Calculation of the thickness of the walls of the house from various materials. Thermal insulation thickness calculator online

AT recent times very sharp discussions about the insulation of walls. Some advise to insulate, others consider it economically unjustified. It is difficult for an ordinary developer who does not have special knowledge in thermal physics to understand all this. On the one hand, warm walls are associated with lower heating costs. On the other hand, the “issue price” - warm walls will cost more to the developer.

Why do you need a wall thermal conductivity calculator

In each individual case, you should consider the required thickness of the heat-insulating material for the walls of your house and calculate how much you will save on heating after heating and after what time the purchased materials and all work will pay off. We have selected the most convenient and understandable services for calculating the required thickness of the heat-insulating material.

Thermal engineering calculator. Wall dew point calculation

The online calculator from smartcalc.ru will allow you to calculate the optimal thickness of insulation for the walls of the house and residential premises. You can calculate the thickness of thermal insulation and calculate the dew point when insulating a house with various materials. The smartcalc.ru calculator allows you to visually see the place of condensation in the wall. This is the most convenient thermotechnical calculator for calculating insulation and dew point.

Insulation thickness calculator for walls, ceiling, floor

Using this calculator, you can calculate the thickness of insulation for walls, roofs, ceilings of the house and other building structures in accordance with the region of your residence, the material and thickness of the walls, as well as other important parameters for thermal insulation. Picking up different thermal insulation materials on the calculator, you can find the optimal thickness of insulation for the walls of your house.

Knauf calculator. Calculation of the thickness of thermal insulation

This calculator allows you to calculate the thickness of the thermal insulation of walls in the main cities of the Russian Federation in various designs on the KNAUF thermotechnical calculator, created by professionals from KNAUF Insulation. All calculations are made at the request of SNiP 23-02-2003 "Thermal protection of buildings". Free online calculator calculation of KNAUF thermal insulation, the service has a convenient and intuitive interface.

Rockwool Wall Insulation Calculator

The calculator was developed by Rockwool to help you calculate the required thickness of thermal insulation and evaluate the cost-effectiveness of its installation. Make a thermal calculation, select a suitable brand of thermal insulation and calculate required amount packs of mineral wool is very simple.

How to remove the dew point from the wall during insulation

Methodological material for self-calculation of the thickness of the walls of the house with examples and a theoretical part.

Part 1. Heat transfer resistance - the primary criterion for determining the thickness of the wall

In order to determine the thickness of the wall, which is necessary to comply with energy efficiency standards, the heat transfer resistance of the designed structure is calculated, in accordance with section 9 "Methodology for designing thermal protection of buildings" SP 23-101-2004.

Heat transfer resistance is a property of a material that indicates how heat is retained by a given material. This is a specific value that shows how slowly heat is lost in watts when a heat flux passes through a unit volume with a temperature difference of 1°C on the walls. The higher the value of this coefficient, the “warmer” the material.

All walls (non-translucent enclosing structures) are considered for thermal resistance according to the formula:

R \u003d δ / λ (m 2 ° C / W), where:

δ is the thickness of the material, m;

λ - specific thermal conductivity, W / (m · ° С) (can be taken from the passport data of the material or from tables).

The resulting value of Rtotal is compared with the tabular value in SP 23-101-2004.

To navigate to normative document it is necessary to calculate the amount of heat required to heat the building. It is performed according to SP 23-101-2004, the resulting value is "degree day". The rules recommend the following ratios.

| wall material | Heat transfer resistance (m 2 °C / W) / application area (°C day) |

||||

| structural | heat-insulating | Double-layer with external thermal insulation | Three-layer with insulation in the middle | With non-ventilated atmospheric layer | With ventilated atmospheric layer |

| Styrofoam | |||||

| Mineral wool | |||||

| Expanded clay concrete (flexible links, dowels) | Styrofoam | ||||

| Mineral wool | |||||

| Aerated concrete blocks with brick cladding | Cellular concrete | ||||

| Note. In the numerator (before the line) - indicative values the reduced resistance to heat transfer of the outer wall, in the denominator (behind the line) - the limiting degrees-days of the heating period, at which this wall design can be applied. |

|||||

The results obtained must be verified with the norms of clause 5. SNiP 23-02-2003 "Thermal protection of buildings".

