Calculator of walls from gas silicate blocks. The choice of foundation for the future building. Adhesive costs

Obtained by mixing sand, water and blowing agents. Round and oval pores with different diameters are evenly distributed on its plane and inside. The quality of the starting material depends on their quantity and uniformity of distribution. Due to the presence of pores throughout the plane, this material has excellent heat-shielding characteristics. The original purpose of gas silicate was to use it as a heater. Further developments led to the conclusion that it is possible to completely build houses from such blocks. Aerated concrete is a lightweight material, which allows you to lift it to a height without much effort. An important factor The popularity of cellular concrete is its low cost and excellent construction qualities.

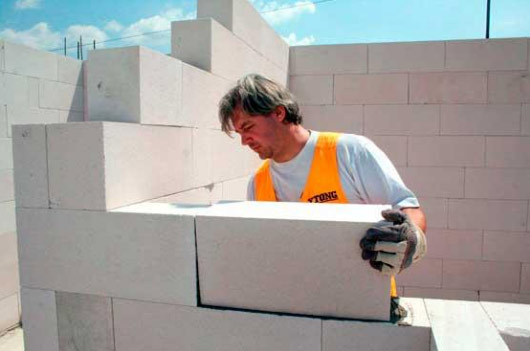

The dimensions of aerated concrete allow you to quickly build the walls of the dwelling

The dimensions of aerated concrete allow you to quickly build the main, load-bearing walls and interior partitions. There are many types of aerated concrete blocks with different thickness from 50 to 400 mm. Most gas blocks are 600 mm long and 200 mm high. However, in direct structures this does not matter, you can put this block in any way, achieving the required thickness. Some manufacturers produce aerated concrete blocks with a convenient tongue-and-groove design, which ensures the construction of a house like a children's designer, only with the use of glue for the blocks. The dimensions of aerated concrete can be 600x300x (100 or 200,250,300, 400) or 400x300x (100 or 150,200,250,300). Different manufacturers have different size ranges.

Wall thickness

Most experts and owners of houses made of foam materials believe that the most favorable will be a house with a load-bearing wall thickness of at least 60 cm (in this case, an aerated concrete block, a layer of insulation, etc. are taken into account). Many are inclined to believe that a thickness of 40 cm is enough for a modern aerated concrete house. Interroom partitions can be of different thicknesses. If you want a large space, thin walls are installed, with aerated concrete dimensions of 600x200x50. If you need to achieve good sound absorption, and there are no restrictions on the area - interior walls can be 10-40 cm.

Aerated concrete blocks  building a concrete house

building a concrete house ![]()

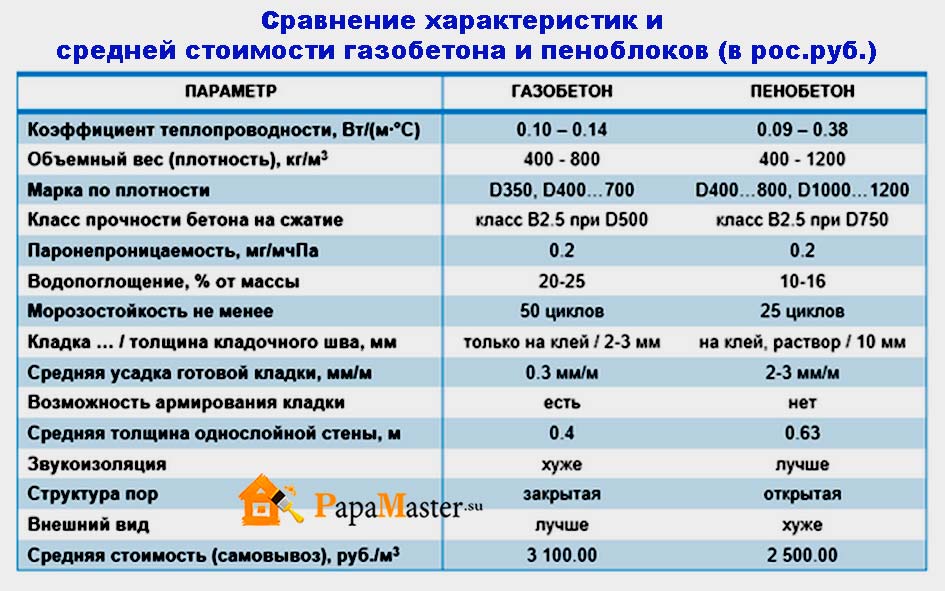

comparison of characteristics and average cost of aerated concrete and foam blocks

comparison of characteristics and average cost of aerated concrete and foam blocks

