Cord for heating pipes with drinking water. Self-regulating heating cables and cable heating installation

A self-regulating cable is used to heat pipelines so that water does not freeze in them in winter. This article provides detailed instructions on connecting the heating cable to the electrical network and how to install it on the pipe that needs to be heated.

Pipe installation

Self-regulating cable installation can be done in several ways:

- inside the pipe

- outside the pipe

- linear - along the pipe

- coils - winding the cable around the pipe in a spiral

With any installation option, in addition to heating the pipe, it is also necessary to insulate it, otherwise all the heat from the heating cable will go into the surrounding space. The thickness of the insulation usually varies from 20 mm to 50 mm, depending on the conditions for laying the pipe: if underground, then a smaller layer of insulation can be chosen, and for above-ground pipes, a thick layer of insulation is needed. For insulation, it is necessary to use moisture-resistant heaters - foamed polyethylene, expanded polystyrene, it will also not be superfluous to protect the thermal insulation layer from damage by placing the pipeline in a protective sleeve from a pipe of a larger diameter.

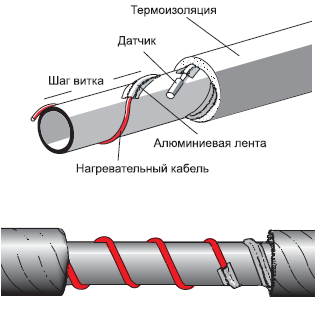

The easiest option is to install the cable along the pipe, the cable is pulled along one wall of the pipe and fastened every 30 cm with adhesive fiberglass tape or plastic ties that can withstand the operating temperature of the cable. Fastening the cable with metal clamps is prohibited. The cable consumption is obvious: how long you need to do heating, this length will need a cable. When installing a heating cable on horizontal pipe sections laid in the ground, in the best possible way there will be a placement of the cable not at the very bottom, but a little to the side - at 4 or 8 o'clock.

Place of fastening of a cable for heating of a pipe.

With this installation of the cable, it will be protected from the pressure of the pipe and the soil lying on top, and will not be damaged, for example, someone will stand on the pipe or something will fall.

Another installation option is to wind the heating cable onto the pipe in a spiral: this provides more contact with the pipe and therefore better heating, but the cable consumption increases, depending on the spiral pitch.

To calculate how much cable will be needed with this installation method, you need to multiply the length of the heated pipeline by the correction factor. It shows how many meters of cable are consumed per meter of pipe and, depending on the pitch of the spiral and the diameter of the pipe, varies from 1.1 to 1.5. The table below shows the cable helix pitches for different pipe diameters and correction factors.

| Pipe diameter, mm | How many meters of cable per meter of pipe? |

||||

| 1.1 m | 1.2 m | 1.3 m | 1.4 m | 1.5 m |

|

| 60 | 43 | - | - | - | - |

| 76 | 51 | 36 | - | - | - |

| 89 | 61 | 43 | 33 | - | - |

| 102 | 71 | 48 | 38 | 33 | - |

| 114 | 79 | 53 | 43 | 36 | - |

| 125 | 89 | 61 | 48 | 41 | 36 |

| 140 | 99 | 66 | 53 | 46 | 38 |

| 168 | 117 | 79 | 64 | 53 | 46 |

| 219 | 150 | 104 | 84 | 71 | 61 |

For pipes with a diameter of less than 60 mm, the additional cable consumption can be neglected.

Installing the heating cable inside the pipe

Another option for mounting the heating cable - inside the pipe - is only possible for pipes of a sufficiently large diameter of 40 mm or more, otherwise the cable will occupy a significant space inside the pipe and interfere with the water flow. This installation option provides for heating small area pipes (it is problematic to put the cable ten meters in), but it allows you to simply replace the cable if it is out of order.

