ALM, the driver sees during loading which of the axles is overloaded or, conversely, underloaded. Proper load placement allows you to avoid overload penalties and improve vehicle handling, and most importantly, effectively use the permissible load capacity of the machine.

2) Remote control of the fleet.

By combining the capabilities of the ALM system and Wialon, you will be able to remotely control the level of loading of the fleet, as well as warn the driver in case of an overload of the car.

In addition, monitoring the operation of the fleet allows the use of rolling stock more rationally, increasing the number of vehicles for heavy work and reducing for light loads.

Each truck has its own load limit, exceeding which can lead to breakdowns and a significant reduction in the life of the vehicle. If the overload is noticed and eliminated in time, this will help to avoid accidents on the road, the risk of breakdown will be significantly reduced, and the service life will not be reduced. A car can last much longer if you take care of it: carry out Maintenance, control oil. Trucks have different suspensions and each of them requires a specific approach to operation. A truck axle load sensor can help with this.

Why you need an axle load sensor

The vehicle axle load sensor is designed to monitor the load on the vehicle. It is usually installed on the rear axle of a truck and, when loaded, provides information about the load level. If this level is exceeded, the driver will learn about it very quickly and will be able to reduce the load. This will help to get rid of the risks of breakdowns and emergencies on the roads during transportation. In addition to the load level, the axle load sensor monitors the time of loading and unloading, as well as the weight of the load. Most often, the sensor is installed on the rear axle of a truck, or on the axle of a trailer. For different types of pendants are used different types sensors. If the suspension is hydraulic, which is usually the case for heavy trucks, then the axles are grouped into circuits and the sensor monitors the change in the pressure level in these circuits.

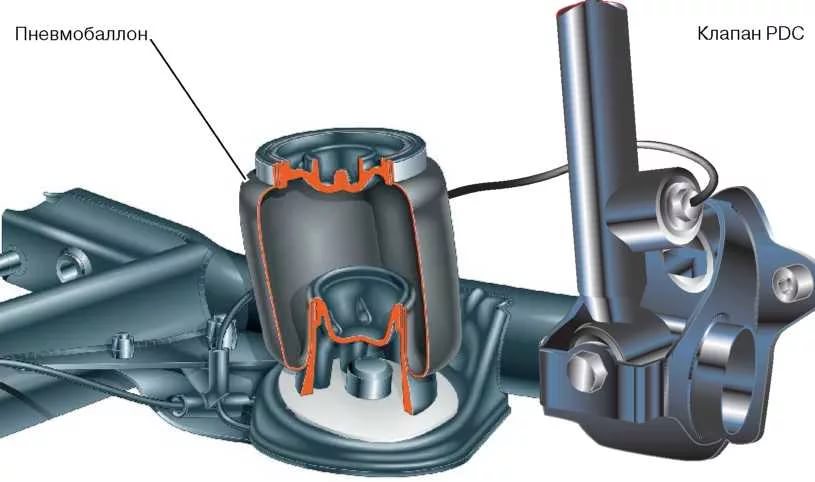

Axle load sensor for a vehicle with air suspension

In the presence of air suspension, the sensor with the help of special tools crashes into the air line. It measures the pressure on the truck axle and transmits the data to the display. The principle here is very simple, since the pressure in the suspension directly depends on the weight of the load. Spring suspension requires a different approach, as it works on a different principle. The sensor in this case is placed on the front axle of the truck, and controls the load level.

Application of axle load sensor in industry

The vehicle axle load sensor also allows you to create and configure a schedule of loading and unloading, which will help to control the work of drivers and counteract various unscheduled trips that can seriously damage the car.The sensor can also be connected to the GLONASS monitoring system - in this case, the data will be sent to the dispatcher or the owner of the car.

Legislation of Russia regarding the carrying capacity of vehicles

At the moment, Russia provides for a fine for exceeding the load on the car. In order to avoid fines, you need to use a vehicle axle load sensor. Its installation does not take much time, but it significantly helps to save money. The operation of a truck is cheaper, and its life and quality can increase significantly.

