Foundation on screw piles calculation of the pile field. Online calculator for calculating bored pile-grillage and columnar foundations

Please note that this calculation of the foundation is simplified and cannot take into account all the individual features of your project. To clarify them, our specialist will contact you shortly.

The calculator does not take into account the internal bearing wall of the building.

Our service allows you to pre-calculate the screw foundation in order to estimate its cost in advance. If you require installation work, a team of experienced builders will be sent to the site, who are fully equipped with the necessary equipment, including generators and water tanks. After you specify a place for your future pile foundation, the builders will begin installation work. You have the opportunity to accept work at the end of the day and discuss with the foreman your questions regarding the pile foundation. Installation of the foundation up to 25 piles lasts only 1 day. We give a 10-year warranty on the foundation made by our specialists.

Accurate calculation, during which the cost is determined screw piles for the foundations of houses and other structures, is performed online based on the parameters entered by the customer. For this, a convenient and visual service is provided.

To calculate the cost of the foundation, enter the necessary data on the soil, dimensions, type of structure and its parameters into the calculator. If you have any additional questions, please ask our specialists. They will help you figure out and correctly calculate the screw foundation. Contact numbers are listed at the top of our website.

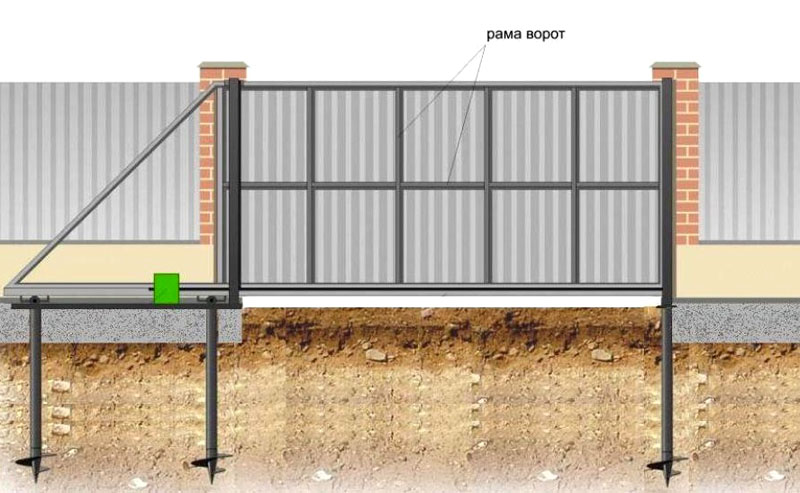

The number of piles. Usually the calculation is carried out on the assumption that the distance between the piles cannot exceed 3 meters. Thus, for a small foundation one-story house 6x6 meters, nine piles are enough. However, for a two-story building, it is better to place them at a distance of 2-2.5 meters from each other.

Pile diameter. It all depends on the potential load of the foundation. Screw piles with a diameter of 89 mm are suitable for an arbor, and for a house you need to choose classic 108 mm ones.

Tip type. The tip of the pile can be welded or cast. The specific option is selected based on the characteristics of the soil. Support elements with a cast tip will cost a little more, but their cost is offset by high anti-corrosion characteristics.

Length. The cost of screw piles, of course, is directly affected by their length. In most cases, it is 2.5 meters, but a specialist in without fail must conduct test drilling to determine the exact lengths of the piles for a particular foundation.

The presence and size of the heads. The heads are welded over the piles and serve as a support for the grillage slab or beam.

The next step is to determine the cost of the binding. Pile tying may be necessary if it is necessary to provide additional stability in the horizontal plane. For example, tying is desirable if the height of the piles above ground level exceeds 50 cm or in case of unstable peat soils. However, even in general case tying piles is never superfluous, since this operation significantly increases the structural strength of the foundation.

In the final determination of the cost of work, additional factors are taken into account: the need to provide installation services, the distance to the site (fuel costs), the availability of electricity at the site (it is necessary to compensate for the costs of delivery and operation of a portable diesel generator).

In areas with shaky, weak soils preferred species foundations for houses and structures - pile and pile-grillage. In particular, the construction of country houses in the suburbs of Moscow, St. Petersburg and many other cities in the European part of Russia is carried out on these foundations.

