Galvanized pipe for gas boiler. Which chimney to choose. Modern types of chimney systems

Approved by an expert

The popularity of using gas heating boilers is due to a number of advantages of natural gas over other types of fuel. But gas, facilitating the solution of the heating problem, is a fuel of increased danger, therefore, the requirements of regulatory services to ensure the safety of the operation of gas boilers, as well as any other gas-powered equipment, are also increased.

The chimney is an integral element of the design of any heating unit, the principle of operation of which is based on the combustion of fuel. The gas boiler is no exception. When gas is burned, visible smoke is not formed that is familiar to the eye, but carbon monoxide is a deadly compound for humans, colorless and odorless, requiring direct and complete output to the outside, which is what the chimney pipe for a gas boiler does - an independent design or an integral part common system removal of smoke from housing.

- complete tightness of the chimney channel throughout;

- the presence of sufficient traction for the complete removal of combustion products from the boiler;

- fire resistance and chemical resistance of the material of execution of the inner surface;

- high temperature resistance;

- equipment of each boiler with a separate chimney;

- the smoke channel along its length should not have more than 3 turns, and the ovals in the configuration are made with a radius of curvature not less than the diameter of the outlet pipe;

- the vertical chimney must be at least 5 m in height - the minimum value that provides the required vacuum and draft;

- the diameter of the chimney pipe for a gas boiler should not be less than the size of the outlet channel of the heating unit;

- inadmissibility of connecting chimneys to ventilation ducts;

- compliance with the requirements of regulatory documents:

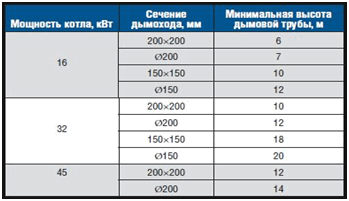

When installing a chimney, it is also necessary to take into account the dependence of its parameters on the power of the gas boiler, as set out in normative documents, but more clearly presented in the table:

Chimney layout options for gas boilers

According to the location of the device, chimneys are divided into:

- internal;

- external.

These types of chimneys are devices whose main structure is located vertically.

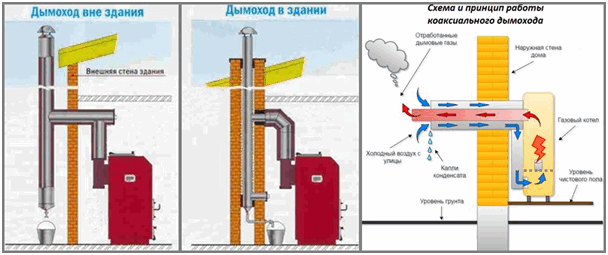

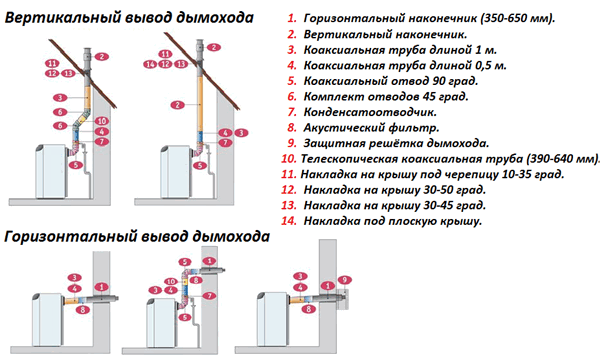

An independent type of chimney is a coaxial pipe in which combustion products and air from the street move towards each other in the channel.

Both types of chimneys are arranged taking into account the requirements of the above regulatory documents, but have individual design features indicating advantages and disadvantages.

Internal chimneys

A chimney mounted inside a building contour limited by external walls is called an internal chimney.

The outer walls of the pipes of such a chimney for a gas boiler are not exposed to the negative effects of the external environment (temperature changes, precipitation, ultraviolet, wind, biological factor), so the design is durable.

In addition, during the movement of hot combustion products through the channel, heat transfer to the air of housing through the walls of the chimney continues - the side surface of the chimney is an additional source of heat, therefore the efficiency of such a heating system is higher, especially in 2-storey houses.

However, this arrangement of the chimney has its drawbacks:

- in case of depressurization of the chimney, carbon dioxide will leak into one of the rooms;

- overheating of the channel surface is dangerous as a fire;

- the places where the chimney passes through the floor slabs need thermal insulation;

- a shaft or a chimney pipe occupy a certain area and volume in the premises, so the factor of their presence must be taken into account when rearranging furniture and choosing finishing materials.

If an internal chimney is arranged during the construction of a house, then there are no problems with its construction - the project contains everything necessary for execution, including the technology for manufacturing an individual foundation for it. If a decision is made to build a chimney of this design in an already built house, then its installation is associated with significant time and money costs, since openings in the floor slabs will be required, and this is damage to the existing finish.

Outdoor chimneys

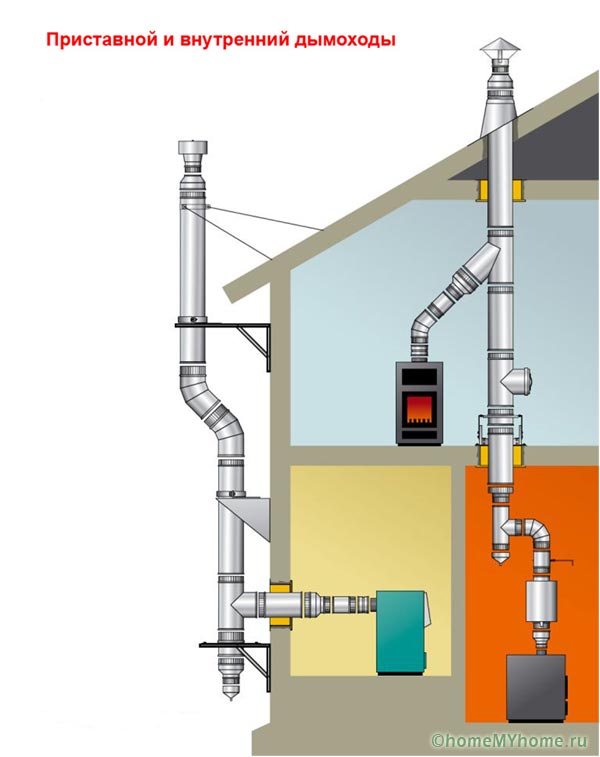

A chimney attached to the wall of a house or brought out through a side wall is called an outdoor chimney.

Advantages of this location:

- ease of construction - the possibility of installation in a populated house without compromising the finish;

- profitability;

- ease of maintenance and repair;

- safety - depressurization does not threaten poisoning.

Disadvantages of outdoor chimneys:

- the need for insulation - to prevent the formation of condensate on the inner surface of the walls;

- impact of negative environmental factors;

- lower efficiency value - the impossibility of using the side surface as an additional heat source.

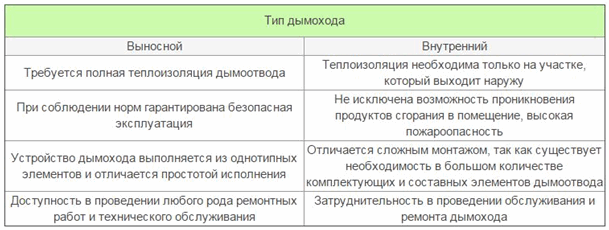

Summary table of characteristics of internal and external chimneys:

Coaxial chimneys

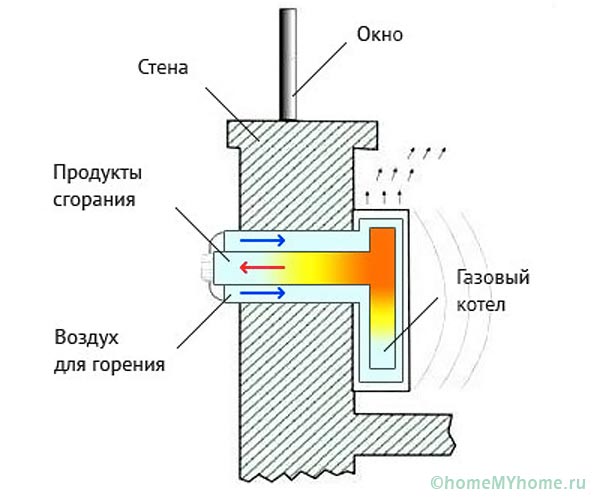

These devices are especially popular when equipped with a gas boiler chimney with a closed combustion chamber. A coaxial chimney is a pipe in a pipe in which two processes take place simultaneously - the intake of outside air into a closed-type combustion chamber and the removal of combustion products from the inside to the street. The coaxial pipe can be used both on wall-mounted boilers and when installing a chimney for floor heating units. The location of the channel can be internal or external, the orientation is vertical or horizontal.