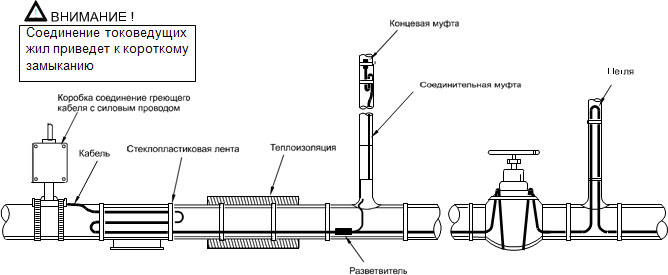

Installation of the cable inside the pipe is especially convenient in the vertical section of the pipeline, for example, where it comes out of the ground under the house and rises up to enter the room. A tee cuts into the pipeline, so that the cable is lowered through the upper outlet into the pipe, and through the side to continue the pipeline towards consumers. For hermetic cable entry into pipes, there are special couplings with seals, it looks something like this:

![]()

To service the cable during this installation, the water supply is turned off, the upper sleeve is removed from the tee, the cable is changed, then everything is assembled back. Perhaps this is the most serious argument in favor of this installation option. If the cable installed outside the pipe breaks, then to replace it, it will be necessary to dig out the pipeline (if it is laid underground), remove the thermal insulation, replace the cable, and then assemble everything back.

Preparing the cable for installation

Before performing the direct installation of the cable, it must be prepared: one end must be stripped and the wires must be prepared for connection to the mains, and the other must be sealed to protect against moisture and short circuits.

The free end of the cable must be well insulated to protect it from moisture and short circuits. It is impossible to connect current-carrying wires to each other; on the contrary, this must be avoided. For insulation, complete with heating cables there is a plug that is put on the end and is melted and tightly fixed with a hair dryer.

The other end of the cable must be stripped of insulation to connect to the electrical network. Instructions for connecting to the mains:

Self-regulating heating cables are used to heat plumbing in places where it is laid above the freezing level of the soil - for example, at the point where the pipeline enters the house. A self-regulating cable has the ability to independently change the intensity of heating in different areas depending on the need: the lower the temperature of the heated object, the more the cable heats up.

Self-regulating heating cables are used to heat plumbing in places where it is laid above the freezing level of the soil - for example, at the point where the pipeline enters the house. A self-regulating cable has the ability to independently change the intensity of heating in different areas depending on the need: the lower the temperature of the heated object, the more the cable heats up. Water pipes located at a depth, at a minimum temperature, are subject to freezing. This leads to disruption of the functioning of the entire plumbing system. To minimize the likelihood of such a risk, you can install a heating cable for the water supply. This element can be located inside or on the surface of the pipes. The possibility of using a heating cable of different lengths allows heating the entire system or a separate part of the water supply system located in the freezing zone.

How does a heating cable work?

The heating of the cable occurs due to the action of the passing current. This heating element is positioned as the main component of the system that provides reliable protection of pipes from freezing. Its operation is based on the conversion of electrical energy into heat.

Heating cable for plumbing is not a carrier of energy. Its main characteristic is the specific heat release. The overall length of the product may vary depending on the needs of the consumer. The cable is distinguished by the presence of a hermetic sheath of a seamless type, which is highly resistant to negative chemical effects and makes it easy to withstand the influence of minimum temperature indicators.

The main heating element of the cable is located inside the protective sheath. In case of temperature drop environment it is connected to the network, and the pipe is heated. With a subsequent increase in temperature, the power is turned off and the heating stops. This method of heating the plumbing system has a number of advantages:

- profitability;

- safety;

- ease of operation;

- versatility.

economy . Using a heating cable for plumbing, you can focus on the ambient temperature and coordinate the operation of the entire system. The ability to adjust the heating power allows you to minimize the level of electrical energy consumption.

Safety . The insulation system protects the heating wire very well from various negative effects of mechanical, chemical and thermal types.

Ease of operation . To start functioning, simply turn on the power to the network and press the button. The ultimate ease of operation of the entire system contributes to the expansion of the range of consumers.

