Comparison of electric heating boilers. Electric induction boilers. Some types of boilers and their characteristics

Most often, electric heating boilers are used as the main source of thermal energy if the dwelling is not connected to gas, and there is no desire or possibility to use a stove or solid fuel boiler to heat its premises. In addition, electric boilers can be used as a convenient backup or additional heating. What types of electric boilers exist, how do they differ and how to choose the best option?

Currently, there are many different models of electric boilers, which differ:

- form,

- size,

- construction,

- power,

- manufacturer and price.

But since electric boilers are intended for use in water heating systems, in addition to the above differences, all of them can be divided into three main groups according to the method of heating the coolant:

- TENovye, using tubular electric heating elements;

- Electrode, or as they are sometimes called - ionic, electrolysis, using the ability of a coolant with certain characteristics to heat up when passing through it AC voltage;

- Induction, using the properties of ferromagnets to heat up using an induction current.

All of them have their own characteristics, advantages and disadvantages, as well as varieties, depending on the design, power, voltage used and manufacturer, which we will consider in more detail below.

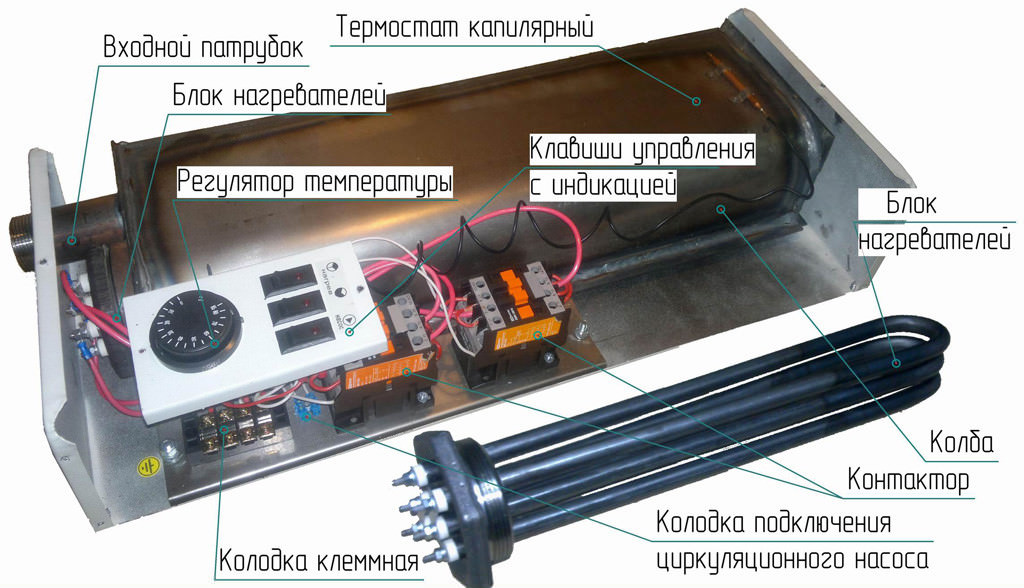

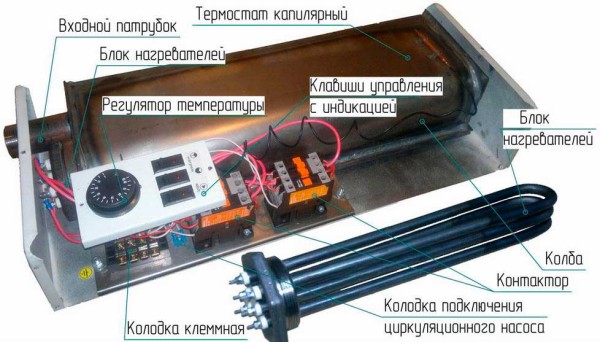

TENovye electric boilers

TENovy electric boiler

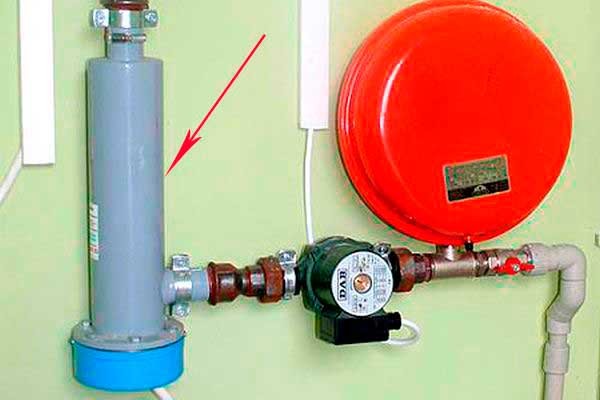

Such electric boilers, as a rule, are a unit with a heat exchange chamber in which one or more tubular electric heaters (TEHs) are installed, as well as an automation unit that regulates and controls the process of heating the coolant. Many designs of electric heating elements are equipped with a circulation pump, an automatic air valve and a built-in expansion tank.