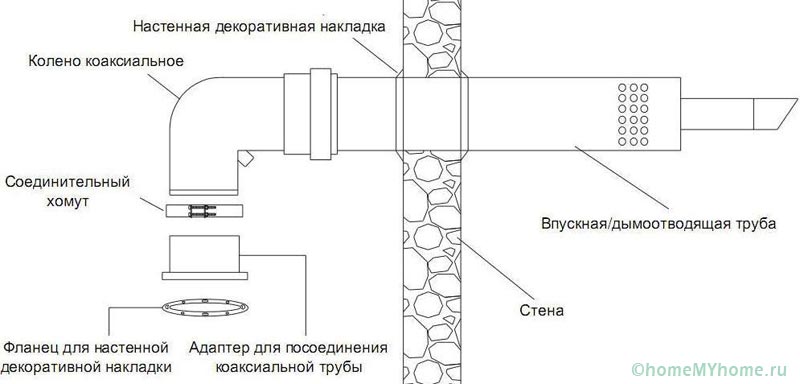

Installation consists in making a through hole of the required diameter in the outer wall, floor slab or roof according to the previously made markings, installing a pipe into it and filling the gaps with heat and moisture resistant sealant.

Types of chimneys according to the materials of manufacture

Chimney pipes for a gas boiler are made of the following materials:

- brick;

- ceramics;

- steel;

- combination of materials.

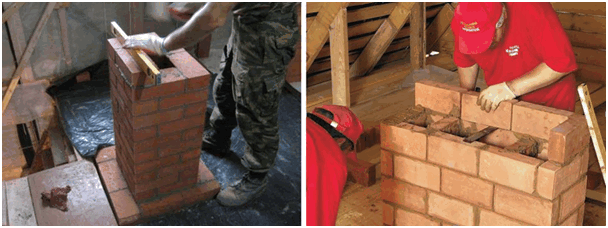

Brick chimney

The ideal section of the pipe through which smoke passes at the highest speed is a circle, and laying out a round chimney from brick is irrational. In addition, a refractory brick is needed, but this does not save the channel walls from soot fouling and destruction due to exposure to condensing acid components of gas combustion products. Therefore, chimneys for heating boilers are laid out of bricks on solid fuel or stoves made of identical material.

The process is labor-intensive, as well as the need for careful selection of heat-resistant bricks and a binder with heat-resistant characteristics.

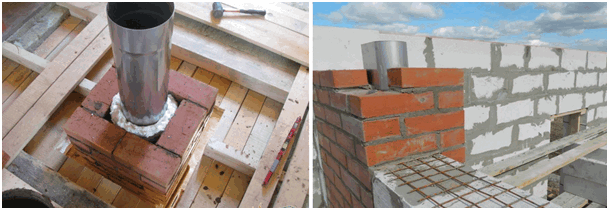

The construction begins with the construction of a solid individual foundation inside the contour of the building without a rigid connection with load-bearing walls and floor slabs. It is not advisable to perform this work on your own, without having the skills to work in laying furnaces, but knowledge of the technology will help control the work of a professional performer.

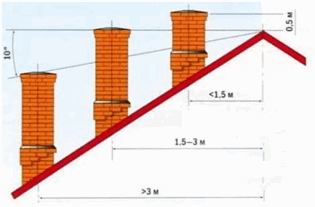

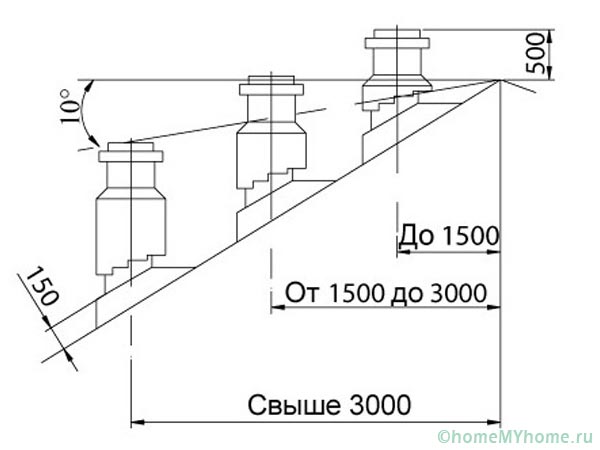

One of the conditions for ensuring sufficient traction is the required amount of elevation of the pipe head above the roof ridge, depending on the location. The diagram demonstrates this better than the description.

But the presence of traction, nevertheless, does not completely eliminate the factor of the destructive effect on the brick of smoke, its acid-forming components and condensate.

You can eliminate the influence of these factors by mounting a chimney from a steel pipe and overlaying it with refractory bricks. The ideal option for the channel material is stainless steel, which is resistant to chemically aggressive substances and moisture.

Based on the nuances of using bricks when constructing a chimney, its use for equipping a heating system based on a gas boiler is not justified.

Chimney from ceramic pipes

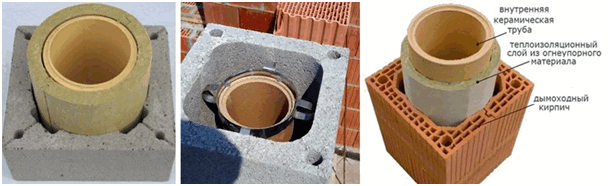

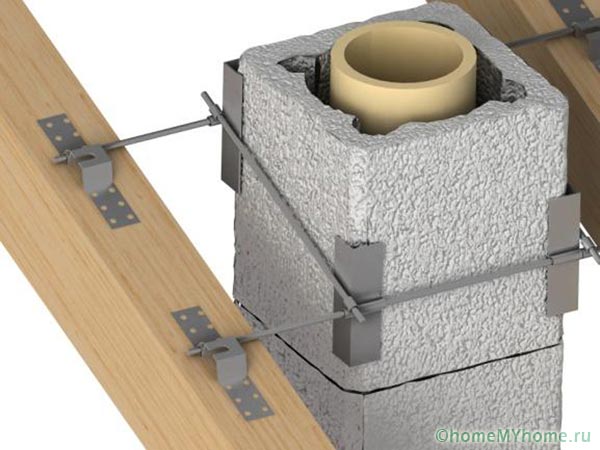

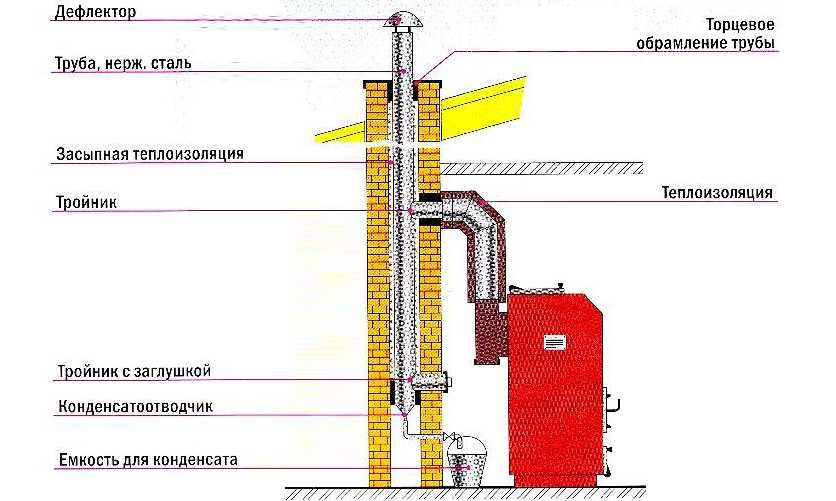

The ceramic flue pipe is a prefabricated structure. The outer hull is a load-bearing frame made of lightweight concrete. Inside it is a ceramic tube. The space between the inner and outer layers is filled with a special heat-insulating material.

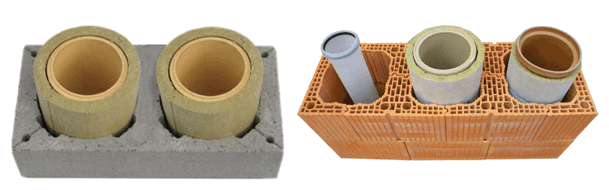

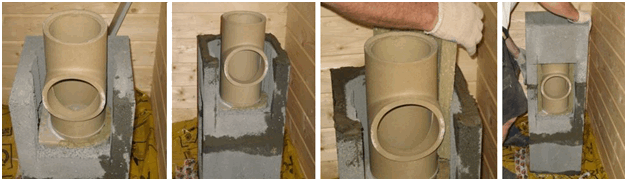

The ceramic chimney is mounted from separate elements 20-60 cm long, having a connecting shaped socket at one end, processed during assembly to seal the joints with an acid-resistant adhesive.

The ceramic channel is insulated from the outside with heat-resistant thermal insulation and lined with hollow claydite-concrete blocks or heat-resistant bricks on cement mortar. The grooves in the blocks contribute to the ventilation of the insulation and neutralize the thermal expansion of ceramics. The design and profile of the blocks can be different - depending on the diameter of the chimney and the number of ceramic pipes in the channel.