Versatility . The design features of the product make it possible to use this heating cable for pipes for heating any plumbing system located underground and on the surface.

Design features

The main functional element of the cable is the inner core. To protect it, a polymer material is used. The overall sheath is made of PVC. It provides reliable protection of components.

Cheaper cable variations are single-core. Such products are characterized by extreme structural simplicity. At the same time, single-core cables do not have an additional conductive core, which is present in two or three-core products.

The heat cable for the water supply is presented in the form of an electric guide of the tape type. The two-layer structure of the product provides additional dielectric strength, as well as protection against abrasion and impact loads.

Heat Cable Variations

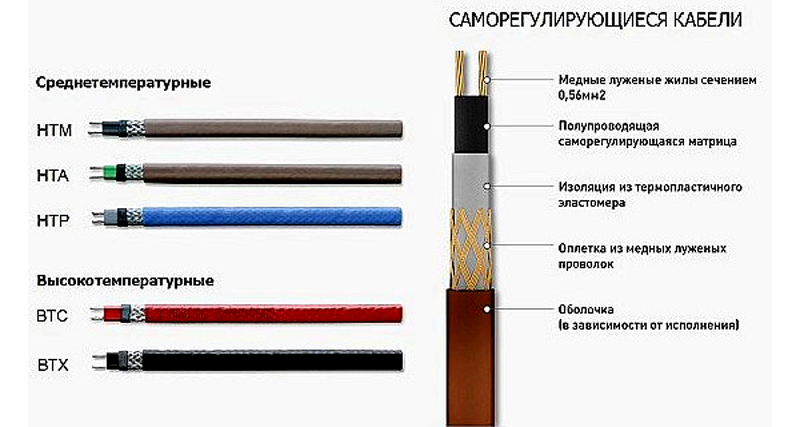

The classification of such products is carried out according to various criteria. The cable can be resistive and self-regulating. There is also another type of product with mineral insulation. Heating of pipes with a cable can be carried out using any of the named product variations.

Resistive cable

The heating of the water supply through the use of such a cable is realized on the surface or inside the pipes. Temperature sensors are installed outside the plumbing system. If the temperature drops below the set level, then the heating is switched on. After reaching a certain temperature threshold, the system turns off.

Resistive type heating cable can be of linear or zonal design. In the first case, we can talk about the sectional design of the product. The zone cable is characterized by the presence of two conductive elements arranged in parallel. The top layer of such a product is presented in the form of a spiral of small diameter.

Mineral insulated cable

The basis of such a cable is a copper core. The top layer is in the form of a magnesium oxide insulator. This ensures stability of operation in the widest possible range.

Self-regulating cable

Self-regulating heating cable for plumbing in a constructive way has much in common with the resistive variation of the product. At the same time, it is distinguished by the fact that there is no insulating coating. Such a heating cable for pipes is able to locally change the amount of heat generated.

Features of the installation work

Heating pipes with a cable minimizes the risk of freezing of the water supply system. Installation work is carried out in two ways, which differ in the location of the main heating element.

Heating cable outside the pipe

The heating cable on the outside of the pipe can be arranged in a linear manner or in a spiral. In the first case, it is best to place it in the lower zone of the pipe. This position will help protect the entire heating system from mechanical damage.

Installation of a heating cable for water supply must be carried out according to certain rules. In particular, it is necessary to ensure the most reliable and tight fastening to the pipe. For these purposes, you can use adhesive fiberglass tape or plastic clamps.

Advice! Before direct installation of the heating cable, it is recommended to carry out foil insulation of the pipe. This will ensure the longest and most reliable operation of the entire system.

Heating cable inside the pipe

The internal connection of the heating cable for the water supply is a more laborious procedure. Manufacturers provide a complete set of additional attributes necessary for high-quality installation.