Electric boilers of this type can be either single-phase (designed for 220 V) or three-phase (380 V). The former, as a rule, have a relatively small power (from 1 to 6-7 kW) and are rarely used as the main heating. Except for a small house. In addition, when using such devices with a power of more than 3 kW, the load on the electrical network of the house increases and it, as well as the input to the house, must be designed for this.

Three-phase heating elements, which are used for heating a house, can be from 6 to 30 kW. If electric heating is selected as the main one, then it is their appearance that should be set. But for this, a three-phase input must be made in the house and all the necessary requirements for this must be met: permission, design technical documentation, measurements of the resistance of the ground loop.

In order for such heating to be more economical, it is imperative to install a billing electric meter and turn on the boiler at the most favorable electricity tariff.

TEN electric boilers can be wall-mounted and floor-mounted with top or bottom connection to the water heating network.

advantage this type of electric boilers is:

- relatively low cost;

- ease of installation;

- the ability to use as a coolant, both water and non-freezing liquid;

- step-by-step power regulation is easily carried out.

Main disadvantages Heating elements of boilers:

- When hard water is used as a coolant, scale forms on the heating elements, which eventually reduces the efficiency of their work (a layer of 0.5-1 mm of scale reduces the efficiency by 10-15%);

- Heating elements sometimes burn out and it is useful to change them, and for this it is necessary to dismantle the electric boiler and hand it in for repair or do it yourself if you have the appropriate skills.

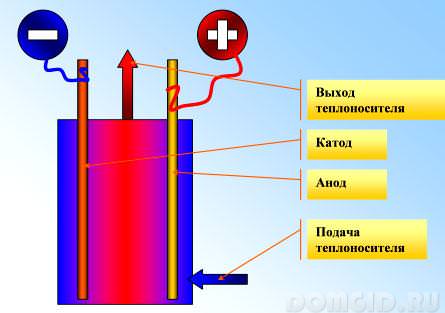

Electrode electric boilers

Electrode electric boilers

Such boilers are more compact compared to heating elements and are very simple in design. The way they work is also different. It is based on the heating of a fluid flow by an alternating current passed between two electrodes. The coolant in this case plays the role of an electrolyte. Therefore, such boilers are often also called ion or electrolysis boilers.

One more distinctive feature of such electric boilers is that the coolant itself in the system must have strictly defined characteristics: have a certain resistance, and hence the content of salt ions, and also be as clean as possible and this must be constantly monitored. Sometimes, instead of water, in such systems, specially designed fluids with optimal characteristics are used.

As well as heating elements, electrode boilers can be single-phase - for 220 V and three-phase, with power from 1 to 16 kW

Benefits such electric boilers can be considered the following features:

- simplicity of design and relatively low cost and high efficiency (up to 98%);

- heating of the coolant occurs directly, without heating elements;

- compactness;

- in the event of a leak and the absence of a coolant in the water heating system, this does not result in the failure of the switched on electrode boiler;

- although scale on the electrodes leads to a decrease in power, but not to destruction;

- less inertia, allowing faster heating of the water heating system and more efficient use of automatic control;

- less sensitivity to voltage drops in the mains - although the voltage drop affects the change in its power, it continues to work.

