Pipe heating: water supply and sewerage systems in the country, a kit for warming up electric plastic products, how to make electric heating with your own hands. Heating pipes for water supply in winter

Add to bookmarks

You can avoid such a problem by laying pipes at such a depth where they will not be afraid of frost. But this is not always possible.

But there is another, more reliable option - heating pipes for water supply. It is the only way to provide a system of continuous water supply to the house or cottage. Moreover, heating can prevent damage to pipes in the event of freezing, otherwise they will simply be unsuitable for subsequent operation, this will disrupt the life of the house, and besides, it can lead to unplanned major repairs.

There are many options for heating pipes.

Heating cables outside the pipes

One of the most effective is electrical heating, which consists of laying a specially designed cable over or inside a pipe.

There are several methods for performing electrical heating by running a cable through pipes for subsequent heating:

- in a straight line along the pipe;

- in the form of a wavy line;

- spiral around the pipe.

When heating pipes made of plastic or metal, one should keep in mind the need for thermal insulation with mineral wool, foam plastic, etc. At the same time, these materials must not pass moisture, otherwise frost protection will not be achieved.

Heating cables inside pipes

More common today cable system internal heating, when the cable is laid inside the pipe. In this method, the cable is in direct contact with the heated medium, which guarantees protection against freezing.

Cables for internal heating are characterized by increased rigidity, as a result of which its installation in straight sections of the pipe is simplified. In addition, the cables are coated with specially formulated food-grade polyethylene to prevent harmful emissions, which ensures that the water transported through the pipeline has a consistent taste.

Please note that when using this heating option, you need to accurately measure the required length of the cable, since neither cutting nor folding into a loop is unacceptable.

Self-regulating heating cables

Self-regulating cables organize not only the heating of pipes, but also, if necessary, the thawing of ice and snow, ensuring a certain temperature in hot water pipelines.

This system is the most reliable and economical to date, due to the fact that heating cable has a unique characteristic, due to which it can change the power in each section of the pipeline, depending on required amount heat transfer: in cold areas - more heat, in warm - less.

Thus, please note that a self-regulating cable will prevent overheating of the pipe, as well as reduce the consumption of electricity spent on heating.

As a rule, a self-regulating pipeline heating cable is mounted on top of the pipe. Its installation is quite simple and can be done independently, and it is easily cut to the desired length. Connected to a 220 V electrical network.

In any case, each water supply system must be considered separately and exactly the system of heating and protection from the effects of severe frosts must be selected, which will turn out to be of the highest quality, efficient and practical in specific case.

Fundamental tasks of pipeline heating systems

When choosing which heating system to stop on, it should be remembered that it has tasks that it must perform:

- The system must help prevent the formation of condensate and freezing of the transported liquid.

- To compensate for heat losses, which is very important if the temperature of the water at the inlet and outlet must be constant, and heating allows you to compensate for heat transfer to the environment. In addition, it is possible to increase the process temperatures to the desired level in the event of a pipeline shutdown.

- Perform process heating, which creates the need to maintain a certain temperature of a particular process. It is worth noting that if heat absorption occurs, then the heating system must have a reserve of power to restore balance.

- To carry out heating of the liquid at the initial stage along the active section of the pipeline in order to organize normal conditions for its delivery to other sections of the pipeline.

In order to effectively solve the problems of heating pipes, self-regulating and resistive cables can be used. It should be noted that a self-regulating cable increases the amount of heat generated when the pipe temperature decreases, and decreases when it rises. Such a cable definitely simplifies the process of designing and calculating the planned system, and at the same time significantly increases the reliability and long-term use, and also significantly reduces power consumption.

When preparing for the installation of a heating system, it is necessary to calculate the power and length of the cable by determining the heat losses of the pipeline, which depend on such parameters as:

- diameter and length of the pipeline;

- type and thickness of heat-insulating material;

- ambient temperature;

- the temperature at which the transported substance is kept in a liquid state.

For, as a rule, materials such as:

- polyurethane foam;

- foamed polyethylene;

- mineral wool, etc.

One more point should be taken into account: the thickness of the heat-insulating layer should be at least 50 mm. In addition, the material should be protected from the possibility of moisture ingress, otherwise its effectiveness will be significantly reduced.

Pipeline heating system: installation

When installing pipe heating, it is necessary to insulate the cable with aluminum tape or pipe in order to prevent contact with heat-insulating materials. Consider the most popular methods for mounting a heating cable on pipes.

Method No. 1. The cable (sometimes there are several) must be pulled along the pipe and attached along its entire length with aluminum adhesive tape.