Approximate estimate - the cost of a house made of aerated concrete

To calculate the cost of a house made of aerated concrete, they are determined with the size and number of storeys of such a structure. Then they calculate how many blocks will fit along the length and height of the walls. AT one-story house with dimensions of 12x12 m, the walls will be 48 m long. We take a height of 3 meters. Having chosen the size of aerated concrete 600x200x400, we determine required amount blocks with a thickness of 400 mm. The construction of 48 meters of walls with a height of 3 meters will take 1000 blocks. This number is determined based on the calculations: 48x3 = 144 m2 - the area that the walls will occupy. From this indicator, the quadrature is subtracted, which falls on windows and doors, for example, 24 square meters. m. If the area of one aerated concrete block is 0.12 sq.m (0.6x0.2), then the required number of blocks will be (144-24): 0.12 \u003d 1000 pieces. When choosing a different size of aerated concrete 600x300x300, the need will be 667 pieces, which is calculated in a similar way. (144-24): 0.18=667. The surface area of one aerated concrete block is 0.6x0.3=0.18 sq.m.

The industry quotes block prices based on cost per unit or per unit. square meter. One gas block 600x200x400 is 0.6x0.2x0.4 (0.048 cubic meters). 1000 such blocks will be 48 cubes. With the cost of a cubic meter of such material being 3,500 rubles ($98), you will need 48x3,500=168,000 rubles ($4,667) to build the main walls of the house. Based on the calculations, one block costs 168 rubles or $4.67. These indicators can come in handy when buying a few missing blocks. Although usually, the amount is calculated with a small margin, because there are cases of unintentional breakage of the material. Wholesale building bases release aerated concrete in packs with a certain amount. If desired, they can break the packaging and release a few blocks to the customer, but most often in such cases they do not waste time on trifles. When blocks with a length of 60 cm, a height of 30 cm and a thickness of 30 cm are taken as the basis, then the construction of load-bearing walls will require 117,300 rubles ($ 3,258). Here are the calculations: one such block is 0.6x0.3x0.3 = 0.054 cubic meters. The total need for blocks with a thickness of 30 cm is 0.054x667 = 36 cubic meters. The price of such blocks is slightly lower, 3450 rubles per cube ($ 96). 34x3450=117300 rubles ($3258). In this case, the walls will be 10 cm thinner, which plays essential role during further operation.

construction stages that affect the cost of houses from aerated concrete blocks 1

construction stages that affect the cost of houses from aerated concrete blocks 1  construction stages that affect the cost of houses from aerated concrete blocks part 2

construction stages that affect the cost of houses from aerated concrete blocks part 2  important to know when building a house from aerated concrete part 1

important to know when building a house from aerated concrete part 1  important to know when building a house from aerated concrete part 2

important to know when building a house from aerated concrete part 2

Internal partitions

For the construction of internal partitions, you can take thin blocks. , 10-15 cm thick, will be enough. The price of such blocks is less - 3150 rubles per cubic meter ($88). If the partitions occupy a total of 50m, then we need to build 50x3 = 150 sq.m of partitions. This will require 1250 pieces of gas silicate, with a length of 60 cm and a height of 20 cm. If in one such gas block with a thickness of 10 cm - 0.012 cubic meters, then 1250x0.012 = 15 cubic meters of gas blocks for the construction of partitions. They will cost 15x3150=47250 rubles ($1313).

Adhesive costs

For laying gas blocks, a special glue is required, the consumption of which is determined based on the need for 1.5 kg of glue per square meter. For the construction of the main walls and partitions, you will need 405 kg of glue, which is calculated based on an area of 120 + 150 \u003d 270 sq.m. We multiply the consumption rate by the area 1.5x270 \u003d 405. Sixteen 25 kg bags of glue should be enough. If a bag of glue costs about 250 rubles ($ 7), then 4,000 rubles ($ 111) will be needed for the entire construction. At the same time, you can make a little mistake, it all depends on the specifics of the bricklayer's work.