You should also take into account the climatic conditions of the zone where the building is being built: for different regions different requirements due to different temperature and humidity conditions. Those. the thickness of the gas block wall should not be the same for the seaside area, middle lane Russia and the Far North. In the first case, it will be necessary to correct the thermal conductivity taking into account the humidity (upward: increased humidity reduces the thermal resistance), in the second case, you can leave it “as is”, in the third case, be sure to take into account that the thermal conductivity of the material will increase due to a larger temperature difference.

![]()

Part 2. Thermal conductivity of wall materials

The coefficient of thermal conductivity of wall materials is this value, which shows the specific thermal conductivity of the wall material, i.e. how much heat is lost when a heat flux passes through a conditional unit volume with a temperature difference on its opposite surfaces of 1°C. The lower the value of the coefficient of thermal conductivity of the walls - the warmer the building will turn out, the higher the value - the more power will have to be put into the heating system.

In fact, this is the reciprocal of the thermal resistance discussed in part 1 of this article. But this applies only to specific values for ideal conditions. The real thermal conductivity coefficient for a particular material is affected by a number of conditions: temperature difference on the walls of the material, internal heterogeneous structure, humidity level (which increases the density level of the material, and, accordingly, increases its thermal conductivity) and many other factors. As a rule, tabular thermal conductivity must be reduced by at least 24% to obtain an optimal design for temperate climates.

Part 3. The minimum allowable value of wall resistance for various climatic zones.

The minimum allowable thermal resistance is calculated to analyze the thermal properties of the designed wall for various climatic zones. This is a normalized (basic) value, which shows what the thermal resistance of the wall should be, depending on the region. First, you choose the material for the structure, calculate the thermal resistance of your wall (part 1), and then compare it with the tabular data contained in SNiP 23-02-2003. If the value obtained turns out to be less than that established by the rules, then it is necessary either to increase the thickness of the wall, or to insulate the wall with a heat-insulating layer (for example, mineral wool).

According to paragraph 9.1.2 of SP 23-101-2004, the minimum allowable heat transfer resistance R o (m 2 ° C / W) of the enclosing structure is calculated as

R o \u003d R 1 + R 2 + R 3, where:

R 1 \u003d 1 / α int, where α int is the heat transfer coefficient inner surface enclosing structures, W / (m 2 × ° С), taken according to table 7 of SNiP 23-02-2003;

R 2 \u003d 1 / α ext, where α ext is the heat transfer coefficient of the outer surface of the enclosing structure for the conditions of the cold period, W / (m 2 × ° С), taken according to table 8 of SP 23-101-2004;

R 3 - total thermal resistance, the calculation of which is described in part 1 of this article.

If there is a layer in the enclosing structure ventilated by outside air, the layers of the structure located between the air layer and the outer surface are not taken into account in this calculation. And on the surface of the structure facing towards the layer ventilated from the outside, the heat transfer coefficient α external should be taken equal to 10.8 W / (m 2 · ° С).

Table 2. Normalized values of thermal resistance for walls according to SNiP 23-02-2003.

The updated values of the degree-days of the heating period are indicated in Table 4.1 of the reference manual to SNiP 23-01-99 * Moscow, 2006.

Part 4. Calculation of the minimum allowable wall thickness on the example of aerated concrete for the Moscow region.

When calculating the thickness of the wall structure, we take the same data as indicated in Part 1 of this article, but rebuild the basic formula: δ = λ R, where δ is the wall thickness, λ is the thermal conductivity of the material, and R is the heat resistance norm according to SNiP.

Calculation example the minimum wall thickness of aerated concrete with a thermal conductivity of 0.12 W / m ° C in the Moscow region with average temperature inside the house during the heating season + 22 ° С.

- We take the normalized thermal resistance for walls in the Moscow region for a temperature of + 22 ° C: R req \u003d 0.00035 5400 + 1.4 \u003d 3.29 m 2 ° C / W

- The coefficient of thermal conductivity λ for aerated concrete grade D400 (dimensions 625x400x250 mm) at a humidity of 5% = 0.147 W/m∙°C.

- Minimum wall thickness of aerated concrete stone D400: R λ = 3.29 0.147 W/m∙°С=0.48 m.

Conclusion: for Moscow and the region, for the construction of walls with a given thermal resistance parameter, an aerated concrete block with a width of at least 500 mm is needed, or a block with a width of 400 mm and subsequent insulation (mineral wool + plastering, for example), to ensure the characteristics and requirements of SNiP in terms of energy efficiency of wall structures.

