Estimated price for laying signal tape. Protective signal tape for underground cable lines

Posted on 10/27/2009 (valid until 10/27/2010)

The study of TNLA is the way to the emergence of new resource-saving technologies.

It seems that everyone reading this article at least once dug up the earth on his suburban area. A few years ago, the author of this article purchased a plot in one of the villages near Minsk. Bringing the land in order for planting plants turned out to be a very problematic task, as the previous owners buried garbage and waste in the ground. The shovel did not pierce the polyethylene film buried in the ground, “springing” back from it, so the exhausted summer resident had to first remove the top layer of the earth, remove the obstacle in the form of a film, and only after that continue digging up the summer cottage.

The properties of polyethylene have been known for a long time. In 1933, raw materials in the form of granules and the first products from it were produced in England. The result was a plastic material with good dielectric properties, shock-resistant, not breaking, with a small absorption capacity, physiologically neutral, odorless. It has low vapor and gas permeability. Polyethylene does not react with alkalis of any concentration, with solutions of any salts, carboxylic, concentrated hydrochloric and hydrofluoric acids. Resistant to alcohol, gasoline, water, oils. It is destroyed by 50% nitric acid, as well as liquid and gaseous chlorine and fluorine. Virtually harmless. Polyethylene is easily recycled by all major plastics processing methods.

The study of foreign construction practice has shown that polymeric materials are widely used in the construction of underground engineering networks and communications as gas and water pipes, insulated cables, etc. There is also a "niche" in power grid construction.

In the Republic of Belarus for protection against mechanical damage cable lines traditionally used solid clay brick (despite the sufficient irrationality of this application). Close communication with our power engineers, builders, as well as the study of the technical regulatory framework former USSR showed that the market has been waiting for a new product for a long time, and the issue of replacing brick with another material has been given attention over the past 20 years.

In the late 1980s Soyuzenergo issued a letter No. 106-25/57 dated December 30, 1986 “On the use of tapes made of polymer compositions for cable protection” and “Decision of the Main Technical Administration and Glavgosenergonadzor of the USSR Ministry of Energy dated June 10, 1990 No. E-4 / 90 on the change the requirements of Ch. 2.3 PUE "Cable lines with voltage up to 220 kV", signed by the deputy head of the Main Technical Department and the deputy head of the Main State Energy Supervision Department of the Ministry of Energy of the following content: "... to gain experience in the operation of cable lines laid in trenches using signal plastic tapes instead of bricks, using these tapes when laying cable lines up to 20 kV. The operating experience of these cable lines did not reveal any negative consequences replacing bricks with signal plastic tape. Considering this, as well as the shortage of bricks, the Main Technical Administration and the Main State Energy Supervision Authority consider it possible to allow a wider use of signal plastic tapes when laying cable lines in the ground. In order to streamline the use of signal plastic tapes, organizations of the USSR Ministry of Energy and the USSR Ministry of Installation and Special Construction have developed technical requirements for the tape (application), which should be followed when choosing the material of the tape and its specifications. In order to expand the scope of signal plastic tapes when laying cable lines in trenches, the Main Technical Department and Glavgosenergonadzor, taking into account the requirements of CHiP 3.05.06-85 "Electrical devices" that regulate the use of signal tape, decide to amend Ch. 2.3 "Cable lines with voltage up to 220 kV" PUE of the sixth edition, supplementing clause 2.3.83 at the end with the text:

“For cable lines up to 20 kV, except for lines above 1 kV, supplying electrical receivers of category 1 *, it is allowed to use signal plastic tapes instead of bricks in trenches with no more than two cable lines that meet technical requirements, approved by the Ministry of Energy of the USSR. It is not allowed to use signal tapes at the intersections of cable lines with utilities and above cable boxes at a distance of 2 m in each direction from the crossed communication or box, as well as at the approaches of lines to switchgears and substations within a radius of 5 m. The signal tape must be laid in a trench above the cables at a distance of 250 mm from their outer covers. When one cable is located in a trench, the tape should be laid along the axis of the cable, with a larger number of cables, the edges of the tape should protrude beyond the outermost cables by at least 50 mm. When laying more than one tape across the width of the trench, adjacent tapes must be laid with an overlap of at least 50 mm wide.

