Types of straw choppers. How to make a straw chopper Build your own straw chopper household appliances

Villagers and farmers often use different mechanisms to make their work easier. Such devices include a straw chopper. Such equipment can be found in the store, or you can make a crusher with your own hands, while saving a lot of money.

Purpose of the device

Straw and hay are the main food for livestock during the cold season. Also, this material is used as flooring, for mulching the ground, for the production of fuel briquettes, etc. Therefore, many owners of private farms are forced to harvest hay in fairly large volumes. A hay chopper makes this task very easy.

Straw and hay are the main food for livestock during the cold season. Also, this material is used as flooring, for mulching the ground, for the production of fuel briquettes, etc. Therefore, many owners of private farms are forced to harvest hay in fairly large volumes. A hay chopper makes this task very easy.

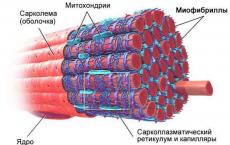

Such equipment may have different sizes and power ratings. The operation of the device is provided rotating knives. Straw is sent to a special compartment. Being processed in the cutting drum, the material is crushed and fed into the return tank.

Design features

Hay grinders can be different. The standard design consists of the following items:

- Electric drive. The speed of processing depends on the power of the part.

- A tank where raw materials (straw or hay) are fed. Its dimensions may vary.

- Shaft with cutting parts. These elements must be made of strong steel.

- Compartment for recycled material. For convenience, it is installed at a slight slope.

- Supports. Often made from thick pipes. The height depends on the size of the engine.

Various elements can be additionally built into the chopper. But to perform basic tasks, the basic configuration is quite enough.

Popular Models

If you do not want to spend time and effort on creating such equipment, it is better to buy a finished device in a specialized store. most popular and reliable models in the domestic market are the following:

- M15. The device is equipped with a very convenient container for supplying raw materials. Engine power - 3 kW. This allows you to process even thin branches. The weight of the equipment is 130 kilograms.

- KP02. Very compact device with high performance. Electric drive power - 1.54 kW. This is enough to process 20 kilograms of straw in one hour. The model is convenient because it is powered by a standard 220 V power supply.

- K-500. A very powerful device that can grind up to 300 kilograms of hay per hour. Such equipment is great for large farms. Raw materials can be loaded directly into the bunker with forks, which significantly speeds up and facilitates the work.

When choosing one system or another, take into account the volume of raw materials that needs to be processed. In the presence of a small number of livestock, it is not advisable to buy high-capacity equipment. In this case, it is better to save money and purchase a more compact shredder.

When choosing one system or another, take into account the volume of raw materials that needs to be processed. In the presence of a small number of livestock, it is not advisable to buy high-capacity equipment. In this case, it is better to save money and purchase a more compact shredder.

It is necessary to choose a product exclusively from proven manufacturers. Poor-quality equipment will not process straw well and will quickly become unusable.

A simple constructive device and the absence of complex mechanisms allow, if you have the skills and desire, to make a hay crusher with your own hands. It is enough to buy a powerful engine, and all additional parts can be found in any household.

How to DIY

If you do not have the desire or funds to buy a "store" chopper, then you can make it yourself. For this purpose, it is sufficient to adhere to the following course of action:

If you have experience in operating equipment for welding and understanding the principle of operation of the electric drive, you can make a hay and straw chopper with your own hands in a few hours. If there are some doubts about the success of such an undertaking, then it is better to go to the store and buy a device that is completely ready for use.

Removal, processing and disposal of waste from 1 to 5 hazard class

We work with all regions of Russia. Valid license. Full set of closing documents. Individual approach to the client and flexible pricing policy.

Using this form, you can leave a request for the provision of services, request a commercial offer or get a free consultation from our specialists.

In agriculture, a hay chopper, like hay itself, is a necessary and useful thing.

