If they park on suburban roads. Carport for a cottage. Lawn grate or do-it-yourself eco-parking

It is not always convenient to drive a car into a garage in a country house, and in the summer it is also too lazy. In addition, guests can come to the hosts. And in that case parking spaces in the garage in the country is certainly not enough. Owners household plots who visit their possessions only in the summer, a garage is not needed at all, and the costs for it are considerable. Leaving vehicles on - spoiling it. The way out of this situation is a do-it-yourself platform for a car in the country. It will allow you to comfortably leave the car for the weekend, and even protect it from bad weather.

Place for the vehicle how to do

When the idea of creating such a parking lot with your own hands has already taken root in your head, it’s worth deciding how it can be done:

- laying method paving slabs;

- pouring concrete;

- crushed stone;

- turf laying method. The article describes in detail

The last two methods are unreliable. But the first two methods are quite suitable in the country. Other methods can be found in the article. It is worth dwelling on them in detail.

For cars

Regardless of the method of implementation, before starting work, it is worth correctly assessing the parking space. It should be level and low. ground water. It is desirable to identify a site near the entrance, then you do not have to lay a long access road, making it a central element of the design suburban area.

You need to stock up on all the necessary tools and calculate the exact size of the site. It is formed on average at the rate of 3 m wide and 6–7 m long per parking unit. If the territory allows, you can do it with a small margin.

The first method is the device of the site by laying paving slabs

The work consists of the following stages:

- . It will experience constant loads, so it must be wear-resistant. Suitable tiles made by vibropressing. She also has good frost resistance, for which special thanks to her. The thickness of paving slabs must be at least 40 cm.

Laying layers of paving slabs

Consider a few important tips according to the choice of paving slabs for the arrangement of a place reserved for a vehicle:

- If you decide to purchase a vibrocast tile, you should be especially careful. Of course, vibrocast paving slabs are bright, have a variety of rich colors and a beautiful smooth surface. The thing is that the glossy sheen and smooth surface of such products can be achieved in two ways: by adding special concrete plasticizers in the production of paving slabs, or by adding more water.

- Remember that truly high-quality paving slabs cannot be cheap.

- Be careful when choosing paving slabs, especially saturated colors. Currently, manufacturers offer the widest range of color solutions for paving slabs, from white to all kinds of rich shades. However, obtaining bright shades is possible only if expensive imported pigments were used in the production of paving slabs.

- The territory is marked with wooden pegs with twine. For greater accuracy, you can mark the outer borders with paint. In the article you can learn about the main ways of laying paving slabs in your summer cottage.

Ready-made parking for a vehicle in the country

- Soil and earth are removed throughout the territory of future work, a pit 50 cm deep is being built.

- At this stage, it is necessary to set the horizontal level in two sides of the site rectangle.

- The earth at the bottom of the pit is compacted. It is better to do this with a vibrating plate, vibrating leg, etc. However, the purchase of such equipment only for arranging a parking zone is not profitable. You can take it for a short-term lease, now more and more companies offer such services. But if it does not work out, then you can work with a manual rammer. You just have to make a lot of effort to do it yourself and it's better to call friends.

- If curbs are planned, install them.

- Creation of a pillow from crushed stone and sand. The pillow has three layers: the bottom 30 cm high is laid with large gravel, then - 5 cm of fine gravel. The uppermost layer, 4-5 cm thick, is made of coarse sand.

- The next step is to mark the site into strips for ease of use. They do this by marking the distance on the threads of the level of 15-20 cm. This is quite tedious work, but it allows you to do the job correctly.

- After marking, the sand is leveled according to the level, while the thread should rise 8-10 cm above the sand. The sand is compacted.

- Before starting work directly with the tile, it is carefully inspected, the tile with marriage is set aside for cutting.

Another type of parking lot is grass cover.

- It is better to fix with a solution of 6 parts sand and 1 part cement. Prepare it in small portions, about one line, so that it does not dry out.

- The solution is distributed over the area of the first line, leveled and compacted.

- Then lay out the tiles. Laying is carried out in front of you so that the master moves along the finished tile. The tile is pressed into the mortar and tapped with a mallet. The distance between the tiles should remain approximately 5 mm. Such laying is carried out row by row, and line by line throughout the site.

- If a row of cut paving slabs is required, it is laid out at the end of the work. To do this, the tile is cut with a diamond disc and broken.