The cost of erecting load-bearing walls and internal partitions

Based on our calculations, to determine the cost of an aerated concrete house, we need a capital of 219,250 rubles. ($ 6090) (only for the construction of load-bearing and internal walls from aerated concrete). This figure consists of the construction of load-bearing walls 168,000 rubles ($4,667), the construction of partitions 47,250 rubles ($1,313), the cost of glue 4,000 rubles ($111). This does not yet include the cost of masonry, transport costs associated with delivery and unloading, cladding, insulation (if desired). In addition, a reinforcing belt of the entire perimeter of the house is needed. It costs more than a layer of blocks.

Full calculation of the cost of aerated concrete houses

- floor slabs;

- windows and doors, accessories;

- plaster cost;

- installation of screeds and floors;

- laying communications.

The cost of a house made of aerated concrete should include the costs associated with the development of design estimates. If, in monetary terms, we conditionally break the house under construction into parts, then we get the following result:

- 1st place - foundation equipment;

- 2nd place - erection of walls and their external cladding;

- III place - arrangement of the roof;

- IV place - interior wall cladding and installation of floors.

These figures are debatable. Each customer has its own requirements, especially those related to interior decoration. Often a huge amount of money is spent on it, exceeding the entire construction. Therefore, it is very difficult to predict the final cost of a house made of aerated concrete. The price of a rough house made of gas silicate can be determined more accurately.

Different opinions about the effectiveness of aerated concrete houses

There are many opinions about the effectiveness of the construction and operation of aerated concrete houses. Many owners were satisfied with the built house and do not experience any inconvenience. Some do not like the fact that such a house cools down quickly, although it quickly gains warmth. It does not suit the owners that it is scary to hang heavy objects on the walls without reinsurance.

Before starting construction, it is advisable to correctly calculate how much aerated concrete is needed for a house or cottage. This optimizes the initial investment in construction, eliminates overpayment for surplus, downtime for specialists during the construction of the building. You do not need to spend additional money and time to deliver the missing materials.

Specialists of the company "ZBIK" in Irkutsk will provide you with professional assistance in the calculations. But initially, you can figure out the numbers yourself by calculating gas blocks for building a house on our online calculator.

Available material types

The dimensions of gas silicate blocks are clearly regulated by the manufacturer. In the case of using materials of our production, you will deal with cellular structures of three standardized dimensions:

- 198x295x598mm, weight of one - 22 kg - type "1";

- 98x295x598mm, weight of one - 11 kg - type "2";

- 398x295x598mm - weight 44 kg - type "3".

Accurate dimensions and the correct geometric shape simplify both calculations and the construction process itself. You can easily calculate aerated concrete for a house, having decided on the parameters and layout of the building.

The practice of several decades of use has shown that cellular gas-filled blocks are an inexpensive, reliable and practical building material. The use of a non-autoclaved gas block in wall structures further reduces the total cost of construction without losing its performance.

Initial data

- The total length of all walls along the foundation is the perimeter of the building.

- The height of the building - is necessary to calculate the area of the wall surface. Also, knowing the height of the walls and the size of an individual element, you can determine the row of masonry;

- total area wall masonry - is determined by the product of the perimeter by the height of the building, minus the total area of \u200b\u200ball window and door openings. By the way, this value will correspond to the area of \u200b\u200bthe required insulation;

- The thickness of the walls - the method of installation and the initial choice of the size of the elements depend on it. This parameter is also affected by the thickness of the adhesive (mortar) joint. But based on the permissible small thickness of the adhesive layer (3-4 mm). This parameter does not significantly affect the final size of the building;

- The number of elements is a calculated value determined by the initial parameters of the building.

- The total mass of gas silicate and the total volume are necessary to determine the optimal method for delivering materials to the facility. When determining the load on the foundation, the mass of the adhesive mortar and the masonry mesh is added to the total mass of the "bricks".

When determining the number of elements for internal partitions, it is necessary to separately calculate according to a similar algorithm. In this case, the thickness of the partition walls is usually determined by the height of an individual element, which is laid on the side face, that is, in half of the block.