The installation of the pile foundation takes place in three stages:

1. Preparatory: drawing up a project, testing piles, calculation required amount material.

At this stage, the type of foundation, the type of piles, their number, technical parameters and the nature of the location are determined.

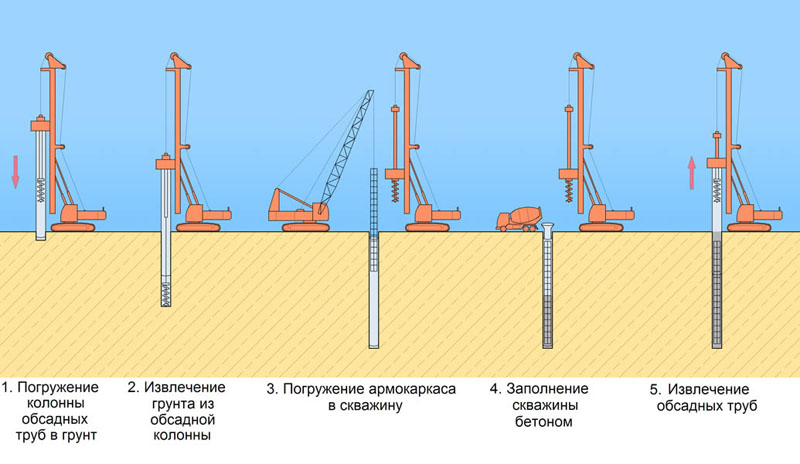

2. Pile driving. Depending on the volume and complexity of the work, it can be done manually or with the use of machinery. There are the following main methods of piling:

- shock;

- vibration:

- vibroimpact;

- screwing (for screw piles);

- drilling (for bored piles).

The location of piles can be single, tape, cluster, continuous, in the form of a field (in stripes or in a checkerboard pattern).

After immersion, as a rule, chopping / cutting of heads follows.

3. The construction of the grillage.

The project may include the following grillages: monolithic, prefabricated, prefabricated-monolithic. They also differ in the degree of deepening: low (recessed into the ground), elevated (at the level of the ground surface), high (above the ground level).

What is the price of a pile foundation

Pile foundation price is made up of the following numbers:

- Drawing up a project and budget.

- Piling test.

- The cost of the piles themselves.

- The cost of their transportation and immersion.

- The grillage device (if any): materials, delivery, work.

Calculation of building loads

The load that falls on the base of the foundation is the sum of the weight of the foundation and the structure. The weight of a structure is the total weight of everything in it, i.e. all structural elements and objects that the structure contains, as well as external influences:

- Walls, roofing, ceilings.

- Windows, doors, stairs.

- Fasteners, insulating and finishing materials.

- Furniture, household appliances and equipment.

- Residents (based on their simultaneous stay in the house).

For a residential building, this part of the load is taken as the product of the area of \u200b\u200bthe structure by a factor of 0.18 (tons per square meter).

- Snow load. Taken from the regulatory bases of the region.

- wind load. It is calculated as the product of the area (S) by the value of 40 + 15h (h is the height of the structure).

The sum of all the given values \u200b\u200bis the load on the foundation from the side of the structure. For calculations, it is multiplied by a correction factor (1.3).

If there are difficulties with reliable reliance on land plot, choose a pile foundation structure. The use of alternative technologies in such situations is accompanied by a significant increase in labor and financial costs. However, in any case, a preliminary accurate calculation is necessary. With the help of the materials in this article, anyone can prepare a project on their own without errors. About what it is pile foundation, calculation of the number of piles and allowable loads- read on.

The above is just one example illustrating possible troubles:

- Problems are created by the constant and seasonal high level ground water. With their presence, even a reliable solid foundation for the house is not able to maintain a stable position.

- Similar tasks must be solved on “weak” soils.

- With a large freezing depth, heaving of the soil is not excluded, so long piles have to be installed.

The pile-screw foundation is not used during the construction of road bridges, where the loads are excessive. But it is he who is well suited for a bathhouse made of wood and a house made of fairly light foam blocks, for metal overpasses, a garage, a carport.

