Which manufacturer is the most durable pvc wall panels. Choosing sheet plastic panels for the bathroom

Hi all! If you want to quickly and inexpensively make repairs in the bathroom, I advise you to take a closer look at PVC panels as a finishing material. Installation of panels is easy to carry out even on your own, and a wide selection of textures and colors allows you to create an attractive design of the room in any style.

Panel types

When choosing PVC panels, it is necessary to take into account the specific features of each type, since the appearance of the finish and the technology of its installation depend on this. There are rack, standard and sheet panels.

![]()

Rack panels(plastic lining). The width of the slats is 10 - 12.5 cm, the standard length is 300 cm. The slats are equipped with a tongue-and-groove lock and are mounted in the same way as a conventional wooden lining. Depending on the model, the slatted panels may have a narrow or wide interlock, you should pay attention to this when buying.

Plastic lining is primarily used for finishing ceilings in the bathroom. It can also be laid on the walls, and depending on the location of the slatted panels (vertical or horizontal), the required visual effect of increasing the space is achieved. Plastic lining is usually produced in plain color, with colored edging or stylized for various types of wood.

Standard panels. This category includes PVC bathroom panels with a width of 25 - 37 cm and a length of 260 to 300 cm.

Manufacturers offer a rich variety of colors, including prints of photographic images or imitation of wall decoration with frieze tiles. Standard Wall panels more durable than rack.

Sheet panels. These are thin, large-sized panels: the width is 80 - 203 cm, the length is 105 - 405 cm. If it is not possible to close the entire wall with one panel, the elements are fastened end-to-end, which is then filled with sealant in the color of the coating. Sheet panels are usually produced in plain color, decorated for tiling or with photo printing.

Sheet panels are a solid thin sheet of PVC, while slatted and standard panels have a special structure and consist of two thin sheets of plastic with vertical bridges between them, which act as stiffeners.

Sheet panels are recommended to be fastened to leveled walls using an adhesive (liquid nails for PVC). Similarly, it is allowed to lay rack and standard panels, but the main way to install them is to mount them to a crate fixed to a wall or ceiling.

This “hides” the space of the room, but makes it possible to do without leveling the walls themselves, and, if necessary, to replace accidentally damaged cladding elements.

PVC panels also differ in surface decoration technology, which affects the appearance and cost of products.

In most cases, drawing is used:

- thermal printing;

- lamination;

- offset printing.

The surface of high-quality panels is additionally treated with a matte or glossy varnish, which improves the appearance of the finishing material and prolongs their service life. Such wall decoration does not fade, does not deteriorate under the influence of moisture and detergents.

Criterias of choice

The choice of PVC panels for the bathroom is a crucial step, which affects not only the quality and durability of the finish, but also its safety for health.

When buying, pay attention to the following points:

- the number of stiffeners (the more jumpers, the stronger the panel, the jumpers should not be deformed);

- appearance (evaluate the uniformity of color, the clarity of the pattern, check whether the images on adjacent panels with a frieze or other pattern fit together correctly - there should be no shifts);

- the quality of the lock connection (panels must be connected without gaps);

- surface quality (there should be no waves and other deformations);

- compliance with the dimensions declared by the manufacturer.

Pay special attention to this, wall panels must have an environmental safety certificate - low-quality plastic emits toxic substances that are hazardous to health. Volatile polyphenols can provoke a number of serious diseases. For this reason, you should not buy cheap panels from unknown manufacturers; it is better to opt for products from well-known Russian and European brands.

Conclusion

The advantages of panel moisture-resistant finishes are obvious - the material is good for wall cladding and installation of boxes that allow you to hide communications. But it is important to use material that is safe for health. High Quality. Products made by unscrupulous manufacturers are easily squeezed and broken.

When thinking about which PVC panels to choose for a bathroom, pay attention to the design of the material. The color and pattern is selected depending on the size of the room and the degree of its illumination. Dark tones and a large pattern will visually make a cramped room even smaller; for small bathrooms, light colors are preferable, imitation of rectangular tiles stretched upwards, panels with a frieze that visually divide the room into a dark bottom and a light top.

Video on the topic "how to choose PVC panels for the bathroom":

Among modern finishing materials are very popular plastic panels. And all this because they are light, hygienic, easily attached to walls made of any material, are not afraid of moisture and are not subject to decay. Plastic panels made of polyvinyl chloride (PVC) are made by extrusion, which gives them the necessary strength and rigidity. In this article, we will define the main criteria for choosing this finishing material.