The role of the chopper in the economy

Hay is both a covering material for crops, and animal feed, and fertilizer for any plants, and much more. With all this, most often the use of hay is necessary in a processed, crushed version. For this, special hay and straw choppers are used, which effectively process raw materials from large armfuls into a fine fraction. They are quite compact devices - crushers.

The hay chopper in the farmstead is distinguished by power, size and configuration. They can be purchased at a specialized store, and their price will be far from cheap. But, having studied some important points of the device, it is quite possible to make a straw chopper with your own hands, and thus save money.

What is a straw and hay chopper

Before you get down to work on making this device with your own hands, you need to study how the feed cutter is arranged. The straw cutter consists of the following structural elements:

- electric motor

- Capacity for loading raw materials (hay or straw). Its dimensions depend on the planned mass of raw materials for processing. To do this, either an ordinary iron barrel (about 200 liters) is taken, which is suitable for grinding small masses, or the container is manually welded to the required dimensions.

- There are some requirements for the container - loading straw into it must be safe, because it is there that sharp knives will work. Therefore, it is desirable that this private bunker has a high cylindrical shape. In principle, it can be low, but in this case, it is advisable to equip it with a lid with a hole where the raw materials will be loaded.

- Area for the engine. Such a platform is a steel plate, 10 mm thick.

- Bracket for engine mounting. In its manufacture, 5 mm metal is used.

- Chopper support. For them, metal pipes are used, with a diameter of 25 mm, and the height depends on the size of the engine. Most often, the support looks like a tripod, but you can also make the design at your discretion.

- Shaft, knives, counter knives. In a do-it-yourself device, the shaft can represent any kind, but must be clearly balanced and even, otherwise the straw chopper will shake mercilessly, which will greatly complicate the entire recycling process. Knives are welded to the shaft and counter-knives behind them, and the distance between them should be minimal. This is what guarantees high-quality and fine-grained grinding. Knives must be very sharp.

- Unloading device. Here, flour, hay and other crushed raw materials are unloaded from the main tank. It has the form of a side pipe attached to the tank, but in such a way that the chopped hay flies out in a centrifugal motion. The branch pipe for convenience should have an inclined look. It is also worth taking care of the container in advance, where the cut will fall, flying out of the nozzle. You can use a regular plastic barrel by cutting a hole on the side.

electric motor

The electric motor is the heart of the machine. It underlies the whole structure, because it sets it in motion. The characteristics of the engine depend on what mass it will need to grind. The larger the mass, the correspondingly, it must be more powerful. For example, for 200 liters, 2.2 - 5.5 kW is suitable, the speed is 1500 per minute. In any case, the revolutions should not exceed 2000 per minute for the safe operation of the entire structure.

Of all these elements, in stages, with their own hands, a straw cutter is assembled for chopping straw.

Manufacturing process

The most important link in the production of a grinding device is its preliminary drawings. It is there that a general view of the structure is built, all dimensions are taken into account and calculated, and the required material and drawing are calculated. For all metal elements, sheet metal 2 - 3 mm thick is used, except for the bracket. According to the dimensions of the drawing, metal blanks are first cut out for each structural element separately, then they are welded.

Required Tools

To make a hay and straw chopper with your own hands, the following tool will be needed in the work:

- Drill

- Grinder

- Locksmith set (the standard version will suffice)

- Welding machine

Installation of equipment

The working unit of the products is a container welded from metal, inside of which there is a disk with knives. It, in turn, is rigidly fixed on the axis of the electric motor. The first is the body of the product, or container. To it, from below, the bottom is welded, and to it - a bracket. A hole is made in the plate for the engine. Then it is securely welded to the bracket, in a strictly vertical position.

Supports are welded to the tank at a certain angle, they can be equipped with scarves for rigidity. It is also advisable to weld "thrust bearings" to the supports. After that, an unloading device is attached to the container.

The household electric motor is attached to the stove by means of bolts and self-tapping screws. A disc with knives is mounted on its axis. Everything is securely fixed. After all this, the installation of the electrical node of the system takes place. Such a homemade straw chopper, with some skills in locksmith tools and welding, can be made by hand at home in one day.