Important! Even for a greenhouse, or other relatively light structure, a calculation must be made. It will help to clarify the quantity and technical parameters of component parts.

Varieties of grillages

By static sounding, or using another technique, it is possible to find out the parameters of the soil on a certain land plot. If they are not sufficient for the intended loads, an appropriate technology must be chosen for the formation of support rods. They will help stabilize the structure.

From this scheme, the main disadvantages are clear:

- requires the use of special equipment;

- the process is complex and lengthy;

- it is necessary to solidify the solution, so there will be restrictions on the performance of work at low temperatures.

For a correct comparison with screw products, hanging piles in subsiding soils are more suitable.

As it sinks, the tip compacts the ground, which helps create a foothold at the bottom. This is not always enough to increase the support loads. It is necessary to increase the size of the entire column, to make thickening of the lower part. Apply various options for combining with bored technology. For example, drill a wide well. It is filled with a building mixture, into which a reinforced concrete pillar is immersed. But in this case, one will have to take into account the difficulties mentioned above, which are associated with the use of "wet" processes.

These shortcomings will be eliminated when choosing a pile-and-screw method. Here, factory-made products with known technical parameters are used. This eliminates possible errors when creating a building mixture.

The corresponding period depends significantly on the temperature, the size of the foundation, its composition. Internal cavities are eliminated by vibration machines. In cold weather, special additives are used. Connection of elements metal frame will also require certain costs.

Quality products of this type cost a lot. They are difficult to transport, move, hammer into the ground. It is not difficult to understand that for work you will need the help of specialists, powerful equipment.

If necessary, this technology is used in the winter.

Such supports can be used in wetlands and other difficult areas. The main thing is that the part with the blades after installation is lower maximum level freezing for the area. This will help prevent extrusion of the structure by bulging forces.

In order for the study to be objective, it is necessary to note not only the advantages, but also the disadvantages, features of the choice, installation and operation of screw foundations:

- The metal is subject to the destructive effects of corrosive processes. Their intensity increases with a certain soil composition. Stray currents have a negative effect. They are formed by strong electromagnetic fields present near power lines, transformer substations, radio relay and cellular communication towers.

- It is not possible to screw the piles by hand near the walls, since the forces must be applied simultaneously from both sides. In this case, you can not do without specialized technological equipment.

- Modern products of this class will perform their functions in full for 50 years or more. But such indicators are provided not only correct installation. Useful high-quality anti-corrosion protection of surfaces, the absence of welded joints. All this adds to the cost.

- The ability of metal piles to hold loads is not great compared to reinforced concrete pillars. But for solving many problems of domestic construction, it is quite enough.

- The use of such technology makes it difficult or completely impossible to create a basement floor, basements.

Important! A metal rod set at a sufficient depth is a typical way to establish an earth connection. If you connect an appropriate electrical circuit to the screw pile for this, an error will be made. This connection accelerates corrosion.

Slab-piled structures with the use of screw supports are rarely erected, which is explained by load restrictions. The most commonly used technology is:

- After studying geology and calculations, products that are suitable for technical parameters are selected.

- They are screwed to a depth determined by calculation. The use of screw parts simplifies this process. They are additional supports that provide reliable fixation in soft soils. Their presence prevents the pillars from being squeezed out by heaving forces during frosts.

- The parts protruding from the ground are cut to the required level using an appropriate power tool.

- For hardening, the cavity is filled with a cement-sand mixture. Reinforcement inside is not created.

