Pipes ventilating plastic square. Choosing and installing a plastic duct for the kitchen yourself

Air ducts are needed for the outflow of exhaust air. Without them, all fats and other impurities would settle on many surfaces. Also, with the help of an air duct, unpleasant odors can be removed from the kitchen. It is necessary to choose such an air duct correctly in order to maintain the ventilation system at a high level of efficiency. This article will show you exactly how to do it; we will also consider what air ducts are (in particular, let's talk about a corrugated air duct), their main advantages, disadvantages, and much more.

Types of plastic pipes

There are many plastic pipes for kitchen hoods. They are divided into:

- polyurethane;

- pvc (polyvinyl chloride);

- polypropylene;

Also they are the following shapes and sizes:

- kitchen. Such designs are ideal for kitchen spaces in style and size;

- Round. These air ducts are used in ventilation systems for long routes;

- Rectangular. Used in everyday life. The dimensions of such an air duct are mainly of two types: 60 * 204 mm and 60 * 120 mm;

- Flexible. This type of air duct is both rectangular and round. Rectangular is used for mounting the hood. Basically, it is used in various enterprises. But a rectangular duct cannot be compared in efficiency with a round duct. After all, the flow of air that passes through it meets much less resistance.

In addition to these types, air ducts are of two types:

- Corrugated. The main disadvantage of this air duct is its unattractive appearance. Not every person wants to have a factory element at home, because they still need to somehow hide it. But the corrugation is easily cut with scissors, and also does not emit extraneous sounds and hums. Corrugated air ducts are made of thin aluminium. The corrugation in the stretched state is about three meters. Experts also say that the corrugation should only bend in a state of compression, otherwise it can simply be damaged.

- Plastic. A plastic air duct consists of various compounds, the basis of which can be PVC, silicone and many other materials. Most often, PVC is chosen for the kitchen, as it is very light and not difficult to glue or solder. The most important advantage of PVC is hygiene. The service life of a plastic pvc air duct is more than 100 years.

Polyurethane and propylene ducts

Above, PVC air ducts were partially considered. In addition to this material, there are two more main ones, from which this equipment is made:

Above, PVC air ducts were partially considered. In addition to this material, there are two more main ones, from which this equipment is made:

- Polyurethane. Their distinguishing feature- strength and lightness. It is believed that a polyurethane duct, if used correctly, can last even longer than a similar one made of pvc. They also have high chemical resistance to any aggressive environment and are difficult to ignite.

- propylene. Propylene is a white, thermoplastic solid material. The air duct from it is quite durable and plastic. From -45 to 85 degrees - it is at this temperature that the correct operation of such air ducts is possible. Their service life is more than 50 years.

Sections of air ducts

The cross-sections of the ducts are selected based on the peculiarity of its location. The advantage of a plastic duct is that it is easily placed between the space suspended ceilings. The appearance of the pipes is such that even if they are in a conspicuous place, the design of the room does not deteriorate at all.

Various fittings and fittings are produced. It is needed to cover certain areas of the hood. With this, it becomes possible to combine several ducts into one network.

Also, manufacturers supply many types of fasteners with which you can achieve a strong attachment to wall surfaces.

Rectangular section

Let us consider in detail such a section of air ducts as a rectangular one. Such an air duct is most often used in private houses or cottages, as well as in laboratories and workshops.

Let us consider in detail such a section of air ducts as a rectangular one. Such an air duct is most often used in private houses or cottages, as well as in laboratories and workshops.

What does this type of duct look like? These are several plastic boxes, in which their width is several times their own height. With the help of a profile, a plastic rectangular duct is quite easy to mount.

Since there are a great many different fittings, you don’t have to worry that the ventilation system will not be airtight.

Compared to round ducts, rectangular ducts are more compact and easier to place so that they are not noticeable.