- After laying, the gaps between the paving slabs are covered with a mixture of sand and cement in the same proportion as for the preparation of the mortar. To do this, the mixture is poured over paving slabs and spread with a hard broom.

The video below describes this method in detail:

The second way is to make a concrete platform for the car

A concrete platform can only be built on stable soils that are not subject to drops and swelling. Before starting planning, it should be borne in mind that the concrete platform should rise about 5 cm above the soil level. This is necessary so that moisture does not accumulate on it, it will damage the concrete screed, and in winter, during temperature changes and freezing water, it can even break it . The coating should have a slight slope (2-3 cm), which is also necessary to protect against water.

- The territory is marked out in the same way as in the case of paving slabs.

- Then the marked area is freed from any items. Sod and soil are removed 10 cm deep.

- A pit is made with a depth of about 40 cm.

- At the bottom of the pit, the soil is carefully compacted.

How to concrete a parking lot for a car with your own hands

- A wooden formwork is installed along the edges of the pit, if a curb is not planned along the edge. If a curb is planned, then at this stage it is installed.

- A sand and gravel pillow is poured onto the prepared soil. For the durability of the coating, the thickness of the pillow must be at least 20 cm.

- Now you need to properly prepare the solution. With his own hands, he prepares from three parts of sand, three parts of crushed stone and one part of cement. Sand for mortar is better to take alluvial, it is cleaner and more uniform. Ordering ready-made concrete will make life much easier.

- The total thickness of the screed must be at least 20 cm. However, it should be poured in stages. For greater structural strength, it is worth using metal fittings. The first layer of it is laid on a sand cushion. If the reinforcement consists of several parts, they must overlap. Then pour a 5 cm layer of concrete. Immediately on top of it, another layer of reinforcement and another 5 cm of concrete are laid. Thus, the required thickness is reached.

- Leave the concrete screed for three days. You can't walk on it at this time.

- When the concrete dries, the formwork is removed, if it was, and the holes from the pegs are sealed. With other features of such an important process as, you can find out in the article.

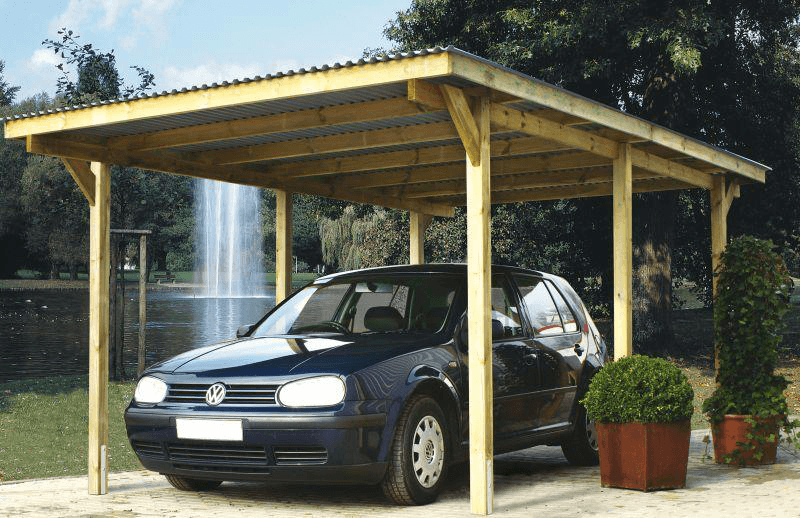

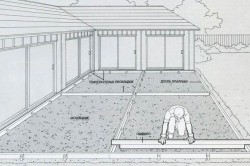

The site can be equipped with a canopy. The principle of their implementation is approximately the same. Only the material from which it is made will differ. Any material can be used as a material for the roof: metal tiles, polycarbonate, soft roof, galvanized sheet and even natural materials. It is desirable that the roof over the car park be in harmony with the rest of the buildings on the site.

When traveling to summer cottages, it becomes necessary to arrange parking for a car at the cottage. A car left in front of the gate on the street will create inconvenience for neighbors and may become prey for intruders. And an unequipped entrance to the site will quickly lead to the formation of a rut from wheel sets, which is filled with rainfall. The view of the suburban area will be rather unsightly. The car, without even the simplest shelter, will be exposed to the sun, rain, hail and snow, which will certainly affect its appearance. The problem is solved by the device of the simplest parking lots without large financial investments.