Table 3. Minimum thickness of walls erected from various materials, corresponding to the norms of thermal resistance according to SNiP.

| Material | Wall thickness, m | conductivity, | |

| Expanded clay blocks | For the construction of load-bearing walls, a grade of at least D400 is used. |

||

| cinder blocks | |||

| silicate brick | |||

| gas silicate blocks d500 | I use a brand from D400 and higher for housing construction |

||

| Foam block | frame construction only |

||

| Cellular concrete | The thermal conductivity of cellular concrete is directly proportional to its density: the “warmer” the stone, the less durable it is. |

||

| Minimum size walls for frame structures |

|||

| Solid ceramic brick | |||

| Sand-concrete blocks | At 2400 kg/m³ under conditions of normal temperature and air humidity. |

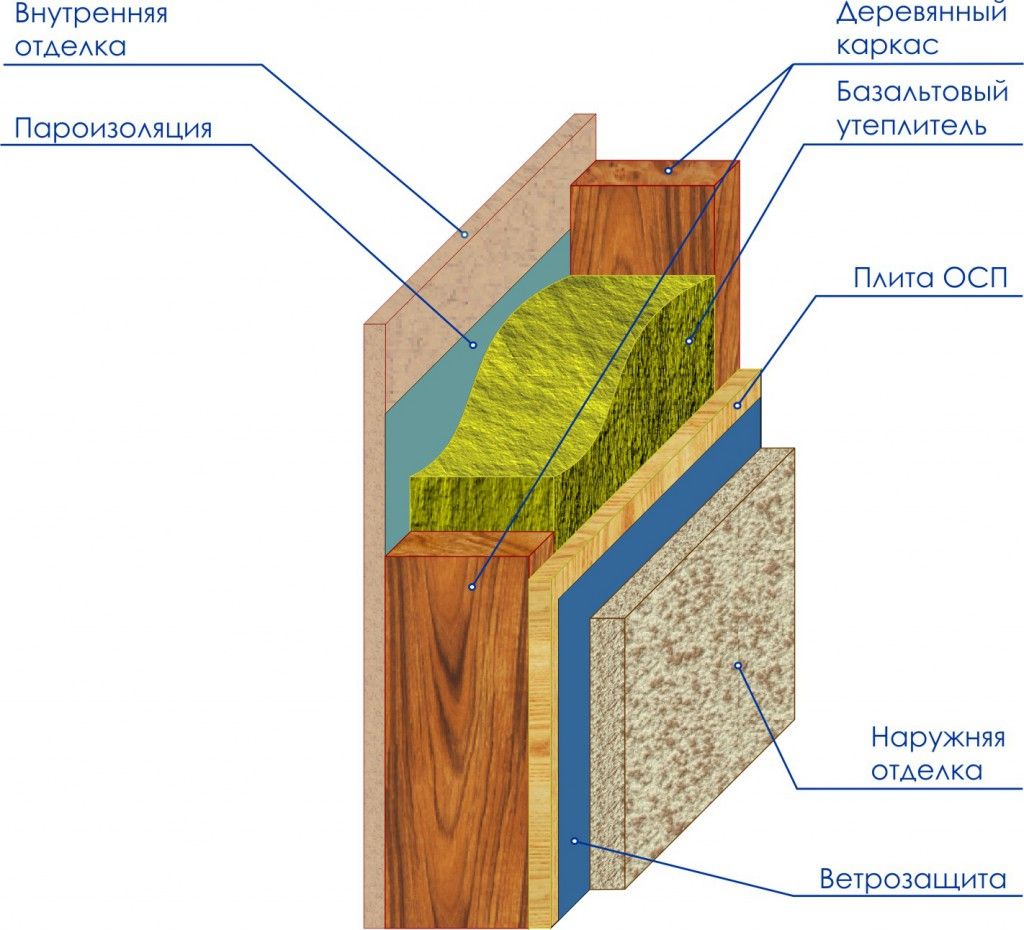

Part 5. The principle of determining the value of heat transfer resistance in a multilayer wall.

