Design standards for chemical analytical laboratories. Requirements for air purification of laboratory premises

Are you creating a new enterprise or workshop in which a laboratory is planned?

Does the current layout of the laboratory not meet modern requirements?

Have you "grown up" and in the old rooms you do not have enough space?

Are there new methods and equipment that do not fit into the existing premises?

Do you just need a new lab?

Development of concepts for intensive water treatment by integrating nano- and membrane technologies. The overall goal is to strengthen the European membrane market by creating nanotechnology for major European membrane manufacturers. Process paths 2 and 3 consider the use of active nanoparticles, such as bionano catalysts, in combination with membranes to remove micro-pollutants, such as chlorinated compounds, nitroaromatic compounds, or redox active metals, which improves water quality.

You need a concept design for a new laboratory!

A common mistake in the construction or redevelopment of a laboratory is to contact a design organization that does not have experience in designing laboratories. The laboratory project is not just drawings, a description of construction materials and a list of equipment, it is also an IDEA that allows you to implement all the tasks assigned to the laboratory with maximum efficiency. The formation of an IDEA is a conceptual design.

The construction (re-planning) of the laboratory is usually carried out in the following sequence:

In accordance with the tests performed, it is selected necessary equipment.

Next is the layout of the premises. It is often necessary to fit a laboratory into the limited space of an already completed building or into the allocated “squares” of a new one, while observing construction, sanitary, fire and other standards.

Next, calculate and purchase required amount materials.

Construction!

Now read the first paragraph again and answer the question: does every design organization employ people who performed tests and worked on laboratory equipment?.. Of course not!

AROSA specialists have real practical experience in laboratories and production.

A conceptual (technological) project is the first stage on the way to the implementation of a new laboratory. On the basis of the concept, almost any design organization will carry out the architectural and construction project necessary for the construction (re-planning) of the laboratory.

I bring to your attention the technological (conceptual) design of physical, chemical and microbiological laboratories for all industries, as well as educational institutions and research organizations. As a result, you will receive the necessary drawings of the future laboratory and a task for designing the architectural and construction part of the project.

The technological (conceptual) project of the laboratory includes:

Blueprints:

layout of premises and equipment;

dimensions of the premises (task for the design of the architectural and construction part);

communication connection points (task for the design of the electrical part);

communication connection points (task for the design of water supply and sewerage);

flows of personnel, materials, products, waste;

classes of room cleanliness and pressure drops (for a microbiological laboratory).

Explanatory note

description of the organization of testing, flows, materials, products, personnel;

technology of work;

proposals for the selection of test equipment and measuring instruments;

preliminary calculation of the required energy capacities;

the need for staff;

measures for safety, labor protection, fire prevention measures;

technological task for the design of electric lighting;

technological task for the design of power electrical equipment;

technological task for the design of the ventilation and air conditioning system;

technological task for the design of water supply and sewerage;

list of waste and methods of their disposal.:

The project can include equipment selected by the customer independently, or selection of new equipment can be performed in accordance with the wishes and budget of the customer.

Upon completion of the work, the customer will be given all the drawings and an explanatory note in electronic form. High-quality terms of reference for architectural design and, specifically, drawings in electronic form - all this is a powerful argument for reducing the cost of an architectural project! After all, a significant part of the work has already been done: it is much easier and faster to make the binding of a conceptual design according to ready-made drawings.