- To the top edge with welding machine attach rectangular pads. Also, to connect other parts of the building, metal mortgages are used, immersed in concrete during pouring.

| grillage type | Image | Features of the technological process | Typical Application |

| Metal beam (I-beam) |  |

To strengthen the base, the cavity of the pipe is poured with concrete. The beam is welded to the mortgage. It is also mono to use a screw connection, install a rectangular platform on top under the grillage support. | Such a foundation fits well with prefabricated structures (sandwich panels). Provides high speed assembly operations, quality connections. |

| Metal channel |  |

The connection node is created using the technologies specified in the previous option. | This base is able to withstand significant loads. In addition to frame structures, brick and wooden buildings are installed on them. In any case, good protection of metal parts against corrosion is essential. |

| wooden beam |  |

Holes are made in the end parts of the beams. A metal pin is welded to the support platform of the screw pile. This knot is going fast. With it, you quickly create a reliable connection. | Such a grillage is lightweight, so it does not create unnecessary loads on the foundation. But we must remember that such a solution is designed for small loads. I use it in the construction of gazebos, baths, outbuildings, and other light buildings. |

| Monolithic concrete |  |

The structure is poured like a normal foundation of the appropriate type. Use removable or stationary formwork, reinforcement. The mortgage is preliminarily installed in the filler of the pile cavity. | This solution is used for the construction of heavy structures. Instead of a monolith, pile-tape structures can be used, reinforced concrete slabs can be installed. |

Screw piles and calculation of permissible loads

For right choice products, you should familiarize yourself with the current range of manufacturers. It is necessary to calculate the loads that they are able to withstand and compare the data obtained with the actual conditions of future operation. Be sure to take into account the planned service life. After a comprehensive analysis of these factors, accurate conclusions can be drawn.

Screw piles: standard sizes

To buy components for a specific project without errors, an accurate calculation is required. But first you need to study the range of modern stores. This information will help clarify your personal requirements.

The following table shows the features of the SVS production line. These products are created using welded joints.

| Name (pipe diameter in mm) | Rated load weight in tons | The price of a pile (250 cm) / head in rubles. | Notes |

| 57 | 0,7-0,9 | 1250-1400/250-280 | These piles are designed for the installation of light structures. In particular, they are used to make supports for fences from a metal (polymer) mesh. Such fences are not exposed to large wind loads. Choose a length sufficient for the underground and upper part of the structure. In this embodiment, instead of a typical head, a plug is used. |

| 76 | 2,8-3,5 | 1400-1500/280-360 | Such products are able to withstand significant loads. They make reliable supports for opaque fences from profiled sheets. To further strengthen the structure, transverse ribs are used, a tape-type foundation is installed. |

| 89 | 3,8-5 | 1490-1600/290-370 | This pipe diameter is suitable for creating supports under "small architectural forms" objects. On such piles are installed stationary awnings, gazebos, economic and household extensions to the main building. They are suitable, for example, for installing a fireplace, stove, large boiler, and other heavy technological equipment. |

| 108 | 5-9,5 | 1680-1750/300-340 | This size is universal. It will be used in the construction of massive fences made of bricks, wooden and prefabricated houses. With proper design and implementation of installation technologies, the building will remain stable even on soft soils. |

| 133 | 9,5-14 | 2200-2300/340-400 | These large piles are used in the construction of heavy structures. They are suitable for using the most massive reinforced concrete connecting elements (grillages). They are combined, if necessary, with slab foundations. |

For your information! The table shows the cost standard sizes. With an increase in length, each additional 10 cm is estimated from 25 to 30 rubles, depending on the diameter.

You also need to pay attention to the following nuances:

- High-quality production is distinguished by a clear organization, the use of standards (SNiP, TU). Compliance of products is confirmed by official certificates.

- They control: the deviation of the pile from the vertical, the absence of defects in welded joints, the shape of the pipe blanks.

- Manufacturers indicate the permissible force, which should not be exceeded during the screwing process.

- To strengthen the structure, the thickness of the blades and the tip is made larger compared to the walls of the pipe.

- Increase the anti-corrosion resistance with the use of phosphating, paint application (layer thickness of 150 microns or more). Some manufacturers recommend using a tape made of polymer material, which is wrapped around the pipe at the transition from soil to air (width 20-30 cm).

Separately, this part of the pile design should be studied. It is she who experiences the greatest loads in the process of screwing, when passing through dense layers of soil. It is also subjected to significant mechanical stress during operation. The headband can be repaired if the need arises. If the blade comes off, the repair will be difficult, and the corresponding section of the foundation may collapse.