A hay cutter or a straw cutter is an indispensable unit in the subsidiary farm. With it, you can quickly and easily grind hay for poultry or young animals, as well as grind straw for warming beds or winter roads, making briquettes for heating. It is not difficult to make a hay chopper on your own, and the practicality and functionality of a home-made device will not be inferior to store-bought counterparts.

The simplest hay and straw chopper is made from a conventional vacuum cleaner. An ordinary plastic or aluminum bucket serves as a working chamber where raw materials are laid, and then a knife is lowered, mounted on a rotating shaft. You can make such a device in a few minutes, but it has one significant drawback: low productivity and impracticality. If the number of poultry or livestock is large, you will need a more reliable hay crusher.

The working unit is the most important part of the straw chopper. It consists of a steel bunker, inside of which there are knives. The knives are attached to the engine axis with a special axis. Usually the bunker is made in the form of a cylinder, and for greater safety, the walls are left high. You can do it with short walls, but then equip the device with a lid.

The main components of the straw chopper:

- Working chamber with lid

- Support,

- Motor,

- gain strip,

- Knives or cutting disc,

- Raw material receiver.

materials

A do-it-yourself hay cutter is assembled at home from materials available to everyone. And its manufacture does not require special technical skills. To make a hay chopper with your own hands, you need to have a locksmith kit, a welding machine, a drill and a grinding machine. From the materials you need:

- Motor (an electric motor from a washing machine is suitable),

- Sheet of metal, with a thickness of about two millimeters,

- Sheet of metal, about three millimeters thick,

- Steel sheet, ten millimeters thick,

- Pipe cut (do not use a diameter of more than 25 mm),

- A strip of metal, 3 mm wide, 25 mm long.

Manufacturing

Instead of knives, you can take a disk from a circular saw or a powerful food processor. A barrel or a piece of pipe with a diameter of at least thirty centimeters is well suited for the role of the body of the device.

Before you make a straw chopper with your own hands, it is advisable to find clear and detailed drawings of the apparatus on the Internet. They will prevent errors in the location of parts and fastening. Manufacturing begins with marking and cutting the workpiece from a pipe cut. An additional bottom is attached to the resulting container by welding, and already to it - a holder for the motor. Several holes are pre-drilled in the steel sheet to simplify the process of mounting the motor. A do-it-yourself straw cutter made from a pipe will turn out to be stronger if metal corners-kerchiefs are welded to the sides. A container for an already crushed product is attached below. Only after that the engine is installed. It is attached to a steel sheet, and cutting knives or discs are mounted on the axis and securely fixed.

The last moment: an electrical cable and a toggle switch are mounted, as well as a cover and an indicator light. The device is ready to work.

A simpler and less powerful do-it-yourself hay chopper can be made from an ordinary washing machine. In addition to the machine, you also need:

- Knives or cutting disc,

- electric wire,

- bucket,

- metal corner,

- fasteners,

- Locksmith set.

A word of advice: if you plan to grind not only hay and straw, but also tree branches, then it is better to use an additional gasoline engine.

How to assemble the device

At the bottom of the case, a small rectangular cutout is cut, approximately 20 by 7 cm in size. Its perimeter is sheathed with metal plates for greater strength. A stand is made from the corner. The height of the stand depends on what is planned to be used as a crushed raw material receiver. For buckets, the stand is made higher than for boxes.

To attach the engine, two small holes are made on the shaft, after which a threaded sleeve is installed on it. The engine is mounted on a shaft, and the whole structure is attached to the bottom of the tank with metal studs. After this, cutting discs or knives are put on the shaft. It is very important to choose the size of the discs so that they do not come into contact with the walls of the working chamber.

Before connecting the motor to the cable, you need to decide on the working and starting winding of the motor itself. This is easy to do with a special tester: the working winding has less resistance than the starting winding. Connect the motor like this:

- One of the ends of the starting winding is connected to the start toggle switch,

- The other end is connected to the main wire and the working winding,

- The free end of the working winding is connected to the main wire and wiring from the start toggle switch.