To facilitate installation, manufacturers offer ready-made sets of ceramic chimneys, which include all the necessary accessories and have a guaranteed service life of 30 years or more.

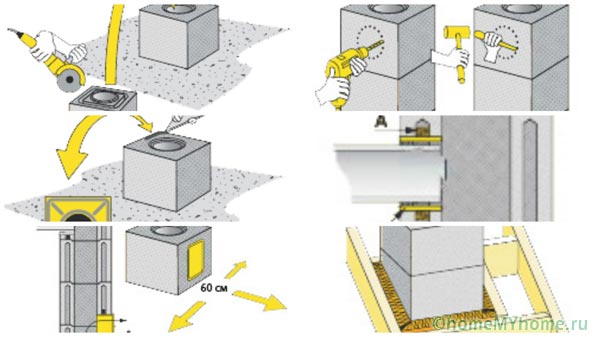

Installation of a ceramic chimney

Ceramic chimneys are rarely mounted outside, as the outdoor version will require an additional reinforcing shell of bricks or blocks.

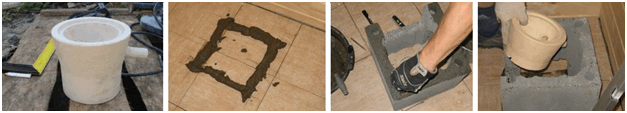

The device begins with determining the exit point of the channel in the roof. Then this place is projected down with a construction plumb line, soft soil is removed, the site is planned, the contour of the foundation is marked out and rubble bedding is made.

Foundation

If the base for the chimney is the foundation of the house (the structure is a pillow) or a concrete floor with reinforcement, then the channel is installed on it, having previously completed the waterproofing of the site.

The dimensions of the foundation in plan and its depth depend on the properties of the soil and the parameters of the chimney - the contour of the section and weight (number of storeys of the building).

Important! The foundation for the chimney is built independently, it should not have connections with the base of the building.

Formwork is installed along the contour marked on the ground, after which reinforcement is made - a mesh of variable profile reinforcement with a diameter of 10-12 mm is laid, connected with a knitting wire with a cell of 10x10 or 12x12 cm.

The foundation is poured with concrete grade not lower than M-200. A week after laying, it will gain 70% strength, and you can start laying the chimney by waterproofing the area under it (roofing material, bitulin).

Block assembly

The laying of ceramic elements is carried out in accordance with the design of the mounting joints; a heat-resistant compound is applied to the joints of the elements before installation, which not only firmly fixes the joint after curing, but also seals it. It is convenient to lay the composition with a mounting syringe, in the absence of a trowel. The excess of the mixture that has come out after installation is immediately rubbed with a piece of foam rubber flush with the joint - there should be no drips or bulges.

Important! It is forbidden to “revive” the prepared, but already hardening composition by adding water and mixing - a significant part of the strength of such glue will be lost.

The laying of the supporting frame is carried out depending on the design of concrete or brick blocks, which are made both solid with a mounting hole in the section, and detachable, laid around the pipe.

In the lower tier, the first module should be located with a device for collecting and draining condensate. To do this, in a concrete or brick block, a grinder makes a slot to bring the outlet pipe out. A mortar is applied to the base, the mounting area of the product is wetted, and the block is placed in place, after which a ceramic module with a branch pipe is also installed on the cement mortar.

The verticality of the mounted sections is controlled by the building level. When laying the walls, it is also necessary to provide for the location of the inspection hatches and the connection of the gas boiler outlet pipe in order to mount these elements in the sections corresponding in height with the desired orientation.

Thermal insulation is laid around the pipe by inserting it from above into a block installed on the mortar with preliminary adjustment of dimensions.

Important! Horizontal joints of ceramic modules and hollow concrete blocks of the supporting frame, when passing through the floor slab, should not be located in its plane - a solid element must pass through the slab, equipped along the perimeter of contact with it with a heat-resistant elastic sealant, neutralizing possible deformations.

To enhance the strength of the outer supporting frame, the blocks are provided with through holes - reinforcing channels, which must be combined during the production of masonry. Before the mortar hardens, pieces of steel reinforcement of a variable profile are inserted into these holes in such a way that the joints of the rods are in the middle of the block, and not on the seam. The diameter of the reinforcement is selected so that after the installation of the rod there is space in the reinforcing channel for filling it with a liquid cement mortar. The reinforcement is straightened and cut into pieces, allowing 2-3 blocks to be fastened together.

The external seams between the blocks or bricks of the supporting frame are also carefully rubbed, and the excess mortar is removed before curing, so that subsequently there is no need to knock on the channel to remove them.

The cross section of a ceramic chimney for gas boilers with a closed combustion chamber is somewhat different - in the blocks of the supporting frame there is a separate channel for air to enter the burners, which, like the reinforcement holes, must be carefully aligned during installation, but the technology of laying structures is identical to that described above.

The top of the pipe must be equipped with a protective cap, which prevents moisture and foreign objects from entering the chimney. The aerodynamics of the gas outlet depends on the shape of the head, so it is better to install the product industrial production rather than experimenting with homemade crowns.

Finishing the outer surface of the chimney in the premises is carried out depending on the interior of the housing, the most practical cladding ceramic tiles with appropriate temperature specifications.

Advantages of a ceramic chimney:

- inner surface ceramic pipes are covered with a layer of heat-resistant glaze, which, unlike brick, does not contribute to soot settling - one of the conditions for good traction;

- the glaze is waterproof, which eliminates the absorption of condensate by the pipe and the destruction of the walls when it freezes - the condensing compounds flow down into a special sump, which ensures the strength of the chimney body;

- low intensity of soot layering - soot practically does not settle on a smooth surface, and most of it flies into the atmosphere along with smoke;

- ease of maintenance - soot is removed much more easily from smooth glazed walls than from brick ones;

- fire safety - even if there is a certain amount of soot in the pipe, it will ignite without consequences, since ceramics are heat-resistant and have low thermal conductivity;

- resistance to chemicals - ceramics do not interact with acids formed during the condensation of moisture and gas combustion products on the pipe walls;

- durability;

- ease of processing - ceramic elements of the chimney do not require special tools.

Disadvantages of ceramic channels:

- significant weight of the structure;

- the need to build a foundation;

- high price;

- the need for precision fitting skills.

Ceramic chimney in steel casing

This design is a more advanced version of the previous device manufactured in Germany. The inner part is made of ceramics, and the outer shell is made of steel elements 60-100 cm long, assembled into a single structure using special crimp-type fasteners. Installation is simple and can be located anywhere, including installation inside the wall - for this, rectangular systems are produced.

With many advantages of a ceramic chimney in a steel shell, this material has a significant drawback - a high price, which hinders the growth of its popularity in everyday use.

Steel chimneys

For the manufacture of such channels, ordinary or stainless steel with a thickness of 0.5-0.8 mm is used. The advantages of stainless steel in this case are obvious - durability, due to resistance to acids formed when nitrogen and sulfur components of smoke come into contact with condensate.

The degree of aesthetic performance depends on the status of the building - cottages are equipped with channels made of stainless steel or with a colored enameled surface, fixed to the walls using decorative designs, country houses can be equipped with ordinary steel pipes painted with aluminum powder.

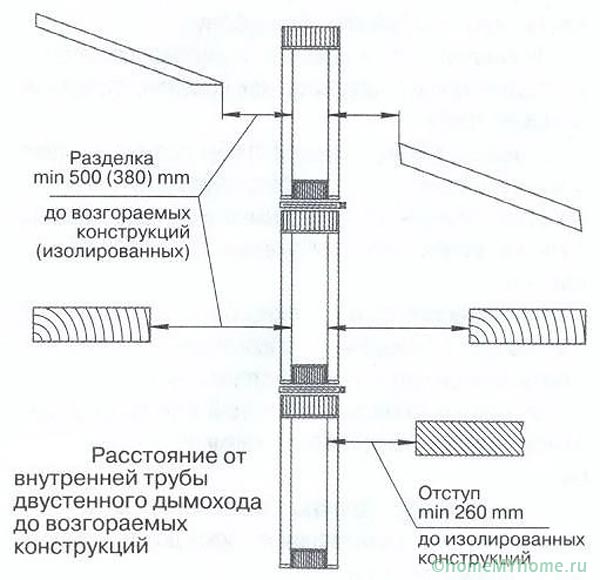

Pipe chimney systems are mainly located outside the housing, fastening to the walls using brackets. various designs, but an internal arrangement is also possible under the following conditions:

- pipe material - stainless steel;

- device for protective thermal insulation of the internal sections of the chimney to prevent burns from direct contact;

- construction of fire-prevention cutting around pipes in places of contact with walls and floor slabs;

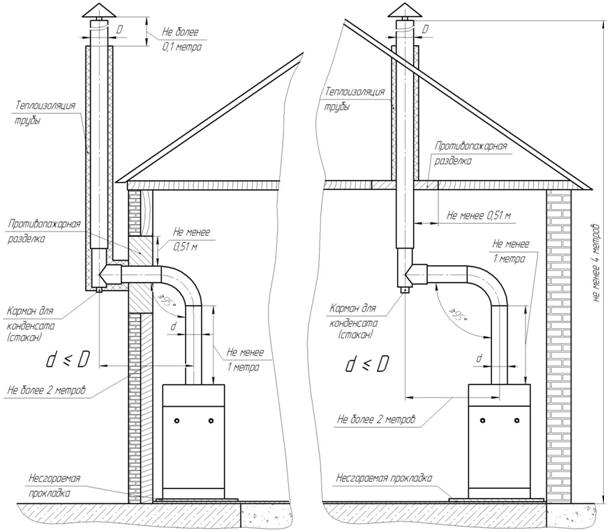

- fulfillment of the requirements for the structural arrangement of the chimney elements:

Mounting

The foundation for steel chimneys is not required, and they can be installed independently.