Important! If the gables of your house are also planned to be built from a gas block, you will also have to calculate their area.

Masonry mesh - it reinforces the masonry, enhancing the mechanical strength of the entire building. Usually each row of masonry is reinforced.

Alternative simplicity

Complete calculation of aerated concrete for a house with an online calculator Everything is simple here...

- Choose one of the three types of block produced by "ZBIK".

- Sum up the lengths of all the walls of the house and enter the value in meters.

- Determine separately the total area of all windows and all doorways.

- Choose wall thickness. The option "2x198 mm" can be used when organizing additional insulation in a two-layer wall structure.

- You automatically receive the required total volume.

Important! Please note that all initial parameters are indicated in meters and square meters.

Further on the gas blocks page, according to the table, you can calculate the estimated cost of the material depending on its type and unit price, or you can contact our manager, and he will advise you on all issues free of charge.

Modern materials used in the construction of houses have similar properties.

Today there are several types.

The most common of them are foam concrete and aerated concrete.

Both building materials belong to the class of cellular.

With equal density and similar composition, the second material is more environmentally friendly and durable.

Its service life is almost twice as high.

Building a house from aerated concrete is a fairly fast process.

The main advantages of the material

Aerated concrete is obtained by autoclave curing at high temperature and humidity. It has a number of significant advantages:

- has a small weight;

- consists of high quality and environmentally friendly components: water, sand, cement and lime with the addition of aluminum powder as a blowing agent;

- does not ignite and does not support combustion;

- easy to process;

- strong and durable;

- moisture resistant.

Comparative characteristics of GB and PB

Despite the fact that the raw materials for both materials are similar basic components, they differ in production technology and different properties of the final product.

The main components of GB and PB:

- water;

- lime;

- cement.

At its construction competitor, porization is achieved by a chemical method - in the process of its production in an autoclave, where high temperatures and pressure, with the addition of a blowing agent.

Hardening occurs naturally. The material shrinks, which leads to cracks.

Finally, it is more difficult to process than GB. The production technology is more complicated, since the autoclave method is used. Due to this, the performance properties of the material are improved.

Many people prefer to trust the construction of aerated concrete houses to professionals who do not make mistakes.

In the manufacturing process, GB acquires its main characteristics: durability, strength, reliability.

According to these indicators, the material is in the lead. Its endurance and rigidity is higher than many other building blocks.

GB is able to maintain its shape and volume during operation.

The cost of building a house from aerated concrete is about 20% higher than that of its counterpart.

Calculation of the average cost of a house made of aerated concrete

If the house is built from blocks with standard sizes: 400x250x600, then the construction of walls may require materials for a total of approximately 195,156 rubles.

It should be borne in mind that the glue will help speed up the construction of a residential building from GB and provide the walls with additional thermal insulation, only if it is of the right consistency.

If a private trader plans to build a house from aerated concrete, then it is important to know how much it is needed.

For this, simple calculations can be made. Let's assume that the walls have dimensions: 6x9x3m.

- First, calculate the perimeter. Add the length and width of the walls and multiply by 2.

- To calculate the area, the resulting value is multiplied by the height: 30x3 = 90 m2.

- Now it is necessary to calculate the area of windows and doors. Subtract the final figure from 90m2. Suppose a house has 2 doors and 10 windows. Their area is 22 m2.

- So, after subtraction, the total is 68 m2.

- Thereafter the final area must be divided by the length and height of the blocks: 68:0,400:0,600=283.

The price of the brigade for laying

The average cost of laying one m3 by a team of professional workers will cost the customer about 1,512 rubles.

The full scope of work will cost the private owner 84,084 rubles. In many ways, the selected building materials and the construction option will affect the final estimate..

At the same time, the cost of a box of aerated concrete houses is about 14,584 rubles per square meter. As an example, a suburban one-story Vacation home with attic.

All calculations presented in the article are approximate.

One of the varieties of aerated concrete, characterized by high strength characteristics, is called a sibit. This material resembles wood in some of its properties. It is also lightweight, breathable and retains heat well. According to the thermal insulation characteristics, Sibit is 3 times better than brick. As a result, the Sibit house retains heat well in the cold season and does not allow the rooms to heat up in the hot summer. In our article, we will describe the features, advantages and disadvantages of this material, and also tell you how to build a house with your own hands from Sibit.

