Thickness of hollow core slabs. Reinforced concrete floor slabs

Reinforced concrete floor slabs are used to separate the floors of high-rise buildings. For the lower floor, they serve as the basis of the ceiling, and for the upper floor, they serve as the basis of the floor.

Therefore, the observance of the quality of the floor slabs is an important and responsible aspect of production, in which only high-class concrete is used, as well as ordinary or stressed reinforcement. It allows to provide reliability, durability and long term of operation of products.

Reinforced concrete floor slabs

By design features concrete floor slabs PC are divided into solid (monolithic) and hollow. Each type of slab is used in buildings for a specific purpose and specified operating conditions.

Monolithic floor slabs are defined by three types.

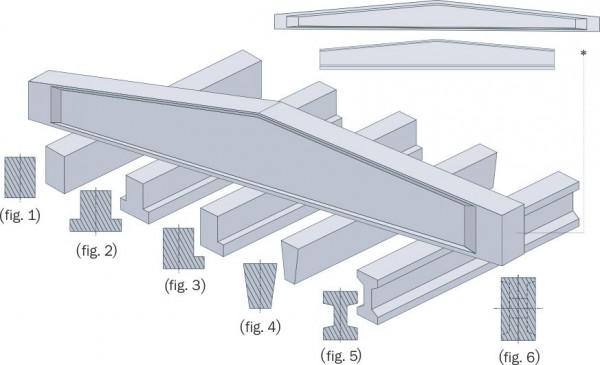

1. Ribbed floor slabs. The structure consists of beams that intersect each other. The empty areas formed by the intersection are filled with concrete. Thus, these plates are ready to withstand fairly large loads. Therefore, their use is most often justified in the construction of industrial and commercial facilities.

2. Caisson floor slabs. This type is similar to the previous one in terms of design, high load capacity and scope. The difference lies only in the smaller thickness of the concrete layer filled between the beams. Caisson slabs are also not used in the construction of residential and private houses.

3. Beamless floor slabs. The design is defined by a flat monolithic slab without the use of beams. They are supported by walls and columns. These plates are used in civil engineering. The smooth surface of the plates eliminates the need for installation suspended ceilings.

All monolithic slabs characterized by high strength indicators, due to which they do not deform and do not sag.

The disadvantages are such parameters as very large weight, high coefficient of thermal conductivity, poor sound insulation. Hollow slabs can easily cope with them. Hollow core slabs differ in shape, dimensions and diameter of internal voids. Depending on these indicators, 15 types of hollow core slabs are distinguished, which have their own separate marking.

Unlike monolithic hollow core slabs, they have much lower thermal conductivity and greater sound insulation due to structural voids inside. In addition, the economic efficiency of hollow core slabs is also more justified by reducing the cost, saving heat inside the building and reducing the requirements for the indicators of the supporting structure of the house.

Additional advantages of hollow core reinforced concrete floor slabs from the manufacturer are the reliability of the design, provided by the factory production conditions, low installation cost and high installation speed.

Floor slab dimensions

The dimensions of monolithic floor slabs are determined by the structural design characteristics of the building and can be completely different. Their peculiarity lies in the fact that they can be made directly on the site.

For hollow concrete floor slabs, the dimensions are defined by length, width and thickness (height).

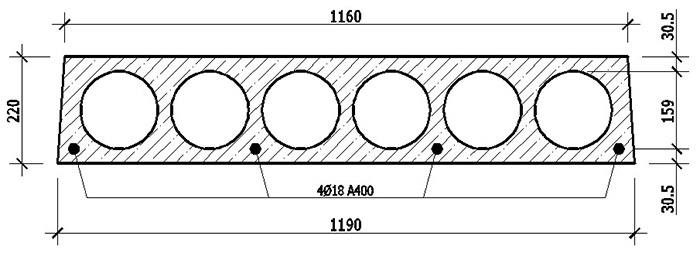

The thickness of the floor slab takes a standard value of 22 cm. It is rarely possible to manufacture slabs with a height of 16 cm. The difference is provided by the diameter of the voids.

The length of the floor slab varies from 2 to 12 m. Most often, slabs of 3.6 - 7.2 m are used even at the design stage. They are considered standard.

Non-standard sizes lead to an increase in cost.