If you plan to build a wall from several types of material (for example, building stone + mineral insulation + plaster), then R is calculated for each type of material separately (using the same formula), and then summed up:

R total \u003d R 1 + R 2 + ... + R n + R a.l where:

R 1 -R n - thermal resistance of various layers

R a.l - resistance of a closed air gap, if it is present in the structure (table values are taken in SP 23-101-2004, p. 9, table 7)

An example of calculating the thickness of a mineral wool insulation for a multilayer wall (cinder block - 400 mm, mineral wool - ? mm, facing brick - 120 mm) with a heat transfer resistance value of 3.4 m 2 * Deg C / W (Orenburg).

R \u003d R cinder block + R brick + R wool \u003d 3.4

R cinder block \u003d δ / λ \u003d 0.4 / 0.45 \u003d 0.89 m 2 × ° C / W

Rbrick \u003d δ / λ \u003d 0.12 / 0.6 \u003d 0.2 m 2 × ° C / W

R cinder block + R brick \u003d 0.89 + 0.2 \u003d 1.09 m 2 × ° C / W (<3,4).

Rwool \u003d R- (R cinder block + R brick) \u003d 3.4-1.09 \u003d 2.31 m 2 × ° C / W

δwool = Rwool λ = 2.31 * 0.045 = 0.1 m = 100 mm (we take λ = 0.045 W / (m × ° C) - the average value of thermal conductivity for mineral wool of various types).

Conclusion: in order to comply with the requirements for heat transfer resistance, expanded clay concrete blocks can be used as the main structure, lined with ceramic bricks and a layer of mineral wool with a thermal conductivity of at least 0.45 and a thickness of 100 mm.

Questions and answers on the topic

No questions have been asked for the material yet, you have the opportunity to be the first to do soTo determine how thick to build a wall when building a house, you need to learn how to calculate the thermal conductivity of the walls. This indicator depends on the building materials used, climatic conditions.

The norms of wall thickness in the southern and northern regions will differ. If you do not make a calculation before starting construction, it may turn out that the house will be cold and damp in winter, and too humid in summer.

The thickness of the walls in the southern and northern latitudes should be different

The thickness of the walls in the southern and northern latitudes should be different

To save on heating and help create a healthy microclimate in the room, you need to correctly calculate the thickness of the walls and insulation materials that we will use during construction. According to the law of physics, when it is cold outside and warm in the room, the thermal energy comes out through the wall and roof.

- in winter the walls will freeze through;

- Significant funds will be spent on heating the premises;

- the dew point will shift, which will lead to the formation of condensation and humidity in the room, mold will start;

- in summer the house will be as hot as under the scorching sun.

To avoid these troubles, it is necessary to calculate the thermal conductivity of the material before starting construction and decide how thick the wall should be built and what heat-saving material it should be insulated with.

What does thermal conductivity depend on?

The conductivity of heat depends largely on the material of the walls.

The conductivity of heat depends largely on the material of the walls. Thermal conductivity is calculated based on the amount of thermal energy passing through a material with an area of 1 sq. m. and a thickness of 1 m with a temperature difference inside and outside of one degree. The tests are carried out for 1 hour.

The conductivity of thermal energy depends on:

- physical properties and composition of matter;

- chemical composition;

- operating conditions.

Heat-saving materials are considered to be less than 17 W / (m ° C).

We carry out calculations

The resistance to heat transfer must be greater than the minimum specified in the regulations

The resistance to heat transfer must be greater than the minimum specified in the regulations The calculation of wall thickness by thermal conductivity is an important factor in construction. When designing buildings, the architect calculates the thickness of the walls, but this costs extra money. To save money, you can figure out how to calculate the necessary indicators yourself.

The rate of heat transfer by the material depends on the components included in its composition. The heat transfer resistance must be greater than the minimum value specified in the regulation "Thermal insulation of buildings".

Consider how to calculate the thickness of the wall, depending on the materials used in construction.

Consider how to calculate the thickness of the wall, depending on the materials used in construction.

Calculation formula:

R=δ/ λ (m2 °C/W), where:

δ is the thickness of the material used to build the wall;

λ is an indicator of thermal conductivity, calculated in (m2 °C / W).

When you purchase building materials, the coefficient of thermal conductivity must be indicated in the passport for them.

The parameter values for residential buildings are specified in SNiP II-3-79 and SNiP 23-02-2003.

Valid values by region

The minimum allowable value of heat conductivity for different regions is indicated in the table:

Each material has its own heat conductivity index. The higher it is, the more heat passes through this material.