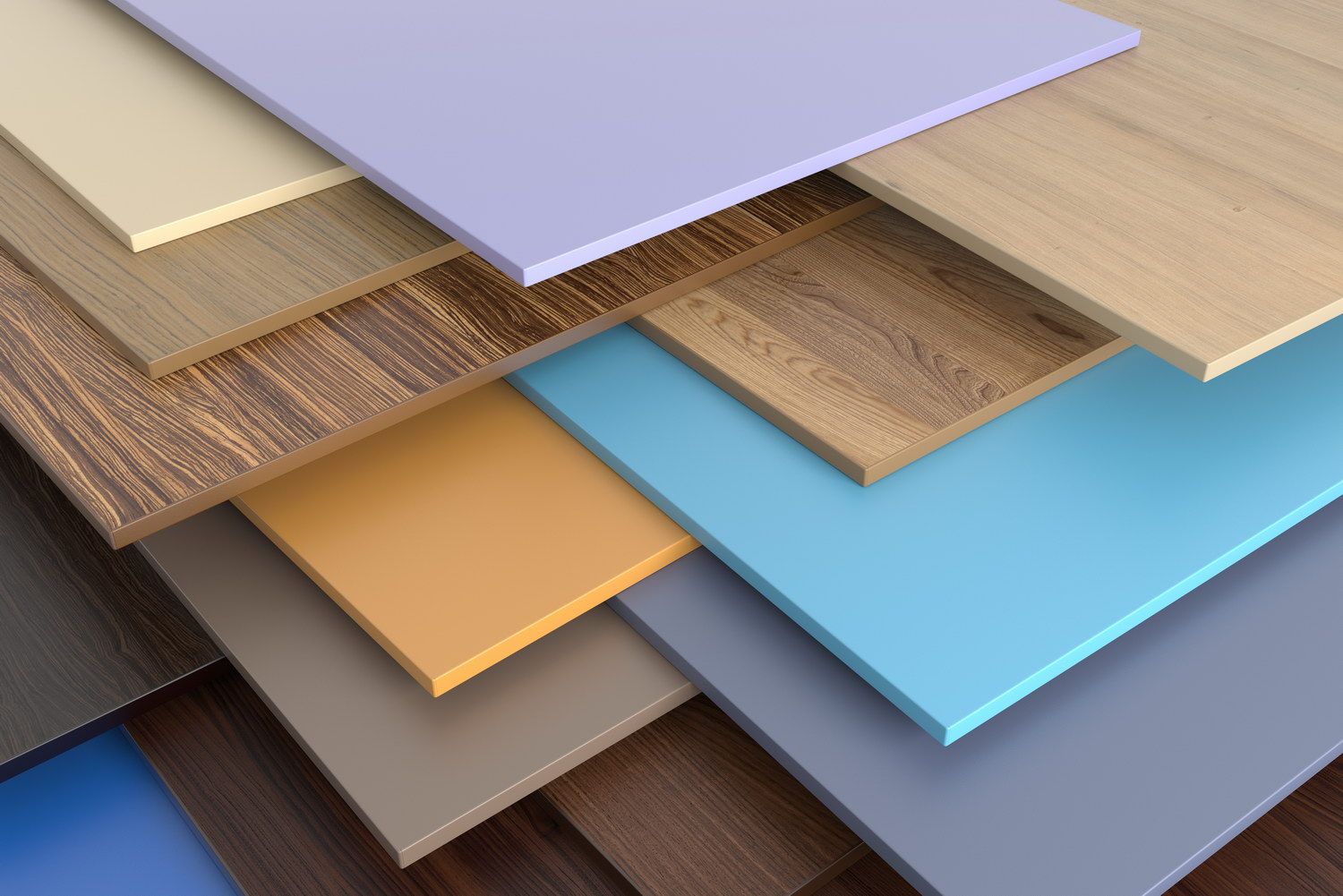

Today, the industry produces huge selection plastic panels produced in Turkey, China, Russia and Ukraine, differing in appearance, color, gloss level and other characteristics. In any hardware store, eyes run wide from their abundance and variety, confusion sets in: so which panels to choose?