The heating cable is inserted into the pipe through the use of special glands. It is strongly recommended to refrain from laying the cable through the stop valves. Also, before installation, care must be taken to remove all sharp edges and threads on the fittings.

The section of the water supply system that will be heated by the cable is most expedient to mount with a minimum amount of connecting elements. In order to ensure effective work cable and uniform heat distribution, it is recommended to take care of high-quality pipe insulation.

The use of pipeline heating using heating cables is desirable if there is a risk of freezing pipes when the pipeline is located:

- in unheated rooms;

- at a shallow depth (up to 1.5 meters);

- outdoors.

Particular attention should also be paid to the places where pipes enter structures - it is here that the probability of freezing is quite high.

Purposes of use and types of heating cables

Purposes of using a heating cable

The heating cable for pipes is used if necessary:

- Frost protection of pipelines.

- Maintaining a given viscosity and temperature of the liquid.

- Prevention of solid precipitation.

- Providing the required fluid flow rate.

Main types of cables

There are two types of cables used for pipe heating:

- Resistive have a constant resistance along the entire length. Structurally, such a heating cable for pipes is an inner core made of high-resistance material, enclosed in plastic insulation, which has a copper braid.

It is usually supplied in lengths that cannot be cut. The power of such a cable is 10-20 watts per linear meter. In addition, it is subject to mandatory grounding.

To prevent overheating of the resistive cable and as a result of its rapid wear and failure, it is recommended to avoid possible overlaps when laying it and install temperature sensors to turn off the system at a certain heating temperature.

- have a variable resistance that changes with temperature. Structurally, such a heating cable for pipes consists of two cores, which are separated by a conductive polymer.

Such cables are supplied in the form of finished products with an electric plug for inclusion in the network, and are convenient for heating pipelines located outside buildings, in particular water supply and sewerage. There are also brands of this cable that can be cut into pieces of arbitrary length and connected using sleeves.

Heating cable device

Ways of positioning the heating cable

Placing the cable on the pipeline is possible in several ways:

- pad. This method is not possible with all brands of cable and is not always effective. There is a specially certified heating cable for drinking water pipes.

- Laying one cable over the pipe along its entire length. In this case, the heating element is laid in the lower part of the pipeline, and the temperature sensor is installed on top.

- Laying two parallel cable lines, when it is necessary to achieve a given output power.

- Spiral cable routing. In this case, depending on the parameters of the heating element and the specified power, the coil pitch is preliminarily calculated. The temperature sensor is placed in the middle between the turns at the top of the pipe.

- Cable laying along a wavy line. This method is used when the heating cable for pipes has a length that is not enough for laying in two parallels or a spiral.

When using any of the methods of laying the cable over the pipeline, the heating element must be covered with thermal insulation after installation.

Heating cable installation

The heating cable is laid as follows:

- Laying begins when all the main work on the installation and inspection of the pipeline is completed.

- Installation of measuring equipment and valves, pressure testing of the system is carried out before laying the cable.

- For removable equipment, the replacement of which is possible during operation, a tolerance of 1-2 meters of cable is left.

- The heating cable for pipes is attached to the pipeline with a special adhesive tape. The use of ordinary electrical tape is strictly prohibited in order to avoid overheating.

As a rule, aluminum tape is used, which, if the cable is laid on a plastic pipe, is also laid between the pipe and the heating element. The cable must not come into contact with either thermal insulation or plastic.

It is possible to wrap the entire pipe with aluminum foil before and after laying the heating cable, which will additionally ensure the most uniform distribution of the generated heat.

- The heating cable for pipes can also be attached to them at intervals of 30-40 cm along the entire length with fiberglass tape or special plastic clamps. The temperature sensor cable is attached in the same way. The temperature sensor must be located at the top of the cable, at the point of the lowest possible expected temperature.

- Over the laid cables, it is necessary to install a layer of thermal insulation, as well as, if necessary, waterproofing.

