Hydraulic press for the garage. Press with electric drive. Do-it-yourself hydraulic press drawing options

Hydraulic press is used to produce high pressure. It is used in many body shops to press various shafts, bearings and gears. Home craftsmen use it to stamp parts made of plastic, rubber or metals. If your workshop does not have it yet, then you can try to make a press with your own hands.

The press has a wide range of applications. Sometimes this is a necessary item in the workshop or in the garage. A small device is often used in car repairs. You can use a press for silent blocks, as well as for pressing out bearings.

Such equipment is used to create briquettes from waste, when gluing two surfaces, as well as for bending metal parts. At the same time, factory devices can be unaffordable for many. If you decide to make such a device with your own hands, then it can be easily adapted to certain tasks.

The principle of hydraulics makes life much easier. Thanks to a simple mechanism, various equipment works effectively.

So, let's take a closer look at why such a device is needed:

- pressing out different bearings, it is used in small auto repair shops;

- bending hardware of various shapes;

- providing pressure to bond the two elements;

- rivet installation.

Try to make a press with your own hands in the garage. Such a device is used for pressing and pressing all kinds of parts. At the same time, the equipment performs a huge range of repairs, maintenance and preventive maintenance.

Let's look at some options:

- even a small car service needs hydraulic press, which you can buy or make on your own. To make such a unit, you need to decide on the installation of a pressure gauge, the mass, dimensions and performance of the piston. Before developing a press, you need to consider car models. A simple design is not suitable for large machines;

- often needed for workshop and home waste paper press. If there is a large accumulation of paper, it must be disposed of. This design has an average power rating and can be powered by the mains. With the help of a small device, you can remove a significant amount of waste paper;

- useful and cardboard press, with which you can press plastic bottles and cans. When installing the device yourself, you need to take into account the parameters of the piston, bed, equipment dimensions and weight. Such a device uses a ready-made or manual hydraulic pump;

- sawdust press used to create briquettes. The resulting briquettes are used for heating private houses. Such a device consists of a table, a power frame, a base and a drive. A jack is often used for a manual mechanism, and an electric motor is suitable for a mechanical structure;

- homemade hay baler is a special box that is installed on a frame structure made of timber. Such frames can be made from a metal profile. The design is made in the form of a box, but without the upper part. You will need some materials to make your own hay press. Dimensional drawings will make the task easier. It is worth using corners, metal slats and processed boards.

To make a hay machine, you need to connect the boards using metal corners. After that, the box is upholstered with slats. This will give strength to the product. Then you need to go to the gate or door, which is fixed on the hinges.

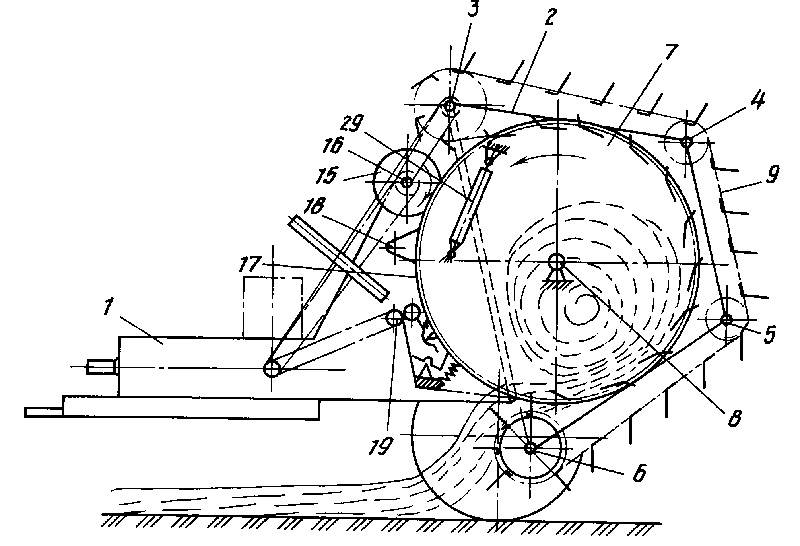

For assembly, you will need an element for attaching to the front, a base for mounting all the nodes, a running part and a transport pick-up. You will also need a special camera with a gearbox and hay. The roll-type pick-up device is used to carry out one cycle of packing and collecting straw or hay.

At the same time, a selection of dried hay is made in the field, as well as pressing the selections. Then rolls are formed from the canvases. Such a process is distinguished by baling without deforming the vegetation. Factory pick-ups have a rather complicated device, which is rarely done at home.

Waste paper units are used in points that are engaged in the acceptance of various secondary raw materials. This unit is different high blood pressure about 15-50 tons, which helps to make small bales. For their loading, you can use any manipulators. Presses for fuel briquettes also have great power.

Such a structure can be made of two types:

- the mechanical version is a simplified design with no big power. In this case, the force can reach one ton;

- more powerful ones include a home-made hydraulic apparatus, the power of which can be up to 4 tons.

Similarly, the production of a press for plastic bottles occurs.

Press design: features of existing devices

To create a significant force on a certain area, a design is used hydraulic press You can buy such a unit in specialized stores. Such a device is an effective and simple device.