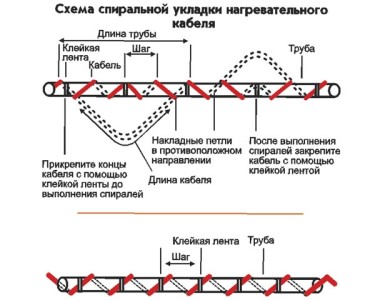

Method number 2. Measure the required footage of the cable, hang it along the pipe in the form of loops. Initially, lightly glue the cable to the pipe with pieces of aluminum tape, then wind the resulting loops around the pipe and use the same tape to attach to the pipe along its entire length.

Method No. 3. The cable must be wound around the pipe at the same time with the required distance between the turns and attached along the entire length with aluminum adhesive tape.

When using any of the above methods, without fail the pipe with the installed heating cable should be marked "200 volts, dangerous, heating cable".

In fact, any type of pipe heating system against freezing for control purposes involves the use of a thermostat, which will guarantee the minimum consumption of electrical energy and the most efficient heating of the water supply system, which makes it possible throughout the year not to encounter difficulties due to freezing of the water pipeline in a private house or in the country. .

The ideal solution for giving, garage, garden plot!

Easy installation and connection.

- Durability and reliability.

- No control system required.

- All you need to do is just plug it in.

A set of heating (heating) cable for heating pipes (pipelines) EBECO FROSTVAKT serves to protect domestic and industrial water pipes (plastic and metal, up to 100 mm in diameter) from freezing at negative temperatures, indoors and outdoors.

You can also use the heating cable to heat downpipes and funnels (the connection of the heating and conductive cable must not be inside the pipe), air conditioner drainage systems, soil in greenhouses and calves.

Cable for heating pipes "Pipeline Protection" consists of a heating self-regulating cable Ebeco EBtrace F10, supplied with 2 - 3 m (depending on the power of the set) connecting cable and detachable connection, designed for 220 volt sockets with grounding (Euro plug). The output thermal power is regulated by the heating element of the cable itself - a polymer matrix, depending on the heat removal environment. Thus, there is no risk of overheating of the heating cable for heating pipes and pipelines.

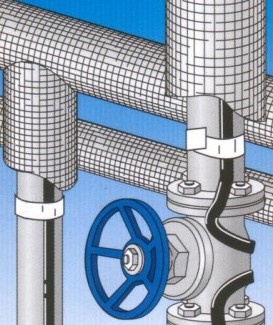

It is used only on heat-insulated pipelines, i.e. after laying the heating cable, the pipeline or pipe fittings (faucets, tees, couplings, flanges, water meters, etc.) must be thermally insulated. At the same time, the heating cable for heating pipes can only be covered with material that can withstand temperatures from 65C (for example, mineral insulation) with a thickness of at least 30 mm.

Pipe heating self-regulating cable can be carried out by laying the cable both outside the pipe and from the inside.

Pipeline heating outside is carried out on newly laid water pipes or on water pipes that can be accessed. In this case, the heating cable is fixed on the bottom surface of the pipe or wrapped in a spiral around the pipe (depending on the diameter and specific site conditions). The cable is attached to the pipe using aluminum tape to transfer heat from the cable evenly over the entire surface area of the pipe (the entire heated section of the pipe must be wrapped with aluminum tape). After that, pipe insulation such as Thermaflex, Energoflex, etc. is put on the pipe.

In the absence of access to the pipeline and the impossibility of providing it, the heating of the pipe with a self-regulating cable is carried out from the inside of the pipe. At the same time, a tee or a saddle is installed at the place where the heating cable enters the pipe (for all types plastic pipes we recommend saddles) with a 1/2” or?” outlet. After installing the saddle or drilling a hole in the pipe, a pipe tie-in is screwed into the saddle, into which, according to the attached instructions, the heating cable is inserted. ATTENTION! Pipelines with a diameter of 20 mm and below are heated only from the outside.

This article will consider the heating of pipes, the main types and tasks of heating systems and their installation.

Currently, in many country houses, water enters the house from a well through pipes, which can freeze during severe frosts and cannot cope with their task. In order not to heat pipes in the country or in country house, pipes can be laid at great depths, where they will not be afraid of any frost, but this task is not always feasible.

Therefore, the only way to protect water, sewer and fuel pipes is heating, which ensures an uninterrupted supply of water or fuel to the house, as well as drainage. In addition, it helps to prevent damage to pipes due to freezing, as a result of which they may become unsuitable for further use.