In addition to the advantages, the following can be distinguished flaws:

- higher probability of electric shock (compared to heating elements);

- very reliable grounding is necessary, therefore, when using such a boiler, it is impossible to use residual current devices (RCDs), since high leakage currents occur due to the specifics of its operation;

- a coolant with a certain resistance is needed in order to provide its necessary electrical conductivity - its constant monitoring is required;

- it is impossible to use ordinary non-freezing liquids as a coolant, and the cost of special ones is quite high;

- over time, under the action of an alternating voltage, electrolysis decreases and the characteristics of the coolant change, and the dissolution (wear) of the electrodes themselves also occurs;

- during electrolysis, a certain amount of gas is released, which, depending on the liquid used as a heat carrier, can even be poisonous, therefore, care must be taken to ventilate the boiler installation site;

- the power of such an electric boiler depends on the temperature of the liquid in the water heating system - when it increases, its electrical conductivity increases, and hence the power consumption;

- it is difficult to implement stepwise or smooth regulation of its power;

- it is not possible to use it for hot single-circuit water supply;

- constant monitoring of the consumed current is required.

Electric induction boilers

Induction electric boiler with control panel

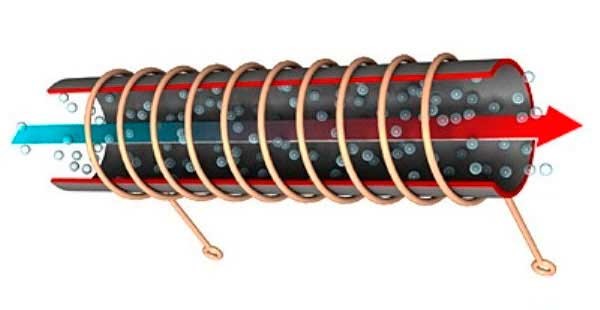

This is the newest type of boilers that use electricity as a heat source. Therefore, now they are often confused with electrode ones. But the principle of operation of such an electric boiler is completely different from the device of the previous type and is based on the ability of an induction current to heat a core made of a ferromagnet placed in a heat-transfer fluid. An example of such a ferromagnet can be ordinary steel.

In fact, an electric induction boiler is similar to a transformer, the primary winding of which is an inductor, to which voltage is applied, and the secondary is a metal core made of a ferromagnet inside or outside of which the coolant circulates. In this case, the resulting induction current heats the core, and that, in turn, heats the coolant. Most often, the core is made in the form of a labyrinth, to increase its contact area with the liquid.

The coolant in such an electric boiler heats up quickly enough, and its type and quality can be almost anything. This distinguishes these boilers from other types. In addition, during its operation, certain microvibrations occur inside it, which prevents the possibility of scale formation, so it practically does not form. This contributes to the fact that the induction electric boiler can operate for a long time without reducing its efficiency, and its efficiency remains the same. Another advantage of such heating devices is that there is no need to replace the heating element after a period of time. Boilers of this type can be of two types SAV and VIN (vortex), differing in design and some characteristics. The service life of induction electric boilers is much longer than that of heating or electrode boilers and is 30 years or even more.

- they are more expensive than heating elements and electrode ones;

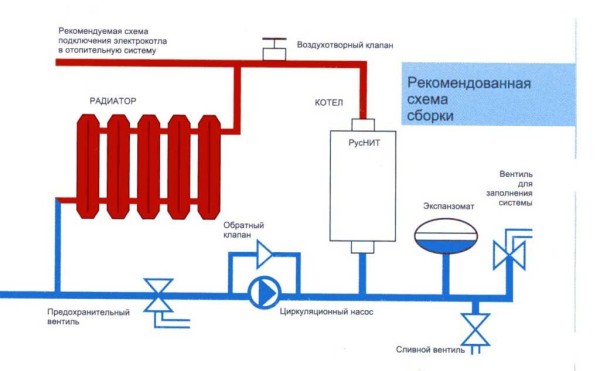

- can only work in water heating systems with excess pressure of a closed type with forced circulation of the coolant;

- have a rather large weight (30-40 kg) compared to other species;

- insufficiently tested in practice, as they appeared on the market not so long ago.

How to choose the right electric boiler

The first thing to do when choosing an electric boiler is to decide on its type, taking into account their positive and negative sides. If you are interested in more cheap option, which can work both on water and non-freezing liquid, then you can choose a heating element electric boiler. But at the same time, it should be taken into account that the water used as a heat carrier should in this case be as “soft” as possible in order to prevent or reduce the possibility of scale formation on tubular heating elements. In addition, you must be aware that a certain place is needed to place it, and sooner or later, you will have to change the heating elements, which rarely have a long service life.

If you want to save space and at the same time get an economical option, you can opt for an electrode boiler. They can be installed directly on the pipes of the heating system. Such electric boilers of low power, at times, are even difficult to notice among the heating pipes. But at the same time, it is necessary to understand that you will have to constantly monitor the composition of the coolant, which is not very convenient, or use expensive special fluids.