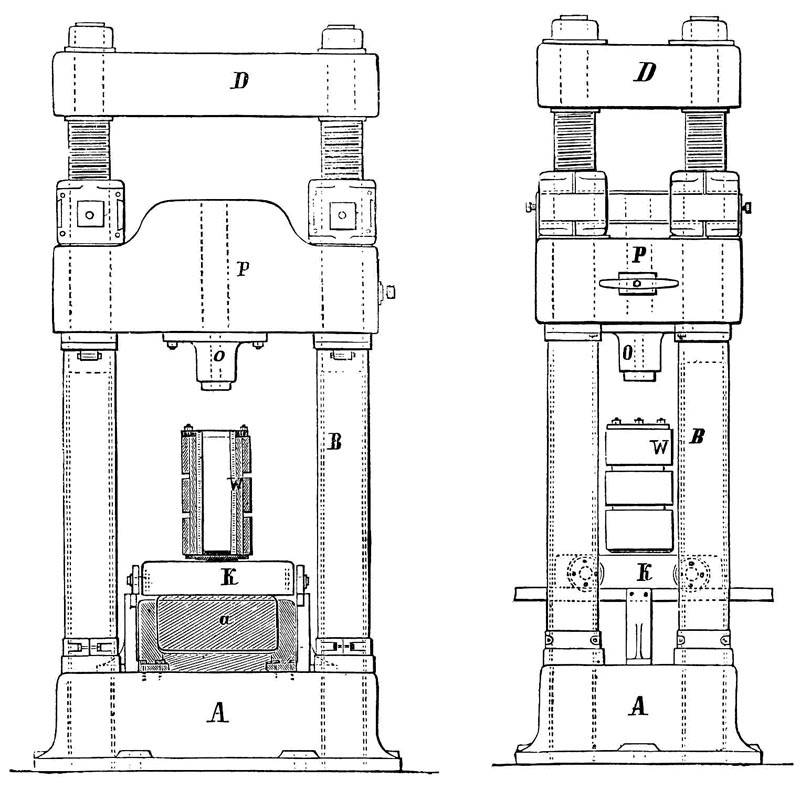

If you decide to make such a design according to the drawings, then you need to figure out what it consists of:

- the bottom or base is necessary for the stability of the structure. It looks like a platform and is made from massive rolled metal. For this, corners made of metal and channel are suitable;

- racks are vertical parts of the structure. The height of the elements is calculated as the sum of the length of its rod, the height of the jack and the thickness of the fixed stop. Racks are made of steel corners welded to the base;

- the fixed stop is fixed in the upper part of the uprights. To make it, the same corner is used as for the racks;

- the jack allows you to develop the necessary effort. This element is attached to the movable stop. It is driven by an electric drive or manual control;

- the movable stop exerts the main pressure on the mechanism. It can be made from corners or strips of steel;

- the return device is used to move the movable stop to its normal position. In this case, springs are used, the degree and length of stretching, which is calculated depending on the parameters of the press.

How to make a simple design can be seen in the video below:

vacuum press

When making a vacuum press with your own hands, it should be borne in mind that the device consists of a thermal module, a table and a vacuum chamber. In this case, the last element often has the shape of a rectangle and is made of a rigid material.

This design has some features:

- the device has only manual control;

- available materials are used for work;

- the speed of work should not be inferior to factory counterparts.

The vacuum design is assembled from the following parts:

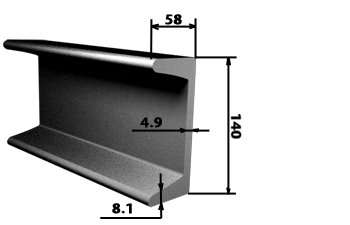

- the bed is made of a rail for a thermal module and a profiled pipe. For work, you will need an electric drill;

- a vacuum table is made from a clamping frame, clamps and a bath;

- a water ring pump is also needed.

By analogy, a thermal vacuum press is also produced.

Press picker

An apparatus such as a baler is installed as a trailer for. It is used in small farm fields and large agricultural areas. After the green mass is cut off by the mower, this device is engaged in its processing. At the same time, rollers are formed from the stems, and after that, using the unit, pressed bales are obtained.

Here are the advantages of using such a unit:

- drying time is reduced, and hay losses are reduced;

- labor costs are reduced several times;

- improves the quality of hay during storage;

- possible self-adjustment hanging device.

The most common option is the roll mechanism. Spring teeth allow you to collect a lot of grass. After that, each portion is rolled into bales. A minitractor with the help of such a press can load up to 20 tons of straw in 20 days. Roll structures have small dimensions.

The roll press type makes briquettes in the shape of a rectangle. The grass in the windrows is picked up by the tines and sent to the pressing chamber. Dimensions can be adjusted by technology. The bales are tightly packed and tied with twine. After that, the block is thrown onto the field.

You can also make a homemade version of the running beam and lumber. In this case, a large box is made of boards and a horizontal method is used to load hay. A rack or screw jack is used as a press. With the help of such a device, you can knit straw bales and press them.

Tabletop mechanical press

The desktop press can work both on automatic, and on manual draft. Such equipment is often made of durable steel.