Material Features

From this type of aerated concrete, you can build both a multi-storey building and an ordinary country house from sibit. At the same time, this material can be used not only for the construction of external and load-bearing walls, but also for the installation of reinforced panels or ceilings.

The foundation for a house made of sibit can be lightweight due to the low specific gravity of the material. As a result, you will get significant savings on materials, the volume of earthworks will decrease, which means that the construction time will increase.

In addition, Sibit house designs are very popular due to the high thermal insulation characteristics of the structure and the optimal microclimate that is favorable for humans, which is formed in the house due to the natural microcirculation of air in the walls.

The basis of Sibit is aerated concrete. The hardening process of this material takes place in a special autoclave. The result is a porous, lightweight and durable material that compares favorably with brick and concrete.

Advantages and disadvantages

Before ordering a house project from Sibit, it is worth exploring the pros and cons of this material in order to make right choice. Among the advantages of Sibit, the following qualities are worth mentioning:

- Finished houses made of this material are distinguished by high heat and sound insulation characteristics. The thermal insulation performance of the material is 3-4 times higher than that of traditional bricks. If you calculate how much money you need to heat an ordinary brick house, then by heating two-storey house from sibita, you can save up to 30 percent.

- Thanks to the cellular structure, a house built of sibit has a favorable microclimate. The material retains heat well. In this regard, the building is very similar to a house made of timber.

- To make sibit, only components of mineral origin are used, so it can be argued that a country house made of sibit or any other building made from this material is an environmentally friendly housing.

- This is a non-combustible material.

- The construction of houses from Sibit is beneficial in that the building is being built much faster than brick house. It's all about block size. If you calculate how many blocks you need to build a house, then their number will be many times (8-10) less than traditional bricks.

- Transportation and laying of material also does not cause difficulties. As a result, you can build a small country house from Sibit with your own hands without using construction equipment.

- The material is easy to handle. It can be easily cut with a hacksaw to the desired size.

- You will be able to reduce the cost of arranging the foundation by two or even three times. All this thanks to a small specific gravity material.

- To build a country house from Sibit, you need much less labor. The thing is that the dimensions of the Sibit block are 6 x 2.5 x 2 dm, and the weight is 18 kg. It can be equated to 20 bricks.

- According to thermal engineering calculations, the thickness of the outer brick wall should be 8 dm excluding thermal insulation material, while enclosing structures made of the described variety of aerated concrete can be 5 dm thick.

- Due to the porous structure, moisture from the room quickly evaporates, which helps to maintain an optimal microclimate.

- Reinforced floor slabs can be made from Sibit, which will not be inferior in strength to reinforced concrete structures. So, each square meter of such a plate can withstand a load of 8 c.

Among the shortcomings of the material, it is worth noting the following points:

- The main disadvantage is the low strength of the material, especially when compared with concrete or brick.

- It is not recommended to hang cabinets, shelves, heavy metal structures, heaters, etc. on partitions and walls made of Sibit. To install them, you need to get special fasteners.

- When building a house, it is very important how many floors you plan to build. So, one-story houses from sibit do not need additional reinforcement, while for construction above 5 floors you will have to make a strong frame.

- Often, developers have a question about how to plaster walls. The thing is that in order to protect porous walls from destruction, it is necessary to apply special vapor- and moisture-proof compounds. If the walls are plastered incorrectly, then the open pores of the material will cause a decrease in the thermal insulation qualities of the enclosing structures and their subsequent destruction.

Attention: the construction of a house from this type of aerated concrete should be carried out in spring or summer, when the temperature is within +5 ... + 25 ° С. If the temperature rises above the specified limit, the blocks will have to be additionally moistened before laying.

Design

There are different brands of sibit. All products are durable and thermally conductive. In order to use Sibit, it is better to take aerated concrete products, the density of which is 1000 kg / m³. They are ideal for creating load-bearing and enclosing structures. If you are building a house with an attic, then to complete it or equip a bare roof, you will need blocks with a density of 300 kg / m³. To make internal partitions, it is better to use elements with a density in the range of 500-900 kg / m³.