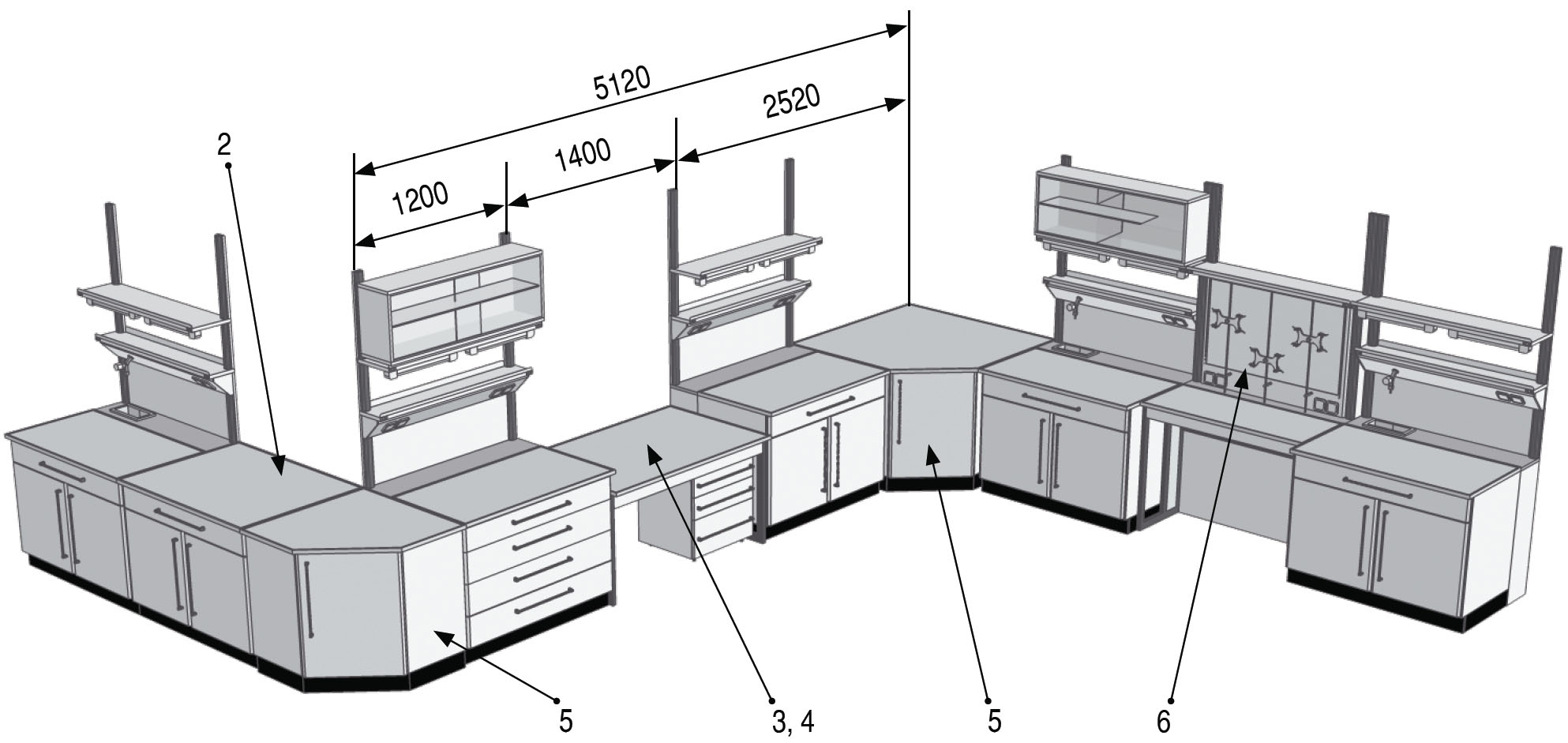

1. All tables, add-on modules and titration units presented in the catalog can be used in island and wall sets in various combinations.

2. Tables "Progress" with a working surface depth of 900 mm can be included in wall sets when there is no need for add-ons, shelves, desktop cabinets. The depth of the working surface of such tables is equal to the sum of the depths of the Progress-650 tables and the Style add-on modules.

3. Desks "Dynamics" can be used both separately and in sets - island and wall-mounted (as shown in the relevant sections).

4. Tables "Dynamics" can be manufactured with non-standard width (600 ... 1800 mm), which allows you to optimally fill the working space of laboratories.

5. For docking wall sets in the corners of the premises (external and internal transitions), tables ProSt-71 and ProMo-5 are used. In tables for external transitions, the dimensions of the working surface are 900x900 mm, for internal ones - 1320x1320 mm.

6. For the convenience of working with the titration unit, it is recommended to use it in a set with a DIN-31 type table with a depth of 500 mm

7. The names of wall and island complexes (MINI-P, MINI-0, etc.) divide them only into overall categories and do not describe the composition. When forming an application, it is obligatory (!) to indicate which products are included in the kit you are interested in.