The width of the floor slab has standard values: 1.0 m; 1.2 m; 1.5 m; 1.8 m. It should be noted that slabs with a width of 1.0 m and 1.8 m are considered rarer and have a higher cost. Therefore, it is advisable when designing to lay slabs with a width of 1.2 m or 1.5 m.

The weight of the floor slab depends on its type and overall dimensions and can take values from a fairly wide range.

Floor slab load

When determining floor slabs, it is necessary to take into account the static and dynamic load on the slab.

A static load is anything that loads a slab without moving relative to it. Anything that is subject to movement is considered a dynamic load.

In addition, the load can be distributed evenly or unevenly, concentrated, etc. But in the calculations of floor slabs for a residential building, only uniformly distributed loads are taken into account.

Estimated distributed load slabs of ordinary residential buildings is taken equal to 400 kg/m2. Taking into account the weight of the plate itself (about 250 kg), screed and ceramics (approximately 100 kg), the total weight reaches 750 kg. Required for the calculation of the coefficient of reliability, equal to 1.2. This results in a floor slab load of about 900 kg/m2.

GOST floor slabs

To comply with the technological process and the dimensions of floor slabs, GOST 9561-91 defines exact requirements, the fulfillment of which allows you to get a quality product that meets all regulatory standards.

To calculate the load on floor slabs, SNiP provides a specific calculation algorithm, which must also be followed to eliminate errors.

Price for reinforced concrete floor slabs

In the task of buying floor slabs, the price always has great importance. The cost of floor slabs is determined by the material used for production and its strength characteristics. In addition, each manufacturer offers its own price, which can also vary significantly.

Profizol LLC cooperates with trusted and reliable manufacturers that are leaders in terms of quality and prices offered.

Therefore, we justifiably recommend buying floor slabs of the Moscow region from the Profizol company. Here you will receive excellent service, information on production, installation and operation, as well as complex comfortable cooperation.

The current prices of reinforced concrete floor slabs can be found by ordering a price list using the form on the website or a callback from the manager.

Building your own home is an important and responsible business, in which there are no trifles. It is quite difficult to think over and calculate every detail, but the main and vital points must be planned in advance, even at the design stage.

One of these cases will be the choice of the main load-bearing elements - floor slabs, which are used not only in multi-storey construction. What are the types of floors, the main dimensions and methods of insulation, as well as possible options overlap in wooden houses- all the information in our article.

Of course, first of all, these elements are distinguished by the type of purpose, the material used and the configuration. Short review each indicator and the main criteria for selecting suitable floors are discussed below.

Advantages

- Affordable cost.

- Relatively light weight.

- The possibility of self-assembly without the involvement of special equipment and additional workers.

- Quick installation.

- Wide choice and possibility of production under the order.

On the video overlap between floors in a private house:

Floor slabs marking and dimensions are indicated

Among the shortcomings, the most characteristic of wood: rotting, destruction under the influence of fungus, insect pests, fire hazard and aging. That is why various formulations for processing are used before installation. They will give the tree additional strength, fire resistance and resistance to bacteriological attacks. Additionally, it is better to wrap the places of contact with stone and metal surfaces with roofing felt to create the necessary waterproofing. For the same purposes, you can use mounting foam.

metal

There are types of different configurations: corner, channel and I-beam. All of them are designed for different loads, but unlike wooden ones, they take up less space, are more economical and more durable. The covered span can be up to six meters. Advantages: fire resistance, pests and rotting are not terrible. Among the shortcomings can be noted the lack of heat and sound insulation. To fix this, you can wrap the ends of the beams with felt, but this is usually ineffective.

As floor slabs for metal beams wooden boards or lightweight concrete are used, which are poured into the formwork. The second method is too time-consuming and is used in especially exceptional cases.

How the floor slab pk 15 is used can be found in this

Reinforced concrete beams

Concrete structures are able to cover spans from 3 to 7.5 meters. Laying frequency is not less than 60 centimeters. The distance between the beams is filled with concrete mortars and hollow blocks.

There are two positives:

- A wider distance is covered than metal and wooden floors are capable of.

- Additional soundproofing and protection against pests is not required.

The negative side: it is difficult to install such a beam on your own, it requires the involvement of specialized equipment, which means an increase in costs.