Axle load sensor failure

If the vehicle axle load sensor is damaged, it will no longer monitor the load level of the truck. A breakdown should be detected as early as possible, because the safety of the car axle depends on it. If the display on which the data is displayed does not work, you need to contact the service department to identify and eliminate the breakdown.

Where is the car load sensor for sale

It is very easy to buy an axle load sensor for a car. Firms involved in its sale are located in every city in Russia. In order to purchase this appliance, it would be better to contact the seller in advance to calculate the purchase and installation price individually. Depending on the type of suspension and the number of axles, the operator will calculate the cost and it will be possible to choose the time to arrive and install the load sensor on the axle of the car, when it is convenient for the driver.To increase the efficiency of cargo transportation, one has to try to transport the maximum cargo in one flight. If you "get carried away" or make a mistake when loading, axial loads can exceed allowable norms. As a result, not only will the wear of the car itself and the road surface increase, but you will also have to pay a large fine. To facilitate loading and avoid possible problems with fines, axle load control systems are installed on trucks. They allow you to quickly and accurately control the load on each of the axles during loading. AvtomonitoringMSK offers the ALM system, which combines the functions of axle load control and vehicle monitoring using GLONASS/GPS systems.

Who needs an axle load control system

The ALM system is designed to control the weight parameters of a car and is suitable for installation on any model of freight transport. It will be useful for both large transport companies and individual entrepreneurs specializing in cargo transportation.

Purpose of the ALM system

Installing a weight control and GPS tracking system allows you to solve the following problems:

- Control over the process of loading and unloading transport. The data is simultaneously available to the driver and company management.

- Control of underload or transportation by the driver of unaccounted cargo.

- Getting information about the flight: route, speed, idle time.

- Weighing cargo regardless of physical parameters.

- Simplification of the loading process and reduction of time for carrying out weight control.

- Prevention of breakage of suspension and body parts, tire wear due to overload.

- Prevention of penalties for overload in relation to the driver and officials of the enterprise.

- Ensuring the safety of the road surface.

How the axle load control system works

The ALM system includes a weight computer mounted in the driver's cab and two axle load sensors installed in the truck's suspension elements.

Thanks to the developers' original algorithms, a pair of sensors determines the actual axle load on vehicles with 2 to 6 axles. Moreover, the calculated data provide the same accuracy as when installing sensors on each of the axles of the truck. This reduces the number of sensors used, increases reliability and reduces the cost of the ALM complex as a whole.

After processing the data received from the sensors, the computer displays the following weight parameters with an error of no more than 2%: gross vehicle weight; net weight of the transported cargo; load on each of the axles of the machine.

The weighing computer can not only display data for the driver, but also transmit them through any GSM tracker with an RS-485 interface. This makes it possible to combine vehicle loading data with route information and transfer them to the Wialon software package.

Wialon capabilities allow real-time monitoring of the movement of the company's vehicles and the current load of each vehicle. All data about this is stored in a database, on the basis of which trip and axle load reports are generated for any period of time.

There is also an additional possibility of operational control of the fleet - sending SMS notifications, email notifications and a pop-up window in the personal monitoring account for dispatchers, company logisticians about exceeding the axle load and the location of the truck.

This is what the user interface looks like

ALM system technical details

The ALM electronic complex includes a computer and a pair of sensors.

The computer has two analog inputs for connecting sensors and an RS-485 connector compatible with the standard fuel level sensor data transfer protocol. The device can operate from a power source with a voltage of 10-50 volts and has a built-in non-volatile memory. The backlit computer display shows the following options:

- load on each of the axles (up to 6 axles);

- total weight of the car;

- net weight of cargo;

- current voltage of the on-board network.

The weight of the computer is 150 grams. The electronic module can operate at temperatures from -30 to 60 degrees Celsius.

Depending on the type of suspension (spring or pneumatic), tilt or pressure sensors can be connected to the computer. The former take data on the gap between the axles and the body frame, the latter on the pressure in the pneumatic cylinders.

An intuitive interface that allows an unprepared person to quickly master the work with a weighing computer.

Easy integration into the Wialon software package and others.

Installing an axle control system will allow you to avoid overloading fines and increase your company's profits by increasing the efficiency of cargo transportation.