When choosing house projects from a photo, it should be borne in mind that the facade decoration used is directly related to the use of one or another brand of gas blocks. The thing is that when using some brands of Sibit, you may need additional protection of the walls from the negative effects of the environment.

Important: to perform waterproofing of walls, it may be necessary to treat with special compounds, special plaster, cladding decorative material. When fixing the facing layer, it is necessary to leave a ventilation gap between the wall and the finish.

When designing houses from aerated concrete blocks, it is very important to make a sufficiently rigid foundation to completely eliminate the risk of wall deformation and cracking. That is why, most often, tape monolithic bases are equipped for such structures.

Mounting sequence

If you want to build a small square house, then a 6 x 6 m building will be enough for a family of 2-3 people. To increase the usable area of the house to 100 sq. m., you can use a small extension, in which it is better to place the kitchen and bathroom, as well as attic floor. If your family has 4-5 people, then it is better to equip a two-story house measuring 6 x 8 m, where the living area will be at least 100 squares.

Foundation

To perform a strip base, you must first prepare the construction site by clearing it of debris and unnecessary plantings. Further work is carried out in this order:

- We carry out a breakdown of the future structure on the ground.

- After that, we dig trenches or a foundation pit, if the house is with a basement.

- The bottom of the trench is carefully leveled and rammed.

- At the bottom we make a pillow of gravel and sand, which we also ram well after wetting with water.

- After that, we proceed to the installation of formwork. It should rise above the ground by at least 30 cm.

- We make a reinforcing cage and install it in the formwork on a pre-filled and hardened layer of concrete 5 cm high.

- We pour concrete and ram.

- Formwork can be removed after 5-7 days.

Walls

Before starting the installation of walls, it is necessary to make a horizontal waterproofing of the base. For this on concrete surface bases we lay two layers of roofing material on bituminous mastic. To perform wall masonry, in addition to sibit and reinforcement, you will need the following tools:

- Master OK;

- wall chaser;

- rubber mallet;

- notched trowel;

- dust brush;

- planer for gas blocks;

- corner;

- saw;

- cord or fishing line;

- level.

Further work is carried out in the following sequence:

- The first row is laid on a cement-sand mortar. The height of the solution layer is 1 cm. First, the corner blocks are laid, and then a fishing line is stretched between them, and the remaining elements are placed. The first row needs to be laid perfectly even, so you will need a level, cord and mallet.

- Some blocks will have to be adjusted to size by sawing them.

- After completing the first row, you need to wait a few hours, during which the solution will have time to grab.

- All other rows are laid in the same way, that is, first the corner elements are mounted, then the cord is pulled and the middle blocks are mounted. It is only worth remembering that the blocks of the second row should be stacked with a shift of 8 cm. Also, in the second row, not a solution, but a special glue can be used to connect the blocks. We use a notched trowel to apply the adhesive. So you will achieve a more uniform seam, in addition, the drying rate of the glue is higher than that of the solution.

- In order for the binder solution to lay down more evenly and the adhesion to be stronger, the surface of the block can be processed with a planer, giving it a roughness.

- Each 3-4 row of blocks is necessarily reinforced. To do this, on the surface of the stacked blocks, several grooves are grooved, arranged in parallel. After cleaning from dust, fittings with a diameter of 10 mm are placed in the strobes. After that, glue or mortar is applied and the next row is laid.

Attention: it is not allowed to connect two reinforcement bars at the joints of blocks and at the corners of the masonry. Mandatory reinforcement is subject not only to the 3rd or 4th row of masonry, but also to the areas above the door and window openings, as well as the row on which the floor slabs will rest.

Overlappings

Laying of floor slabs is allowed only on a monolithic reinforced concrete armored belt. To make it, do the following:

- Blocks are cut to a thickness of 10 cm and stacked along the edges of the wall opposite each other. Thus, you will get a kind of fixed formwork.

- A reinforcing cage is placed inside the formwork.

- The space is then filled with concrete.

- When the concrete has gained the necessary strength, the floor slabs are laid. The ends of the plates are closed with ax blocks.

Tip: reinforced concrete slabs are not the only floor option, you can use metal or wooden beams or aerated concrete slabs.