Usually these are monolithic slabs in which there are no clearly defined configurations, otherwise they are also called beamless. Most often, reinforced concrete hollow panels or solid slabs of lightweight concrete are used.

Hollow core slabs series 1.141 1 are used exactly as indicated

Advantages

- High strength.

- Withstand loads over 200 kg/m².

- Not subject to decay and damage by pests.

The disadvantages will be the need to attract special equipment for installation, as well as taking into account the standard dimensions of the plates when planning a house. Some businesses can make slabs to order, but this is also an additional cost. Also, for the installation of plates, a sufficiently strong foundation and a wall thickness of at least 25 cm are required. The gaps between the plates must be sealed with cement.

monolithic

If the configuration of the building does not allow the use of standard prefabricated slabs, you can choose the next option - pouring the reinforced concrete structure on your own. This process is laborious and lengthy, but the efforts will pay off handsomely due to the long service life and strength characteristics. ![]()

For this you need to install bearing beams, formwork and reinforcement system. The entire structure is poured with concrete, for which cement of a grade of at least 200 was used. The slab is aged for at least 28 days until completely solidified. Pouring is carried out immediately, for this you need at least a concrete mixer of a decent volume, ideally it is better to purchase a ready-made solution in required quantity. As a rule, for bearing capacity a layer of concrete from 10 to 30 cm will be enough.

About what size of timber can be used when overlapping a house is described in this

Prefabricated - monolithic

An improved version of the previous version, where hollow blocks are used instead of floor slabs, they are poured from above with layers of concrete. The advantages will be easier installation and good coating quality. Thanks to such structures, any possible architectural projects can be implemented. The disadvantage is the laborious process of laying and transporting blocks.

How to insulate floors

- The best solution would be to purchase ready-made mineral wool slabs.

- Make the bottom layer from a sheet of roofing material, filling it with clay (mixed in half with sand), slag and sawdust from above.

- Special wood boards made from sawdust and concrete. You can buy them ready-made or you can make your own. To do this, 0.3 parts of cement mortar, 4 parts of clay, 1.5 lime and 2 parts of water are used for one part of sawdust. The plates are formed to a given size, dried a little and used as thermal insulation.

The video shows how to insulate the interfloor ceiling in a private house:

Floor slabs of the modern assortment open up wide possibilities for individual construction. Thanks to many options, it is possible to implement the most unexpected architectural projects and ideas. When erecting buildings, you can combine and modify existing types load-bearing structures, the main thing, first of all, be guided by the basic safety rules.

Overlappings various sizes – important element any building. The strength of the house depends on them, so you need to choose materials for construction very carefully. Even if the object is one-story, one cannot do without overlapping the basement. Concrete slabs have been and remain the most reliable and cost-effective option for solving such problems.

In Moscow, more than a hundred firms offer to buy products from reinforced concrete factories. Some of them represent manufacturers directly. These are various joint-stock companies based on the basis of existing plants (concrete goods No. 5, No. 21, Mospromzhelezobeton, etc.).

There are a minority of such companies, only a few dozen, but it is from them that you should place an order. The rest of the firms are intermediaries or sellers of used panels. The offered assortment is usually small, and it will not be easy to find the required size at an affordable price.

Concrete and reinforced concrete slabs are mass-produced by reinforced concrete factories using rather sophisticated equipment. Although the mandatory certification of such structures has been abolished, most manufacturers continue to work in accordance with the requirements of GOSTs. That is why the types and sizes of products are unified - there are no non-standard solutions. So during construction, you need to plan in advance which floors will be used.

1. Full-bodied (PTS).

They are made in the form of a solid monolith with metal reinforcing reinforcement inside. The weight of the PTS is very large (up to 7 tons), which must be taken into account when calculating the load on the foundation, but this disadvantage outweighs the high strength. They are used in capital construction and in the construction of multi-storey buildings.

The marking of solid slabs consists of two parts. The index indicates the thickness of the monolith:

The letter designation classifies the slabs according to the type of bearing on the bearing walls:

- PD - on 2 sides (produced with a thickness of 2PD-6PD);

- Fri - on 3 sides (only 3PT-6PT);

- P - along the entire contour (in all sizes).