Cast tips are more expensive than the examples above by about 25%-35%. But their use allows you to create more reliable designs. The absence of welded seams provides increased resistance to corrosion processes. Such a foundation is capable of performing its functions for 80 years or more. Therefore, good economic results can be obtained. But in any case, it is necessary to apply high-quality technologies for installation operations, take into account chemical composition soils, the presence of stray currents.

When choosing, you should give preference to products from a responsible manufacturer. These fairly simple products are produced not only by reputable enterprises, but also by numerous workshops. The use of artisanal techniques does not allow to ensure the ideal quality of metal processing, the creation of reliable connections. There are cases when welded tips, after special surface grinding and painting, were passed off as more expensive, cast modifications.

A thorough check will help prevent problems. In the store, you should find out the origin of the goods, view the supporting documentation, certificates.

To solve individual engineering problems, the following solutions are used:

- This option is intended for the construction of buildings in the Far North, or when performing work in severe frosts. The serrated tip is easier than the standard one to sink into frozen ground. The width of the blades is reduced to the values shown in the figure. The wall thickness is increased up to 16 mm.

- This design is suitable for installing a columnar foundation in watered soils.

- So that in severe frosts the heaving forces do not push the pile out, the diameter of the blades is increased to 800-850 mm.

Article

The content of the articlePile foundations are the least labor-intensive type of foundation. Even the calculation of the foundation on screw piles does not cause any particular difficulties. Therefore, foundations on piles are popular not only in "domestic", but also in commercial construction. In addition, the pile has practically no "contraindications for use."

However, in this article we want to tell you not about the advantages of foundations on rod or tubular supports. Our goal is to acquaint readers with the theory and practice of calculating such grounds.

Calculation of a pile-screw foundation: general information

Design stages of pile-screw foundations

But enough theory. Let's move on to practice and carry out a rough calculation pile foundation for a house made of timber with dimensions of 6 by 4 meters, divided by one interior partition.

An example of calculating the foundation on screw piles

In most cases, the calculation of the pile foundation (including the screw type) is carried out on a special software product - the so-called "foundation calculators". But the entire sequence of calculations carried out by such a “calculator” can also be done manually.

Determination of soil characteristics

As mentioned above, all soil characteristics are determined in the course of engineering and geological surveys. However, for the construction of small foundations for relatively light structures, you can also use averaged tabular data by linking the bearing capacity of the soil with the type of soil.

True, in this case you will have to dig a pit that exposes a layer of soil at the depth of the pile. Moreover, as a pit, you can use a pit for a septic tank.

And if sandstone is found at the bottom of your pit, then the bearing capacity of your soil is 5-6 kg / cm2. Well, if you dug to the loams, then the bearing capacity will decrease to 2-3 kg / cm2. As a result, the average bearing capacity will be equal to 3-4 kg/cm2.

Collection of loads

The collection of loads involves the calculation of the mass of building materials, operational, snow and wind loads.

The mass of a 6x4 meter structure is determined by volume and specific gravity building materials. On average, about 12 cubic meters of timber are spent on such a house for load-bearing walls and another 3-4 cubic meters for arranging the roof, basement and attic floors. With a specific weight of a tree of 550-600 kg / m3, such a volume of sawn timber will “pull” 9-10 tons.

The operating load is calculated based on the area of \u200b\u200bthe building multiplied by the average weight of equipment, furniture and residents. And with an average weight value of 350 kg / m2, the operational load is 8.4 tons (6x4x350).

The operating load is calculated based on the area of \u200b\u200bthe building multiplied by the average weight of equipment, furniture and residents. And with an average weight value of 350 kg / m2, the operational load is 8.4 tons (6x4x350).

The wind load is determined by the floor area multiplied by the coefficient (40 + 15H), where H is the height of the facade of the house. With a facade height of 3.5 meters, the wind load is 2.2 tons (6x4 x (40 + 15x3.5)).

The snow load is calculated from the roof area multiplied by the coefficient of the average snow cover weight (180 kg/m2 for mid-latitude dwellings). And with a gable height of 2 meters, the area of \u200b\u200bthe gable roof of our house is 34 m2. As a result, the snow load is 6.1 tons (34x180).