Round ducts

Advantages and disadvantages of plastic pipes

pros

- the material is environmentally friendly, so you do not have to worry that in housing or environment any harmful substances will enter;

- in terms of their properties, plastic air ducts are significantly superior to metal ones;

- installation of plastic pipes is easier than metal pipes;

- plastic air ducts are not subject to corrosion;

- plastic air ducts cost much less than similar metal ones.

Minuses

What can not but rejoice plastic duct has virtually no downsides. The only drawback is that such air ducts have low fire resistance.

Installation of air ducts

Required Tools

Basic installation rules

The air duct must be stretched as much as possible when it is installed. To cut plastic, you first need to measure its length and make a mark with a marker. Then cut it with a knife.

Before connecting the duct to the hood, it is necessary to carry out the sealing process. After that, the duct itself needs to be fixed with a clamp.

Attention! The sagging of the duct should be no more than 50 millimeters.

After these operations, the launch and testing begins. ventilation system. If you do this not with your own hands, but with the help of a master, then you will pay more than 1000 rubles for installation and connection.

Are there any errors in the installation of plastic air ducts? Yes, and the main one is the following: the air flow in a spiral is not taken into account. This error can result in rapid wear of the ventilation equipment.

To avoid this error, it is enough to consult with the seller and take a plastic air duct of a slightly larger diameter.

Conclusion

Today, the use of plastic air ducts has greatly increased. This can be explained by the fact that technical specifications These products are highly durable and have a long service life. In addition, they are not subject to corrosion, so they are not afraid of any small scratches.

From this article, you learned about what air ducts are and how to properly install and use them. Remember that their choice must be taken with special care, because a properly selected air duct will ensure the almost complete absence of any problems associated with it.

Attention, only TODAY!

Comments:

The hood has long been considered a mandatory component of the kitchen. This is a mechanism designed to forcibly withdraw from working area cooking odors and fumes.

Having such a device, you can significantly reduce the fogging of glass on the window from the side of the kitchen, as well as get rid of the spread of "aromas" (especially unpleasant ones) from cooking and burnt dishes throughout the home. Hoods also have another functionality, no less important, which is appreciated by many housewives, highlighting the hob.

Self-installation of an air duct with an exhaust hood is very feasible as part of a renovation in the kitchen. The work, although it seems somewhat painstaking, is simple. We need to consider how things are in reality.

When the installation of the hood in the kitchen is carried out with high quality and in accordance with all the rules, they provide for the installation of a ventilation duct, which will run from the hood to the ventilation outlet from the kitchen.

Installation of an exhaust kitchen device without an air duct

Not all hoods need a duct connection. Flat appliances with a distinctive visor purify odors in the kitchen through special internal filters.

All other devices require a duct connection.

Installation of a flat hood consists in attaching a suspension under the hood to the wall surface and hanging the device itself.

Back to index

Installation of a kitchen hood and an air duct for the hood

To carry out all the work yourself, you will need:

- drill;

- jigsaw;

- pencil with tape measure;

- screwdriver

Connecting an exhaust device inside the home electrical network involves preparing tools or seeking qualified help from a professional electrician.

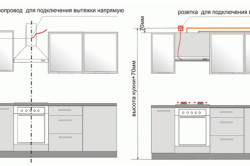

The exhaust structure is mounted either on the wall surface or on the lower edge of the kitchen cabinet. In both situations, it is required to ensure the laying of an air duct from the exhaust device housing to the entrance to the general house ventilation system. In the kitchen apartment buildings there is definitely one. When arranging an exhaust device in an individual sector, it will be necessary to carry out an air duct to the street in advance. This can be done both through the outer wall and along floors to the attic and roof.

Back to index

Preparing the duct for the duct

You can purchase a soft box (like an aluminum corrugation) or a hard one (made of plastic). Installation of plastic boxes with connecting elements, allowing you to change the direction of the duct and extend it, is considered a more reliable option.