- The hay grinder is ready.

Farmers are gradually moving away from manual labor. Owners in small private backyards are actively introducing small-scale mechanization to increase labor productivity. Such means include a straw chopper. Similar factory-made devices are commercially available, but it is not always advisable to purchase them due to their high cost. The fact is that the chopper device is extremely simple, and you can make it yourself.

Working principle and standard model

Explanations on the purpose of the grinder are unnecessary for those farmers who keep livestock. In addition, the device can be used for the production of fuel briquettes from hay or straw at home.

Manually chop the right amount of material for livestock feed is an extremely labor-intensive event in terms of time and effort. And you should not even think about the production of fuel briquettes in this way.

Some masters make handicraft shredders from the minimum set of improvised materials. Usually, old vacuum cleaners or pumps are used, in which the electric motor is working.

Tools of this type are easy to manufacture, but their productivity is extremely low. It is only enough to prepare food for ten rabbits. A larger farm requires more raw materials.

As a result, you need a reliable straw chopper for private backyards, which you can do yourself. Power should also be at a level that will allow the device to work for up to several hours without stopping.

Description of the typical design

A typical design implies the elements from which the device is made. Their minimum set can be supplemented by an auxiliary one. The goal is to improve the comfort of working with the device.

Standard chopper set:

- The bunker is a container of sufficient volume. Usually they take an old barrel or a large can, where the processed vegetation is laid.

- The electric motor is installed at the bottom of the bunker. The main thing is that its power is sufficient to work non-stop and for heavy loads.

- An axis on which knives are fixed in an amount from 3 to 6. It is fixed directly to the axis of the electric motor.

The basis of the device is a hopper with sharp knives, which are rigidly fixed on a steel disk. The disk is mounted on an axis, which is the shaft of the electric motor or is connected to it through a gearbox.

The bunker is a container for laying material - hay or straw, which require grinding. It is the cutting process. For safety reasons, the hopper is made as high as possible so that when loading raw materials, hands do not touch the knives. The shape of the container is usually cylindrical, but you can find the shape of an inverted cone. Set the container on a stand, usually in the form of a tripod. The height of the stand is such that an electric motor can be installed below. The latter is fixed on the bottom.

Sometimes the bunker is made small in height, but with a lid for safety reasons. The lid must have a hole for loading raw materials.

Production according to the flow principle is created by installing a waste mass dump. Through the device, the crushed material is ejected from the hopper. This allows you to add raw materials continuously. That is, stopping the motor to get a cut and add raw materials is not required. This results in significant time savings. It will be made from the bottom of the bunker. The shape is not important, the main thing is that there is a slope for the material dump.

A disk with knives placed on it is an extremely difficult part to manufacture. The design can be arbitrary. The goal during assembly is to achieve maximum balance so that the device does not shake from vibrations during operation.

Scheme of work

The container is usually a plastic barrel. It is advisable to cover it with a lid, and make a hole on the side so that the cut does not scatter in all directions. The operator only needs to feed the raw material and release the container with the cut in time. Ideally, several are used, changing as they fill.

Materials and manufacturing process

The manufacture of a house grinder begins with a drawing on paper. This allows you to have a visual representation of the design and identify shortcomings or refine important nuances at the design stage. Reworking the finished product will turn out to be more expensive, and extra time will be spent.

Assembly materials:

The electric motor is the main part of the device, which defines its characteristics. Choose a motor depending on the volume of the hopper for the straw chopper. The greater the mass of raw materials at one load, the more powerful the engine is required. Usually, an electric motor with a power of 2.2 to 6 kW is installed on a hay and straw chopper for private farmsteads. The speed of revolutions should not exceed 2 thousand / min for safety reasons. Optimal - 1.5 thousand / min.