The most attractive option today are induction electric boilers. They take up little space and the coolant can be used, practically, any, and their shelf life is impressive. But such a boiler will cost almost twice as much as the previous two types.

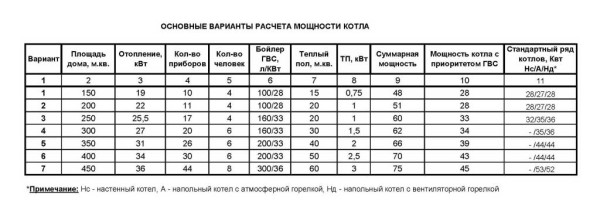

The choice of the power of an electric boiler of any type depends on whether it will be used for main heating or as a backup or additional one, as well as on the area of \u200b\u200bthe room or house that will have to be heated. If it is used as the main source of heat, then its power should be such that for every 10 m2 of heated area (with a ceiling height of 2.5-2.7 m and good thermal insulation of external structures) there is 1-1.2 kW. If it is used as additional heating, for example: to maintain the temperature in the system in between the operation of another heating device, then a power of 1-3 kW may well be enough.

In addition, when choosing an electric boiler, it is important to pay attention to the reliability of the manufacturer. Although such products from reliable manufacturers are more expensive, in the future their operation can be cheaper if you take into account the cost of repairing or replacing cheaper, but not reliable samples. So, in any case, the choice is yours.

Related videos

Which boiler is the easiest to use? I don’t know if you will be surprised or not, but electric is quite seriously claiming this role. Only a couple of hours can pass between its installation and commissioning. Many are seduced by this simplicity, but also daunted by the prospect of paying hefty energy bills. In this article, we will look at the advantages and disadvantages of devices of this type, and also find out what to look for when choosing. Shall we start?

Features of electric heating boilers

electric boiler

electric boiler Although there are 3 different types electric boilers, they also have common features, which we will now group. This is the so-called introductory information, which will give us the first general idea about the device.

- you for sure will require a three-phase 380V network for operation equipment. The fact is that any 220V socket is designed for a current of 16A. Multiplying 16A by 220V, we get a power of 3520 watts. Devices with power up to 3.5 kW you can turn on into a regular 220V socket.

- According to the manufacturers, the maximum power of a single-phase electric boiler that you can connect to a 220V network is up to 12 kW. However, it is better not to take risks and listen to smart advice.

Connect all boilers from 7 kW and more powerful to a 380V network! This will save you from possible overheating of the wiring and equipment breakdowns.

- The efficiency of any electric boiler is 99-100%. In fact, all the expended energy is converted into heat. An exception may be an incorrect installation of equipment, when heat can “spread” over the body of the equipment. Of course, this is not a big disadvantage, because it will also serve common cause- heating the air in the room.

- Do not forget that electricity is a rather expensive source of heat and get ready for impressive bills in advance. However, do not be afraid in advance, because electricity is the most efficient, convenient and safe way to heat your house or apartment in the winter cold.

Types of electric boilers

After we have summarized some information, now let's deal with particulars. There are 3 types of units that fundamentally differ in design and, accordingly, in the principle of operation. Let's take a closer look at what each of these 3 potentials are.

heating element

Heating element boiler

Heating element boiler This is one of the most popular types of boilers. The design and principle of its operation is similar to a conventional storage water heater: Several tubular heating elements (heaters) are placed in a large tank. The circulation pump is responsible for the movement of the coolant (water or antifreeze).

An important minus: Heating elements quickly become covered with scale, reducing the efficiency of the system, and fail. This is quite understandable, because the hardness of water in the country is most often increased. However, there is a way out of this problem: you can not open, but a closed circuit, when the coolant is not replaced with a new one.

Separately, it is worth highlighting the presence of sensors that are responsible for maintaining the desired temperature. There are 2 types of sensors: the first maintains the desired water temperature. But the second type is much “smarter”: it focuses on the air temperature in the premises, and not the temperature of the water in the system. It's much more convenient and efficient.

Induction

Electric boiler of induction type

Electric boiler of induction type Yes, you thought right. The work of such a boiler is based on the phenomenon of electromagnetic induction (take place in the 7th grade of the school).