All panels are conditionally divided into ceiling and wall. There is no direct ban on the use of wall panels on the ceiling, and ceiling panels on the walls, but a slight finger pressure test unambiguously interprets that, having low strength, these panels cannot be used for wall cladding.

An additional distinguishing element is the length. Typically, ceiling panels are 6 or 12m long, while wall panels are shorter - 2.7, 3 and 6m.

The thickness of the ceiling panels is gradually reduced by manufacturers, before it was 8mm, then it became 7mm, now there are 5 and even 4mm, and wall panels are usually produced with a thickness of at least 10mm.

Many buyers consider the cheapest panels, but do not want to pay attention to the fact that a quality product cannot be cheap.

After all, the vast majority of Chinese plastic panels are made from low-grade raw materials, bad adhesives and varnishes. In the future, they will quickly lose their appearance and, most importantly, begin to release toxic substances, even the option of provoking an allergic reaction of the human body is not excluded.

So, you should purchase panels thoughtfully, comprehensively considering and paying attention to the following factors. The main types of plastic panels are:

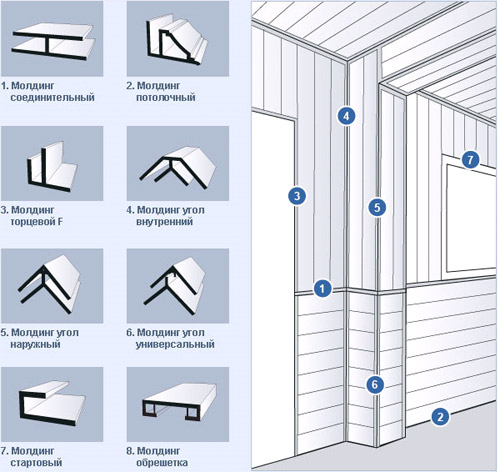

- 1. Plastic lining - used in the decoration of walls and ceilings, special fastening brackets are used for fastening. Embossed panels are often referred to as lining, because they create an imitation of a wooden panel "lining".

2. Plastic panels for tiles. It is advisable to use square tiles having a width of 30 to 98 cm.

3. Sheet panels - resemble plywood. Their main difference lies in the installation - fastening is done with glue or nails. Joints are sealed with sealant or sewn up with rails that have the structure and color of the panels

From the point of view of the design of the room, it should be emphasized that there is a diverse color palette of panels on sale that allows you to satisfy any desire of the buyer.

All panels are conditionally divided into glossy, matte and semi-gloss.

All panels are conditionally divided into glossy, matte and semi-gloss.

Their technical characteristics are the same, and the difference lies solely in the surface layer. This is achieved by using a varnish that creates a layer of protective film on the front surface.

When choosing plastic panels, you must carefully study the following parameters:

- 1. The thickness of the front part - a large thickness has significant strength.

2. The number of stiffeners - the more, the stronger the panel. The external state of the stiffeners must be identical without visible deformations. A high-quality panel has more weight, which corresponds to its thickness and the number of stiffeners.

3. The outer surface must be evenly painted, and viewing the stiffeners is not allowed. It is easy to check the quality of the panels - just press it down with a deflection of up to 50% and look at the result. There are no dents in high-quality panels, mainly due to the low content of chalk.

4. Panels must fit snugly and firmly into the groove. The type of joint in the panels is seamless and embossed. The most common at present is seamless, but it should be called conditionally seamless, because even with the highest quality installation, the joint is still visible.

Poor manufacturing or incorrect storage and transportation of plastic lead to its inevitable deformation and, as a result, to the impossibility of perfect joining of its parts.

Characteristic advantages and disadvantages of plastic panels

Like any material, plastic panels have their advantages and disadvantages. Let's start with the positives.

Like any material, plastic panels have their advantages and disadvantages. Let's start with the positives.

According to the manufacturers, all plastic panels are environmentally friendly, do not burn, have soundproof properties, light weight, good moisture resistance, durability, easy to clean and, moreover, are inexpensive.

The disadvantages of plastic panels are as follows:

- low strength, scratches, dents and chips remain on the surface (one sufficiently strong blow or strong pressure leads to a crack);

panels have a limited scope;

initially there is a specific smell;

being a universal material, plastic panels are usually used for interior decoration.

Installation of plastic panels

can be performed both horizontally and vertically and even at any angle.

can be performed both horizontally and vertically and even at any angle.