Assembly is done from the bottom up. The design should include a condensate sump with a pipe for draining it.

Prefabricated elements are interconnected by shaped joints, the contact surfaces of which are covered with heat-resistant silicone sealant before assembly, which allows dismantling the desired fragment during spot repairs. Crimp clamps are additionally applied over the joints.

The depth of the pipe fitting on top of each other is determined by fire regulations - not less than the radius of the mounted element.

It is allowed to have one horizontal pipe section in the contour, but with a length of not more than 1.0 m.

The step of the chimney mounting brackets on the wall is 1.5-2.0 m, each turning point (elbow) needs to be individually fixed to the base.

If the roof of the house is made of combustible materials, then a spark deflector is installed at the end of the pipe.

To reduce the formation of condensate and increase draft, the outer sections of the chimney are insulated with stone wool - a method that prevents it from getting wet. In the upper part of the pipe, where the insulation layer ends, a collar is installed on the channel with a downward slope along the perimeter to prevent moisture from entering the insulation from the end.

The part of the pipe facing the roof is attached to the base with three stretch marks, evenly distributed along the circumference at 120 degree intervals.

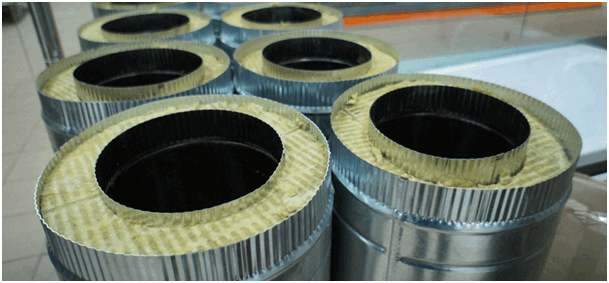

Sandwich chimneys

Sandwich pipes are two steel shells of different diameters, between which a heat-resistant insulation of a certain thickness is placed. This design allows you to mount the chimney pipe for the boiler from elements that are already equipped with thermal insulation on the outside, so sandwich chimneys are equally suitable for both outdoor and indoor installation.

According to the material of execution of sandwich pipes, the following types are produced:

- both shells are made of stainless steel;

- inner tube made of stainless steel, outer tube made of galvanized steel.

However, the resistance of steel to oxidation does not yet determine the degree of its suitability for use in smoke ducts.

In the production of sandwich pipes, the following types of stainless steel are used:

- AISI 430;

- AISI 439;

- AISI 316;

- AISI 316i;

- AISI 304;

- AISI 321;

- AISI 310S.

The most inexpensive materials are steel grades AISI 430 and AISI 304, but their use is appropriate - only for outer shells. The highest quality are AISI 316i, AISI 321, AISI 310S, used for both external and internal pipes, and this must be taken into account when choosing a material.

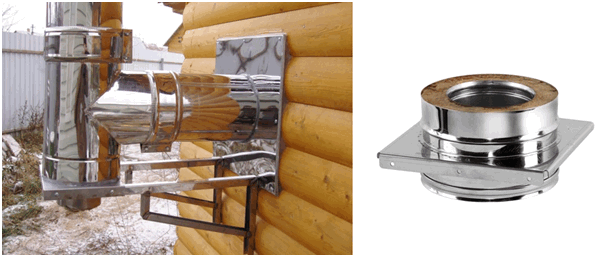

Mounting

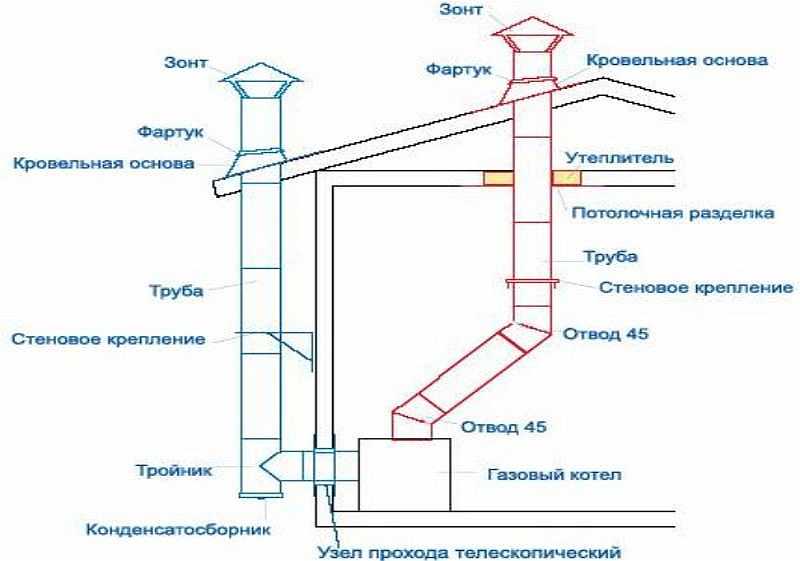

The construction of an external sandwich chimney begins with the installation of the starting node on the outer wall of the building. At the starting node, the first element of the sandwich chimney is installed - the base plate.

A tee is installed on the base plate, from which the vertical part of the chimney is mounted, and an inlet hole is made in the wall according to the marking in order to equip the entrance with a fireproof passage and thermal insulation.