Having laid a heating cable, you will forever forget about such a problem as frozen pipelines and the need to take measures to defrost them. By installing the heating system correctly, you, among other things, will be able to significantly save on its energy consumption.

Domestic winters are sometimes so severe that the sewerage and water supply system freezes. At the same time, the water supply to the house does not just stop, the consequences can be much sadder. Pipes can be broken by ice and all communications will have to be laid again. A reliable and economical way to prevent disaster is to use a self-regulating plumbing heating cable. This simple method of heating will keep the system even in the conditions of the far north. How the device works, its types and basic principles of installation - in this material.

For what purposes is a self-regulating heating cable for plumbing useful and how it works

A heating cable for plumbing is a special type of wire that can change its temperature, focusing on the thermal conditions surrounding it. The colder the pipe becomes, the more the wire heats up.

Where is the system used?

Warming self-regulating cables for plumbing, they are used when installing roofs, floors, cornices, plumbing and sewerage. There are three applications for this device:

- in individual housing construction for heating engineering networks;

- in the commercial sector for heating pipes and fire extinguishing systems;

- at industrial enterprises operating in harsh climatic conditions.

How the device works

Cable construction:

- conductors made of copper, carrying out voltage throughout the length of the device;

- a heating matrix that regulates the temperature and heats the cable;

- several layers of insulator;

- a metal screen that protects the wire from accidental damage and interference. This screen is grounded;

- protective outer layer.

The multilayer structure of the wire is not susceptible to external influences and has a long service life.

The operation of a self-regulating heating cable is similar to that of resistive wiring. The more the conductor heats up, the more the resistance increases and vice versa, with a decrease in the strength of the electric current, the power decreases.

The matrix in the core of the device regulates the conductivity of the device.

Related article:

The cable is used to prevent freezing of the water supply system. How to choose it correctly in order to solve the task without unnecessary costs and difficulties, we will talk about this in more detail in the article.

Pros and cons of the device

Like any device, the heating wire has its advantages and disadvantages. You should know about the first, and fight the second with the help of competent installation and proper operation:

| pros | Description |

| Uniform heating | The cable heats up along its entire length, the heating is uniform and gradual. |

| Reliability | Elements of the system are resistant to sudden voltage drops in the network. Several degrees of protection prevent overheating even when overlapping. |

| economy | The power consumption for such a system is relatively low, moreover, savings are achieved due to self-regulation. |

| No length restrictions | The heater works effectively regardless of the length. |

| No need for maintenance | The device is autonomous and practically does not require maintenance, except for cases of mechanical damage. |

| Ease of installation | You can install the cord inside or outside the pipe on your own, without involving hired specialists. |

Types of heating cables

The heating wire has several varieties:

- Resistive - with current conductors that are heating elements. This heating wire has a certain length that must not be shortened.

- The zonal design has parallel conductors wrapped with high resistance wire. Heating occurs from the interaction of the winding and the core.

- Cable with self-regulating system. Contains a semiconductor matrix that reacts to temperature changes outside the cable.

The first two types of cable are used for arranging underfloor heating and heating utilities. Zone and resistance cables can be used to heat pipes with a maximum diameter of 4 centimeters. A self-adjusting cord will be more expensive, but such a system pays off faster than other types.

How to calculate the length and wattage of a self-regulating pipe heating cable

Each device installation option has its own characteristics. There are two ways to place the wire: outside and inside the pipe. External installation is possible when laying engineering networks. If the pipes are already in the ground, it remains only to apply an internal lining and use a self-regulating wire.

Important! Inside water pipes Only food-grade plastic coated cable can be used.

What you need to know for calculations:

- P wire (indicated on its side);

- pipe dimensions;

- type of heat insulator;

- temperature fluctuations in the area of residence.

The formula looks like this:

Cable length = Safety factor x pipe length x heat loss / P wire

Preliminary calculations can be made based on power indicators: D up to 25 mm - 10 W per meter, up to 40 - 16 W, up to 60 - 24 W, up to 80 - 30 W, above this indicator - 40 watts per meter.