An electric motor with a rotation speed higher than optimal can also be adapted for installation in a structure, but it is not connected directly to the shaft. For this use a reduction gear, often belt. You can use gear. The reduction gear allows you to increase the output from the motor and chop root crops and even small branches.

The motor is connected to the shaft on which the disk with knives will be installed. A tube can act as a shaft, but only a straight one, without distortions. This is necessary for proper balance, otherwise vibration will occur, which is unacceptable.

The knives are mounted on the shaft so that there is a minimum distance between them and the counterblades. This will ensure high-quality grinding of raw materials.

Device assembly

It is necessary to assemble with high quality, adjusting the details. The service life and safety of a household straw chopper depends on the quality of the assembly. The device contains moving parts and loose connections may come loose during operation. This is fraught with injury to the operator.

Assembly order:

- They work with the container and install an electric motor on it. In the absence of a bottom in the bunker, it is welded. A bracket and a metal plate are installed from below, where the electric motor is attached. The plate is fixed with a tank, and the engine is attached to it.

- Above the motor, inclined supports are installed, which will serve as a bracket for installing an unloading device. It is mounted in the place where the supports are connected to the edge of the bunker.

- Attach the motor with screws or bolts. The axis of the motor must be located above the inclined supports.

- Form a cutting tool. For this, pieces of high-quality carbon steel are suitable, which can be taken from the spent blade of a metal-cutting machine. The disk is taken in such a size that the installed knives on it do not touch the walls of the bunker.

- A disk with knives is fixed on a vertical axis. The axle can be made from a durable steel pipe. The main requirement is that the pipe be flat, without bends, as they will provoke vibration, which will affect the reliability of the device and its safety. The axis with knives is mounted on the motor shaft.

- Install a cover on the hopper, which will increase the safety of the device.

The finished product is placed on a stand, which is fixed on the floor. A do-it-yourself straw chopper is desirable to paint. This will prevent its corrosion, and the device will last a long time.

Hay from a do-it-yourself home crusher is in no way inferior in quality to products from a factory-made device. It only takes check the condition of the knives. The power of a home-made apparatus is sufficient not only for making chopped hay or straw, but also for chopping fresh grass. Such food is useful for livestock, because it is easier for them to chew. Dry straw can be used to make fuel briquettes for personal use and for sale. It will pay for the device.

Independent work on the machine, even with a new motor, will be cheaper than buying a finished one in a store. The market is flooded with Chinese products, the quality of which is questionable. And shredders of European manufacturers are expensive and not suitable for small farms.

It just so happened that the owner of a private economy constantly needs various devices and means of small-scale mechanization, including a straw cutter. Of course, similar units of different designs and performance are commercially available, there are plenty to choose from. But it’s much cheaper to make a straw chopper on your own, especially since the device is primitively simple. In this article you will find tips on how to make it in the easiest way.

Straw chopper design

A homely owner who has a land plot, and in addition there are different living creatures, knows very well why such a machine is needed. We will only supplement the list with one more area of application: you can grind hay and straw to make fuel briquettes at home. If someone has conceived such a thing, then one cannot do without a straw cutter, try manually cutting or chopping such an amount of straw.

Home craftsmen have adapted to make various handicraft straw choppers from old pumps and vacuum cleaners. The principle of their operation is the same as that of knives mounted on a rod rotated by an electric drill. The bunker is an ordinary old bucket, in which grass or straw is laid, after which rotating knives are lowered there and thus grinding takes place. Descriptions of such devices are easy to find on the Internet.

Only these mechanized cutting tools are too inefficient and impractical, and will fit only to prepare food for a dozen rabbits. For the production of briquettes or other purposes, when you need to process a lot of raw materials, you will need a reliable home-made straw chopper with sufficient power and productivity. This is exactly what we will be making.

The heart of any straw cutter is the working unit, which is a metal hopper with sharp knives rotating inside. The latter are rigidly fixed on a steel disk, and that one is on the axis of the electric motor. The bunker has a cylindrical shape and for safety reasons it is made high so that you cannot accidentally touch the knives with your hands when loading the straw. At the bottom of the bunker there is a branch pipe for ejection of chopped straw, for convenience it is made inclined.