The main element is a pipe made of dielectric material with a ferromagnetic rod inside. Water circulates through this cylinder (pipe). The entire outer surface of the pipe is an induction coil through which current flows, thus causing the rod (which, you remember, is inside) to heat up. And the hot rod already heats the water.

The advantages of these boilers are undeniable:

- Long service life- the design of the boiler is very simple with a minimum of nodes and there is simply nothing to break in it.

- Small dimensions- many times less compared to traditional boilers. Therefore, it is very easy for them to find a free place in a house or even an apartment.

Minus one, but significant: a very complex automation unit, which is not included in the boiler device itself, but is located separately. It is he who can break down, since the number of electronic components inside is large.

Electrode

Electrode boiler

Electrode boiler This is one of the least popular electric boilers, now we will explain why.

Briefly about the principle of operation: in a container with a tank there is a coolant, as well as 2 rods - a cathode and an anode. Water has its own resistance, and by passing through it alternating current water molecules break up. Negative ions are attracted to a positively charged electrode and vice versa. It is this chemical process that causes the water to heat up.

Of course, such a design, at first glance, is very simple and reliable. It would seem, what could be wrong? But everything is trite and simple: in order for the boiler to function as intended, water of special quality according to GOST, which has a certain resistance, is required.

Also, electrodes degrade over time, so you'll need to change them from time to time.

Advantages and disadvantages

Of course, each type of boiler can boast its own advantages, but let's find out in general what electric boilers are good for, but let's not forget about their disadvantages.

pros:

- Environmental friendliness– no combustion process takes place in this equipment, so there is no need for smoke extraction and removal of combustion products.

- Elementary installation- you do not need to organize the chimney system, and there are no restrictions on the choice of its location at all.

- Does not require fuel supply- Simply connect it to the mains. You will not need to puzzle over the fuel supply, as is the case with other types of boilers

Minuses:

- The high cost of electricity. Perhaps this is one of the most significant disadvantages. Also keep in mind that every year it is increasing.

Costs for heating a house with an electric boiler: an example of calculation

Let's take into account several factors:

The efficiency of the electric boiler is 100%. This means that the production of 1 kW of heat consumes about 1.04 kW of energy.

The price of 1 kW is 3.4 rubles(we took the average value, since this figure is different for the regions of the country).

For a house with an area of 90 sq.m. from the southern part of the country we will need an average of 15 kW.

Daily consumption will be 15*24= 360 kW/h

monthly consumption electricity, if the device heated water constantly, would be 360 * 30 = 10800 kW / h

Money spent per month- 10800 * 3.4 \u003d 36720 rubles.

We calculated this amount with a surplus, because the boiler will not plow 24 hours a day. Therefore, you can safely reduce it by 1.5-2 times: about 20-23 tr. he will "eat" you.

It can be concluded that an electric boiler will be cost-effective only for heating a small house or apartment. Heat with its help an area of more than 150 sq.m. is simply inappropriate.

Choice characteristics

Having received primary information about the types of electric boilers, now let's take a closer look at the question: how to choose an electric boiler? What to pay attention to? To do this, let's go through the important parameters.

Connection type

Simply put, this is the number of phases of the network to which you will need to connect the device.

Single-phase boilers - the simplest household units that can be connected to a regular 220V outlet. There were cases that additional permission was required for such a connection, as electricity consumption increased.

Features of the boiler 220V

- Almost all single-phase boilers belong to the category of heating elements.

- Low-power units can be connected to a conventional outlet, which means that they are suitable for installation even in an ordinary 2- or 3-room apartment.

- The design and operation principle are very close to those of a conventional water heater.

- You do not need permission from government agencies for the installation and operation of equipment, since a single-phase boiler is equivalent to a conventional boiler.

- The cost of heating a house with single-phase devices is slightly higher than with three-phase ones.

A 220V boiler will work in plus if you purchase it for a house / apartment with an area of \u200b\u200bno more than 90-100 sq.m.

Three-phase boilers - this is all equipment with a power of more than 12 kW.

Features of the boiler 380V

- Three-phase devices are only of 2 types: electrode (they quickly heat the coolant, suitable for a system with a closed water circulation circuit) and induction (they consume the least electricity, but they have large dimensions and weight).

- You will need permission to run a separate three-phase grid into a house or apartment (this permission is more difficult to obtain for an apartment than for a residential building).