By means of a manual press are processed:

- polymers and plastics;

- cardboard and foam rubber;

- all kinds of metals;

- rubber and leather.

With the help of a mechanical press, bearings and bushings are pressed out, stamped, as well as die-cutting of small products. Such a unit allows you to save time on the manufacture of parts.

The device of the hydraulic manual device produces force with the help of a hydraulic cylinder rod. This element contains a liquid that is compressed under pressure. The unit is used to compress, deform and connect parts.

The punching option is used for punching holes in sheets different materials. Manual mechanical devices are necessary for crimping tubular sleeves and cables.

vibropress

Vibropress allows you to reduce the time of holding construction works and reduce their cost. The device device assumes the presence of three drives: hydraulic, mechanical and pneumatic. The vibpressing technology is at the heart of the unit operation.

Even if you have instructions and the necessary drawings, creating a vibropress with your own hands may not work. This can happen due to incorrect calculations, inaccurate setup and low productivity.

Press with electric drive

The hydraulic press with electric drive has a simple device. Most often it consists of a thick corner and a channel. All elements are connected with thick bolts.

Particular attention should be paid to the frame, as it will be subjected to significant mechanical stress. In this case, the thickness of the metal must be sufficient.

Such a device is often used in production and industry. The force is generated by the operation of an electric motor. The use of such a mechanism helps to reduce the time of many technological processes.

Garage hydraulic press device: main characteristics

How to make a hydraulic press sometimes you need to know to make such a unit for your garage. At the same time, practical designs can be made from improvised raw materials. The garage unit will require a manual drive, as well as a hydraulic pump. It is necessary to decide on the type of installation: it will be desktop or floor. A drawing with dimensions will also come in handy.

For the production of a hydraulic press, it is important to decide on the model variant. Here they can be:

- complex hydraulic design requires specialized equipment and time to work;

- manual mechanism can be done independently;

- The standard tire changer design is two speed and has a hand pump. The piston is mobile;

- the floor model is equipped with an overload valve and a manual pump drive.

For self-manufacturing, you will need fasteners, a cutting tool and a welding machine. The advantage of the garage assembly will be the ability to control each stage of installation work.

It is important to determine the type of construction. Horizontal devices are used for bending, straightening and cutting individual elements. And vertical equipment is required for pressing out and pressing parts. The hydraulic plant is used for waste disposal. At the same time, waste paper, plastic waste and corrugated cardboard are pressed.

Also, devices can be desktop or floor. In this case, the desktop mechanism can be installed on a workbench. The presses differ in carrying capacity.

Floor structures have a wide range of desktop adjustment. This option can have a load capacity of up to 20 tons. With their help, disassembly and assembly of nodes is carried out.

There are special safety rules for working on such equipment:

- for work, you should work in clothes without parts that can get under the press. It is important to protect the hair from such a hit;

- special glasses are used for the eyes;

- in the working area there should be no children and strangers;

- parts are placed in the center of the press;

- only high quality oils are used for jacks.

An important drive is a manually operated hydraulic pump. He is able to perform reciprocating movements in the working part. Hydraulic cylinders can be plunger and piston. This largely depends on the quality of the liquid used.

To make a simple assembly for the garage, you need a bottle jack. For a small workshop, you can choose a mechanism that can create a force of up to 10 tons. This will reduce the size of the device. You will also need a welding unit, a hacksaw, a grinder and discs for cutting metal.

Before assembly, it is important to choose only a good jack and make a solid base for it. Such a press consists of a hydraulic pump, a pressure gauge, a frame with a bed and a hydraulic cylinder. In some designs, the cylinder and pump may be replaced by a jack.

The hand press has the following advantages:

- simplicity of the device;

- lack of safety mechanisms;

- the location of the desktop does not affect the working force of the structure;

- there is a possibility of adjustment of length and height of the working course.

The disadvantages include the insignificant speed of the working surface.

How to make a device for the garage can be seen in the video:

Do-it-yourself hydraulic press drawing options

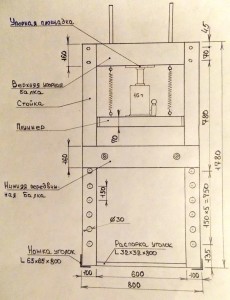

An important part of any press is the frame. To make a manual hydraulic press with your own hands, the drawings must be chosen very responsibly. The bed consists of a frame, inside of which there is a jack with a tool.

The hydraulic press frame must have increased strength, as it will experience loads in two directions at once.

The lower part of the frame is designed to ensure the stability of the entire structure. To calculate the internal opening of the frame, parameters such as the thickness of the operating mechanism and the free play of the stem are summarized.

To increase the height of the workpiece, it is necessary to ensure the adjustment of the free rod of the jack. Here is what you can do for this:

- in the upper part of the frame contour, another plate is installed, which can move along the guides;

- a removable emphasis is made for a mobile platform;

- from a solid piece of metal, you can make several gasket inserts.

If the correct drawing is used, the hydraulic press will turn out to be of high quality and durable.