Consider how to make a parking lot for a car with your own hands in the country.

Choosing the right place

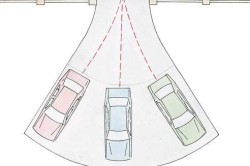

The parking place should provide convenient entry and exit of the car from good overview. The site should be level and slightly raised above the surface of the adjacent road. The dimensions of the site depend on the number of cars that will be parked on it. For one small car, a width of 2.5 is enough, with a length of 5 m. For overall transport, you will need 3.5 by 6.5 m. When planning parking for 2 cars, the required dimensions increase by 2 times.

The structure can be made in the form of a full-fledged closed garage, an open area with or without a canopy.

Parking for a car in a country house made of rubble

This is an easy-to-execute and cheap option in terms of money. Suitable for all types of soil, including heaving.

Scope of work:

- marking the perimeter of the site with fixing the corners with wooden or metal pegs, along which a strong twine is stretched.

- soil development to a depth of 30 cm with the removal of all weed roots;

- a sand cushion of 10 cm is arranged on a leveled surface with a thorough compaction of the sand; to increase the degree of compaction, the sand is wetted with water;

- installation around the entire perimeter of prefabricated concrete curbs, this is necessary to hold the crushed stone platform under the weight of the car. Blocks are installed with small gaps through which water flows. Instead of prefabricated elements, it is possible to pour a monolith with a formwork device, but this will necessitate a technological break during the hardening of the concrete mixture;

- laying geotextiles to prevent the germination of weeds;

- parking from crushed stone in the country is carried out only from crushed granite or river gravel.

- backfilling of crushed stone to the top of the curbs. The lower layer is covered with material of fractions 30…60 mm, the upper one — 5…20. Both layers are carefully compacted. Laying the top of the fine fraction will fill all the voids and allow easy leveling of the surface. It is imperative to provide for a slight slope (about 2 cm) from the center to the edges for drainage;

- for the convenience of entering the parking lot in front, it is recommended to lay on a crushed stone pillow for a strip of concrete paving slabs;

- if it is planned to wash the car in the parking lot, a shallow drainage of perforated plastic or ceramic pipes can be laid around the perimeter. Pipes are laid with a slope to drain water.

When deciding how to fill the parking lot in the country, it is important to know about the inadmissibility of using crushed limestone, which, when wet, gets wet, turning into a dirty mess.

The crushed stone platform is strong and durable; water will never stand on it, which will easily seep through fine gravel. The only drawback is that if you do not shelter with a canopy, you will have to perform periodic cleaning of fallen leaves.

Important: it is necessary to start off on a gravel site without slipping, so as not to violate the integrity of the coating.

Concrete pavement for parking in the country

Concrete is laid only on sites with soils not prone to frost heaving.

The work is carried out in the following sequence:

- Soil development to a depth of 10 (for a light car) to 20 cm with the removal of weeds along with the roots.

- Installation of formwork from edged boards to the height of the coating with fixation with strong pegs.

- Laying a layer of geotextile on a compacted sand cushion.

- Installation of beacons in compliance with the necessary slopes (if a canopy is not provided).

- Laying concrete mix class ≥ B20. Concrete can be ordered from centralized concrete plants with delivery by an automixer or prepared independently directly at the construction site. The lower 5-layer is laid, leveled and covered with a reinforcing road mesh with cells of 10 × 10 cm with an overlap of 10 cm, then the top layer of the same thickness is poured without interruption. Compaction is carried out by vibrating screeds or vibrating platforms. Leveling with smoothing is done with a long trowel.

- The next day, beacons are pulled out with sealing of the resulting furrows with cement mortar.

- Surface ironing.

- After 3 days, the formwork is disassembled. The site is covered with wet burlap on hot days or plastic wrap on cool days.

- Check in concrete surface allowed after 4 weeks, when the concrete gains 100% strength.

Such parking is distinguished by reliability, practicality and durability, but more costly in terms of cost and execution time.

What else can you make parking in the country

For heaving soils, parking is good using paving slabs 5 cm thick. The dimensions are 30 by 30 or with sides of 50 cm. The tiles are laid on a cushion of crushed stone with sand or on a cement-sand mixture, with small gaps for drainage. Horizontal alignment is done with a rubber mallet. It is recommended to lay curbs around the perimeter of the parking lot. The tile is easily laid by one person to obtain an original and durable coating. Instead of tiles, you can use natural stone, granite and basalt paving stones or clinker bricks.