Installation of plastic air ducts is not particularly difficult. They can be sawn, like any plastic item, connected using fasteners that are purchased the day before. To avoid mistakes, the duct route is marked on paper in advance, indicating the exact dimensions of the knees. The elbow is the part of the duct from turn to turn. It is worth immediately paying attention to what size and shape the vent in the kitchen room has. To examine it, remove the protection grille before viewing. It is necessary to study the output hole, because often the lattice is rectangular in shape, and the hole itself is round. Then you have to take care of purchasing an adapter from a rectangle box to a round ventilation hole.

Tip: if there is a single ventilation outlet in the kitchen, it is necessary to provide for incomplete closing of the hole with a box. The remaining gap will be needed to supply the kitchen space with natural ventilation. It is covered with an additional lattice. If natural ventilation if it is possible to decide differently, then the dimension of the box, in comparison with the ventilation duct, will not matter.

Connections between duct bends must be absolutely tight. An acrylic or silicone compound is used to seal the air vents. This sealant is applied to the edges of the box before inserting the section of the box into the structure.

Tip: before finally fixing the duct, you need to try to assemble the entire structure so that each element falls on its own “route”. After that, the system must be disassembled and designed with the participation of the sealant.

Back to index

Step-by-step instructions: self-installation of the duct

Duct installation includes the following steps:

- First of all, they determine the installation site and prepare it. The hood is mounted in place, depending on the model chosen. For this, measurements are made using a tape measure of the required installation level. Apply markup. In the situation when the surfaces of the cabinet, placed above the hob, do not allow the required mark level to be met, they are slightly filed. Basically, the required height of the lower part of the exhaust device above the stove is entirely determined by the power of the installed engine. On average, this value reaches 50-70 centimeters.

- After the control of the level of placement of the device is completed and the necessary markings are made, the sides of the cabinet are sawn off to the desired length. For this, a jigsaw with a “clean cut” wood file will do. Using such a power tool, you can get enough high quality took a sip. If such a tool cannot be found, then a carpenter's saw may well replace it.

- All work is carried out after dismantling the cabinet from the wall surface and giving the piece of kitchen furniture maximum stability. To obtain the highest quality surface, when working hand tool they try to provide an angle between the working blade of the tool and the surface of the cabinet in the range of 20-30 °. Otherwise, chips will appear on the opposite side, which will not fail to spoil the appearance of the piece of furniture.

- The next step is to form a hole with a large d for mounting a through metal duct. The latter represents corrugated pipe or a smooth-walled pipe. For this, a flange is applied at the place of the planned placement of the holes. It serves as a template for marking holes.

- Then, using a drill with an appropriate drill (d - at least 8 mm), a hole is drilled through the wood inside the marked markings.

- A jigsaw file is inserted into the hole formed and the required element is carefully cut out in accordance with the markup.

- If the file has been chosen appropriately, then it provides a high degree of cut quality. If there was no such file, then the edges are also treated with sandpaper. Then the prepared cabinet with holes is installed in its original place.

- In order to provide power to the engine of the device and the lighting system, the hood wires are connected to the power supply.

- The penultimate step is to attach the ventilation system to the location. The body of the device is installed and markings are made for the fasteners. Next, holes are drilled at the marked points, d of which corresponds to 2/3 d of the screws. Then hang the body.

- Upon completion of the installation of the exhaust device, an air duct is connected to it using steel clamps.

- Finally, the system is tested for performance.

Plastic air ducts are a novelty, which, due to a number of advantages, has become very popular. They are used both in everyday life for organizing a kitchen hood, and for creating a ventilation system in public buildings.

Application: from apartments to shopping malls.

Air ducts are used:

- For kitchen hood. In this case, air ducts are used to provide an outlet to the ventilation shaft. Advantages: easy installation, aesthetic appearance, the possibility of painting in different colors, noiselessness;

- For ventilation. They are mounted in private houses, apartments, shopping malls, restaurants and other public and commercial buildings. Advantages: non-conductivity of electricity, corrosion resistance, aesthetics, efficiency.