When using a signal tape, laying cables in a trench with a cable cushion device, sprinkling the cables with the first layer of earth and laying the tape, including sprinkling the tape with a layer of earth along the entire length, must be carried out in the presence of a representative of the electrical installation organization and the owner of the power grid.

In fairness, I would like to note that on the eve of the complete collapse of the USSR, the NPTO "Belstroynauka" of the Gosstroy of the BSSR developed recommendations for the pilot-industrial introduction of protective polymer coatings when laying electrical cables with a voltage of 0.4–10 kV, where, in particular, to physical and mechanical properties, polymeric materials used to protect underground cables were required to have a tensile strength of more than 10 MPa. Unfortunately, the accumulated potential of the building science of the BSSR was not practically in demand in the power grid construction of the already independent Republic of Belarus, where in the second decade of the 21st century brick continues to be used everywhere to protect underground cable lines, which is regulated by clause 2.3.83, in our opinion, morally and technically obsolete, the 6th edition of the EMP, the last changes to which were made before August 31, 1985. At the same time, the use of the protective properties of polyethylene tapes studied by Belarusian scientists was limited to the development of "Temporary instructions for the use of signal tapes", approved by some regional power grids of the Republic Belarus.

Rice. 1. Appearance ribbons.

Communication with Lithuanian power engineers on this issue showed that the Lithuanian SSR, despite its active desire to secede from the USSR, most fully complied with the instructions of Soyuzenergo letter No. for cable protection. It was from that time that Lithuania began to develop its own technical normative documents regulating and rationalizing the use building materials for protection of underground cable lines. Were introduced technical terms: “Polyethylene signal tape for cable lines” and “Polyethylene protective tape for cable lines”, standards for their production have been developed, their areas of application have been determined. The Soviet “Electrical Installation Rules” were revised into “Electrical Equipment Installation Rules”, which have gone through several reprints in this short period due to the increasing scientific and technical integration of Lithuania with the European Union. In this regard, I would like to cite the translation of the chapter in the currently valid version of the Lithuanian "Rules for the installation of electrical equipment", dedicated to underground cable lines:

"VII. Cable lines in the ground

169. The protection of cables laid in trenches from mechanical damage depends on the significance of the cable, its stress, depth and location. The mechanical strength of cable protective equipment (protective tapes) must be at least 6 MPa.

Cables with a voltage of 110 kV and above must be covered reinforced concrete slabs not less than 50 mm thick.

Cables with a voltage of 6-35 kV in the city must be protected from mechanical damage by covering them with special caps, plates, solid clay bricks or protective tapes 1.5–5 mm thick at a distance of 0.10–0.15 m above the cable, or the cables must be laid in ceramic, plastic, asbestos-cement or cast iron pipes. The width of the protective tape for one cable must be at least 100 mm, for two cables - 200 mm. When using protective tapes at a distance of 0.3 m from the ground, for each parallel cable, a signal tape with a thickness of at least 0.5 mm is laid with the inscription “Attention! Cable!".

Cables with a voltage of 6-10 kV, laid in uncultivated land, at a depth of at least 0.7 m, and with a voltage of 35 kV at a depth of at least 1 m, must be protected from mechanical damage by covering them with protective tapes and laying signal tapes at a depth of 0.3 m from the ground.

If cables are laid in pipes or they are covered with special caps, plates, solid clay bricks, then it is not necessary to lay signal tapes.

It is not necessary to protect cables with a voltage of 6-35 kV in arable land from mechanical damage, however, at a depth of at least 0.5 m from the ground, a signal tape must be laid.