Most effective method pipe freezing protection today is the electric heating of pipes, using a special cable placed on top of the pipe or inside it.

Heating cables on pipes

Heating for pipes is usually done with heating cables running through the pipes.

Currently, several methods of such pipe freezing protection are most often used:

- Laying one cable or several in a straight line along the pipe;

- Cable laying in the form of a wavy line;

- Wrapping the cable in a spiral around the pipe.

The heating of plastic or metal pipes implies that the pipes are insulated with heat-insulating materials such as mineral wool, polystyrene, etc. At the same time, reliable protection against freezing will be provided only if thermal insulation material completely impervious to moisture.

Heating cables inside pipes

The most widely used pipe heating system today is the installation of heating cables inside the pipe.

In this case, the cable is in direct contact with the heated medium, which provides reliable protection.

Such a cable usually has a high rigidity, which simplifies its installation on straight pipe sections. In addition, such cables have a special coating made of food-grade polyethylene, which prevents the appearance of harmful emissions during cable operation, so the taste of water does not change.

Important: When installing heating on pipes with such a cable, accurate measurements of pipe sections should be performed, since cutting or folding the heating part of the cable into a loop is prohibited.

Self-regulating heating cables

Heating scheme

The function of self-regulating heating cables is not only heating pipes, but also melting ice and snow in gutters and drains, as well as maintaining the desired temperature in hot water pipelines.

This method of heating pipes today is the most reliable and economical way to protect pipes from freezing due to unique property heating self-regulating cable, which allows you to change the power allocated for each specific section, depending on the required heat transfer conditions.

In cold sections of the pipe, such a cable emits more heat, and in warmer sections, less.

Important: the use of a self-regulating cable avoids overheating of the pipe and reduces energy consumption.

Self-regulating cable is usually installed on the surface of the pipe. With the help of such a cable, heating pipes with your own hands is quite simple, it can be cut to the desired length (0.5 - 100 m) and connected to a 220 V power supply.

In each case, you should choose the heating system and which seems more practical, which will allow you to qualitatively and effectively counteract the effects of the most severe frosts on water supply and sewerage pipelines.

The main tasks of the heating system

When planning how to heat a pipe, it should be borne in mind that the heating system must perform several basic tasks:

- Prevent freezing and condensation of fluid in pipes.

This is true not only for protection water pipes in winter, but also for heating fuel lines, preventing excessive thickening of products even in warm climates. - Compensate for heat loss, which is especially important when the temperatures of the gas or liquid must be the same at the inlet and outlet of the pipeline, since heating is able to compensate for the transfer of heat from the pipe to the environment.

Besides, at the same time heating to process temperatures of the stopped pipeline is provided. - Performing process heating, at which it becomes necessary to maintain the temperature of a particular process in a pipe in a given range.

In this case, in the case of heat absorption during the heating process, the system must have a power reserve. - Warm up at start. The system must heat the liquid flowing through the active section of the pipe, providing normal conditions for its transportation in the remaining sections of the pipeline.

Both self-regulating and resistive heating cables can be effectively used to successfully solve pipe heating problems. At the same time, a self-regulating heating cable with a decrease in the temperature of the pipeline increases heat generation and reduces heat generation when the temperature rises.

The use of such a cable makes it possible to significantly simplify the design and calculation of the system, as well as significantly increase its reliability, service life, and significantly reduce the consumption of electrical energy.

The power and length of the cable is determined by performing a calculation that determines the heat loss of the pipeline, depending on the following parameters:

- Pipeline dimensions;

- Type and thickness of thermal insulation;

- Ambient temperature;

- The temperature that maintains the liquid.

The following materials can serve as thermal insulation of the pipeline:

- polyurethane foam;

- Foamed polyethylene;

- Mineral wool;

- Other materials used for pipe insulation.

Important: the thickness of the thermal insulation layer must be at least 50 mm. In addition, the heat-insulating layer should be protected from moisture, which significantly reduces its effectiveness.

Pipe heating installation

heating installation process

When installing a pipeline heating system, special attention should be paid to insulating the cable with aluminum tape or an aluminum pipe, preventing it from direct contact with thermal insulation.

Let us consider in more detail the main methods by which the cable is installed on pipes for domestic use:

Important: in each case, a pipe equipped with a heating cable must be marked “200 volts, dangerous, heating cable”.

In almost every case, a thermostat must be used to control the system that protects pipes from freezing, since only its use guarantees minimal energy costs and the most efficient heating of water supply pipes, which allows for all year round not experience problems associated with freezing cold or hot water pipes.