On free sale there are additional solid slabs of PTVs concrete (new and used) with a standard width of 39 cm and a length of up to 7 m. They are used when the total width is insufficient to cover the required area.

| Brand | Length, mm | Weight, kg | Price, rubles |

| PTVs-24-4 | 2 390 | 480 | 1 620 |

| 26-4 | 2 590 | 522 | 1 760 |

| 28-4 | 2 790 | 562 | 1 890 |

| 30-4 | 2 990 | 602 | 2 020 |

| 32-4 | 3 190 | 642 | 2 160 |

| 34-4 | 3 390 | 682 | 2 280 |

| 36-4 | 3 590 | 722 | 2 420 |

| 40-4 | 3 990 | 802 | 2 650 |

After the letter designation, the dimensions of the concrete floor slabs in decimeters are indicated - first, the length of the panel, rounded to the nearest integer, and through a hyphen or a dot, its width. Third digit - permissible load per floor, reduced to centners per m 2.

For solid slabs in the marking, according to the current GOST 12767-94, the class of reinforcement used is indicated last. Additional letter indices mean other characteristics of reinforced concrete products: frost resistance (m), use of lightweight concrete (l), seismic resistance (s), embedded parts, etc.

2. Hollow (PTM).

Lightweight products weighing up to 3 tons with through voids of round or oval cross section. They are in demand among private developers, so factories produce them in a large assortment. In addition to relatively low weight, they are distinguished by smooth surfaces for finishing, which makes it possible to widely use PTM when creating floors from concrete in residential construction. Additional heat and noise insulation properties also speak in favor of PTM.

Standard boards of the PC brand are double-sided by the type of support. Three- and four-sided have an additional prefix to the letter designation "T" and "K", respectively. Their length is 4790 - 6950 mm, and the width is in the range from 1040 to 2420.

Depending on the parameters of a particular floor slab, it can be classified according to the characteristics of voids in concrete. With a certain hole diameter, products of different thicknesses are assigned their own index from 1 to 7.

| Thickness - 220 mm | 260 mm | 300 mm | |||||

| Hollow diameter, mm | Brand | Hollow diameter, mm | Brand | Hollow diameter, mm | Brand | ||

| 159 | 1pc | 159 | 4pcs | 203 | 6pcs | ||

| 140 | 2pcs | 180 | 5pcs | 160 mm | |||

| 127 | 3pcs | Elliptical | PG | 114 | 7pcs | ||

A round-hollow PB 260 mm with 159 mm holes stands apart. Its difference is due to a different production technology - without the use of formwork. Such an overlap in the process of continuous molding of concrete in the factory can be immediately cut to size. In this case, the width is selected from a number of standard values from 1 to 1.8 m.

Lightweight products can be used in the construction of houses with a height of no more than 2-3 floors. Thick metal reinforcement in the concrete body is located only along the perimeter, and the surfaces are reinforced with thinner steel wire. In this regard, the strength of hollow species is lower than that of monolithic concrete with full reinforcement.

The cost of hollow core slabs with a width of 1.5 m (1490 mm):

| Brand | Length, mm | Weight, t | Price, rubles |

| PC 21-15-8 | 2080 | 0,97 | 4 060 |

| 30-15-8 | 2980 | 1,425 | 4 230 |

| 38-15-8 | 3780 | 1,75 | 6 240 |

| 48-15-8 | 4780 | 2,25 | 6 650 |

| 60-15-8 | 5980 | 2,8 | 7 400 |

| 70-15-8 | 6980 | 3,27 | 11 160 |

| 80-15-8 | 7980 | 3,73 | 18 410 |

| 90-15-8 | 8980 | 4,19 | 19 770 |

3. Ribbed (PTR).

U-shaped concrete slabs are solid products, but they are distinguished by their cross-sectional shape and high strength. In fact, this is a system of beams, the gaps between which are filled with concrete.

As a result of this manufacturing technology, PTR concrete slabs acquire additional stiffeners, allowing them to withstand the highest mechanical bending loads and even seismic activity. Mainly used for flat roofs industrial facilities(hangars, warehouses, garage boxes), as they are expensive for private construction and are not suitable for finishing.