Cables with voltage up to 1000 V, laid at a depth of 0.35–0.7 m and in those sections of the routes where there is a possibility of damage (for example, in places of frequent excavations), must be protected with slabs, caps, solid clay bricks or laid in pipes . In other cases, in the city, as well as under the pavement and in uncultivated land at a depth of 0.3 m from the surface of the earth, in arable land at a depth of 0.5 m from the surface of the earth, it is enough to lay only a signal tape ... "

In January 2009, having summarized all the available information and assessed the relevance for our country in the conditions of the global economic crisis of a new resource-saving technology, Interbeltrade LLC decided to start developing technical documentation for the production of products that had never been produced in the Republic of Belarus before. The main problem that had to be solved was the requirements for the product and the properties that this product should have, since there are no technical regulatory legal acts for such products. I will not describe all the attempts to get intelligible information from practitioners in this area, I will only quote verbatim the recommendation received from the power engineers: “We believe that you will have to go to the State Standard, everyone knows there ...” Indeed, the advice turned out to be sensible. The appeal to BelGISS (the leading enterprise of the State Standard in the field of technical regulation and standardization) and the subsequent scientific and methodological assistance not only solved the problem, but also showed the importance and significance of knowledge and application of TNLA. The range of existing polymeric materials is diverse: GOST 26996-86 "Polypropylene and propylene copolymers", GOST 16338-85 "Low pressure polyethylene", GOST 20282-86 "Polystyrene general purpose”, GOST 19459-87 “Polyamide cast copolymers”, GOST 16337-77 “Polyethylene high pressure". These standards set the range of raw materials for protective signal tape.

Analysis of the requirements laid down in the TNLA data determined the requirements for the tape we are developing: tensile strength, frost resistance, specific surface electrical resistance, and electrical strength. Comparative analysis the values of the physical and mechanical properties of the above polymers, as well as the end products obtained on the basis of these polymers (GOST 12998-85 "Polystyrene film", GOST 10354-82 "Polyethylene film"), made it possible to draw an unambiguous conclusion in favor of the use of high-pressure polyethylene for production of protective and signal tape for the protection of underground cable lines.

In June 2009, TU BY101333870.002-2009 “Protective and signal tape of the LZS series” LLC “Interbeltrade”, Minsk, were registered in the State Standard. In September 2009, State Production Association Belenergo agreed on the technical specifications without comment, thereby allowing the use of protective signal tape in the power grid construction of the Republic of Belarus. The protective signal tape is made of high-pressure polyethylene (or its waste) and is used to protect cable lines up to 20 kV from mechanical damage and to mark the places for laying cables laid in trenches underground. The protective-signal tape has a red front side with a warning inscription (Fig. 1) and should be laid in a trench above the cables at a distance of 250 mm from their outer covers on compacted fine soil poured onto the cable, without debris (Fig. 2). With such laying, a 3.5 mm thick polyethylene sheet has an increased resistance to mechanical stress.

Rice. 2. Laying the tape in the trench above the cable.

Despite the fact that, according to European requirements, the minimum value of the withstand mechanical load for the material used in the protection of underground cable lines should be at least 6 MPa, and from the recommendation on the pilot-industrial introduction of protective polymer coatings when laying electrical cables, NPTO "Belstroynauky" Gosstroy of the BSSR follows the requirement for tensile strength of such coatings is more than 10 MPa, the specialists of our company decided to set much higher strength requirements for their tape. From the protocol issued during tests on the protective signal tape by the Testing Center of OAO Stroykompleks, it follows that the minimum value in MPa for longitudinal tension of this product is 14.86, and in transverse tension - 13.99. At the same time, according to STB 1160-99 "Brick and ceramic stones", the average tensile strength of solid clay brick grade 150, used to protect underground cable lines, is 2.8 MPa in bending. In addition, the test report of the Testing Center confirmed the high resistance of the protective signal tape to shock loads.