Do-it-yourself hydraulic press: how to make

Figuring out how to make a press with your own hands is not difficult. To do this, you need a welding unit, an angle grinder, a hacksaw and a steel profile. A jack is required for the manufacture of a hydraulic device. The shape of such a mechanism should be bottle.

When making a homemade hydraulic press, you will need a jack weighing from 2 to 100 tons. Depending on the purpose, the press can be both floor and desktop. The last option is more compact.

To make a hydraulic press with your own hands, you will need a grinder, a welding machine and a metal drill, as well as drills of different diameters. All kinds of channels, corners and pipes made of metal are used as the starting material. Any hydraulic press consists of movable and fixed elements. The movable ones include return mechanisms and a movable stop, and the fixed ones include racks, stops and a base.

The base of a hydraulic press for a garage can be made from any materials at hand. In order for the structure to be stable, it is necessary to place the center of gravity as low as possible. For a floor device, the base is made of thick-walled corners and channels.

In the manufacture of desktop equipment, you can use a pipe with thick walls and a square section. Iron can be used if the thickness of the metal is about 10 mm. For the base you will need a high-quality emphasis and racks. Such elements are made from improvised materials.

Article

Periodically, in almost every garage, it becomes necessary to carry out various works that require the use of pressing methods. To implement this kind of tasks, a special device has been created - a hydraulic press. With a strong desire, a simple garage press is assembled without any problems with your own hands.

Purpose and principle of operation of the press

The considered unit allows you to process a variety of products and materials using pressure. A special liquid is responsible for the operation of the mechanism. In the system under consideration, it is under high pressure.

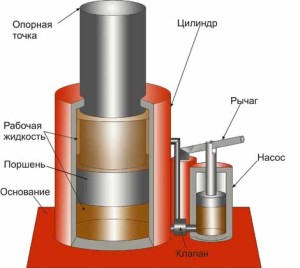

The design consists of two main cylinders, they are also chambers. In a smaller container, the pressure of the liquid increases and it is transferred to the working container, which has an increased size.

Between themselves, the cylinders are connected using a special channel or pipeline. In a large compartment, a liquid (usually a special oil) exerts a force on a special piston. From there, the force is transmitted to the installed executive tool and then to the workpiece.

As a rule, the working cylinder is installed in a vertical position. In some situations, its installation is performed in a horizontal position.

The press can develop forces up to several thousand tons. The specific value is selected in accordance with the characteristics of the workpieces being processed and the tasks performed.

The presses are widely used in the processing of pipes, the pressing of various products, the production of various kinds of pressed rubber blanks, wood chips, plastics, etc.

Options for using a homemade press

In the garage, such a press will be an excellent assistant for self-repairing the car and performing other tasks. For example, by building a homemade press, you can press out the bearing yourself, and then press in a new product instead. That is, you do not have to go to a car service and spend money.

The press will allow you to straighten, securely glue various parts under pressure, squeeze out liquid, bend a metal product, compress old bottles, cardboard, cans and other similar materials.

Ready-made pressing equipment of factory production costs quite a lot of money. With self-assembly, you will have to spend money only on the necessary components. An additional advantage of self-assembly of the press is that you will personally control the process at every stage and will be able to get a unit that will the best way tailored to your needs.

Design features of a homemade press

For a private garage, a press with a capacity of up to 10-15 tons is enough. Otherwise, focus on your own needs.

The pressure in a large tank is usually created using an integrated or separate pump. The easiest option to perform is a press assembled on the basis of a bottle jack with a hand pump provided.

Think about what kind of work you will do using a homemade press, and determine the required force of the unit. Only after that, go to the store to buy a jack and select it in accordance with the previously determined force value.

Before assembling the press, you need to select a suitable drawing of the mechanism, but it is better to make it yourself. Of the ready-made solutions, a drawing of any press designed and assembled on the basis of available rolled metal and simple hydraulic equipment is suitable for you.

The disadvantage of ready-made drawings is that they will not always meet your specific needs. As a result, you can spend a lot of time adjusting the structure to the parameters of the purchased jack.

There are 2 main options for assembling a garage press, namely:

- the jack is placed on the base of the frame and exerts upward pressure;

- the jack is fixed closer to the top of the frame, and the pressure is applied downward.

Before assembling the press, be sure to check the correct working position for your jack. If the manufacturer said that the jack rod should move up, then this is exactly how it should be - you can’t turn the tool over.

Most often, structures are assembled that provide for the installation of a jack on the basis of the bed. The second option is more highly specialized and is used mainly in professional metalwork workshops.

Press project preparation

One of essential elements the structure under consideration is the frame. It is a frame. A jack is placed inside such a frame. The bed must have sufficient strength to withstand the force generated by the jack with some margin. The stock is needed for the reason that during operation the press will exert pressure immediately down and up, and without a stock, the structure may simply break.

The base of the bed is best done in the form of a platform. Select the width of the platform opening in accordance with the dimensions of the materials that you plan to further process on your press. Under any circumstances, the opening must be larger than the total dimensions of all elements of the equipment to be placed.

To determine the appropriate height, you need to add together the following parameters:

- jack dimensions;

- the value of the working stroke of the main tool rod;

- thickness of the mobile table;

- the height of the pressed workpieces.