Thus, the collection of loads assumes that at least 26.7 tons of the total weight of the structure will press on the soil and foundation.

Calculation of pile parameters

Before you calculate the number of screw piles for the foundation and determine the spacing of the supports, you should calculate the bearing capacity of one pile. To do this, you need to multiply the area of \u200b\u200bthe heel (helical blade) of the support bearing capacity of the soil.

The heel area is selected according to a special table, which indicates the diameter of all normalized (produced according to GOST) screw piles. The smallest diameter of such a pile is 300 millimeters. Therefore, the area of the foot of the support is 706 cm2.

And when bearing capacity soil of 3-4 kg / cm2, the bearing capacity of the pile will be equal to 2.1-2.8 tons.

Thus, 10-12 piles are enough to hold a load of 26.7 tons.. The dimensions of the supports are taken according to general recommendations. For example, for wooden structures in most cases, a CB108 support with a rod diameter of 108 millimeters is advised.

The immersion depth of the support is determined by the level of soil freezing. Therefore, most supports are immersed to a mark of 2.5 meters or more.

The pile field is considered based on the rigidity of the grillage beams. And if a metal or wooden grillage is laid under our house, then the maximum step (the distance between two adjacent supports) will be 2-2.5 meters. Moreover, when forming a pile field, it is necessary to lay supports under the interior partition.

It has long been no secret that the correct choice of the foundation for the house and the quality of construction determine the service life and comfort of life in it. It is necessary to calculate screw piles for the foundation even at the project development stage, since without this information it is not possible to prepare an estimate, purchase tools and materials.

Design features

Metal screw piles for the foundation, due to their versatility, have earned wide application among developers.

What are the features of piles?

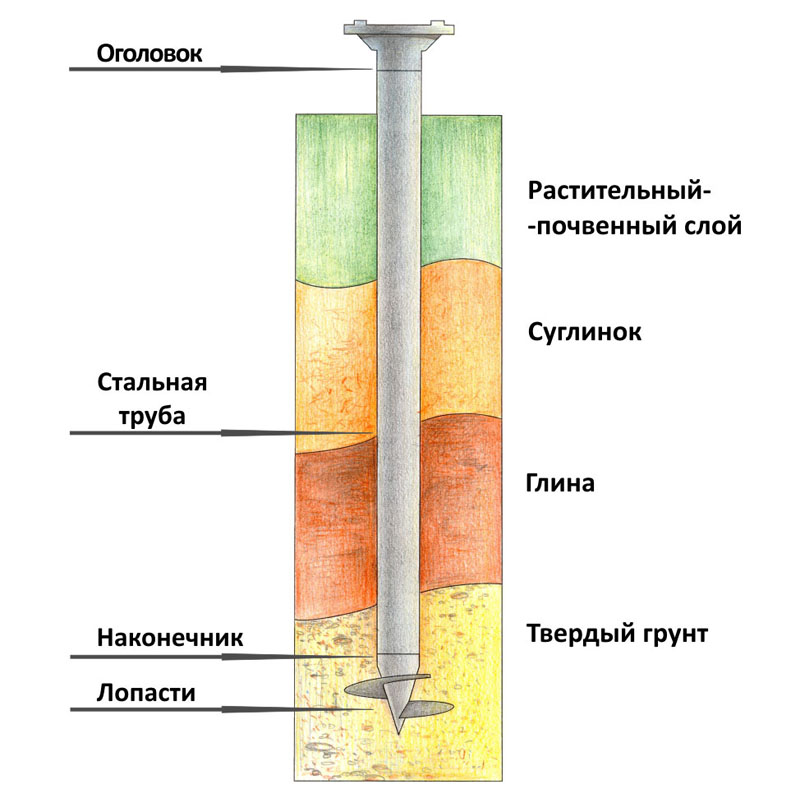

- Design. This is a welded pipe with a sharp end, on which blades in the form of a screw are welded - a fixing element that does not allow the pile to move from its seat when the soil swells, stably holding the entire building.

- performed with a clear control of the verticality of the pipe, is done mechanically or manually. The main requirement is that drilling occurs to a stable layer of soil. Screwing of piles is made irrespective of a season and rainfall.