Note. Some craftsmen make a bunker of small height, but with a lid where a small hole is made to load raw materials.

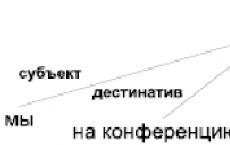

The bunker rests on a tripod of such height that an electric motor can be placed below, attached to its bottom by means of a plate. The detailed drawing of the straw chopper is shown in the figure:

1 - bunker; 2 - cover; 3 - tripod support; 4 - electric motor; 5 - engine mounting plate; 6 - control panel; 7 - amplifying band; 8 - control buttons; 9 - outlet pipe; 10 - engine mount bracket; 11 - thrust bearing; 12 - scarf; 13 - lamp - indicator; 14 - disk with knives; 15 - faceplate; 16 - rubber gasket; 17 - jumper; 18 - M5 bolt (8 pcs.); 19 - scraper; 21 - hinges for the cover.

Note. A disc with knives is a rather difficult part to manufacture. Therefore, the design of the knives can be arbitrary, as long as your product is well balanced and does not make the whole machine shake from vibration.

The operation of the apparatus is simple. By turning on the electric motor with the button and opening the lid, straw is loaded into the hopper. A ready-made cut flies out of the side pipe; to catch it, it is worth adapting some kind of container. A plastic barrel with a hole cut out on the side is suitable, then the straw will not scatter in all directions.

Tools and materials

From the toolkit, you will need the usual locksmith set that every diligent owner has. In addition, you need a welding machine, an angle grinder and a drill. As for the materials, we will present the list provided for by this design, and you can use the metal available on the farm. So, to make a household shredder, you will need:

- one - or three-phase electric motor at 1500 rpm;

- sheet metal 2 mm thick - on the cover and jumper;

- the same, 3 mm thick - on the bunker, branch pipe, scarves and thrust bearings;

- metal 5 mm thick for the bracket;

- steel plate 10 mm thick;

- pipe Ø25 mm or the same corners - on supports;

- metal strip 25 x 3 mm - for reinforcement.

Knives are made from high-quality carbon steel, for example, St45, or cut from an old circular saw, you can - from hacksaw blades of metal-cutting machines. A piece of pipe Ø300 mm or an old barrel can save you the extra work of making the machine body. To make connections, electrodes and bolts with nuts are needed.

Advice. If you have found an electric motor with a speed of over 2000 on your farm, then it is highly undesirable to directly put knives on its shaft. It is better to spend more time, but to make a more powerful machine with a belt drive, in which it will be possible not only to chop straw, but even crush branches and root crops. The diagram below shows a straw chopper device with a decrease in speed and an increase in power:

The metal must be marked and cut blanks in accordance with the drawing. Cut pipes and angles to the required length and clean. The bottom is welded to the hopper, and a bracket for mounting the electric motor is attached to it. The steel plate is attached vertically to the bracket, first you need to make holes in it that match the counterpart of the engine. For tightening, scarves are welded to the side of the plate.

Supports are attached to the body at an angle, scarves are also welded to them, playing the role of stiffeners. When a do-it-yourself straw chopper is already on supports, a chaff ejection pipe is attached to it. Then the electric motor is bolted to the plate, and knives are mounted on its axis and securely fixed. Lastly, a cover is attached and the electrical part is installed.

It is not necessary to repeat the construction presented in the article. The main thing is to correctly make a working unit with knives, and you can adapt an electric drive to it in any convenient way. Just remember that the number of revolutions of the shaft of the cutting part must be within 2000 rpm. And then, if the range of knives is not more than those shown in the drawing. Otherwise, the machine will become a source of increased danger.

Conclusion

If you have all the tools and materials, you can make such a useful chopper with your own hands within one day. Especially when you have good locksmith and welding skills. But even if the work takes much longer, it will save you money, and this is important.