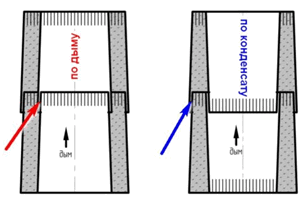

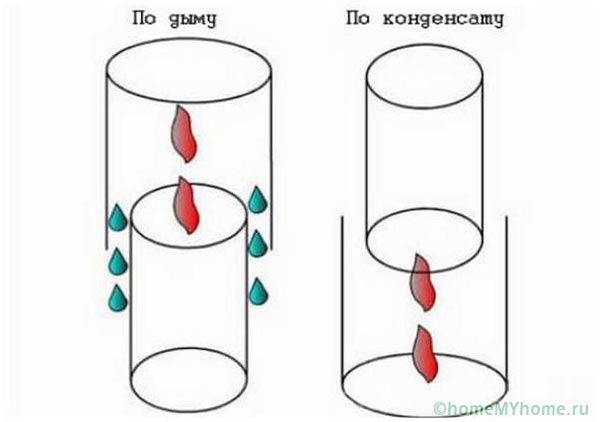

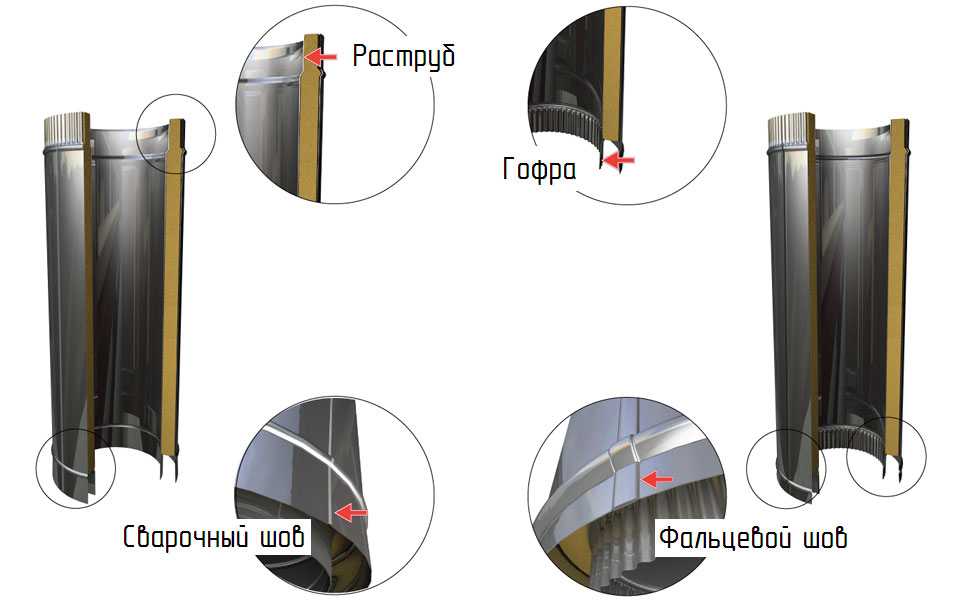

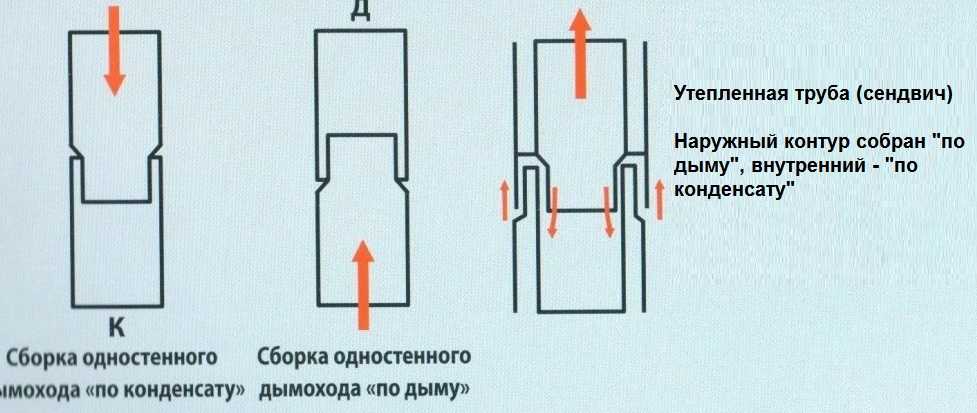

Between themselves, the fragments are fastened by inserting the ends into each other, made in compliance with the required fitting dimensions of the diameters. Crimp clamps are installed over the landing joints. But when installing nozzles, two methods of their orientation are used - “by smoke” and “by condensate”.

When installing sandwich pipes, the following rule must be observed:

- the assembly of the horizontal section to the tee is carried out “by smoke” - the next fragment is put on the previous one;

- the vertical section of the chimney is assembled “by condensate” - the next fragment is inserted into the previous one.

Both methods of pairing are necessarily performed using a sealant.

Upon completion of installation, the upper part of the chimney is attached to the base with braces using a special clamp and eyelets.

Self-installation of a sandwich chimney is simple only at first glance. In practice, this operation requires professional skills to perform many types of work, including at height. In addition, not only the efficiency of the gas boiler, but also the safety of people living in the house depends on the quality of workmanship and compliance with technical standards. Therefore, it is recommended to take on the independent installation of a sandwich chimney, which includes many small but important nuances, only with the participation of a professional mentor.

Conclusion

The installation of a chimney for a gas boiler is a very responsible procedure, and taking into account the cost of materials for the execution of modern structures, it is quite expensive to undertake it without knowledge of the technology and skills in performing roofing, construction, installation and finishing works. However, knowledge of the operation algorithm and the basic requirements for chimneys will facilitate the current control over the performance of work by a professional contractor.

A properly arranged chimney is the most important part heating system. That is why gas workers have reasonable requirements for this device. A well-arranged system allows not only the gas boiler to work efficiently, but also ensures the safety of the residents of a private house. The operation of such gas appliances occurs without visible smoke, but this is not at all a guarantee that carbon monoxide will not accumulate. It is very dangerous because it negatively affects the human body.

Residents of private houses need to understand the chimney for a gas boiler in order to properly operate it. And those who are just going to install a gas heater should be aware of what types of chimneys exist and what requirements they have.

Types of chimneys for a gas boiler

brick construction

Brick pipes for gas boilers began to be installed at a time when there were no other materials. Currently, some homeowners are building them, although such a pipe by its design is complex and time-consuming to install. In addition, it takes a long time to build such a brick system and it is not cheap.

Brick pipes for gas boilers began to be installed at a time when there were no other materials. Currently, some homeowners are building them, although such a pipe by its design is complex and time-consuming to install. In addition, it takes a long time to build such a brick system and it is not cheap.

Such a brick chimney in its own way technical specifications significantly inferior to more modern systems, because its inner surface is very often overgrown with soot, as a result of which the removal of fuel combustion waste is slowed down.

Ceramic construction

Such a system already has many more positive qualities. They are especially noticeable in cases where the installation is carried out by hand. Ceramic chimney is very reliable and quite simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive aspects, this design is not in great demand.

Such a system already has many more positive qualities. They are especially noticeable in cases where the installation is carried out by hand. Ceramic chimney is very reliable and quite simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive aspects, this design is not in great demand.

Coaxial design

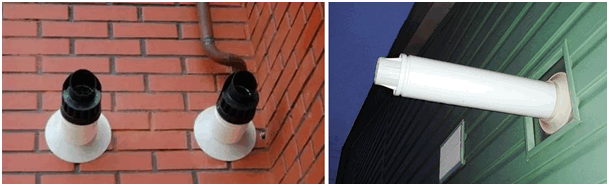

Such a system has significant differences from other designs in all respects. She has a neat appearance, and the shape of the pipe compares favorably with all other pipes and is output through the wall.

Such a system has significant differences from other designs in all respects. She has a neat appearance, and the shape of the pipe compares favorably with all other pipes and is output through the wall.

Although such a chimney is small, it works very efficiently due to its structure and special coating on the inner walls. Condensation never forms inside it, and this is very important for heating systems that run on gas fuel.

Stainless steel sandwich construction

Such a system is considered the most popular, because it has a number of significant advantages over other designs. Such chimneys come in various modifications., and this is important. They have a large number of tees, various transitions and other parts that are performed at different angles. Thanks to this, you can assemble a structure of any complexity.

Such a system is considered the most popular, because it has a number of significant advantages over other designs. Such chimneys come in various modifications., and this is important. They have a large number of tees, various transitions and other parts that are performed at different angles. Thanks to this, you can assemble a structure of any complexity.

The stainless steel sandwich chimney consists of three layers. middle layer- heat-insulating, made of mineral wool. The thickness of the insulation layer is 5-10 cm and it depends on the place where the chimney will pass, and average temperature in winter. A correctly selected pipe will not contain condensate, on which the correct operation of the entire system depends.

The stainless steel construction has a perfectly flat inner surface, which makes it easy to remove combustion products. And thanks to the mirrored outer surface, the system looks very presentable.

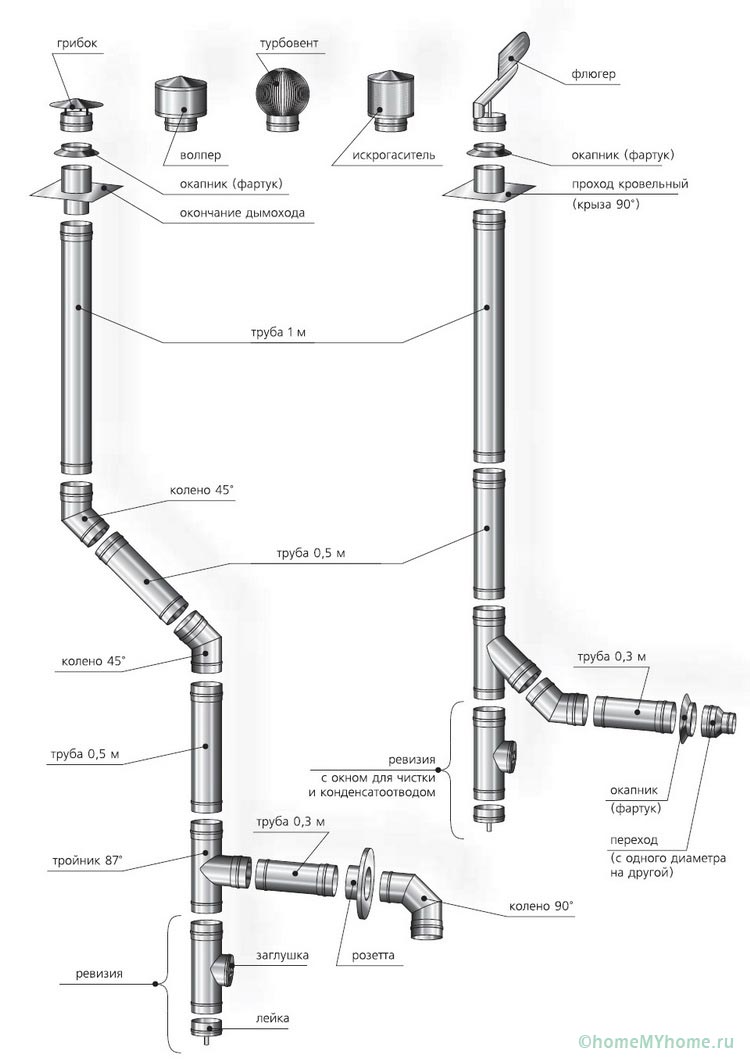

Elements of a gas chimney

Regardless of which chimney is installed (except for brick), it will definitely need additional elements. These include:

- an adapter that connects the pipe of the heating boiler and the chimney;

- telescopic pipes;

- revision tee, which has a special fitting in the lower part, used to remove condensate;

- bends;

- passage pipe;

- main wall mounts - clamp and bracket;

- tip having a conical shape.