They find their application in the decoration of loggias and balconies, and are also often used as a ceiling material in the bathroom, corridor and kitchen.

Sewing walls with plastic is extremely simple, therefore, it is done by hand without any problems.

a) Initially, it is necessary to bring the temperature of the plastic panels closer to the temperature of the room - if they brought it from the cold, then let them adapt.

c) Walls with a high-quality dry surface must be sanded, in this case the adhesive will lie perfectly, therefore, the panels will last a long time.

d) Cutting panels is easy, using a hand saw for wood or metal.

e) good appearance cutting and drilling of panels must be performed on the front surface.

f) But you need to remove the protective film from the plastic panels at the last stage, as it protects the surface of the panel from cuts and scratches.

Finally, a video on the topic from Roman ...

Was this article helpful to you? Subscribe to site updates to receive the latest articles on renovation and interior design before anyone else!

Due to the nature of the bathroom, few finishing materials can be used in the renovation of this room. But if before it was only ceramic tile, now the latest developments in this area allow you to have more choice materials that will help you realize any of your fantasies. And as an example, we will consider the use of plastic bathroom panels. They are also called PVC panels.

Today, they confidently take second place after tiles, because they have undoubted advantages, which we will discuss below, and also allow you to quickly and efficiently decorate a bathroom at minimal cost. Even if you are not a professional in this matter, you can easily cope with all the work on your own.

In addition, in any hardware store you will find a large assortment of plastic sheet panels that imitate not only all kinds of textures, but also a wide color palette and pattern. This allows the use of plastic panels in any room, regardless of their size, although designers recommend using lighter shades in small bathrooms to make it visually larger.

Plastic bathroom panels

When buying plastic sheet panels, try to carefully inspect them so that they have as few protrusions and cracks as possible, since moisture will accumulate in these places later on, which will lead to the growth of mold and mildew, not to mention dark spots that are unlikely to decorate your bathroom. And if you still want to combine tiles and ceramics, then plastic sheet panels for tiles are suitable for you.

Mounting

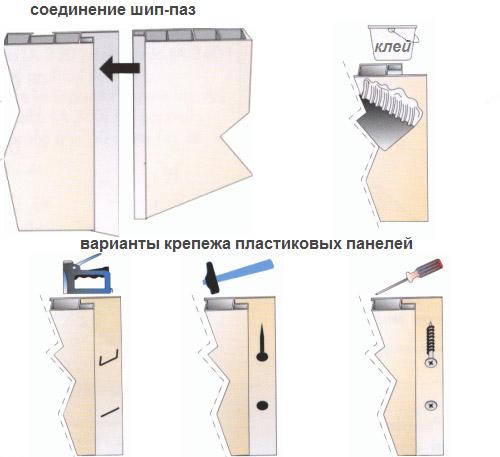

You have two options for attaching plastic sheet panels:

- using self-tapping screws;

- or glue.

In the first case, you have to mount guides on the walls, which are also sold in hardware stores. The advantage of this option is that you will not need to perfectly align the walls in the bathroom, although leaving tubercles or depressions is also not recommended. The downside is that you have to spend enough time and effort to fix the sheet panels, as well as drill a lot of holes for self-tapping screws.

Sheet panels for the bathroom

In the second case, you will simply need to carefully plaster the walls, since you will be gluing plastic panels to a bare surface, without using any other fasteners, which means that everything must be perfect, otherwise it will affect the quality of the finish. Here you will save a lot of time, but the disadvantage of this option is that if you want to remove the panels and change to new ones, you will have to tinker a lot, tearing them off the walls in the truest sense of the word. So it's up to you which one to choose.

If you stopped on the rails, then you will mount them horizontally to the floor under the ceiling, below and in the middle. But if you want to make a more durable structure, you can additionally fix a pair of rails about a quarter of the distance from the floor to the middle of the wall, repeating the same at the top.

Here is what you have to do when installing plastic sheet panels in the bathroom:

But if the walls in the bathroom are sheathed with drywall, then the best option- these are hidden fastening brackets, since this material gives perfectly even walls and you do not have to install guides and thereby save centimeters in small rooms, not to mention time. But if you have concrete or brick walls, then for each individual bracket you have to drill holes and put chopsticks in them. But when mounting plastic panels on rails, you will screw screws into the panels or use fastening brackets.