If you place the cable outside the water supply, you can increase the heating using a different location:

- parallel (suitable for thin pipes);

- serpentine (quickly warms pipes);

- spiral winding (used for temperature stabilization).

Material prices

Prices for self-heating cables for plumbing depend on the power. Consider the cost of a pipe heating kit using the example of Teplolux products:

| Model | Cost, rub | Specifications |

| 5 490 |

|

|

| 1 123 |

|

|

| 3 040 |

|

|

| 2 795 |

|

|

| 6 833 |

|

|

| 1 944 |

|

|

| Freezstop-25-3 set | 2 401 |

|

How to connect a heating cable inside and outside communications

Fixing the wiring over the pipe is possible only in the process of laying networks. If the nets are already under the ground, consider whether it is worth spending money on excavation or whether it is better to use the second, internal option.

outdoor installation

With an external location of the heating wire, the fastening occurs with the help of aluminum tape. It not only firmly presses the cable to the pipe, but also acts as an additional heat insulator.

There are several winding options, consider them in more detail:

| Winding option | Image | Peculiarities |

|

This option for the location of the wire is suitable for areas with a harsh northern climate. The pitch of the coil of the cord is five centimeters or more. In this case, when calculating the length of the wire, you need to multiply the length of the pipe by 1.7. | |

|

This type of winding will also require an additional length of cord, about 1.4 times the length of the pipe. The snake itself will not stay on the surface, it must be secured with tape. | |

| This is the easiest but least effective method. The cord is laid along the pipe and is equal to its length. |

Advice! When spiral winding in hard-to-reach places, the following technique is used: loops are wound in large turns and then wrapped in the opposite direction.

On nodal connections, the following types of winding are used:

Laying a heater inside the pipe is justified if communications are installed earlier and there is no way to remove them for external processing. This method of heating has its own nuances that will have to be taken into account:

- the internal clearance of the pipes will decrease;

- blockages may appear due to an increase in plaque on the cable;

- installation of the cord is possible only on straight pipes or communications with a small bend.

Despite all the difficulties, the internal type of gasket also has advantages: an easy installation method and low energy consumption.

The sequence of laying the heating cable for the water supply inside the pipe

| A photo | Description |

|

A gland and spurs are put on the wire |

|

AT necessary place installation of a tee for cable entry into the system |

|

The cable is pushed to the place that is most exposed to low temperatures |

|

The gland is fixed and insulated. |

The final stage - connection and thermal insulation

An important stage in the installation of pipe heating is connecting the cable to the mains. First of all, it is necessary to protect the ends of the core from moisture with the help of heat shrinkage. How to connect the ends of the wire, see the video:

In order for the device to work without interruption, a thermostat and an RCD should be connected.

Note! The thermostat can only work normally with a system whose length does not exceed fifty meters.

After connecting to the network, it is necessary to install reliable thermal insulation. For these purposes, you will need polyurethane insulation, cut along. They wrap the water and sewer network.

- For water pipes, an external cable with a power of at least seventeen watts per meter is required.

- Oversized cables consume a lot of electricity, so consider whether you need to take the system more powerful than required.

- For plastic pipes you should purchase a self-regulating heating cable for plumbing.

- The selection of cable power depends on the diameter of the pipe and the laying method.

- For internal heating of a pipeline in the central part of Russia, a cable power of ten watts and a heater three centimeters thick are sufficient.

Results

Severe frosts and poorly laid pipes can lead to an emergency with water supply and sewerage. When laying engineering networks, it is important to ensure that communications are below the freezing point of the soil and insulate them with a self-regulating heating cable for water supply.

If you got a house with freezing water pipes, you can fix the situation by installing a heater inside the pipe. It is easy to install the system on your own by purchasing a ready-made set of insulation.