Chimney pipes for gas boilers, the photos of which you see below, consist of the listed elements without fail.

Chimney for a gas boiler, photo

Requirements for a chimney for a gas boiler

The device of any chimney must comply with the requirements SNiP 2.04.05-91 and DBN V.2.5 - 20-2001. Otherwise, it will be performed incorrectly, and not only effective work gas boiler, but also the health and life of the residents of the house.

The device of any chimney must comply with the requirements SNiP 2.04.05-91 and DBN V.2.5 - 20-2001. Otherwise, it will be performed incorrectly, and not only effective work gas boiler, but also the health and life of the residents of the house.

Such rules must be approached with all responsibility, since ignoring them entails trouble with the gas service, and even a fine. Any violation will still need to be redone in accordance with established standards.

For normal operation chimney for a gas boiler, the requirements are as follows:

- Condensate must be removed using a special moisture collector installed at the bottom of the pipe.

- Chimneys for a gas boiler must have good draft, this allows the system to work more efficiently.

- In order to have good traction, in the process of assembling the structure it is very it is important to achieve the maximum tightness of the connection of parts.

- The chimney must be vertical without any concessions. In accordance with the rules, a slope of 30 degrees is allowed.

- A piece of pipe with which the gas boiler is connected to the chimney system, must always have a vertical section.

- With a room height of three meters the total length of the horizontal connecting sections must not exceed this height.

- Particular attention is paid to the tightness of the fit of structural parts at the joints, for maximum tightness. This is necessary so that hot gases do not penetrate the chimney.

- The tip of the chimney that goes through the roof, should be no less than half a meter above it. If the roof is flat, then the head should be one meter higher.

The size of the chimney for a gas boiler must comply with the following formula: P * L > S, where P is the perimeter of the pipe section, L is the length of the chimney, S is the internal surface area of the boiler.

Do I need to make a chimney when installing a gas boiler? Of course, because a gas boiler cannot burn without an exhaust hood. The main functions of this design are the removal of combustion products (smoke and carbon monoxide) from the room, as well as providing thrust, due to which the gas burns evenly.

Is it possible to install a chimney on the boiler with your own hands? Of course. You just need to carefully study the rules for installing the hood and the features of its operation.

Article content

Chimney device

There are many methods and materials for arranging a chimney. But, no matter what material you choose, the basic principle and procedure for installing the hood will not change from this.

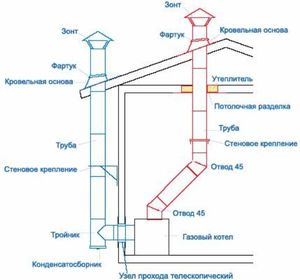

Any chimney for a gas boiler includes the following components:

- boiler pipe;

- a pipe with a damper that allows you to adjust the level of thrust;

- flue pipe;

- tee for connecting the boiler pipe with a chimney;

- a glass with an inspection window in which condensate accumulates;

- mounting brackets in the form of single and bandages;

- tip in the form of a cone;

- insulation.

All these components are necessary to ensure the correct operation of the chimney. If, for example, a sump is not made, condensate will collect in the pipe, moisten the soot and worsen traction.

Insulation is necessary for thorough insulation all points of contact hoods with building elements to avoid fire, say, wooden beams. In addition, the thermal insulation of the entire chimney significantly improves traction.

Basic requirements for the arrangement of the chimney

Installing gas boilers is the most common option for space heating. However, do not forget about its chemical activity and explosiveness.

To prevent an attempt to warm up from turning into a disaster, the following points should be considered when installing a chimney:

- The narrowing of the chimney channels and the presence of ledges in them is unacceptable.

- Any deformation of pipes is strictly prohibited - compression, perforation, deflections.

- If you are using a rectangular pipe, its aspect ratio should be no more than 1:2. It is better if it is a square section.

- In the lower part of the chimney, a dripper is required, in which condensate will collect, and an inspection hatch. This "appendicitis" should be below the level of the chimney outlet from the gas boiler.

- The entire chimney structure must be 100% tight. Joints and bends of the chimney pipe at the level of ceilings are not allowed.

- The chimney must have a perfectly smooth inner surface.

- At the junction of the chimney, its elements must enter each other to a depth corresponding to their radius.

- All parts of the pipe that pass through the street or unheated rooms must be.

- For boilers that do not have a draft stabilizer, it is necessary to install a damper in the hood in an easily accessible place. As a rule, it is placed on the section of the pipe connecting the boiler to the exhaust pipe.

If it is necessary to bend the flue pipe, the following parameters must be taken into account:

- the radius of curvature of the pipe cannot be less than its diameter;

- the number of bending knees cannot be more than three;

- the slope of the chimney section should not exceed 30 degrees;

- on bends, it is desirable to provide inspection hatches that allow collecting condensate.

Remember, non-compliance with the requirements and rules for arranging a chimney for a gas boiler, neglecting such seemingly trifles as condensate, soot, the level of pipe bending, can cost you and your family life or health.

Chimney pipe options

There are two options for the location of the chimney:

- internal, when the pipe passes through the house and goes directly to the roof;

- external, when the pipe is brought out into the street through the wall at the level of the boiler and rises along the wall.

External location

The external location of the chimney is considered safer, as it eliminates the leakage of carbon monoxide into the room.

However, this option for installing a chimney requires insulation of the pipe along its entire route, as well as decorative work to mask it, if required by the exterior of the house.

If you still decide to install an external chimney, remember that the pipe must be led out of the wall as far as possible from the location of the windows and rise to a level of at least 2 meters above the ground.

Internal arrangement

With the internal version of the location of the chimney pipe, the height of its rise above the roof of the house depends on the distance between the pipe and the ridge of the house.

- if the horizontal distance from the chimney to the ridge does not exceed 1.5 meters, the lifting height should be 0.5 meters;

- if the same distance is from one and a half to three meters - the upper level of the chimney can correspond to the level of the ridge of the building;

- if the distance from the ridge to the chimney exceeds 3 meters, some calculations will already be required here. We draw a horizontal line from the ridge to the exit point of the chimney pipe. We draw the second line at an angle of 10 degrees, in relation to the first. It is this line that will show us the level of the rise of the chimney.

Types of chimneys and features of their installation

Modern gas boilers have two main features that significantly affect the choice of material for chimney construction:

- Low temperature of ejected combustion products. This option allows you to use almost any .

- Together with carbon monoxide, a modern boiler emits condensate into a fairly in large numbers. This problem requires a more responsible approach to the choice of material, since many materials are susceptible to corrosion. Condensate thrown into the chimney can lead to the destruction of the chimney, the appearance of corrosive pores that will interfere with draft, etc.

Arranging a chimney pipe for gas boilers with the help of one of the most popular and oldest ways.

This is due, first of all, to the cheapness and availability of the material. In addition, asbestos-cement pipes are quite light and easy to install.

However, this material has a number of disadvantages:

- the structure can only be installed vertically. On it is impossible to make bends;

- asbestos-cement pipe absorbs condensate, which can lead to destruction and accumulation of soot;

- in the event of a soot fire inside the structure, the chimney may be destroyed, since asbestos cement does not withstand temperatures above 300 degrees;

- this material complicates the arrangement of cleaning hatches and condensate sedimentation tanks.

- Due to the low heat capacity, the asbestos-cement chimney requires mandatory insulation.

Another fairly well-known material for is galvanized steel. This material is easy to install, allows you to make bends, cut hatches or equip gas condensate sedimentation tanks. His problem is that although galvanizing protects steel from corrosion, but not for long. The service life of such a chimney, as a rule, does not exceed 5-6 years.

The brick channel is the oldest and most famous way of arranging chimneys.

In the case of wood-burning stoves, it worked flawlessly, however, when burning wood, condensate is released in a much smaller amount than when burning gas. Due to the increased release of condensate, the brick begins to strongly attract soot and absorb moisture, as a result of which the chimney begins to collapse.

In addition, the installation of such a chimney is quite complicated, and also requires certain skills. Make aesthetic brickwork standing on the roof, much more difficult than just installing the product.

Choice and installation of a chimney (video)

Modern popular developments for arranging a chimney

Together with new boilers, new materials for chimneys are also entering the construction market. The most suitable materials for this purpose are:

- furanflex - reinforced plastic with high-strength fibers;

- stainless steel.