By the way, if you bought an apartment in a new building, then it is better to use plastic sheet panels in the bathroom, because for the first 3-4 years, the house will shrink, which slightly deforms the walls and can completely warp the tiles.

Paneled walls

We use self-tapping screws

In order to install plastic panels on the crate using staples or self-tapping screws, you will need the following tools and materials:

- pvc panels in required quantity, plus with a small margin;

- profile for the construction of the crate;

- plastic profiles or wooden bars;

- a hammer;

- a construction stapler with a set of staples or self-tapping screws (cloves);

- a construction knife and a hacksaw for metal with a fine tooth;

- screwdriver;

- roulette;

- pliers;

- pencil or marker;

- building level;

- ladder.

Before attaching plastic decorative panels, treat the finished surface with special moisture-resistant and anti-fungal compounds. It is better to use plastic profiles, because the wood will break down under the influence of moisture in the bathroom. You mount the profiles on the wall horizontally to the floor with a distance of up to 5 cm, while you will install the panels themselves perpendicularly, otherwise moisture will accumulate at the joints, which will lead to the growth of fungus between the plastic panels for the bath.

When installing profiles, constantly control their installation using the building level. Otherwise, the PVC panels will not stand up straight and the coating will have drops. In most cases, fastening starts from the left corner to the right or from the far corner to the doorway. But you can be guided by your ideas on ease of installation.

There is a huge selection of panels on the market.

In the corner where you start work, install the finishing element, because then you will not be able to do this. Each of the PVC panels consists of two fixing shelves: on the left there is a narrow part (shelf), which you will insert into the groove of the already installed panel, and on the right - a wide shelf, thanks to which the panel is fastened to the crate with screws or brackets.

The first PVC panel is inserted with a narrow shelf into the groove of a pre-installed corner, and is attached to the crate with brackets (self-tapping screws). According to the same scheme, all other plastic sheet panels are installed - one is inserted into the other and fixed. The main thing is that all parts are tightly adjacent to each other.

Where plastic panels come into contact with corners, window openings or door jambs, you will attach special mounting components (finishing elements). This will allow you to beautifully and neatly decorate places near windows and doors, as well as corners. But in order for air to enter under the fixed plastic panels, you should leave a small gap near the floor and under the ceiling. Additionally, these slots will compensate for the change in the linear dimensions of the PVC panels under the influence of temperatures in the bathroom.

Technology does not stand still, and you can fasten sheet panels using a special plastic profile and clips. What are the advantages of this method:

Liquid Nails

If you have good and even walls in your bathroom, then you can do without the crate, and immediately glue the plastic sheet panels to the wall. You can use a tool such as liquid nails or other special glue designed for this type of work in the bathroom. But at the same time, keep in mind that you will not be able to use those formulations that contain solvents of organic origin.

For work in this case, you will need the following tools:

- brush for glue;

- putty knife.

- soft sponge or rag to remove excess glue.

Here's what you have to do to get it right and not have to redo anything:

At the same time, do not forget about the installation of finishing elements so that the interior of the bathroom is beautiful.

5 installation mistakes

By doing repairs with plastic panels in the bathroom yourself, you will have to avoid these common mistakes among beginners:

According to consumer and specialist reviews, plastic sheet bathroom panels are an inexpensive and practical way to decorate rooms. BUT simple rules for the installation of sheet panels, allow you to install them without the involvement of professional builders.

Bathroom PVC panels are an option that allows you to change the interior, save money by giving up tile tiles, which are quite expensive. Plastic panels for the bathroom have long been a popular finishing material. They look good, do not require special care.

What is this material?

The cladding material is plastic panels. They have internal perforation and a pattern printed on the front. The length of the panels is usually 2 m 70 cm or 3 m. Material of this size is most often enough to finish any room. The cost of the material is low, it attracts buyers. Finishing tiles can cost several times more. The panels are easy to install.

The stores offer a wide range of materials. You can choose any color. It is necessary to choose light-colored plastic panels for a small area. It goes well with several different colors.

Panels in the bathroom can be installed independently, without the involvement of outside forces. Their standard height allows you to close the gap from floor to ceiling. The width is usually 25 cm. But when choosing, you need to look at the dimensions, as they may be different for some manufacturers. For 1 m of wall or ceiling, 4 panels are needed. It is quite simple to calculate the total amount of material per room. For fasteners, you need to purchase more guides and corners, which are called profiles, moldings.