Estimated calculations for a conditional cable line confirmed the reduction in the cost of its construction when using this tape. To deliver the protective-signal tape to the construction site, a crane and heavy trucks are not needed, as required by the delivery of bricks, and the use of machines and mechanisms is not required when laying this tape directly into the trench to protect the cable, and the laying itself takes little time. The weight of a roll of 50 meters of tape 250x3.5 mm is 35 kg. With a brick width of 12 cm, 417 pieces are needed for a shelter of 50 meters of cable. brick, its weight will be about 1330 kg. We also consider (an important circumstance in favor of the use of tape to protect against mechanical damage to the cable) that the use of solid clay bricks is advisable only for its intended purpose - exclusively for the construction of buildings.

In conclusion, I would like to say that the study and application of domestic standards allows you to create new products and technologies that are not inferior to foreign counterparts.

| Discuss on the forum |

|

| |

|

Cable lines for the transmission of electricity from the source to the consumer can be laid in trays or channels, along special overpasses or galleries, in pipes, tunnels, or fixed on the walls of buildings. However, the most common way is to lay the cable in the ground. Its popularity is primarily due to its cost-effectiveness, as well as the good protection of the conductor from the effects of weather conditions and electromagnetic fields. Cable laying in the ground takes place in several stages, performed in a strictly defined sequence.

- selection, marking and breakdown of the cable laying route

- mechanized or manual trenching

- sand bed filling device

- cable laying (if necessary, pulling in pipes)

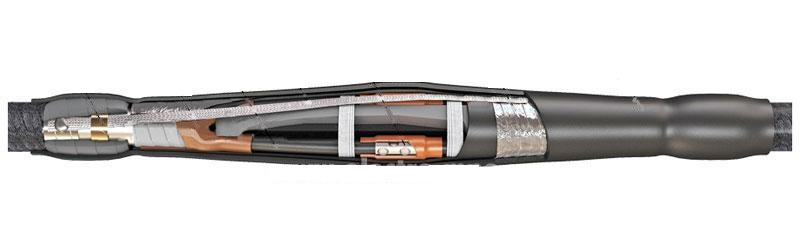

- installation of couplings

- cable powder

- cable protection with a brick (if provided by the project)

- signal tape laying

- backfilling the cable line trench with soil

Proper gasket power cable in the ground and the stages of laying in trenches affect the price of work per linear meter.

Selection, marking and breakdown of the route for laying the cable in the ground

The route must meet several requirements. First of all, it is necessary to take into account the safety of operation, as well as to provide for the possibility of its subsequent maintenance. At the same time, in order to reduce the cost of work and materials, the route should, if possible, be laid along the shortest distance.

The distance from the cable to other communications, forest plantations, building foundations, roads, supports and other obstacles should not be less than the minimum established by the standard. If this requirement cannot be met, additional measures are taken to protect the cable.

Mechanized or manual digging of a trench for cable laying

Regardless of the method of carrying out earthworks, they can be carried out only after obtaining the necessary permits issued by the relevant administrative authorities. When crossing with other communications or passing the route in the immediate vicinity of them, coordination with the operating organizations is also required.

Before digging a trench, the route is carefully inspected for the presence of substances in the soil that can destroy the protective sheath of the cable. If there are any, and there are no ways to bypass these sections, measures are taken to additionally protect the cable. The standard trench depth for laying cables in a settlement is 1-1.2 meters, but it can be changed depending on the type of soil and other conditions.

The device for adding a pillow of sand under the power cable

The sand cushion provides a reduction in the mechanical load on the cable during subsequent soil compaction. The thickness of the sand layer is at least 100 mm. It is allowed to use ordinary quarry sand, as well as loosened soil without foreign inclusions.

Cable laying and pulling in pipes

The cable in the trench is laid with a small margin, wavy twists. This is necessary to exclude its tension and rupture during soil subsidence and temperature fluctuations. In places where it intersects with other communications, when passing at a shallow depth, if it is necessary to protect against aggressive environments or in other cases where there is a high risk of damage, the cable is placed in plastic, asbestos-cement, ceramic or steel pipes.