Both of these materials are lightweight, easy to install, allow you to easily make cleaning hatches with sedimentation tanks, and also do not absorb condensate or soot.

From these materials, you can make a coaxial chimney. This development is considered the most high-tech and popular among specialists.

The principle of the device of such a chimney is the placement of one pipe into another without contact with each other. The elements are connected only by jumpers. This way of arranging the chimney not only perfectly removes carbon monoxide, but also provides oxygen to improve the combustion process.

D To remove combustion products inside the furnaces of heating appliances, chimneys for a gas boiler in a private house of different designs from different materials are used. The standards SP 7.13130 specify the requirements for cross-sections, height, location of chimneys, safe schemes for passing through structures made of combustible materials.

Chimney from a gas boiler on the facade of the house

Chimney requirements and installation rules

The products of combustion are high temperatures, therefore, chimneys for must fully comply with the standards of SP 7.13130. It is not allowed to use factory products that have not passed the certification of the Russian Federation.

The main provisions of the code of fire safety rules are:

- internal chimney cross section - 14 x 14 cm - 14 x 27 cm, depending on the thermal power of the boiler (3.5 - 7 kW, respectively) for concrete, brick, ceramic structures, the area of \u200b\u200bround or asbestos-cement pipes must correspond to these dimensions;

- height - 5 m minimum from the firebox to the deflector;

- chimney thickness - 6 cm for heat-resistant concrete, 12 cm for ceramic bricks, not standardized for asbestos cement, sandwich.

The height of the deflector (an umbrella structure that protects the pipe from rain, wind) relative to the ridge depends on the degree of remoteness of the chimney from it:

- 0.5 m higher within 1.5 m;

- flush with the ridge at a distance of 1.5 - 3 m;

- at the level of an imaginary line at an angle of 10 degrees relative to the horizontal drawn from the ridge to the pipe, at a distance of more than 3 m from it.

When the chimney is moved outside, bends are allowed within 1 m from the axis of the root pipe to the side at an angle of less than 30 degrees relative to the vertical. The cuttings should exceed the thickness of the ceilings with decorative ceiling linings by 7 cm with a uniform distribution of this size from the bottom / top.

The distances from the outer surfaces of the structures to the wooden elements of the load-bearing structures (battens, rafters, beams, crossbars) must be greater than the indicated dimensions, depending on the material of the chimney:

Attention! It is forbidden to combine chimneys with ventilation ducts without a special project. On the other hand, combustion products from two boilers can be launched into one pipe if necessary.

Chimney structures

When choosing a chimney or channel, you should focus on the best combination of construction budget, resource, maintainability. Depending on the materials used, chimneys for a gas boiler in a private house are fastened with clamps to the building envelope or rest on separate foundations.

In all vertical structures, a serious problem is the formation of condensate, which is released when hot gases come into contact with cold pipe walls. In coaxial modifications, which are more often located horizontally, this minus is absent. In addition, it is enough to give a slight inclination of the pipe to the ground, so that any condensate flows out of it without additional costs on its own.

Related article:

A special publication of our online magazine provides recommendations for choosing weathervanes for different types chimneys and some installation nuances.

The installation of a chimney for a gas boiler in a private house is carried out according to the general scheme for asbestos-cement, sandwich, ceramic pipes. For coaxial aluminum, plastic pipes the schematic is not needed. In the manufacture of masonry from blocks, modules, bricks, standard stonework techniques are used.

Sandwich installation

Chimneys from two pipes of different diameters, inserted one into the other, with a heat insulator between them, are called sandwiches. The design reduces outdoor temperature walls (increased fire safety), eliminate the formation of condensate (useful for increasing the resource).

A sandwich chimney of a wall-mounted gas boiler is mounted in a private house using two technologies:

- for condensate- the upper elbow is inserted into the socket of the lower one, when condensate drains in the annular space, its penetration into the channel, ignition is excluded;

- by smoke- the upper pipe is put on the lower one, preventing the penetration of combustion products into the room.

Attention! Gas boilers have gases with low temperatures at the exit from the combustion chamber. Therefore, the technology "by condensate" is used.

The chimney assembly technology looks like:

- installation of a gate valve on the outlet pipe of the boiler to adjust the cross section of the chimney channel;

- installation of pipes to overlap "by condensate";

- production of cutting from a steel box attached to the ceiling from below;

- passage of the chimney cutting, building up to the roof;

- fastening to the crate of the roof - a plate with a conical branch pipe located at the right angle to it, depending on the slope of the slopes;

- fixing the sandwich pipe of the chimney to the roof with a comfrey (conical collar of a complex profile), which decorates and seals the joint.

After that, it remains to install one of the elements on the mouth of the pipe:

- volper - a deflector for increasing traction with a flat cover;

- weather vane - deflector to improve traction of the original design;

- fungus - a cone nozzle to protect against precipitation.

These elements are made of stainless steel, fully consistent with the style of sandwich chimneys.

Stone and brickwork

Chimneys for a private house can be built into brickwork (only in a carrier inner wall) or created from blocks. Domestic manufacturers produce several types of chimney modules:

- concrete - used only together with ceramic pipes passing inside them, the outer surface is square, the inner is round;

- ceramics - pressed out in special forms, then fired in furnaces, have the design of an inner tube, an outer square thin-walled box, connected by stiffeners.

The Ukrainian company Schiedel produces chimney blocks from pumice of volcanic origin. The modules are called Isokern and are a budget option for individual developers. The material is much lighter than concrete, ceramics, the only drawback is the rough inner surface, the lack of Russian certificates. Regional fire safety services accept structures made of this material in 50% of cases.

Brick chimneys are built into the walls at the stage of erection of enclosing structures. For laying blocks, it is necessary to concrete a separate foundation. On the other hand, pipes can be placed in any convenient place, there are no problems with passage nodes, truss systems, overlays.

Asbestos cement pipe

In aggressive advertising of sandwich chimney manufacturers, the main disadvantage of asbestos is the lack of environmental safety. In fact, only safe raw materials and technologies are used in domestic production. According to the reviews of masters who install all types of modern chimneys, an asbestos-cement pipe has the following advantages:

- is self-supporting - no need to attach to the walls;

- does not condense moisture - there are no leaks inside the combustion chamber;

- resistant to combustion products - the resource is higher than that of concrete, brick;

- cheaper than ceramics - the cost is much lower.

Installation of an asbestos-cement pipe is extremely simple:

- the first pipe is installed on the foundation, fastened with racks or a frame;

- the chimney is increased to the desired height, the pipes are connected by couplings;

- the top is covered with a deflector, a hatch is made below for installing a cleaning door.

The tie-in from the boiler is carried out with a steel elbow, which can be replaced if necessary.

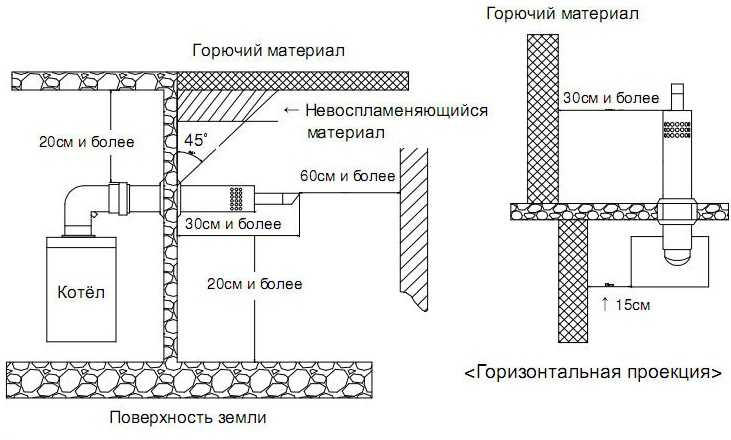

Installation of a coaxial structure

Unlike other chimney modifications, a coaxial pipe can only be used for closed combustion chambers. (supercharging) is a mandatory operating condition of the system. The design of a coaxial chimney is similar to a sandwich, however, instead of a heater, there are jumpers between pipes of different diameters. The inner pipe is used to remove combustion products, the outdoor air necessary for burning natural gas is sucked into the annulus.

Unlike conventional chimneys, the pipe does not have to be pulled vertically through all floors. Instead, a 90-degree bend is put on the outlet pipe, the coaxial chimney is attached to it horizontally, goes out through the nearest wall, observing the fire safety distances:

- the maximum length of the horizontal part is 3 m;

- at least 0.2 m to the ceiling, floor, ground;

- more than 30 cm from the chimney axis to the wall surface;

- at least 60 cm from the mouth of the pipe to the opposite wall.

The coaxial structure can be brought vertically above the roof, horizontally through the wall, or connected to a smoke channel built into the brickwork of the wall.