Equipment power

It depends on how accurately you can set the temperature of the coolant, as well as the ease of use of the unit. There are currently 3 possible options.

- stepped: typical for heating elements boilers, in the design of which there are several heating elements. The regulator is responsible for connecting / disconnecting part of the heating elements, thus allowing you to change the temperature of the liquid. The classic boiler scheme is as follows: 3 heating elements are provided, the first of which gives 50% of the total power of the unit, and the remaining two, 25% each. The disadvantage of this method is that you can set only one and 4 possible power values: 25.50, 75 or 100% of the total power. No other intermediate values can be set. Thermostats and valves on radiators in rooms will help you regulate the temperature more accurately.

- Smooth: a more convenient way, since you can set absolutely any desired value for the power / temperature of the coolant that you like. This is different from the step system. Smooth adjustment is ensured by the presence of a rheostat. Another advantage of this system lies in its economy. Imagine that for a comfortable temperature in the house, you need the boiler to operate at 60% of capacity. With only a staggered system, you would have to set it to 75% and remove the excess with a thermostat. On the one hand, you will achieve the desired temperature, on the other hand, you will spend extra kW of electricity on unnecessary 15%.

- Without adjustment. The simplest boilers with low power do not have this feature at all.

Which package to choose

There are 2 ways in front of you: buy a boiler in the basic configuration and separately purchase all the necessary components and parts (expansion tank, pump, filters, etc.) or immediately purchase a fully equipped boiler.

Experienced people advise you to purchase a boiler that is completely ready for operation right away, since it will cost much less than buying everything separately. The difference is that you still have to pay for the installation of these units, while everything will be installed in the boiler.

Case features

This information will be especially useful for families with small children.

Before buying, make sure that the device of the boiler was necessarily provided with a voltage stabilizer! In our country, the current parameters differ from ideal ones, and voltage surges are an ordinary thing. The stabilizer will eliminate the failure of sensitive parts of the boiler, such as automation of circulation pumps.

Inexpensive models have a significant drawback: in order to reduce the cost, the manufacturer does not use metal for the manufacture of many elements, but plastic. This is bad because over time from high temperature plastic components will melt, and the unit will quickly fail. Therefore, it is better to add money and buy an initially good boiler than to spend money on buying a new one.

Types of automation for an electric boiler

None, even the cheapest boiler, can do without automation. She is responsible not only for adjusting the temperature, but also for the safety of use. There are 2 main categories:

- Mechanical automation- as you understand, it consists of mechanical relays, thermostats and limit switches. To her benefits can be attributed to a small price, and the disadvantages are too loud sounds when switching, as well as low accuracy of temperature control. Therefore, boilers with mechanical automation are used for heating non-residential buildings.

- Electronic- despite the higher cost, it fully justifies itself. The use of electronic thermostats and thermostats allows you to reduce energy consumption by 20%, in addition, the noise during operation is several times lower.

How to reduce energy consumption: tricks and nuances

Of course, looking at rising electricity bills, the first thought that comes to mind is: “How can I reduce them??”. There are several ways to help you knock down this fee a little.

- Find out if your area has preferential electricity tariffs. As a rule, they operate at night, when the rate is reduced by almost 1.5 times. You just need to connect heat accumulators to the heating system. They will help you heat water at night, and use it already in the counting time of day.

- The 2nd method is valid only for the southern regions and at positive temperatures outside. You can use air conditioners for heating, which use partly the heat "taken" from the outdoor air. The ratio is not bad: they convert 1 kW of electricity into 5 kW of heat.

Finally, we provide you with an informative video in which you will learn in detail about choosing an electric type boiler:

Today we will talk about electric heating boilers, what are their advantages over other heat sources and what disadvantages they have.

What are they

Water-heating boilers are currently used for heating residential premises.

The main task of these boilers is to convert the energy of the boiler power source into thermal energy, which is transferred to the heat carrier.

As a heat carrier, water is most often used, which circulates through the pipelines of the heating system laid throughout the house.

But there are several heat sources that will give off energy. The most common are gas boilers, in which thermal energy is released due to the combustion of gas.

Another type of boilers is solid fuel. They also use combustion to release thermal energy, but only firewood, coal, etc.

Electric heating boilers

Recently, electric boilers have begun to gain popularity.