In this case, the jack is installed on the base of the frame, and the upper part of the frame will take over the function of supporting the workpieces. The transfer of force from the jacking rod to the workpiece is carried out by means of a mobile working table. The table itself is mounted on a frame. A jack is placed between the frame and the table.

The table is installed in such a way that it can move freely along the frame in the up and down directions, supported by the side rails.

Springs of sufficient rigidity are placed on the sides of the hydraulic jack. One eye of each spring is attached to the base of the support frame, the second - to the mobile table. The installed springs will compress the hydraulic jack into the starting position with the stem hidden. Select the spring size and stiffness according to the characteristics of the jack.

The stroke of the jacking rod, and with it the height of the parts being pressed, can be adjusted in several ways:

- by installing a screw drive at the top of the frame. This element must be equipped with a steering wheel. During the operation of the press, it will be possible to screw in the screw, which will reduce the size of the clearance for blanks inside the frame;

- creating a removable movable mobile table. If necessary, it can be attached to the frame with rods or bolts. First, holes must be made in the frame, the step of which in height should be somewhat less than the stroke of the jacking rod;

- using interchangeable pads. For the manufacture of these elements, a hollow or solid steel profile is well suited;

- using the methods described above in combination.

All significant dimensions must be entered in the drawing. In this case, the dimensions should be given taking into account the dimensions of the jack, the workpieces, as well as the rolled metal, which will be used to assemble the hydraulic press.

What to collect a press from?

No special tools are needed to assemble the press. The only difficulties for a beginner may arise using a welding machine. Beginning masters are recommended to train on inverter-type units - they are the easiest to learn. If desired, welding work can be entrusted to a qualified craftsman.

Tools for assembling a homemade press

- Apparatus for welding and electrodes.

- Bulgarian with a disk for metal. In the absence of a grinder, you can use a hacksaw, but it is longer and more difficult to cut with it.

- Electric drill.

- Screwdriver.

- Level.

- Yardstick.

The main power unit of the installation under consideration is a hydraulic jack. The need to use pullback springs was mentioned earlier. You can take door springs, springs from the front seats of the car, and any others that fit the given requirements.

If you fix the jack in the lower position, you can use a special bridge fungus for the device of the retracting device - it is simply put on the stem, after which the springs are attached to the base of the frame and directly to the fungus. The fungus of the bridge should be with shifted splines.

Select the dimensions and the required volume of rolled metal in accordance with your hydraulic press drawing.

Rolled metal for assembling a homemade press

Press Assembly Manual

In the process of assembling a garage press, refer to your drawings at each stage. In general, the sequence of work is quite simple. You just need to step by step follow the suggested recommendations.

First step

Cut the metal into parts of the appropriate dimensions, guided by the drawing. If the drawing provides for holes in any structural elements, drill them with an electric drill.

Second step

Weld the base from segments of a square or rectangular pipe. Docking seams boil from below and above. Fasten the steel plate on top. For fastening, use welding. Using welding, make a design in the form of the letter "P". The corners of this design must be strictly 90 degrees. Weld the structure to the base, and you will get a finished frame.

Third stage

Make a mobile desktop. Use a pipe or channel for this. The length of the pipe must be cut so that it is slightly less than the gap between the racks of the bed. Weld to the main pipe a small part of the pipe that you previously prepared for the stem of your jack.

The guides of the mobile table are made from pieces of steel strip. The width of the guides should be equal to the width of the frame. Insert the pipe into the space between the racks of the bed, put the steel strips on the sides and securely tighten the structure with bolts and nuts. Make a replacement adjusting stop in the same way. The only difference is that opposite the racks you need to make holes for fixing at the required height.

Fourth stage

Fix the retract springs according to your drawings. Pull back the movable work table and install the jack.

Now your personal press is ready. In the future, the jack can be quickly removed from the structure and used for other tasks.

Successful work!

Video - Do-it-yourself press for the garage

Every car enthusiast knows that it is quite difficult to do without or press in the garage. This device is indispensable when working with bushings, crankshafts, for mounting bearings, bending sheet metal, fittings, etc. In some situations, a vice can help you out, but this method is ineffective when it comes to overall parts. The pressing method allows you to cope with tasks of any complexity. Do you think that it is difficult to make a press for a garage with your own hands? Then our article will be useful for you.

A garage press can generate force from several tens to several thousand tons. This value is calculated individually. The device is actively used for:

- Metalworking (stamping, straightening, bending, forging);

- Manufacture of steel profiles, wood chip products;

- Pressing of various materials (plastic, rubber, etc.);

- Briquetting.

How to use garage press in your home workshop? Having spent a little time, effort (and a small amount of money), you free yourself from expensive visits to car services to replace a silent block or bearing.

Please note: for personal use or a small workshop, a jack that creates a force of up to 10 tons is optimal. This will help make the device smaller overall.

You can easily make any metal blank, straightening, glue several parts (made of plastic, iron, cardboard), and even squeeze out oil. A homemade garage press is a necessary and multifunctional device.