For ribbed concrete slabs, two types of installation are distinguished:

- with support on the shelves of crossbars (1P);

- with installation on the upper part of the support beam (2P).

The first type is produced with a length of 5050 or 5550 mm and a width in plan from 740 to 2985. The second has only one standard size- 5950x1485 mm.

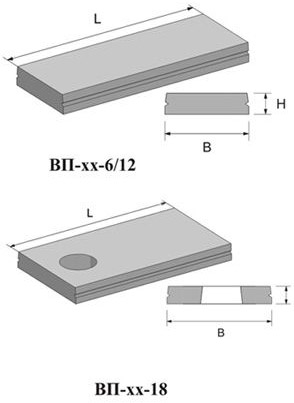

4. Chamber floor slabs (VP).

They are used to cover wells, trenches, thermal chambers and collectors as a protection of mechanical units and communications located in them. These are products of small sizes, maximum - 5 m 2, but with a wide choice of thickness from 16 to 36 cm. Concrete plates ceilings of chambers can be either solid or hollow, with one or two hatches or without them at all.

Standard dimensions

When developing a project for a future home, it is worthwhile to first clarify the dimensions of the slabs at the nearest reinforced concrete factory, and calculate the floors based on what the manufacturer can offer. This is the most suitable option if you need to reduce the cost of construction without sacrificing quality. It is easier to correct something in the project of the future house than to try to fit the floors to the finished box later.

Otherwise, you will have to buy additional PTVs elements or even order the manufacture of a limited batch of concrete slabs. The most expensive will be a large tent, covering the entire floor.

1. The length varies between 1.6-12.0 m. Depending on their technical equipment, one of the manufacturers also offers 15-meter concrete products. However, in construction, floors of an average length of 3.6-7.2 m are more often needed - they are produced in large volumes, so the cost is optimal.

2. There are much fewer width options - only 5 possible sizes from 0.6 to 2.4 m, and it will not always be possible to find those. More often, manufacturers are limited to two or three sizes: 1 m (990 mm), 1.2 (1190) and 1.5 (1490). This is enough to mount the overlap of the required width.

Tip: For a typical object, it is cheaper to buy 4 floor slabs of 1.5 m each than 6 meter ones.

3. The thickness of the majority is standard - 22 cm. Differences are regulated by separate GOSTs for each type of floor.

Products with the same dimensions differ significantly in their characteristics. Impact on performance properties a large number of factors:

- Brand of concrete (from M150 for low-rise construction to capital M500) and its special qualities - moisture resistance, frost resistance, etc.

- The class and diameter of the applied reinforcement is in the range of 12-22 mm.

- Density of concrete reinforcement.

- Manufacturing technology (with or without prestressing of reinforcement).

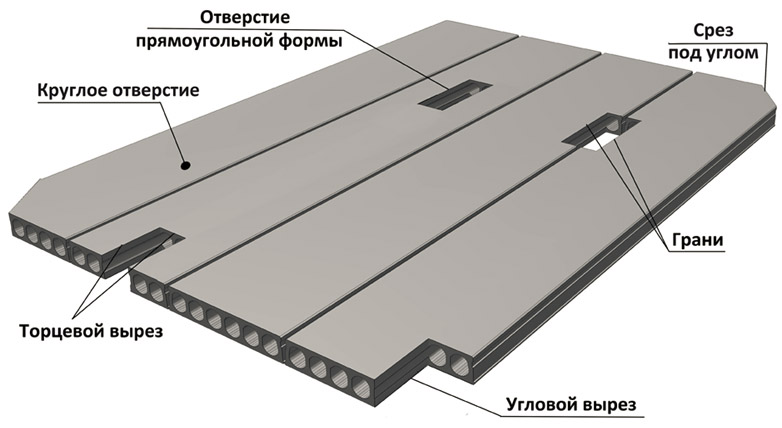

- Design features (the presence of mounting loops, cut side slots or hatches).

Depending on the combination of these properties with standard sizes, the cost of the plates also changes.

Pricing Features

The prices of concrete products, mass-produced at reinforced concrete factories, can be called quite democratic. Although it all depends on the size and characteristics of the material. However, their specificity is such that the estimate will have to include the cost of both the plates themselves and their delivery. The farther from the construction site the concrete goods plant, the more expensive the purchase will cost.