Cable powder

The powdering of the cable is carried out in stages. First, it is covered with a layer of sand 100 mm thick. It is also allowed to backfill with soft soil, in which there should be no foreign solid inclusions. Before backfilling, the insulation resistance of the cable is checked, the absence of a short circuit to the ground and between the cores.

Brick cable protection

In cases where there is a high risk of mechanical damage to the cable, for example, as a result of maintenance work located in the immediate vicinity of the communications route, additional cable protection with a brick can be used.

Laying signal tape to avoid damage to cable lines

Laying signal tape reduces the risk of cable damage during earthworks mechanically. It is laid at a distance of 250 mm from the cable surface without breaks. The tape is made of polymeric or other materials that are resistant to aggressive environments, and a warning inscription “Caution cable!” is applied to its upper side.

Backfilling the cable line trench with soil

The final backfilling of the cable line trench with soil is carried out sequentially, while every 200 millimeters it is compacted. The soil used for backfilling should not contain solid inclusions - stones, construction debris

Installation of connecting cable boxes

Installation of couplings is necessary in cases where the total length of the route exceeds the length of the cable in the coil. Before installing the couplings on the length of the cable determined by the technical documentation, the protective covers are sequentially removed. At the same time, a special heat-shrinkable tube is put on the cleaned conductors, which provides insulation from each other after mounting the coupling. If there is a screen in the cable, it must be restored by soldering.

Question: Good afternoon, Lilia Yakovlevna! Could you tell me, please, what price should be applied for covering the cable with signal tape? Is it correct to use the price FERm08-02-143-01 “Covering a cable laid in a trench with a brick: one cable”, excluding the cost of mechanisms? Do I need to apply a reduction factor to the basic salary? Or should a different rate be used? Thank you.

Answer: Incl. and Question #63.

Hello! The question of determining the cost of laying a signal tape has been standing for a long time. The need to create estimated standards for this type of work has already "overripe". Of course, there is a ready-made recipe, but it does not at all meet the aspirations of the estimators. The only correct answer is contained in paragraph 2.3 (third paragraph from the bottom) and 2.15 of MDS 81-35.2004, as well as paragraphs 1.4 ÷ 1.5 of MDS 81-37.2004, where in such situations it is proposed to develop appropriate individual estimated standards for the work technologies provided for in the project. After analyzing the available solutions of the estimators (methods for determining the estimated cost) of this issue and posted on the forums of various sites, I was once again convinced of the ingenuity of the estimators. The used (proposed) standards of the following Collections: No. 12 GESN-2001 (FER, TER) "Roofs" (roof fencing or as a device for vapor barrier gasket in one layer), GESNm-2001 (FERm, TERm) No. 8 "Electrical installations" (covering cable laid in a trench with bricks with the replacement of basic materials), No. 10 “Communication equipment” (laying an identification tape), do not reflect the consumption of resources, and therefore the cost of working on the use of a signal tape in cases of laying electrical cables for different voltages. Many, I believe, mistakenly believe that the signal tape is laid simultaneously with the cable and the working run, while unwinding the tape roller along the laid cable, will complete the job. It wasn't there! Please study the technology for performing work not only on laying the tape, but also pay special attention to related work, namely the thoroughness and accuracy of backfilling the trench with soil, with the cable and signal tape laid in it. The use of signal tapes is regulated by the PUE and SNiP 3.05.06-85 "Electrical devices". In clause 2.3.83 "Laying cable lines in the ground", chapter 2.3. "Cable lines with voltage up to 220 kV" PUE lists the rules and requirements for these works, and here are some of them:

“It is not allowed to use signal tapes at the intersections of cable lines with utilities and above cable boxes at a distance of 2 m in each direction from the crossed communication or box, as well as at the approaches of lines to switchgears and substations within a radius of 5 m.