However, before you start creating a hydraulic press with your own hands, it is important to understand the principle of the mechanism. The unit consists of two chambers of different sizes. Under the influence of pressure from the smaller cylinder, the liquid is transferred to the enlarged cylinder.

Both chambers are interconnected by a special channel through which the working solution circulates. The larger container contains the piston. When the liquid used (usually a special oil) fills the large chamber, the piston is lowered and thus actuates the operating tool.

In most cases, the working cylinder is fixed in a vertical position, but sometimes it is more rational to install the container horizontally. How to do the press correctly? What you need to buy for design useful homemade? Let's figure it out.

Garage Hydraulic Press Assembly: Tool List

The first step is to purchase a hydraulic bottle jack. Professionals recommend purchasing a bottle jack with a built-in hand pump, as the press assembled on its basis is the easiest and most convenient to use. A high-quality jack needs a reliable foundation, because otherwise the entire unit will fall apart under high pressure.

In addition to the jack, you will need:

- Welding machine.

- Hacksaw for metal.

- Bulgarian.

- Discs for cutting steel.

- Electrodes (E42).

- Screwdriver.

- Electric drill.

- Roulette.

- Level.

- Channel (not lower than No. 8).

- Profiled pipe (rectangular or round, at least 4x4 cm).

- Profile corner (50x5).

- Sheet steel.

- Steel strip (thickness - not less than 10 mm).

- A piece of pipe (length about 10 mm).

- 2 springs (for emphasis).

Important: a beginner "auto mechanic" may have difficulty working with welding machine. Experienced craftsmen advise you to practice on inverter-type devices or trust a professional master.

Project preparation

We offer to consider detailed drawings that will help you in creating the project. After all, before you assemble your press, you need to understand its design and calculate the ideal dimensions.

The bed is the main element of the apparatus. This is the frame inside which the jack is located. It must be as strong as possible.

The most reliable base of the bed is the platform. When calculating the width of the platform, it is important to take into account the dimensions of the materials that you plan to process on the press.

The upper part of the frame will serve as a support for the workpieces. The mobile table is mounted on a frame and transfers the force from the jacking rod directly to the workpiece. When mounting the table, it is important to consider that it must move freely along the bed up / down.

Rigid springs are fixed to the base of the bed on one side, and to the desktop on the other. During operation, the springs will compress the jack, actuating the jack rod.

Assembling a garage press: step by step instructions

Have you already purchased everything you need to assemble? Then you can consider that a reliable press in the garage with your own hands is almost ready!

Step-by-step guide and diagram of assembly of a garage press:

- We cut out the necessary parts from metal in accordance with the drawing.

- We weld the base. To do this, you will need a piece of pipe and a steel plate. We weld the butt joints, fix the plate on top. You should be able to steel structure resembling the letter "P". The corners of the structure are strictly 90 degrees. We weld the letter "P" to the base - the bed is ready!

- We make a mobile table. To do this, you will need a channel or pipe, as well as a steel strip from which you will construct the guides.

- The last step: fixing the springs.

A reliable pressing machine, made by you personally, is ready! Now you can fix many breakdowns yourself, and invest the saved money in improving your favorite car! Is there some more .

"Motorhome" after the construction is filled with various devices and details. More and more motorists are ready to purchase a press for the garage. The purchase is useful, however, expensive. Let's look at creating a device with our own hands.

When it is necessary to carry out straightening work, to make manipulations with sheet material, the press is indispensable. The equipment will perform any locksmith work, pressing out and pressing in bearings.

Factory presses for a high-capacity garage turn out to be cumbersome. Handmade products have a compact and simple design. To repair a vehicle, a 20-ton effort of a home-made device is enough.

What are garage presses?

- hydraulic technology.

- pneumohydraulic device.

Two-chamber form with pistons (chambers are connected by an oil pipeline);

The pneumatic piston, under the action of compressed air, pumps oil into the cylinder cavity. For convenience, the unit is equipped with a pneumatic pedal. This garage press only works with compressed air.

According to the type of execution, the products are floor and desktop type. The first option requires additional space. Another type of press is compact, but with less power.

Design features of presses in the factory

- The frame is reinforced with additional stiffening ribs. Thick hardened steel is the basis of the bed.

- The device is easily attached to the floor or table. Height working area also easy to fix.

- To reduce the effort during pressing, the factory provides a mechanical lift equipped with a rotating handle.

- The purchased press for the garage is always equipped with an automatic rod return system, a mechanism with a safety valve helps out in case of overloads.

- All components of the jack are built into a monoblock system, the body will protect against damage.

- Built-in sensors and timers show load forces.

Hydraulic jack as the basis for a do-it-yourself press

Hydraulic press for garage - diagram

Any garage press with a jack core will adhere to fundamental physical rules when working. The volume of liquid under pressure will remain unchanged.

Thanks to these features, home-made garage presses process a given surface without loss of power. The technique is beneficial in that the pressure through emphasis on the object is much greater than the effort human body change the shape of an object.

The hydraulic jack has 80% efficiency, so the do-it-yourself press has excellent compression strength. This effect is achieved due to the large gear ratio between the pump plunger and the cross section of the jack cylinders.