The construction of eco-parking, consisting of a rigid plastic grate sown with lawn grass, is popular. Such a coating is durable (does not bend under the weight of even a heavy car), resistant to temperature extremes and drains water well. The durability of the parking lot is about 25 years. After clearing the site with the removal of all vegetation, the grating is laid with tight fixing. Fertile soil is poured into the lattice cells at a third of the height, and perennial varieties of lawn grasses are sown. In dry years, periodic watering is necessary. The parking lot looks like a lawn with an attractive appearance. The only negative is the high cost.

For open areas, it is desirable to install a canopy to protect the machine from precipitation and ultraviolet radiation. Sites located next to the house can be covered by a continuation of the roof of the main building. For separately located parking lots, a frame is constructed from shaped or round pipes fixed on the foundation structure, covered with polycarbonate ≥ 6 mm thick, corrugated board or ondulin. For a collapsible roof, you can use a tarpaulin or a dense awning. The height of the canopy is 2.5 m.

All the advantages of self-arranged parking will come to light soon and will delight you with additional amenities and practicality.

- How to choose a good place?

- Necessary tools and materials

- We prepare the base and additional drainage

- We select the coverage for the site

- Arrangement of the roof and tips on the topic

A platform for a car in a country house with your own hands can be built even by an inexperienced craftsman. But what benefits does it have?

Cover options for the site: asphalt, paving slabs, concrete screed, ecological lawn cover.

A summer resident can be envied in many ways: clean air and environmentally friendly products, a river, a forest. It is possible to list all the advantages of giving a very long time. But there is only one drawback: the village infrastructure does not provide for parking and parking lots. There is only one way out: do-it-yourself parking in the country should be created. At a minimum, you will not leave your car in the scorching rays of the summer sun. And by and large it will be a place where you can leave your car in safety or carry out minor repairs.

How to choose a good place?

For the car, it is necessary to make a dense platform and provide a roof over it. It is worth starting the construction of a mini-parking with an analysis of the area (in architecture, this process is called explication). After all, you don’t need problems with additional re-equipment of the entire summer cottage? First of all, determine the place for which the entry will be the most optimal. It would be nice if the site was in a straight line with the direction of entry-exit. And it will look good, and it will not spoil the overall design of the site.

The second condition for choosing a place is the deep occurrence of groundwater. A slight elevation will keep the site (and car) clean in any weather, as all precipitation will quickly soak into the soil. If there is no hill on your site, then it can be artificially organized, while providing drainage along the perimeter of the future parking from pipes dug into the soil, with longitudinal holes.

Back to index

Necessary tools and materials

So, you have chosen a place for a future parking lot and are full of desire to get to work. For this you will need:

- bayonet shovel;

- river sand;

- crushed stone;

- vibrorail;

- ruberoid;

- nails and hammer.

Back to index

We prepare the base and additional drainage

First of all, it is necessary to remove the soil to a depth of at least 10 cm. If the soil is loose or groundwater is in close proximity to the surface, then the depth of the pit must be doubled. Drainage will need to be made around the perimeter. An additional pit can be suitable for this (it must be located around the perimeter to a depth of 20 cm from the main parking plane).

Pipes with holes on the side surfaces are laid in the pit. Pipes can be replaced with ordinary expanded clay or crushed stone of an average (up to 3 cm) fraction. We cover the drainage pit and the site with sand, having previously placed any waterproofing agent.

It is not needed to combat excess moisture, but it will help to fight the breaking shoots of plants. We tamp the sand (or spill it with water) and cover the entire surface with rubble. The layer of crushed stone should be at the level of the cut of the earth.

Back to index

We select the coverage for the site

The main part of the site is ready. It can be left in this form, but most motorists prefer to provide a more aesthetic coating for their site.

The options here are different:

- asphalt;

- paving slabs;

- concrete screed;

- ecological lawn.

In all cases (except for the use of the lawn), perimeter fencing will be required (except for the place where the race will be carried out).

For this, either a sidewalk curb is used, or ordinary boulder stones. These elements are laid first, and then the coating itself is laid. Asphalt should be attributed to the most unclaimed materials. In the summer heat, a specific smell of oil emanates from it, which is unacceptable in summer cottage conditions.