The signal tape should be laid in a trench above the cables at a distance of 250 mm from their outer covers. When one cable is located in a trench, the tape should be laid along the axis of the cable, with a larger number of cables, the edges of the tape should protrude beyond the outermost cables by at least 50 mm. When laying more than one tape across the width of the trench, adjacent tapes must be laid with an overlap of at least 50 mm wide.

When using a signal tape, laying cables in a trench with a cable cushion device, sprinkling the cables with the first layer of earth and laying the tape, including sprinkling the tape with a layer of earth along the entire length, must be carried out in the presence of a representative of the electrical installation organization and the owner of the power grid. At the same time, work should be carried out in compliance with such paragraphs of this chapter of the EMP as paragraphs 2.3.84 ÷ 2.3.87, etc.

In addition, you should remember and be aware that signal tapes are used as underground warning signals about cable networks and pipelines laid in the ground and they are not protective, saving insulation, cable sheaths or pipes from mechanical damage. I draw the following conclusion: it is necessary to draw up estimated standards, taking into account the technology and features of the work on laying signal tapes of all sizes and the number of cables in the trench. Signal detection tapes "Electro" LSE 150 ÷ LSE 900 (respectively, the width of the tape: 150, 250, 300, 450, 600, 750 and 900 mm) are used to identify the electrical cable with the logo "CAUTION CABLE" is produced in winding on rollers of 100 p .m, thickness - 300 microns and red color (GOST 2245-002-21696750-04). For comparison, I will give the characteristics of other tapes used, for example:

"Signal detection tapes LSO 40, 70 "Optics" are designed to identify the optical cable. The color is yellow, the text on the tape is "Caution, optical cable". Width 40 and 70 mm, tape thickness 100 microns, roller winding 500 meters.

“Signal detection tapes LSS 40, 50, 75, 100 LSS “Communication” are designed to identify the communication cable. The color is orange, the text on the tape is "Do not dig, below the cable." Available in widths of 40, 50, 75 and 100 mm, thickness 300 microns. Roll winding 250 meters.

It turned out a lot and for a long time, but I wanted it to be clear to everyone, namely: compilers of estimated standards, designers, installers, customers, inspectors, etc. I wish you success! Sincerely, L.Ya. Podyniglazova

When drawing up a project for laying a cable line, the need to lay a signal tape should be taken into account. What value should be taken into account? Is it possible to use the price of FERm, specifying the conditions for covering the cable laid in the trench with a brick? What factors should be taken into account in this case? We answer these questions with the head of the estimated norms department of the TsNIIEUS company, Lidia Podyniglazova.

According to the expert, the need to determine laying costs has existed for a long time. However, there are still no regulations in this area. And to resolve the issue by only excluding the cost of operating mechanisms is not fully correct. It is necessary to develop individual estimated standards that allow you to take into account the types of work provided for in a particular project.

At the same time, most design organizations use standards that are completely unsuitable for this type of work. Non-specialized publications reflect neither technology nor resource consumption. Therefore, in the end, the costs of buying and laying the signal line turn out to be completely different from what was provided for in the project. And this is already a discrepancy with the estimate and significant financial problems.

Accounting for installation technology

The inattention shown by designers to the preparation of cost estimates for laying the signal tape is based on an erroneous idea of the features of the work technology. Most of the technique seems to be extremely simple: here the cable is laid, here a man with a reel in his hands runs over the trench and unwinds the signal tape. Then you just need to dig a trench, what other additional costs can there be?

But installation according to current regulations looks completely different! The technology includes the main and related works regulated by the PUE for laying cable lines in the ground. In particular, they note that signal tapes cannot pass at the intersections of cable ducts with other engineering communications. That they should not be laid over cable boxes, but only at a distance of two meters from them in each direction. They cannot be located in the immediate vicinity of substations, transformer devices, but only at a distance of at least five meters. There are other norms that are important to consider when drawing up a project estimate. We will talk about them in a new review.

03.11.16