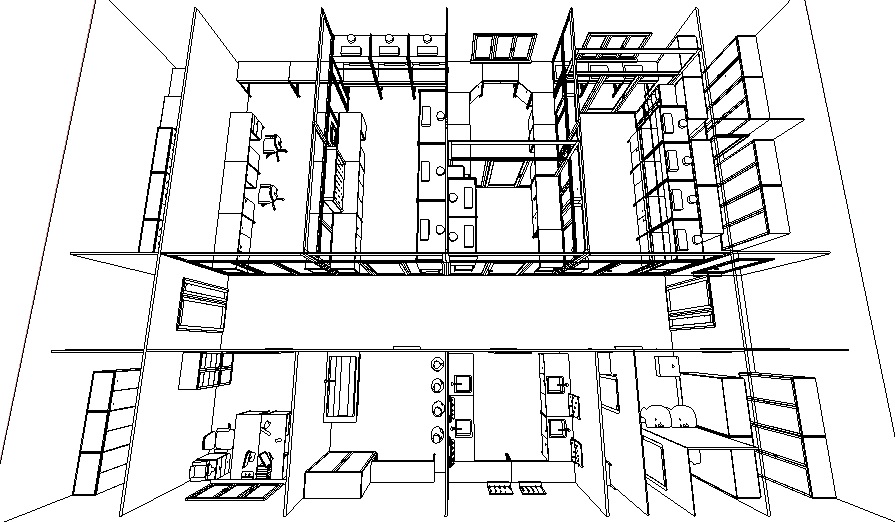

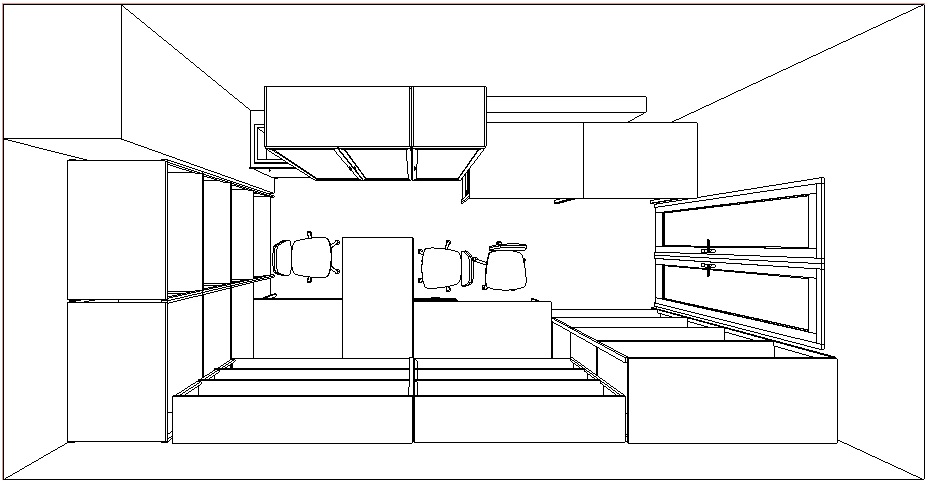

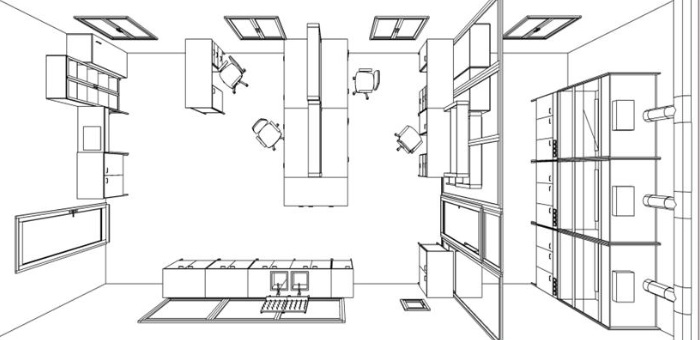

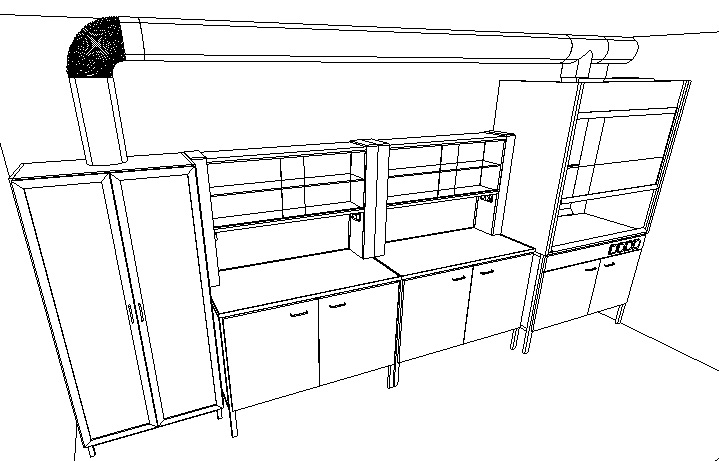

Sketchy 3D design projects:

Chemical laboratory at a machine-building enterprise

Mobile laboratory based on a block container

In educational, medical and research institutions, pharmacies, dental clinics, our specialists repeatedly face typical tasks of organizing modern system supply and exhaust ventilation.

- Design of ventilation systems

- Cleanroom Ventilation Projects

Sanitary standards, technical specifications, manuals and installation rules

The solution offered by our HVAC company is the preparation of the project, the choice of inexpensive and durable equipment, installation and commissioning and maintenance of the facility.