More aesthetic concrete platform. A concrete screed is produced in several stages: first, the surface is rammed with a vibrating screed, then a layer of concrete (5 cm) is laid, and it is reinforced. You can use any metal elements for this, connecting them together by welding or tying with wire. Concrete (5 cm) is again laid on the reinforcement, and the surface is leveled with a rule. It is not necessary to follow the horizontal direction: it is even better if the concreting creates a slight slope at the edges. Parking in this case will never be damp - the water will drain to the edges on its own.

Paving slabs are laid on a substrate of a mixture of sand and concrete. Such a composition is leveled on the surface of the site and compacted with a vibrating screed. Next, we lay the coating elements tightly to each other. To ensure the level, all elements are tapped with a rubber mallet.

Lawn coating is considered the most beautiful, but it should be attributed to the most expensive. To provide such coverage, you will need to purchase a special cellular mesh, the holes of which are filled with soil and sown with grass. Even if water enters such a parking lot, it is quickly absorbed by the soil and the root system. The car can be washed without much concern for the cleanliness of the site.

When arranging a suburban area, sooner or later the turn of parking comes. Let only a small patch be allocated for the site - its device must be taken with all responsibility.

Public roads in holiday villages are usually narrow, and it is inconvenient to park on them.

Own parking is more practical and safer. So that the wheels of the car do not get stuck in a rut during rain, the site must be thoroughly equipped. Coverage is chosen based on financial capabilities and estimated labor costs. The best option- reliable coating with stable characteristics, independent of the season and precipitation. The main types of coatings: crushed stone, concrete, paving bricks, geogrids.

Bulk coating for car parking

Crushed stone coatings are the most economical: they perfectly pass water and do not crack. A crushed stone parking lot differs from garden paths with a similar coating in a greater thickness of the bearing layer of sand and gravel. For parking a passenger car, it should be 20 cm. Pay attention to the material for the carrier layer. Lime gravel quickly grinds to powder in the bottom layer, turning into mud when wet, and even with a non-woven lining, quickly overgrown with weeds. River gravel of fraction 30-60 shows itself much better. It does not crumble, does not cake and easily passes water. The final backfill is made from fine gravel crushed stone of fraction 5-20, which fills the voids well and levels the surface with high quality. In the future, the site will be easily paved over a gravel base.

Our reference

The bulk platform has its drawbacks. The uneven surface makes it difficult to clean in winter and move in heels. Fallen leaves and small debris are clogged between the pebbles, and it is difficult to remove them from there. In addition, crushed stone that spreads outside the site must be periodically poured and leveled.

Filling the parking lot with concrete

The guaranteed strength of the parking lot will be provided by a concrete coating, which will become an excellent foundation for paving slabs. A concrete parking lot can do without paving, in which case it must be treated with a hydrophobic compound to prevent cracking due to temperature fluctuations. In general, the cost of parking will depend on the thickness and class of concrete, the type of reinforcement.

To fill the parking lot with concrete, install a wooden formwork of a suitable height (every 5 m must be broken with an expansion joint), cover the surface with a 5 cm layer of concrete mixture and, before it sets, lay the reinforcing mesh, pour concrete again on top. The parking lot must have a concrete pavement with a thickness of more than 10 cm, for a heavy car - thicker. To avoid the accumulation of water, it is necessary to provide a slope and arrange a storm sewer. The site will gain the necessary strength in a month.

Paving of a platform for a car

The parking device with paving brick paving significantly adds cost, but it also looks more elegant. The shade can be chosen in unison with the coating of garden paths or the finish of the basement.

The parking device with paving brick paving significantly adds cost, but it also looks more elegant. The shade can be chosen in unison with the coating of garden paths or the finish of the basement.

This type of parking lot consists of a carrier layer of sand and gravel, which is arranged in the same way as in the case of crushed stone parking, but with a greater depth to the thickness of the paving bricks.

The brick gives a smooth surface, does not crack in winter, passes water well, especially when laid on high-quality sifted sand.

How to arrange a base for parking

For parking lots with a bearing layer of sand and gravel, it is important that the coating does not “walk”. Therefore, the carrier layer is arranged in a shallow pit, where 10 cm of sand is first poured and rammed.