Raychem Pipeline Frost Protection Heating Systems provide freeze protection for liquids in plastic and metal pipelines and maintain proper pour points for oil. This system is nothing but cable heating pipelines.

Heating cables FroStop Green (10 W/m at 5 C) and FroStop Black (18 W/m at 5 C) are used for heating pipelines

In conditions of negative ambient temperature, thermal insulation is not able to fully protect pipelines from freezing on their own.

Severe weather conditions can also lead to blocked fuel lines.

In cold conditions, thermal insulation alone cannot fully protect downpipes from freezing, and to compensate for heat losses, Raychem heating cable is used, which is one of the main elements of the pipeline electric cable heating system.

Raychem pipe protection systems prevent liquids from freezing in plastic and metal pipes.

Most often, in winter colds, the danger of hypothermia of water pipes, both domestic and domestic, located right down the street or in an unheated basement or located at a shallow depth in the ground increases significantly.

We heat the pipeline

Raychem heating cables are placed and mounted in straight sections directly on pipes under thermal insulation.

Flexibility of heating cable installation

Heating cables can be cut to desired lengths on site for ease of installation.

A fairly simple and effective solution is cable heating of pipes of a water supply system using a self-regulating heating cable. Ultra-modern self-regulating properties neutralize overheating of Raychem cables, despite the rather thick layer of thermal insulation. Thanks to this feature, the cable for heating pipes will not burn out, working efficiently and reliably for a long period of time.

Reliability of self-regulating cables

Heating cables do not overheat even when overlapped. Thus, the system is maintenance-free.

Convenient supply of heating cables

Raychem heating cables are supplied on a reel (can be ordered in any desired length).

Manual and description of components

Application area

Freeze protection of pipes. Maximum external exposure temperature + 65°C

- heating cable FroStop Green 10 W/m at 5°C and alternative heating cable FroStop Black 18 W/m at 5°C

Heating cable length calculation

The heating cable is mounted on the pipe in straight sections. On short branches (up to 3 m), it is advisable to lay the heating cable in a loop instead of a T-branch. The total length of the sections of the heated pipe:

- + approx. 0.3 m per power supply

- + approx. 1.0 m per T-branch

- + approx. 1.2 m per junction for 4 circuits

- + about 1 m in the presence of additional sources of heat loss (latches more than 2” and pipe supports without thermal insulation)

- = total required heating cable length

Thermostat AT-TS-13 for automatic control of cable heating temperature

- Adjustable temperature range: - 5°C .. + 15°C

- Ambient controlled thermostat

- Maximum switching current 16 A, 250 V alternating current

- JB16-02 - Heat-resistant junction box for power supply and branching of heating cables

- CE20-01 - Connection and termination kit

- Heat shrink technology.

- Oil seal M20.

Choice of thermal insulation to protect pipes and heating cable

Frost protection for temperatures down to -20°C.

Heating cables for pipelines

Raychem Pipeline Heating is a frost protection system that keeps water lines, fire lines, sprinkler systems and fuel lines from freezing in cold winter conditions. Due to the wide range of applications, the heating cable for pipes is universal for domestic, industrial and commercial facilities.

The Raychem Pipe Frost Heating System reduces overall installation and operating costs.

This energy-saving solution includes self-regulating cables and an automatic control device that controls the temperature and turns on the system only when and where it is needed. The heating cable for pipes works on the basis of a special semiconductor matrix that can change its conductive properties depending on temperature changes. That is, it turns on the system when the temperature indicators decrease and vice versa, turns it off when the indicators reach elevated values.

FroStop Green and FroStop Black anti-freeze heating cables are suitable for pipes and pipe heating made of any material (copper, stainless steel, plastic, composite materials or threaded pipes) without restrictions. In addition, the cable for heating pipelines can be laid both inside the pipe and outside. To select the laying method, there are certain recommendations that specially trained specialists are familiar with. It would be advisable for them to entrust the installation of pipe heating.

For plastic pipes, ATE-180 aluminum fixing tape must be used. Heating cables in frost protection systems should be covered with fastening tape along the entire length of the cable. Thermal conductivity coefficient of thermal insulation λ = 0.035 W/(m K) or lower.

Important note: Frost protection heating cables with a fluoropolymer protective sheath (eg BTV2-CT) should be used for solvent-based, mixed and/or bituminous thermal insulation. Modern systems heating pipes must necessarily meet all the above requirements. It is in this case that we can talk about economical, convenient, reliable and durable work.

The choice of thermal insulation. Frost protection of pipelines for temperatures up to -20 C