Usually decorated in order not to spoil the view of the room with unnecessary details. It can be painted in a color that matches the tone of the kitchen, or wallpapered. A decorative box is often used for camouflage purposes.

Variety of diameters and shapes

Plastic air ducts come in two shapes: rectangular and round. Consider their features and sizes:

- Rectangular. Their dimensions: 110x55mm, 120x60mm, 204x60mm. Are applied to the organization of ventilation in industrial rooms, residential buildings, extracts for kitchen. Rectangular pipes, due to their shape, are easy to install. It is so easy to fix them that such ducts are often used for installation in difficult conditions, for fastening under suspended ceilings. A rectangular duct may have an atypical design: the width is 4 times the height. Such flat structures are assembled by hand. They can be used for exhaust hoods, but they are distinguished by a high level of noise and high resistance to air currents;

- Round. Plastic can have diameters of 100, 125 and 150 mm. Such an air duct is distinguished by increased efficiency, achieved due to less resistance to air flow, as well as a reduced noise level. At the same time, if rectangular shapes fit well into the interior of the kitchen, then plastic round air ducts do not have such a neutral appearance.

What plastic structures for exhaust or ventilation are better to choose? Everything depends on your requirements. If you wish to provide increased efficiency and low noise, it is better to prefer a round duct if the aesthetics are rectangular.

Plastic pipes are divided into two types:

- Flexible. Used in chemical laboratories, for the organization of permanent and temporary ventilation systems, for the removal of smoke and the removal of polluted air from construction sites. Plastic products flexible type withstand temperatures from -35 to +90 degrees. Their inner diameters can be from 60 to 500 mm;

- Rigid. are produced in widths from 100 to 1000 mm. Plastic rigid structures are made of material with a thickness of 3 mm and 5 mm.

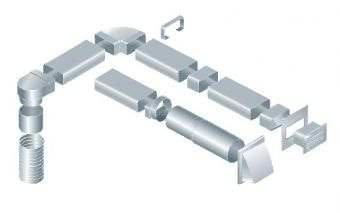

Elements of a plastic duct

Advantages and disadvantages of plastic products

Plastic air ducts are not in vain so popular, because they have unique advantages:

- Corrosion resistance. If corrugated metal duct, so often used to organize the hood, quickly corrodes, then plastic products in this regard are much more resistant;

- Smooth inner surface. Plastic products do not have roughness on the inner walls. The smooth surface reduces the resistance to airflow, which increases the efficiency of the hood or ventilation. Such an air duct is less noisy. It, after appropriate processing, does not attract dust, and this reduces the frequency of measures to clean the system and saves on its maintenance;

- Low cost. Plastic designs are quite cheap. In addition, such air ducts are economical in operation;

- Easy installation. You can cut, correct plastic pipes before installing them;

- Safety. Plastic air ducts are environmentally friendly, they do not contain harmful additives and are safe for the environment;

- Ease of transportation. Ease of transportation is achieved due to their strength and lightness;

- Versatility. They are suitable for exhaust, ventilation, and other systems. Can be operated at temperatures from -40 to +90 degrees. Rectangular, rigid, flexible - their use is almost unlimited;

- Durability. The service life of polypropylene pipes reaches 50 years, PVC products - 100 years;

- Other unique qualities. Designs are resistant to wear, moisture, ultraviolet radiation. Can be used in aggressive chemical environment.

Nothing is perfect, and the air ducts in question are also not without flaws. Their main disadvantage is the low level of fire resistance.

This limiting factor often leads one to prefer the reliability of metal over the advantages of plastic. For this reason, such an air duct is rarely used for industrial ventilation in fire departments. Also, air ducts are quite difficult to install in private houses that have steam protection.

Despite their shortcomings, air ducts are in great demand and are widely used in a variety of industries. Experts are confident that with high-quality installation, the air duct will last a very long time and provide efficient work ventilation system.

The service life of some products can reach a hundred years. They are ideal for residential installations. Plastic, due to its unique qualities, has long taken a leading position in the organization of many types of communication systems.