Peculiarities

The device cannot control the height of the rod lowering, so the homemade pressing apparatus each time drops the pressure in the chamber to zero in order to start a new pressing cycle with an updated stroke of the rod. Hydraulic press for a garage from a car jack and a handy utility. The length of the do-it-yourself unit is guided by the gap of the side racks of the press.

Stop adjustment methods:

- a removable and detachable fragment of a rectangular metal profile is fixed with a frame with bolts or welding;

- holes are made in the side posts at the planned distance, into which the lower additional stop is placed. Communication with racks and emphasis occurs with the help of nuts and bolts.

These techniques can significantly speed up the compression processes, since the time for moving the stop to the workpieces will be reduced.

Platform

The base with your own hands should be as strong as possible, because the same pressure is exerted on the platform as on the workpiece. Otherwise, the structure will fall apart.

Channels (metal profiles) with reinforced stiffeners are welded in a characteristic shape with additional seams.

Step-by-step installation of a jack in a future garage press:

- the movable stop is retracted with the help of special device. The edge of the rod in the retracted form must be inserted into the latch, so make sure that the jack is correctly placed between the stop and the platform;

- further, depending on the purpose, the “foot” of the jack is welded to the mobile stop or fixed with a fastening system. Bolted mounting in garage presses is preferable, since the master can at any time remove the lift from home-made equipment to perform a different range of work.

A bridge mushroom is bolted to a movable table with two springs (acts as a rod). Then two metal strips are welded to the nut under the stud. This is how the upper surface of the lift is obtained. Two studs are welded with two puller hooks.

This garage press is easy to maintain and easy to install in a new location.

Which jacks are best for do-it-yourself pressing machines?

The most optimal solution would be to use a single-rod bottle device, since:

- lever;

- crank;

- screw;

- eccentric presses do not have a lot of pressure power on the object.

A single rod bottle jack can lift from 2 to 100 tons, which is important when creating a power press.

The bottle version is compact, so it will fit perfectly into the small space of a private garage or workshop.

Cylinders interconnected by means of a pipeline or a special channel are fixed in a vertical position (in rare cases, in a horizontal position).

Possible malfunctions of the units

Self-made presses for the garage, like the factory version, can become unusable, therefore, they require careful maintenance and timely restoration work. The most common breakdowns:

- Oil leakage.

- Accumulation of air bubbles in the mechanism.

Escaping oil will damage seals and seals. If an incident occurs, get ready to replace the analog seals. The old oil is removed by pumping the system with the lever up and down. The press is disassembled: the rod and pistons are tested for corrosion, deformation and contamination. Blockages are removed, defective fragments are replaced with new elements. After the new repair kit is installed, new oil is poured.

An unpleasant phenomenon significantly reduces the efficiency of the device, which leads to slow operation of the stem or a complete stop of the mechanism.

Air bubbles should be removed from the system in a timely manner by vigorously pumping the pump with the bypass valve open and the oil tank cap open. Strong air currents will pass through the working chamber of the lifting device and enter the oil tank. After the procedure, the oil reservoir plug and the bypass valve are hermetically sealed.

Mechanical presses

This technique is useful for those who want to minimize the efforts, costs for the disposal of waste paper and industrial waste.

The press pays off already in a couple of seasons of operation, because:

- mobile;

- assembly is inexpensive;

- saves electricity consumption;

- practical to use.

A self-made design of a compact size will find its place in the garage space. Technology is beneficial all year round, as its operation does not depend on weather conditions.

To avoid unnecessary purchase costs, you should try to make a homemade press from a jack with your own hands. By their own technical specifications such an installation will not differ much from analogues made in industrial conditions.

A short list of works that can be reproduced using a homemade press:

- stamping from various materials. It can be carried out both hot and cold.

- Works on the bending of rolled metal.

- Extrusion of profiles of various modifications.

- Pressing items.

- For self-pressing and pressing bearings.

Types of jacks suitable for the manufacture of a press

Jacks that go on sale or come with a car do not have so many varieties. And not all are suitable for the manufacture of the press. Among those needed:

- Mechanical rack jack. It has a fairly simple design. Consists of a guide rack with gearing teeth. Good for lifting and holding loads. Due to its design, due to the small area of pressure on the fulcrum, which is shifted to one side, it is practically not suitable for the manufacture of a press. You can, of course, try to make a structure from two jacks, but the production of a frame and the use of such a number of jacks will be unprofitable.

- Mechanical (rhombic) screw jack. Raises the load due to the rotational-translational movement. That is, when the screw rod is twisted, the horizontal diagonal of the rhombus rises along with the support platform on which the load is located.

Suitable for making a press. It has a drawback: you have to apply too much physical effort to achieve the desired result. - Hydraulic jack. Most best option for making a press. It has a pressure point, which is located in the center of the device. With little physical effort, you can lift more than 60 tons of cargo (depending on the size of the jack). Disadvantages: the stem rises only upwards. True, it is possible to remake the mechanism itself to work in an inverted state.

- Rolling hydraulic and pneumatic car jacks. By their structure and design, they are not worth the effort and financial investment for the manufacture of the press.