Heat transfer rates for various materials

The values of heat conduction by materials and their density are indicated in the table:

The thermal conductivity of building materials depends on their density and humidity. The same materials made by different manufacturers may differ in properties, so the coefficient must be viewed in the instructions for them.

Calculation of a sandwich structure

When calculating a multilayer structure, sum up the thermal resistance of all materials

When calculating a multilayer structure, sum up the thermal resistance of all materials If we build a wall from various materials, for example, brick, mineral wool, plaster, the values \u200b\u200bmust be calculated for each individual material. Why sum up the resulting numbers.

In this case, it is worth working according to the formula:

In this case, it is worth working according to the formula:

Rtot= R1+ R2+…+ Rn+ Ra, where:

R1-Rn - thermal resistance of layers of different materials;

Ra.l - thermal resistance of a closed air gap. The values \u200b\u200bcan be found in table 7, clause 9 in SP 23-101-2004. A layer of air is not always provided for when building walls. For more information on calculations, see this video:

Based on these calculations, it can be concluded whether the selected building materials can be used, and how thick they should be.

Sequencing

First of all, you need to choose the building materials that you will use to build the house. After that, we calculate the thermal resistance of the wall according to the scheme described above. The obtained values should be compared with the data in the tables. If they match or are higher, good. If the value is lower than in the table, then you need to increase the thickness of the wall or insulation layer, and perform the calculation again.

If there is an air gap in the structure, which is ventilated by outside air, then the layers located between the air chamber and the street should not be taken into account.

How to perform calculations on an online calculator

To get the required values, it is worth entering into the online calculator the region in which the building will be operated, the selected material and the estimated wall thickness.

To get the required values, it is worth entering into the online calculator the region in which the building will be operated, the selected material and the estimated wall thickness.

The service contains information for each individual climate zone:

- t air;

- average temperature during the heating season;

- duration of the heating season;

- air humidity.

Indoor temperature and humidity are the same for each region

Indoor temperature and humidity are the same for each region Information that is the same for all regions:

- indoor temperature and humidity;

- heat transfer coefficients of internal, external surfaces;

- temperature difference.

In order for the house to be warm and maintain a healthy microclimate, when performing construction work, it is imperative to calculate the thermal conductivity of the wall materials. This is easy to do on your own or using an online calculator on the Internet. For more information on how to use the calculator, see this video:

For a guaranteed accurate determination of the thickness of the walls, you can contact the construction company. Its specialists will perform all the necessary calculations in accordance with the requirements of regulatory documents.