In order to save money, the main carrier layer can be sprinkled with secondary crushed stone (construction waste, brick breakage) of a large fraction of 40-100. The depth of the pit depends on the thickness of all layers: sand, carrier layer and paving. The sand-gravel mixture should be well compacted and laid from the bottom and in the middle with geotextiles with a density of 200 g / m.

Lawn grate or do-it-yourself eco-parking

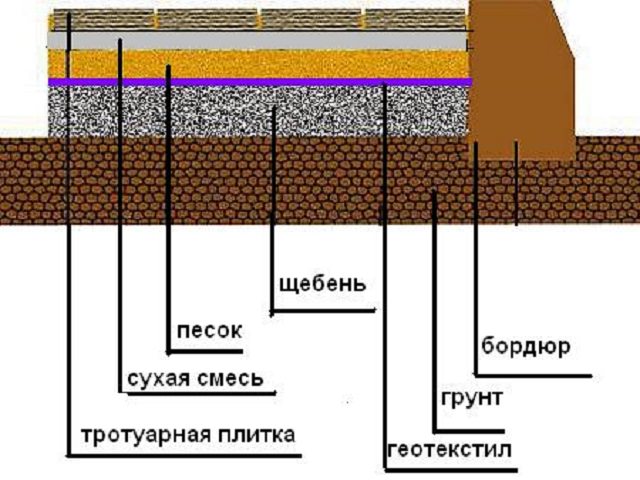

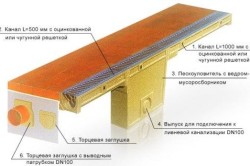

1 - soil. 2 - crushed stone. 3 - geotextile 160/200 g / m 2. 4 - sand and gravel mixture. 5 - lattice 6 - fertile soil. 7 - grass.

Eco-parking is a special type of coating that combines the beauty of a green lawn and durability.

When organizing this type of parking, lawn grates are used - plastic or concrete modules that are resistant not only to serious mechanical loads, but also to significant temperature changes.

They perform a protective function: they keep the grass root system from being damaged by tires and prevent soil from being washed out. Due to the through structure and sand and gravel base, the platform, lined with a lawn grate, has natural drainage. Manufacturers indicate on the marking of gratings permissible load, But a car survive almost everything.

Gravel in the grate

If you are not concerned with the decorative appearance of your parking lot, but solely with its practical use, you can not sow a freshly laid grate with grass.

The cost of parking will decrease, and in the future it will not require annual care in the form of sowing seeds. It is enough to fill the cells of the plastic grate with gravel.

The surface of the parking lot is cleared of debris, leveled and covered with a layer of broken brick or gravel (30 cm). The surface is compacted with a vibrator and concreted. A layer of sand 20 mm is poured, leveled and compacted. Cover with geotextile to prevent weed growth. Lay the grate. The cells are covered with gravel with a margin of 10-15 mm for shrinkage. Boundary edges help prevent gravel from spreading off site.

Concrete lawn grate

The concrete lawn grate has its own significant mass, which allows it to be used in sloped areas or on loose soils where soil subsidence is possible. It is more suitable for operation on sites with dense soil, where it is practically impossible to ensure good drainage of groundwater and effective water removal during heavy rainfall. Concrete lawn grates are not so demanding on the preparation of the carrier layer and are suitable for installation without thorough tamping of the soil.

Do-it-yourself eco-parking from a lawn grate - photo

Potholes and ruts will not form at the eco-parking. And the lawn, crushed by wheels, after watering, regains a neat appearance.

Plastic modules (polypropylene, polyethylene) designed for eco-parking devices are lightweight (5-11 kg/sq.m.), durable and resistant to ultrasonic radiation. The system of locks provides a reliable connection between the modules and helps to distribute the load between them. During installation, you can cut and fit the modules to size with a knife. The covering from such lattices protects the soil from landslides and erosion, possesses high resistance to loadings.

1. Marking the boundaries and preparing the foundation. A leveling sand cushion is poured at the bottom of the pit. After leveling, it is rammed or spilled with water, then re-leveled. Then - a bearing layer of crushed stone (or a sand-gravel mixture) with a layer of 20-50 cm, depending on the planned load. To prevent mixing of layers and to exclude subsidence of the soil, we lay a layer of geotextile with a density of about 200 g/m. From above we lay a leveling layer of sand (or gravel) 3-5 cm.