As a result, the most optimal will be the use of a screw or hydraulic jack. The principle of the press device for these types will be identical.

The screw jack can operate in all positions relative to the plane. But it is quite difficult to create a lot of pressure with it. Almost all types of hydraulic jacks work in one position - perpendicular to the plane. However, this the best option, since with relatively small physical exertion, quite a lot of pressure can be created.

Create a project

Before you start making a hand press, you should think carefully about what goals it will be intended to achieve, approximately determine how much effort the jack will need to achieve them.

There are quite a few schemes for this mechanism. But such drawings may have one small drawback. Although the manufacturing principle is almost the same for everyone, when creating the project, a calculation was made to perform certain functions. And they are not suitable for everyone. As a result, after the work is completed, some elements of the installation will have to be finalized or redone.

The most reliable option would be to create or redo an existing drawing yourself, having calculated in advance what basic functions the mechanism will perform.

We can immediately say that there are two types of installation of a homemade press:

- The jack is located at the bottom of the bed base. The pressure of the rod is upward, thereby raising the movable platform (table) along the frame. That is, the pressure on the manufactured part does not occur from above, as in the usual pressing options, but from below.

- The jack is mounted on a movable platform, almost on top of the frame. By activating the work of the rod, it rises up and rests against a rigidly reinforced platform located at the top of the base. Under the influence of pressure, the lower movable platform, together with the jack, moves down along the frame. The lower part will be the working surface of the press.

Bed assembly

One of the main elements of the press is the bed, or base. When choosing a material for its manufacture, it is necessary to take into account the force with which the jack will act on this structure.

When using a jack, which has a force of not more than 5 tons, a channel brand 8P is quite suitable, up to 10 tons - 10P, up to 15 tons - 14P

The base itself has the shape of a frame. The frame opening must correspond to the intended width and height of the material being processed. In this case, it is necessary to take into account the dimensions of the jack and the free movement of its rod.

So, option one. The bed consists of two racks, reinforced with support legs for greater stability.

The movable table is made of a twin channel in such a way that the movable part of the table can move freely both up and down the skids. The legs and support are not subjected to large loads, in addition to their weight and the weight of the press. Therefore, they do not have special requirements in the manufacture. The only recommendation: there should be a lower crossbar, which will give the structure additional rigidity.

There are springs on both sides of the support table (they will help return the stem to its initial state), the jack will be between them. Eyelets intended for fastening springs are made parallel to one another. One is on the table and the other is built into the base of the support frame. The stiffness and size of the springs is selected in accordance with the weight of the jack and its dimensions.

All elements (except for the movable table) are fastened together by welding on both sides. In the corners, you need to weld "kerchiefs" or corners to create structural strength.

In this manufacturing option, the jack is mounted in the center of the movable table and is located between the springs. Starting to work, the rod rests against the upper part of the frame, and since it is rigidly welded together with the table, it begins to move down along the frame. The bottom of the table will create pressure between its base and the bottom of the frame.

There is also a second option. To make a press from a jack in the second way (when the jack creates pressure with the stem down), you can use a mechanical or modified hydraulic tool (which can work upside down).

The design of the frame is done similarly to the previous version. The jack is attached to the top of the base, pre-equipped with a metal plate (with drilled holes for mounting). The sliding table can be made another by installing it at the bottom of the frame. It is required to make bolt fastenings for it on the frame. By moving this movable bar along the base, it will be possible to adjust the gap between the upper point of the extended rod and the base of the structure. The first table, as in the previous version, will move along the bed under the action of a jack. The result should be an adjustable and fairly reliable tool.

Making an emphasis for the press

When making a hydraulic press with your own hands, you additionally need to make an emphasis on it. To do this, you can use the same material as for the racks. In this case, the workpiece should be the same length in length with the width of this design. The next step: you need to weld these two parts together and connect them to the base.

The stop consists of two corners, the size of the wall is 40-50 mm. The length is chosen relative to the size of the frame, but within 30-50 cm. Between themselves, all workpieces must be welded together strictly at an angle of 90 °.

Jack completion

The lack of a hydraulic jack, as a result of which it cannot perform its functions in an inverted state, can be tried to be corrected. Action algorithm:

- In addition to the jack, usually on top, an expansion tank with a capacity of at least 250 ml is installed. Using a silicone tube, the tank is connected to the oil filling hole. For a tight fit, you can use fittings with threads made on them. As a result, in an inverted state, a layer of air (due to which the rod does not move) will be displaced by oil, which will be supplied by gravity from the expansion tank. As a result, the jack should work.

- In this version of the refinement, the jack should be disassembled. Pump the plunger by removing the upper clamping nut from the jack body and draining the oil from the system in advance. Remove the filler cup, it is attached by a sealing cuff at the base of the jack. The whole problem is in the glass, where the oil in an inverted state does not reach the liquid intake hole. You can fix this problem by pressing a tube tightly into the hole almost the entire height of the glass.

It is quite simple to make a hydraulic or mechanical press, using only improvised material for work. Having lost a little time, as a result, you will be able to get an excellent tool with a fairly wide range of applications.