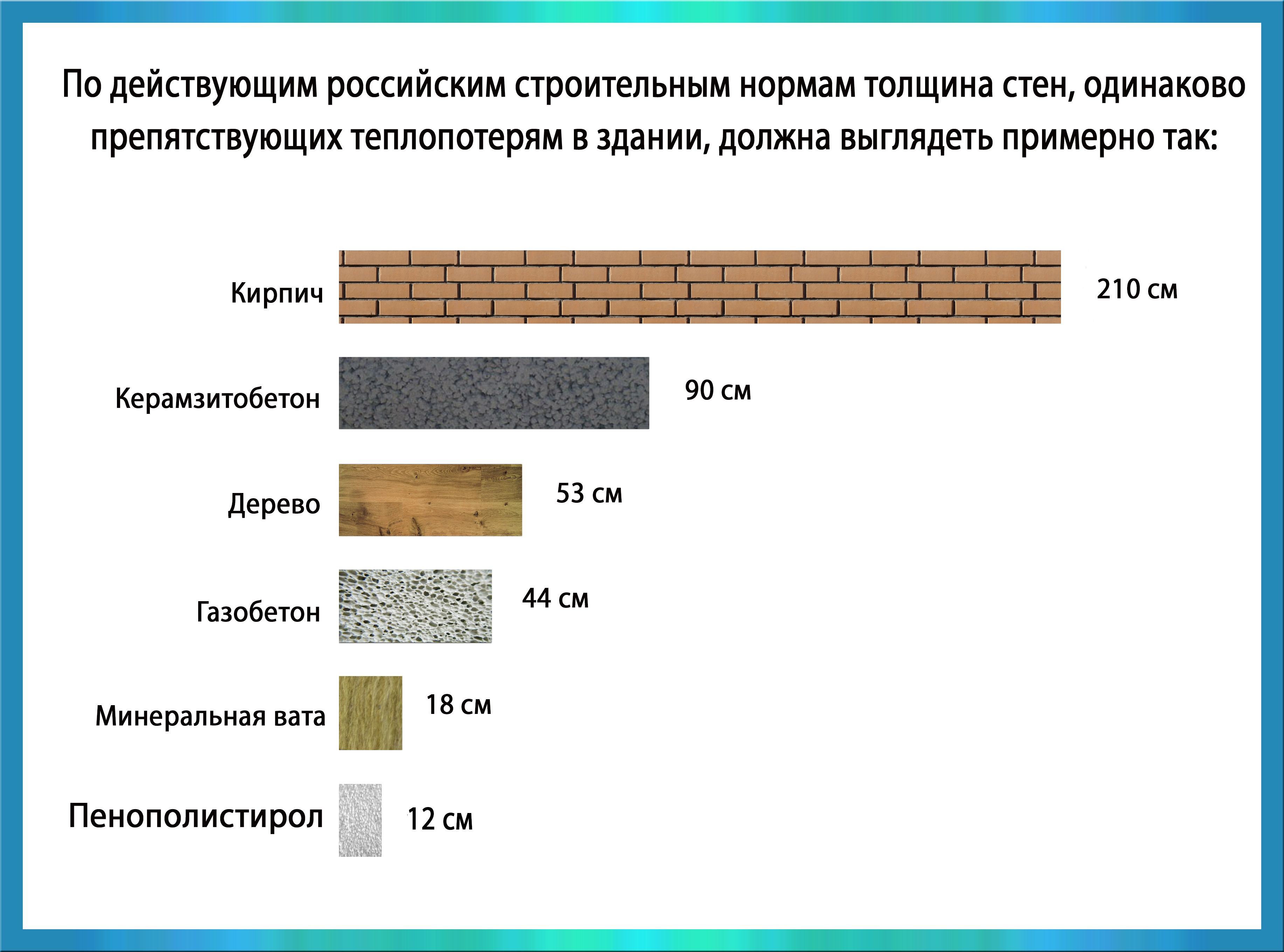

To build a warm house - a heater is required. Nobody is objecting to this. In modern conditions, it is impossible to build a house that meets the requirements of SNiP without the use of insulation.

That is, a wooden or brick house, of course, is possible to build. And they build everything. However, in order to comply with the requirements of Building Codes and Rules, its coefficient of resistance to heat transfer of walls R must be at least 3.2. And this is 150 cm.

Why, one wonders, to build a "fortress wall" of one and a half meters, when it is possible to use only 15 cm of highly efficient insulation - basalt wool or foam plastic to obtain the same indicator R = 3.2?

And if you do not live in the Moscow region, but in the Novosibirsk region or in the Khanty-Mansiysk Autonomous Okrug? Then for you the heat transfer resistance coefficient for the walls will be different. What? See table.

Table 4. Rated resistance to heat transfer SNiP 23-02-2003 (document text):

We carefully watch and comment. If something is not clear, ask questions through or write to the site editor - the answer will be in your e-mail or in the NEWS section.

So, in this table we are interested in two types of premises - residential and domestic. Residential premises, this, of course, is in a residential building, which must comply with the requirements of SNiP. And household premises are insulated and heated baths, a boiler room and a garage. Sheds, pantries and other outbuildings are not subject to insulation, which means that there are no indicators for the thermal resistance of walls and ceilings for them.

All requirements governing the reduced resistance to heat transfer according to SNiP are divided by region. The regions differ from each other in the duration of the heating season in the cold season and the extreme negative temperatures.

A table showing the degree-days of the heating season for all the main cities of Russia can be seen at the end of the material (Appendix 1).

For example, the Moscow region belongs to the region with D = 4000 degree-days of the heating period. For this region, the following indicators of SNiP heat transfer resistance (R) are established:

- Walls = 2.8

- Ceilings (floor of the 1st floor, attic or attic ceiling) = 3.7

- Windows and doors = 0.35

To make, we use the calculation formula and used in construction. All these materials are available on our website - available by clicking on the links.

With calculations for the cost of insulation, everything is extremely simple. We take the resistance of the wall to heat transfer and select such a heater that, with its minimum thickness, will suit us according to the budget and fit into the requirements of SNiP 23-02-2003.

We are now looking at the degree-days of the heating season for your city where you live. If you live not in the city, but nearby, you can use values 2-3 degrees higher, since the actual winter temperature in large cities is 2-3 degrees higher than in the region. This is facilitated by large heat losses in heating mains and the release of heat into the atmosphere by thermal power plants.