Aerated concrete is a material widely used in modern construction due to the fact that it has high technical performance and convenient construction parameters. The technology of building a house from aerated concrete is completely unique due to the specific cellular structure of the material itself.

Such porosity is achieved due to the fact that aluminum powder is added to the solution for making blocks.

Developers prefer this particular building material because it has such advantageous qualities as:

- Small weight of piece materials due to their porous structure;

- Fast installation of light blocks;

- Low construction cost.

Features of aerated concrete houses

Artificially created material has a number of advantageous characteristics that determine its competitiveness in the modern market. The priority parameter of gas blocks is undoubtedly its low weight. The process of creating masonry with such lightweight blocks is noticeably simplified, which can minimize the time for building a building.

The construction of a turnkey aerated concrete house is a fairly popular service for construction companies today. Such popularity is achieved not only due to the speed and efficiency construction works, but also due to the cost-effective operation of buildings made of aerated concrete.

The following facts can be attributed to the features of this kind of structure:

- The minimum amount of energy spent on space heating during the cold season, in contrast to brick buildings;

Note! In order to minimize the additional costs of heating brick premises during the construction phase, a variety of heaters are laid. Aerated concrete masonry, in turn, does not need to carry out such work, while maintaining the standard thickness of masonry from blocks.

- Building a house from aerated concrete does not require the builder to have specialized skills or work experience;

- The large size of building blocks can significantly reduce the complexity of construction work;

- The insignificant weight of each piece element causes small costs for the transportation of material to the construction site;

- For the production of blocks from aerated concrete mortar, only safe, natural components are used, which indicates the safety of the product, both for people living in aerated concrete house and for the environment;

- Aerated concrete does not emit environment no toxins, harmful gases, vapors and suspensions;

- Aerated concrete is a non-combustible material, so it can be used on structures of structures of any fire safety class. Such masonry will perfectly resist fire and prevent its spread, and will also contribute to the self-extinguishing of the flame.

In the photo - a gas-block structure

The accuracy of the geometry of each piece product makes it possible to make laying with a minimum width of joints between elements of no more than 4 mm. Such a tight joining of masonry parts makes it possible to exclude such a phenomenon as cold bridges. In this way, the ability of the walls of the building to save heat inside can be preserved.

The thermal conductivity of aerated concrete blocks is 0.1-0.12, provided that there is no need to insulate thick walls. In addition to excellent thermal insulation parameters, aerated concrete has soundproofing characteristics.

Note! The ideal microclimatic indicators of an aerated concrete house are achievable due to the porosity and breathability of this material. The vapor permeability of aerated concrete masonry allows the building to be finished with any type of material that creates a ventilated facade. In addition, the blocks have a flat surface, which saves on finishing.

The cost of building a house from aerated concrete blocks

If you want to know how much it costs to build a house from aerated concrete, you should understand that the cost of building a residential building directly depends on such parameters as the density of the selected building material and the thickness of the walls of the structure being erected.

The smaller these parameters are, the lower the price will be and the larger the internal area of \u200b\u200bthe building being built. The calculation of this cost is usually made by the designer in the process of drawing up the project.

As previously noted, aerated concrete has a fairly low weight and its laying does not require much experience and special skills. It is thanks to these factors that each owner can take up the construction of the structure with his own hands, thus saving even more.

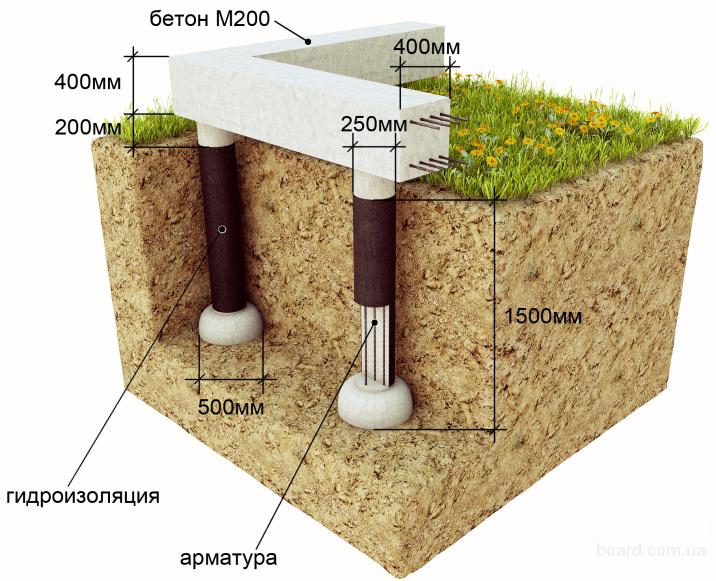

Choosing a foundation for a future building

In order to find out the answer to the question of how much it will cost to build a house of aerated concrete, you need to decide what kind of foundation the building will have.