Types of electric boilers

Compared with the first two types of boilers, electric ones have a number of positive qualities:

- Installing an electric boiler is much easier;

- Such a boiler does not require an exhaust hood to remove combustion products, since they are not;

- Due to the lack of combustion chambers where fuel is burned, electric boilers are much smaller in overall dimensions;

- In most cases, these boilers are wall-mounted, so they take up little space and do not require a separate room.

The main parameter of any boiler, including an electric one, is its efficiency - the coefficient of efficiency, indicating the percentage of source energy that is converted into thermal energy.

Electric boilers have an efficiency of 94-98%. This indicator is quite high, but, nevertheless, part of the energy is still lost, 100% efficiency is not able to "give out" more than one of the existing boilers.

Modern electric heating boilers are divided into three types according to the heating elements used:

- heating elements;

- Electrode;

- Induction.

There are also design differences, but this is more aimed at expanding the choice of certain parameters - installation methods, power sources - single-phase network or three-phase, boiler control methods, the number of circuits for the coolant - one circuit or two.

All this may somewhat affect the design of a particular type of boiler, but in general, their principle of operation is unchanged.

ENERGY SAVING! Savings are achieved by normalizing the structure of the electrical flow, dynamic absorption or release of reactive power, reducing resistance losses, and eliminating power surges in the network. DETAILS ON THE BLOG OF A GOOD ELECTRICIAN >>> .

Heating element type

Consider the features of each boiler. So, in heating elements heating boilers, the conversion of electrical energy into thermal energy is carried out tubular heating elements, and heat transfer is carried out only over the contact area of the heating element and the heat carrier.

Such heating elements are used in many heating devices.

As for the complete design of such a boiler, it consists of a body from which the inlet and outlet pipes come out.

Inside the case there are heating elements, a power unit that supplies electricity to the heating elements, fuses that provide emergency shutdown in case of malfunction, as well as a control unit that sets the boiler operation mode, temperature, etc. and temperature sensors.

Since in this boiler water is heated in flow mode, it is not necessary to include a circulation pump in such a heat supply system, the water moves independently.

As for tracking sensors, two types of sensors are used in heating elements.

The former is more common as it is included in the design of the boiler. Such a sensor measures the temperature of the heat carrier.

The second type of sensor - measures the air temperature in the room, so it is easier to make a more accurate debugging of the boiler operation mode with such a sensor.

But such a sensor is remote and it should not be located in the boiler, but in the room heated by it.

Electrode type

The second type of electric boilers - electrode, operate on a slightly different principle.

In them, as such, there is no heating element, only special electrodes are located inside such a boiler.

The task of these electrodes is to transfer electrical impulses to the heat carrier - water. And since water has resistance, when passing through it electric current, it is split at the molecular level into positive and negative particles, which rush to the electrodes of the desired polarity.

THE BEST PROTECTION FOR YOUR HOUSE AND BASEMENT! The season has begun, when rodents massively return to warm places where they can survive the cold winter, and these are houses, summer cottages, basements with food supplies. We need effective protection against uninvited guests and it exists - it is a universal repeller of rodents and insects. HERE PEOPLE'S OPINIONS ABOUT THE DEVICE >>> .

The whole process is accompanied by the release a large number energy (heat). That is, the water itself heats up due to its resistance.

The boiler itself has an outwardly simple design - a body with outlets for connecting it to the heating system, and electrodes are located inside.

Some models of boilers are equipped with a control system, but there are also models for which the control and protection unit is purchased separately.

It is worth pointing out that with this type of heating, spontaneous circulation of water does not occur.

When using this type of heating boiler, it is necessary to have a circulation pump in the heat supply system.

induction type

The third type of boilers is induction, which uses electromagnetic induction for heating.

In such a boiler, due to the inductive coil, a core made of a ferromagnetic alloy is heated, and he already gives this heat to the carrier.

Such a boiler consists of an all-metal housing in which an inductive coil is placed in a sealed compartment so that it does not come into contact with the carrier. The core is located in the center.

Water, as a carrier, passes through the channels, flows along the core, taking heat from it, and heated out of the boiler.

Details of the advantages and disadvantages

Their common advantages are:

- Simple boiler design (regardless of type);

- A minimum of detachable connections facilitates installation and eliminates the appearance of leaks;

- Do not require any type of fuel;

- Virtually silent operation;

- No need for a chimney;

- Environmental friendliness of use;

- Explosion safety.