Table 4.1. Degree-days of the heating season for the main cities of the Russian Federation (Appendix 1):

To use this table in calculations where the normalized resistance to heat transfer appears, you can take the average values of the internal temperature of the premises at + 22C.

But here, as they say, the taste and color - someone likes to be warm and sets the regulator in his air to + 24C. And someone is used to living in a cooler house and keeps the room temperature at + 19C. As you can see, the cooler the constant temperature in the room, the less gas or wood you use to heat your home.

By the way, doctors tell us that living in a house at a temperature of +19C is much more beneficial than at +24C.

Instruction

The determination of the thermal conductivity of materials is carried out through the coefficient of thermal conductivity, which is a measure of the ability to transmit heat flow. The lower the value of this indicator, the higher the insulating properties of the material. In this case, the thermal conductivity does not depend on the density.

Numerically, the value of thermal conductivity is equal to the amount of thermal energy that passes through a section of material 1 m thick and 1 sq. m in area in 1 second. In this case, the temperature difference on opposite surfaces is assumed to be 1 Kelvin. The amount of heat is the energy that a material gains or loses when heat is transferred.

The formula for thermal conductivity is as follows: Q = λ*(dT/dx)*S*dτ, where: Q is the thermal conductivity; λ is the thermal conductivity; (dT/dx) is the temperature gradient; S is the cross-sectional area.

When calculating the thermal conductivity of a building structure, it is divided into components and their thermal conductivity is summarized. This allows you to determine the measure of the ability of a house structure (walls, roofs, windows, etc.) to pass heat flow. In fact, the thermal conductivity of a building structure is the combined thermal conductivity of its materials, including air gaps and a film of outside air.

Based on the value of the thermal conductivity of the structure, the volume of heat loss through it is determined. This value is obtained by multiplying the thermal conductivity by the calculated time interval, the total surface area, and also by the temperature difference between the outer and inner surfaces of the structure. For example, for a wall with an area of 10 square meters with a thermal conductivity of 0.67 at a temperature difference of 13 °, heat loss in 5 hours will be 0.67 * 5 * 10 * 13 = 435.5 J * m.

The thermal conductivity coefficients of various materials are contained in the thermal conductivity table, for example, for vacuum it is 0, and for silver, one of the most thermally conductive materials, 430 W / (m * K).

During construction, along with the thermal conductivity of materials, the phenomenon of convection, which is observed in materials in liquid and gaseous states, should be taken into account. This is especially true when developing a water heating and aeration system. To reduce heat loss in these cases, transverse partitions made of felt, wool and other insulating materials are installed.

When installing heating devices in residential buildings, industrial and office buildings, it is often necessary to know the volume systems heating. It is good when the customer provides such data, but this does not always happen. There are methods for estimating the total volume systems and its individual components depending on the power.

Instruction

To calculate the volume of coolant in the heating system during its replacement or reconstruction, use the special calculation tables available in reference books. So, one section of aluminum radiators has a coolant volume of 0.45 liters, a section of new cast-iron batteries - 1 liter, a section of old cast-iron batteries - 1.7 liters. In one running meter of a pipe with a diameter of 15 mm - 0.177 liters of coolant, and if pipes with a diameter of, for example, 32 mm are used, then the volume will be 0.8 liters and so on.

One of the common cases when you want to find out the volume systems heating- installation of an expansion tank and make-up pumps. Total volume systems heating at the same time, calculate by adding the volumes of the boiler, heating appliances (radiators) and the pipeline part systems according to the formula: V = (VS x E) / d, where V is the volume of the expansion tank; VS - total volume systems(boiler, radiators, pipes, heat exchangers, etc.); E is the expansion coefficient of the liquid (in percent); d is the efficiency of the expansion tank.

When calculating, take into account such a factor as the expansion of the liquid. For water systems heating it is approximately 4%. If ethylene glycol is used in the system, the expansion coefficient will be approximately 4.4%.

For a less accurate volume calculation systems heating use the power based formula: 1 kW = 15 hp. For such approximate calculations, you need to know the power systems heating, while the need to calculate in detail the volume of pipelines, radiators, the boiler itself and other elements systems disappears. Example: if the heating power for a residential building is 50 kW, then the total volume systems heating VS is calculated as follows: VS \u003d 15 x 50 \u003d 750 liters.