Indicators affecting the calculation

The calculation of screw piles for the foundation will require determining the total load on the base of the house, which consists of:

- The masses of the building, installed on the foundation. When designing a house, the mass is a calculated indicator, it is determined by the materials used in the design.

- Additional load, including snow, furniture, equipment and people. Information for must be taken from approved normative documents SNIP No. 2.01.07-85. The payload in the form of people and furniture is taken on average 150 kg per m 2.

- To determine, it is necessary to conduct engineering and geodetic studies, since without these works the object will not pass the state examination. The calculation is performed in accordance with SNIP No. 2.02.03-85.

For private construction of houses up to 3 floors, research can be done on your own.

After performing the calculation of nominal loads, a safety factor of 1.2 must be taken into account.

Types of piles

It is impossible to calculate the foundation of screw piles for a house without first selecting their type. Each standard size is calculated for a specific type of object being built.

Pipe diameter, mm |

Purpose |

|

Under the supporting pillars of various types of fencing. |

||

For light country buildings. |

||

Heavy fences, one-story frame-type houses, gazebos, verandas. |

||

Buildings in 2 floors of frame type, as well as wooden buildings made of timber. |

||

Under houses of medium gravity from foam blocks. |

||

For heavy brick structures and two-, three-story houses. |

||

Rarely used for residential buildings, more for industrial facilities. |

The choice of length depends on:

- Horizontality of the construction site: if there are significant differences in height, then a choice of piles of various lengths is possible.

- The nature of the soil. Reliable installation involves screwing to a stable ground and below the freezing level of the soil by 25 ÷ 40 cm. In this case, the pile part should go into the ground no higher than 1500 mm.

Length standardized:

- Short: 1.65÷2.5 m.

- Long: up to 11.5 m (500 mm pitch).

Calculation of the number of screw piles for the foundation: stages

You will need:

- Scale plan of the site on which the planned base is to be applied with center lines.

- Attach to communication lines: a sewer pipe from sanitary rooms and from the kitchen, with a drawing of diameters.

- Results of engineering-geological studies.

Location:

- Single - point supports for light structures or country houses.

- Tape - a consistent arrangement with a certain step.

- Kustom - for heavy houses with many partitions and for each support in a frame building.

The calculation of screw piles for the foundation is carried out taking into account the features of the layout:

- The distance between the support points must be at least 2500 mm.

- The pile should be installed in places of peak loads, which are concentrated in the center of the intersection of perpendicular lines, namely:

- in the corners of the building.

- At the junctions of load-bearing walls and partitions.

- Intermediate supports should be installed evenly, including along the diagonals of the main cells of the building.

- The size of piles and blades is determined depending on the type of load and soil characteristics.

Soil influence on calculation

Whatever screw piles are chosen for loading, it is impossible without determining the bearing capacity of the soil. So, the soil does not always have the necessary composition to withstand the building without subsidence.

Important! The selected pile should not exceed the load bearing capacity of the soil.

To determine, the composition of the soil is first determined, and then compared with the characteristics given in the table.

Soil type | Soil resistance kg / cm 2 for a pile lowered by 2m (SNIP 2.02.03-85) |

||

small, wet | |||

small, wet | |||

loams | |||

In order to calculate the screw piles for the foundation, it is required to determine the type of soil:

- Sand of a coarse fraction: 2.5 ÷ 5 mm one grain of sand, up to 2 mm - medium. Does not change its size.

- Sandy loam is obtained by mixing sandy with a small percentage (10%) of clay rock.

- If the clay content is up to 30%, loam will be obtained. When wet, the mixture does not spread, but can be rolled into a ball, but cracks appear when pressed.

- If a lump of wet soil does not crack under pressure, but is plastically crushed, the clay composition is above 30%.

Note! The higher the clay content, the higher the swelling of the soil.

- Peat - soft and airy composition does not imply bearing loads.

The proximity of groundwater and the degree of moisture resistance is determined by drilling a well to the depth of lowering the pile. If water has formed in a standing pit, then there is a moisture-saturated soil with a close location of the aquifer.

Screw piles for the foundation: customer reviews