Of course, all construction work begins with the selection of a building site.

Official data will determine:

- Type of soil on the site;

- depth of soil freezing;

- The level of occurrence of groundwater.

All these data must be known in order for the construction process to be successful, and the finished structure does not present unpleasant surprises.

The long operational period of the building is a parameter that should largely depend on the competent choice of the type of foundation and also its correct laying. The cost of building a house from aerated concrete directly depends on what kind of foundation structure will be chosen, so this issue should be approached very carefully.

Advice. Many, not very experienced and competent developers, assume that the lightness of the gas-block material does not require laying a solid foundation for the building. However, the fragility of this building material may indicate quite the opposite.

Foundation types

There are several types of foundations that are suitable as the basis for a gas block building:

- Columnar;

- Tape;

- Slab.

Columnar base of the house

In order to reduce the amount of work with the earth and the complexity of constructing structures of this type, bored piles are used.

The instructions for laying such products are as follows:

- Holes are prepared with the help of specialized equipment;

- Prepared piles are placed in the pits;

- Piles are poured with concrete raster.

The disadvantages of this design include small area coverage and low resistance to horizontal loads. Professionals categorically exclude the possibility of laying the foundation of this type for buildings, the design of which provides for the presence of a basement, basement or garage.

There are also some conditions and a certain sequence of laying, which must be observed during the construction of a columnar foundation:

- Piles are located in places of increased load and in the corners of the building. The optimal distance between the elements is 2 m;

- The laying depth of each pile should be 25 cm more than the soil freezing index;

- The distance between the posts is filled.

Strip foundation

This type of foundation is reinforced concrete structure built directly under the load-bearing walls of the building. This version of the base is perfect for building houses with a basement. The disadvantages of this type of construction include the complexity of laying this type of foundation.

The conditions for laying such a design include:

- Along the perimeter of the building, it is necessary to dig a trench with a depth of at least 0.5 m;

- A sand cushion 40 cm high with compaction is arranged in the trench;

- Wooden formwork is installed;

- Reinforcement is made;

- The concrete solution is poured.

Slab base

For aerated concrete buildings, the most suitable option is the construction of a slab foundation. In this case, monolithic concrete slab acts both as a foundation for the building and as a floor for the basement.

There are the following features of the arrangement of the foundation of this type:

- The optimal thickness of the slab for the base under the building should be about 40 cm;

- Arrangement of the drainage system;

- Laying waterproofing in two layers;

- Knitting a frame from reinforcement;

- formwork construction;

- Pouring, leveling and compacting the mixture.

Construction stages

Once the type of foundation has been chosen, it is time to start building according to the following steps:

- Laying the foundation of the selected type;

- Implementation of horizontal waterproofing by applying a cement-sand raster in order to level the surface for the installation of gas blocks;

![]()

- Laying aerated concrete, starting each row from the corner in the dressing, i.e. with an offset of half a block:

- Reinforcement of masonry with fiberglass mesh between layers of finishing materials;

- As a floor for such a building, aerated concrete slabs or concrete multi-hollow slabs can be used;

- The construction process is completed with the production of exterior and interior decoration.

Finally

- this is undoubtedly the most modern and economical solution for the construction of a durable and reliable structure. It is certainly possible to calculate the cost of this construction at the design stage, and this calculation can be done by a professional designer or developer on their own, using an application such as aerated concrete house construction calculator.

The only thing you can be sure of is that such construction will be many times cheaper than building the same building from brick or other building materials. And besides, such construction will be many times easier and will end much faster.

And the video in this article will allow you to learn even more about the construction of buildings from gas blocks.