When making calculations, keep in mind that in the case of application in the system heating new and modern radiators and pipes volume systems will be somewhat smaller. Detailed information can be found in the technical documentation of the equipment manufacturer.

Sources:

- Calculation of membrane expansion tanks

- "Designer's Handbook", I.G. Staroverov, 1990

- heating volume

Timber beams are the most economical option for a home. They are very easy to install and to manufacture. Compared to reinforced concrete and steel beams, wooden beams have low thermal conductivity. But any beams should be carefully calculated and installed.

You will need

- - ruler;

- - calculator;

- - planer.

Instruction

Calculate the bending strength of the section, given the ratio of 5:7, which means - if you take in height beam 7 measures, then you need to take 5 measures in width. A beam with this ratio will be very strong in both torsion and bending. Be aware: if you take the width more than the height of the beam, then an excessive deflection will appear. If you take it the other way around, then there will be a bend to the side.

Permissible beam deflection floors count based on this ratio - 1/200 or 1/300 of the length of the beam. For example, if you take beam , whose length is 600 meters, then after calculations we get that the deflection is 2 or 3 centimeters.

Sharpen with a planer beam from the side where the beam faces down, by the amount of allowable deflection. That is, give it a kind of arch appearance. So you will ensure that the ceiling will not go down with a “bubble”, because in the middle the beam will become thinner, and everything will remain the same at the edges.

Install beam - you can immediately see that it is arched to the top with an arc. This will not be constant, from the action of beam loads floors straighten up.

Take into account the own weight of the beam, because it also gives a load. For interfloor floors, choose beams with a weight load of 190 kg / m2, but not more than 220 kg / m2, operational (temporary) load - 200 kg / m2. Lay beams floors along the span section, which is shorter. The installation step is equal to the installation step of the frame racks.

Related videos

note

Do not make floor beams more than 20-30 centimeters, so as not to get a floor thickness of 0.5 meters - this is an irrational use of the space of a house under construction.

Useful advice

It should be noted that the optimal span (taking into account that the beam is wooden) is taken at least 2.5 meters, but not more than 4 meters. The beams that you laid side by side and they are of the same height summarize their loads. In order for the floors to withstand a large load, lay the beams vertically, that is, one on top of the other and do not forget to fasten them together.

Sources:

- Cover beams. Interfloor and attic floors. Calculation of the section and length of floor beams

When erecting a building, be sure to remember about its thermal insulation. Areas where building rules for laying insulation are violated are called cold bridges. Usually, moisture, or a “dew point”, appears in them from the side of a higher temperature (indoors), which brings about the formation of fungus and mold. Illiterate warming of your home will bring depletion of the family budget.

Instruction

Determine the design of the outer walls. It depends on the following factors: climatic, economic, design features of the object and others. Determine the surface finish of the exterior walls (interior and exterior). The scheme of exterior and interior decoration depends on the decision of the exterior and interior of the building. This automatically adds several layers to the wall thickness of the house.

Calculate the heat transfer resistance of the selected wall (Rpr.) This value can be found by the formula, and you need to know the material from which the wall is made and its thickness: Rpr.=(1/α (c))+R1+R2+R3+(1 /α (н)), where R1, R2, R3 - heat transfer resistance of each layer of the wall, α (v) - heat transfer coefficient of the inner surface of the wall, α (n) - heat transfer coefficient of the outer surface of the wall.

Calculate the minimum allowable heat transfer resistance (Rmin.) for the climatic zone where construction is underway using the formula R=δ/λ, δ is the thickness of the material layer in meters, λ is the thermal conductivity of the material (W/m*K). Thermal conductivity can be seen on the packaging of the material or determined from a special table of thermal conductivity of the material, for example, for PSB-S 15 foam plastic, with a density of up to 15 kg / m3, it is 0.043 W / m3, for mineral wool, with a density of 200 kg / m3, - 0, 08 W/m.

Thermal conductivity - the ability of a material to exchange heat with the environment. The higher the thermal conductivity, the colder the material. The highest thermal conductivity is in reinforced concrete, metal, marble, the lowest is in air. As a result, materials based on air, such as expanded polystyrene, are extremely warm. 40 mm foam plastic = 1m brickwork. The coefficient has a constant value for each climatic zone, it can be found in the reference book DBN V.2.6-31:2006 (Thermal