Good savings will be able to those who are in the suburbs. There are also quite a few operating construction plants that manufacture reinforced concrete products, but their prices are slightly lower than in Moscow.

Used items will cost the cheapest, but not enough to afford the risk. Firstly, when buying them, it is necessary to choose only those concrete slabs that do not have visible damage. Secondly, it should be remembered that steel reinforcement bars have their own metal fatigue life.

It is difficult to imagine modern capital buildings without concrete or reinforced concrete structures. In particular, slabs are used as facades and partitions, intermediate floors and coatings, in the construction of foundations and roads, channels for engineering networks, and much more. The versatility of the products allows them to be installed in industrial and residential facilities, in the construction of multi-storey buildings and individual cottages. The range of boards produced makes it possible to choose them optimally for the needs of a particular type of structure.

Varieties of floor slabs

Concrete and reinforced concrete slabs manufactured by manufacturers differ in several parameters that determine the final price of products:- by type of concrete - they are molded from heavy, light and dense silicate concretes;

- By internal structure- solid (or full-bodied) and multi-hollow (hollow);

- in thickness, length and width - the dimensions are regulated by the relevant standards;

- according to the option of resting on load-bearing walls or crossbars - cantilever (for balconies and canopies), beams (on two sides), three- and four-sided;

- along the section profile - rectangular, beveled and ribbed (trough-shaped);

- according to the method of manufacture - monolithic and prefabricated;

- according to manufacturing technology - injection, vibration, continuous molding;

- according to the reinforcement method - prestressed and ordinary, unstressed.

It should be noted that the price of hollow core reinforced concrete slabs differs from solid concrete counterparts, as well as their weight and strength indicators. But despite the fact that hollow-core slabs can withstand a smaller load, their performance characteristics make it possible to mount products as interfloor floors in high-rise residential buildings. The presence of internal voids significantly reduces the load on the walls and, as a result, on the foundation, which has a positive effect on general design structures. The voids are always located along the direction defined as the length of the slab, but not always its indicator is greater than the width.

An interesting fact is that for a slab resting on four sides, the smaller dimension in plan is taken as the length, and for the other two types of products, the side that does not lie on the supporting structures is taken as the length.

The peculiarity of reinforced concrete slabs is the presence of reinforcing meshes in the body of concrete, due to which the price of products increases compared to concrete counterparts. The solution reliably protects metal rods from aggressive environments, so they do not corrode or rust. In turn, the metal helps to keep the concrete solid, taking on the tensile forces. There is no metal reinforcement in concrete products, on the basis of which it can be concluded that their strength characteristics have lower scores.

Monolithic reinforced concrete slabs are able to take various forms, from the simplest to the unimaginably complex. Their frame is securely connected to the entire structure. monolithic house, forming a single whole with it. Due to this, the thickness of the bearing walls and the consumption of concrete are reduced, resulting in a reduction in the total price of materials required for the construction of the facility. But the monolith has serious disadvantages, compared with prefabricated slabs, consisting of:

- in a long period of curing concrete;

- in the need to install and remove formwork (except when using a fixed structure).

Prefabricated floor slabs allow you to mount the building quickly, as they are already ready to be delivered to the construction site. In this case, in addition to the speed of erecting the box, you can significantly save on labor costs. Ultimately, the use of individual reinforced concrete slabs becomes a more profitable option when installing a house of a simple configuration.

It can be concluded that it is more expedient to pour monolithic floor slabs if the building has a complex shape in plan or non-standard dimensions.

Concrete slabs with prestressed reinforcement are made uniaxially or uniaxially stressed. Even before concreting, metal rods are pulled onto various structures:

- bench stops;

- matrices;

- molding trays.

In the process of gaining strength with a mortar, certain forces are transferred to concrete from stressed reinforcement located in channels directly in the body of the structure, or in grooves located on the outside. The adhesion of the two materials is ensured by an anti-corrosion coating injected into the channels or by a cement mortar. Hollow concrete floor slabs are produced heavily reinforced, regardless of their dimensions.

Solid floor slabs

Solid reinforced concrete products intended for intermediate floors are manufactured according to GOST 12767-94 standards. The products are quite bulky, so they are rarely used in the construction of residential buildings. But they are indispensable where the presence of increased mechanical loads is expected.