When installing gas boilers, it is necessary to strictly observe the norms. Also, strictly according to the standards, it is necessary to mount a chimney for a gas boiler. Though the temperature flue gases low and has no color, it will cause no less harm, but more - because leaks are poorly defined. Therefore, you must immediately do everything diligently, paying special attention to the tightness of the joints.

Requirements for chimneys for gas boilers

All requirements for smoke channels are prescribed in regulatory documents - SNiP 2.04.05-91 and DBN V.2.5-20-2001. Their implementation is mandatory. To summarize, everything can be reduced to several points:

These are the basic requirements. It is imperative to fulfill them. They provide the required degree of security. After all, the fact that the exhaust of a gas boiler has no color does not mean that it is harmless. Therefore, all aspects of security must be given maximum attention.

Boiler designs and chimney construction methods

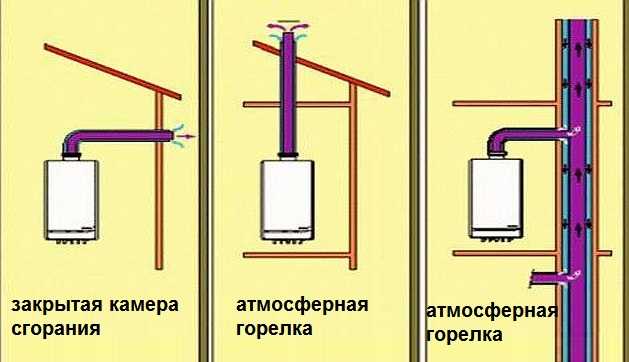

There are two types of burners for gas boilers:

It is clear that the choice of the type of chimney primarily depends on the type of combustion chamber. In one case, it should be a coaxial pipe, in the other, a regular one. But besides this, there are many more nuances in terms of design.

What material

A chimney for a gas boiler in a private house can be made from different materials. The main requirement is resistance to chemically aggressive substances, inability to pass gases. Traditionally, several materials are used. Let's talk about the advantages and disadvantages, the features of the assembly of each of them in more detail.

brick chimney

Today it is no longer the most popular type of chimney. It turns out to be heavy, at high altitude it requires a foundation. In addition, laying a brick chimney takes a lot of time.

However, this kind chimneys has a number of negative qualities. The first one is in its inner walls are not smooth, which contributes to the accumulation of soot, impairs traction. The second is to brick is hygroscopic. Therefore, the condensate flowing down the walls is absorbed, which contributes to rapid destruction.

To solve these problems, a smooth pipe of suitable diameter is inserted inside the brick chimney. Usually it is a pipe made of stainless steel or asbestos. When building such a combined chimney, attention should be paid to the following things:

- The joints of the liner pipe must be sealed. If these are ordinary or stainless steel sandwich pipes, everything happens as standard - we collect the chimney through condensate. If the liner is made of asbestos-cement pipes, you will have to take care of the tightness of the joints. And to cover the joint with cement is not an option. Such a connection is in no way airtight - condensate will be absorbed. You will have to come up with airtight clamps, use hydrophobic (water-repellent) compounds. Moreover, they must also be chemically resistant. As an option, lubrication of the joints with heat-resistant sealants with an operating temperature of about 200 ° C can be considered.

- In order for condensate to form as little as possible, it is better to insulate pipes (even inside a brick casing). To do this, it is desirable to use a heater that is not afraid of getting wet.

- At the bottom, a condensate collector must be attached to the liner pipe. Access to it should be free.

If you make a chimney for a gas boiler according to these rules, then even with abundant condensate release, it will be easy to deal with it.

Stainless steel - single wall pipes and sandwich

Modern gas boilers are designed so that the temperature of the flue gases at the outlet is not very high. This is why condensation always forms. With good traction, most of it flies into the pipe, with good insulation, the rest evaporates. So it turns out that liquid is not always present in the condensate collector. But the condensate itself is formed during the operation of the gas boiler all the time. Sometimes more, sometimes less. In this regard, the requirements for stainless steel for the chimney are high: it must withstand prolonged contact with caustic substances. These requirements are met mainly by food grade stainless steel. Yes, it costs a lot, but only it will serve for years.

Now about how to make a chimney for a gas boiler from a single-wall pipe or from sandwich pipes. In order for condensation to form in minimal quantities, it is desirable that the chimney does not cool down. That is, it must be insulated. And although the sandwich chimney has a gasket made of insulation, with an external gasket (on the street) it is also better to insulate it - it will last longer, traction will be better. But in this embodiment, less insulation is required - one layer, while an ordinary pipe may have to be wrapped in two or even three layers. So the cost of arranging a chimney from a single-wall stainless pipe and sandwiches will be comparable. Just in the first case, you will have to use a larger amount of insulation, in the second, less.

If we talk about reliability, then sandwich chimneys are more reliable, if only because they consist of two layers of metal. By the way, if you insulate the chimney, the outer pipes can be made of galvanized steel - they do not come into contact with condensate, the temperatures are low, and the appearance is unimportant, since everything will be wrapped with insulation.

Ceramic chimneys

Ceramic chimneys are good for everyone: they are durable, reliable, well tolerate contact with aggressive substances. But they have two significant drawbacks. First, they are expensive. The second one is heavy, so when installing a high chimney, they require a foundation. And this is an additional cost to the already considerable amount. But the life of such a chimney is calculated in decades.

Asbestos-cement pipes

Once it was the most popular type of material in the construction of chimneys for a gas boiler in a private house. The material, of course, is porous, has rough walls, and its cross section is not ideal (not round, but rather oval). But this is probably the cheapest option.

When using asbestos-cement pipes for the chimney of a gas boiler, it is necessary:

- Make it as straight as possible, trying to make the joints even.

- Sealing joints. As already mentioned, just covering it with cement is not an option. A sealed connection is required. Several solutions to the problem are the use of hydrophobic additives in the mortar, coating the dried cement mortar with sealant, and the use of airtight clamps.

- To reduce the amount of condensate, make the pipe high and insulate well.

In general, nothing new, all the same rules as for the materials described above, but the hassle with joints is added. So as a result, the price of a chimney made of asbestos pipes is almost the same as that of stainless steel.

For boilers with an open combustion chamber

For gas boilers with an atmospheric burner, a smoke channel is required that provides good traction - the removal of combustion products occurs due to the movement of air through the pipe. Therefore, it is made as straight as possible, preferably with smooth walls. There are two versions:

Which option is better? An external chimney is easier to implement - with a conclusion through the wall. It is only important to pass through the wall correctly (observe the fire gap if the walls are combustible). But this option requires good insulation, high-quality fastening to the walls. And even under such conditions, there is usually a lot of condensate. Therefore, the installation of a tee and a condensate collector at the outlet is mandatory.

In the case of the exit of the chimney through the roof, there are at least two difficult moments - the passage through the floor of the first floor and through the roof. In these places, special passage nodes are installed. They provide an adequate degree of fire safety.

Features of the assembly of metal pipes

If they use sandwich pipes or single-walled metal pipes, then the external chimney for a gas boiler is assembled “by condensate”. That is, inserting the top tube inside the bottom one. This is possible due to the presence of a corrugated edge on one side.

When assembling the chimney inside the building, the structure is assembled “by smoke”. In this case, it is more important that gases do not enter the room. Therefore, the pipes are unfolded so that the upper element is put on the already installed one.

There is a third option - to assemble two circuits in different ways: the outer one for smoke, the inner one for condensate. For such an assembly, it is imperative to use sandwiches, since only they have two circuits. This is the best option, as the protection is complete, but the assembly is difficult.

Chimneys in the mine (box)

So that communications do not spoil the interior, they are often “packed” into a shaft - a specially built box. Inside there are, as a rule, a chimney (or chimneys, if there are several devices), ventilation ducts, there may be water supply, heating, and sewage risers. In any case, it is better to close the chimney pipe with thermal insulation. If the heater can still not be used in a heated room, then in the attic (especially if it is cold), insulation should be mandatory. Use basalt wool with a temperature regime of operation of at least 300 ° C.

Insulation will positively affect the temperature inside the chimneys, which will increase traction and reduce the amount of condensate. But do not forget that we are talking about gas boilers, and they have a low temperature of combustion products.

For closed combustion chambers

A coaxial chimney looks like a pipe in a pipe. The design is delivered ready, assembled quickly and without problems. You only need to know the diameter of the outlet pipe and the parameters - height, length.

The coaxial chimney device is the simplest. The pipe rises above the boiler and turns 90°. From it to the ceiling should be at least 20 cm. Then it is carried out through a hole in the wall, from the outside it should end at least 30 cm from the wall.

Coaxial chimney device for a gas boiler - distances and norms

The height relative to ground level is also normalized - the pipe outlet must be at least 20 cm above the ground, and the distance to the nearest wall - from the end of the pipe to the wall must be at least 60 cm.