These positive qualities are inherent in all types of electric boilers. But each type has its own individual advantages and disadvantages.

So, TENovye boilers are very compact, and often have an attractive design.

They are inexpensive, easy to install and connect. Water can be used as a heat carrier, as well as non-freezing liquids. The coolant circulates spontaneously through the system.

The main disadvantage of this type of electric boilers is the formation of scale on the heating elements.

Because of this, the boiler may increase its electricity consumption, but eventually it will require maintenance.

Electrode boilers have their advantages. They are even more compact, cut into the heating system, so they are almost invisible.

Their cost is also low, and they are relatively easy to install.

They have complete safety of use, in case of lack of water, they simply turn off. They do not form scale.

But such a boiler has enough shortcomings.

- Firstly, the coolant must be prepared, because it must have a certain resistance.

- Secondly, only water is used as a carrier, other liquids are not used with such a boiler.

- Thirdly, water circulation must be ensured, so the installation of a pump is inevitable.

- Fourthly, the electrodes gradually dissolve in water during operation, so they will need to be replaced over time.

Now about the advantages of induction boilers.

In them, as such, there is no heating element, therefore, its possible breakdown is excluded, therefore, such boilers are considered very reliable.

Also, they practically do not form scale, so they are not subject to maintenance. They can be used as a carrier and non-freezing liquids.

Among the shortcomings, they have a high cost and significant overall dimensions.

About economy

In terms of performance, boilers are selected on the basis that per 10 sq. m. area for efficient heating should account for at least 1 kW of power consumption, this is provided that the boiler is single-circuit, if it has two circuits, then 25% must still be added to the power consumption.

When choosing a boiler, not only its type is taken into account, but also its productivity, the area of \u200b\u200bthe room that it must heat, the cost of equipment, the availability of space for its installation, efficiency, and service life.

But it also depends on the room itself - its area, whether the walls have been insulated, which windows and doors are installed.

Based on this, it is decided whether it will be economically feasible to heat the room with electric boilers.

For example, heating a large room with them is inefficient, but it can be used as an additional one to a boiler that uses any type of fuel.

This all indicates that the efficiency of using the boiler and its cost-effectiveness is an individual matter.

For some rooms, primarily small ones, this method of heating can be very economical, for medium-sized ones, calculations should already be made.

Some types of boilers and their characteristics

Let's take average models. Of the heating elements, for example - Galan Geyser Turbo 12 kW.

This boiler has a cylindrical shape, can be used both floor and suspended.

The length of this heater is 500 mm, the power is 12 kW, therefore it is indicated that it is capable of heating a room up to 300 cubic meters, although, as already mentioned, it all depends on the thermal insulation of the room itself.

This model comes with a control box. It is three-phase, therefore it works from a 380 V network.

But the model Galan Geyser-9 can already work from a network of 220 and 380 V.

This model is also very compact, its length is only 360 mm. Its power is 9 kW, and can work with a coolant up to 100 liters. The manufacturer indicates that this boiler is capable of heating a room up to 340 cubic meters. m.

But this manufacturer does not produce induction boilers. Therefore, we will consider one of the models of the manufacturer SAV of the PROF series.

Consider the parameters of the SAV 5 model.

This boiler has a power of 5 kW. At the same time, it is able to heat a room up to 200 cubic meters. It works from a 220 V network, as for the size, you can’t call it small, its height is 640 mm with a width of 455 mm.

Popular with readers: Is it worth buying.

Briefly about the installation

Installing any electric boiler is not particularly difficult. The main task is the supply of pipelines to the boiler, and with the correct location of the pipeline for supplying and discharging water.

The diameter of the pipes must match the diameter of the inlet and outlet pipes.

After the boiler is either fixed on the wall, or installed on the floor.

Then the pipelines are connected to the nozzles. If the design requires the presence of a circulation pump, then it must be installed on the inlet pipe.

It is also imperative to install taps that shut off the water both at the inlet to the boiler and at the outlet.

All pipelines must be connected using sealing materials.

If there is a pump, it will also need to be turned on so that it creates fluid movement.

The last step will be to connect the boiler to the electrical network, and it must be used with suitable parameters when powering the boiler.

Then a trial run of the system and a check of its operation, as well as adjustment and installation of operation parameters, are already carried out.