Laboratory ventilation design

Basic design requirements ventilation systems in laboratories, it is compliance with the norms and rules (SNiP) for safe and efficient air exchange. There are 3 main types of laboratory facilities:

- chemical laboratories;

- microbiological laboratory (bacteriological);

- medical laboratories (dental, stomatological, prosthetic).

Photo: ventilation in a chemical laboratory

Requirements for air purification of laboratory premises

In each of the above premises, the conditions for an effective air exchange system specified in the customer's specification are met. In addition to the standard calculation of the frequency of general air supply, the installation of individual exhaust hoods is required to quickly reduce the level of gas contamination and humidity above laboratory tables and cabinets. The project must take into account the size and functionality of the laboratory.

AT chemical laboratories polluted air is removed through the exhaust ventilation system to the street, without additional processing. The buildings of testing chemical laboratories and research institutes are located, as a rule, in areas remote from residential areas, which allows the removal of increased concentrations of harmful substances through roof fans or through ventilation openings.

Photo: ventilation system of the microbiological laboratory room

In microbiological laboratories, MDR, etc., it becomes necessary to install bacteriological filters, usually with the addition of silver, which neutralize dangerous microorganisms. Periodic replacement of expensive ventilation filters leads to unacceptable growth financial costs. Such "blows" on the budget can close any, the most profitable laboratory. StroyEngineering offers a "budget" solution - reusable bacteriological filters. Weekly/monthly, depending on operating conditions, cleaning and disinfection reduces the cost of maintaining laboratory ventilation systems, without compromising the safety and health of staff and visitors.

In dental offices, in addition to chemical reagents, high levels of hazardous polymer and ceramic dust are released. The carcinogenic properties of materials that are harmless to the oral cavity are manifested when they enter the lungs, where, forming organic bonds, they can lead to undesirable consequences for the dental laboratory staff. Air circulation in dental clinics requires increased energy consumption, a constant supply of heat in the cold season and air conditioning in the summer months.

Rules for good air purification in laboratories

A photo: supply and exhaust ventilation dental laboratory

Ventilation, with air circulation, is unacceptable for all types of laboratories listed above! Forced ventilation systems in laboratories are equipped with high-performance exhaust units with umbrellas, suctions, fans, air ducts, mines. Supply valves ensure safe air exchange and do not allow contaminated/polluted air to enter the clean air supply system. AT high-rise buildings, it is possible to combine exhaust system one or more laboratories into one ventilation shaft.

When it is vital to save energy and ventilation units in laboratory modules are turned off during non-working hours, our company installs an automatic switch / switch. The timer starts the units in the mode of enhanced air purification an hour before the arrival of employees in order to “ventilate” the laboratory premises and ensure safe working conditions. When ordering a ventilation cabinet with remote (remote) control, this function is enabled in the ventilation cabinet automation settings.

To solve problems with heat loss, StroyEngineering offers inexpensive mechanical ventilation systems with air recovery. Constant temperature StroyEngineering in the room is supported by central air conditioners improved by our specialists, inverter type, which are controlled through a central remote control or through a switchboard (cabinet) of automatic ventilation and air conditioning.

In fire-hazardous premises, design engineers calculate an emergency (fire-fighting) ventilation system with smoke removal. The safety of personnel is put at the forefront, therefore StroyEngineering guarantees the connection of all additional engineering systems (water supply, electricity, heat supply) into one whole. We take requirements seriously industrial ventilation and implement turnkey projects.

Specialization - security

StroyEngineering LLC specializes in the design, installation and maintenance of safe ventilation systems in Moscow. We not only provide laboratories with clean air, but also houses, apartments, cottages, office centers, shops, industrial premises.

StroyEngineering LLC specializes in the design, installation and maintenance of safe ventilation systems in Moscow. We not only provide laboratories with clean air, but also houses, apartments, cottages, office centers, shops, industrial premises.

Qualified StroyEngineering specialists will eliminate any malfunction, carry out prompt diagnostics and maintenance of ventilation equipment at facilities of any complexity. For customers from Moscow and the region - especially favorable conditions for the calculation of industrial ventilation systems!

Our climate company develops integrated supply and exhaust systems for efficient cleaning and air conditioning at low prices. Our clients - a fitness center with a swimming pool, hot catering shops, office space and conference rooms in Moscow, country cottages near Moscow - received not only quality systems air exchange with remote control, but also climate safety.

Popular projects and selection of climatic equipment for their installation

- Ventilation in the apartment

- Ventilation grilles

- Conditioning office space with office equipment

- Ventilation for a cottage

- Duct fans

The next material is ventilation in pharmacy outlets and pharmaceutical laboratories!