Solid slabs are classified depending on the method of support:

- on two sides - 2PD - 6PD;

- on three sides - 3PT - 6PT;

- on four sides (along the contour) - 1P - 6P.

Digital marking indicates the dimensions of the thickness of the reinforced concrete product:

- 1 - 100mm;

- 2 - 120mm;

- 3 - 140mm;

- 4 - 160mm;

- 5 - 180mm;

- 6 - 200mm.

The dimensions of the plates in the plan are:

- in length - from 3.00 to 6.60 m;

- in width - from 1.20 to 6.60 m.

The regulations state that reinforced concrete slabs must, in without fail have:

- embedded parts or structural elements in the form of outlets of reinforcing bars used for joining with reinforced concrete and metal frame elements;

- through channels for the passage of hidden electrical wiring or other engineering communications;

- mounting loops.

Floor slabs are subject to requirements for frost resistance and water resistance, for strength and quality of manufacturing materials, including reinforcing bars. Concrete sagging is not allowed on embedded parts, and reinforcement outlets are protected to avoid injury.

Also important is appearance concrete surfaces- even the lowest price of products should not become decisive when buying products if they have defects in the form of cracks, chips or deep shells.

Slabs with voids made of reinforced concrete

A feature of hollow core slabs is their low thermal conductivity and high sound insulation, relatively low weight and affordable price. Both sides of the product have a front side, one of which becomes the ceiling of the lower floor, and the other - the floor of the upper level.

Plates are manufactured according to the GOST 9561-91 standards, which provide for their division into several groups:

- PC - with round voids and leaning on two sides;

- PCT - on three sides;

- PKK - on four sides;

- PG - with pear-shaped voids and leaning on two sides;

- PB - made by the method of continuous formless molding.

Hollow-core slabs are produced with a thickness of 160 ... 300 mm, but the most popular is the size of 220 mm. Round holes have different diameters - from 114 to 203 mm, depending on the thickness of reinforced concrete products. The coordination dimensions of the plates are:

- length - 2.4 ... 12m;

- width - 1 ... 6.6 m.

Reinforced concrete products must have additional structural elements described above for solid slabs. As a reinforcement of the ends of the slabs, sealing of voids with cement mortar or other accessible ways specified in the standards or working documentation.

Ribbed ceilings

Ribbed floor slabs are used, as a rule, in industrial construction. Due to the peculiar stiffeners, they are highly resistant to mechanical damage, but they do not look aesthetically pleasing on the ceilings of residential premises due to an uneven surface. Depending on the purpose, ribbed slabs can be laid in the form of a trough - with the ribs up, but more often they are mounted more traditionally - with the ribs down.

The considered floor slabs are manufactured in accordance with the requirements of the standards:

- for products with a height of 400 mm - according to GOST 27215-87;

- for prestressed slabs 300 mm high - according to GOST 21506-87.

Both standards indicate that ribbed panels can be made of heavy or lightweight concrete, and used:

- both in heated and unheated buildings, as well as in the open air;

- in the temperature range - from -40 to +50 degrees, but subject to additional requirements, extended operating limits are allowed;

- with estimated seismicity up to 9 points;

- in a non-aggressive, slightly or medium-aggressive gaseous environment that has any effect on the concrete surface.

Ribbed slabs with a conventional frame are subdivided according to the way they are supported on crossbars:

- 1P - installation of products is provided for on the shelves of crossbars;

- 2P - laying is carried out on the upper part of the support beam.

In turn, 1P floor panels have eight sizes, and 2P - only one. In the first case, the length of the products is 5.55 and 5.05 m with a width of 0.74-2.985 m. In the second case, the dimensions of the slab remain the same - 5.95 * 1.485m.

Prestressed floor panels are manufactured in three standard sizes, differing from each other in width and shape in plan. Their length is 5.65 m, and the width:

- for P1 - 2.985m;

- for P2 - 1.485m;

- for P3 - 0.935m.

In addition to dimensions, the normative documentation specifies the characteristics and requirements for concrete, reinforcing bars, embedded parts and the finished product as a whole, and possible tolerances are also determined. Manufacturers are obliged to strictly comply with them.