Advantages of PVC panels and bathroom decoration

Finishing panels have a number of advantages compared to other materials:

- excellent moisture resistance;

- low cost;

- rich colors;

- the ability to join parts vertically and horizontally;

- durability;

- wear resistance;

- ease of assembly.

Moisture resistance makes it possible for the material not to get wet and not deform. Special locks form a solid sheet, beyond which water also does not penetrate. Plastic is much cheaper than tile. Various colors allow you to create any design in the room. Holes should be cut for lamps and pipes. Special experience for working with panels is not required.

Plastic installation work is carried out in several stages:

- it all starts with the preparation of the wall;

- the method of fastening is selected;

- panels are cut to length;

- a plastic corner is placed in the corner;

- the panel is inserted and fixed on the crate;

- other parts are installed.

First you need to free the room from unnecessary things. Then the old finish is removed from the walls. If the wall is even and does not require repair, then it is enough to get a good glue on which the panels will be glued. But this method is not the most common. It is better to make a small crate with your own hands from special guides or wooden slats treated against moisture. The elements of the crate are attached to the wall with dowels. The distance between the slats is 40-50 cm. The plane is checked by the level and the rule.

When installing panels with your own hands, most often you have to cut them in width. You can do this with a sharp knife. After completing the main work, the joints and corners can be covered with sealant so that moisture does not get in. It is recommended to install plastic panels in a house older than 3-5 years. A new house can settle and damage the cladding. If the bathroom has a heated towel rail, then a distance of 3-4 cm must be left between it and the lined surface, otherwise the plastic may deform due to temperature.

Lined surfaces are very easy and simple to wash, they are perfectly drilled, moisture does not pass through them. To perform the work, tools and materials are required.

How to choose PVC panel? The growing popularity of wall panels for wall and ceiling decoration is not accidental. When repairing an apartment with your own hands, this is very practical. Let's first understand what a "good PVC panel" means and what it depends on. The following are 8 points to pay attention to when buying a PVC panel.

I invite you to the group on Subscribe.ru:

"Apartment renovation, useful tips, home and family"

Choice of pvc panels

What is a good PVC panel?

PVC panels (plastic lining) are one of the types most often used for wall or ceiling decoration in the bathroom. The bathroom is characterized by high humidity, so condensation, fungus and mold will form on the surface of the walls and ceiling over time.

The finishing material must be suitable for the environment, and therefore good PVC panels must have properties such as moisture resistance and resistance to rotting and material deformation.

How to decorate the bathroom with panels, read.

What you need to pay attention to when choosing PVC panels

1. Thickness. The face of the panel should be as thick as possible. This affects the resistance of the material to mechanical stress, which is very important. After all, if the panel loses its integrity, moisture will penetrate through the gap, which will collect either in the panel or under it. And the constant presence of moisture in it (or under it) contributes to the appearance of mold, fungus, deformation of the lining and a change in the original color of the panels.

The surface thickness of inexpensive panels is 1.5 mm. Good ones have 2.5 mm.

2. View. good panel should be even. That is, the color should be uniform, and there should not be any dents on its surface, such as prints of ribs.

3. Number of ribs. The more stiffeners, the stronger the panel. On average, panels have 20 ribs. 29 is the best option.

4.Rib quality. The ribs themselves must be even, of the same thickness and located strictly perpendicular to the front of the panel.

5. Panel connection. Pay attention to the connection of the panels, they must fit snugly and completely into the docking groove.

6. The weight. The wall thickness of the lining and the number of ribs affect the weight of the panels. Therefore, the heavier the panel, the better.

7. Price. Lining is good, but it is cheap. Be careful, it is unlikely that a quality PVC panel will be sold at a low price. You usually have to pay extra for quality. Buy PVC panels at least in the middle price category.

8. Chalk quantity. A quality PVC panel has a low chalk content. The amount of chalk is fairly easy to spot. Bend the lining not very much, so that it bends by 30-50%. If there is a little chalk, no dents will remain.

To choose pvc panel high quality, remember another important point: not only the quality of the lining will affect how well it will serve you, but also how to install it. For example, if the most expensive panels are not installed tightly enough, then moisture will seep between the panels and fungus and mold will form quite quickly. Therefore, also understand well how to install PVC panels correctly.