Channel coloring calculator. Design values for I-beams and channels

ATTENTION!!! You are in the Help Section!

Here you can: download GOST and find out the main characteristics of the type of rolled metal you are interested in.

If you want to know the prices of the main Suppliers of rolled metal products in your region, choose the Supplier with the lowest price or compare the prices of metal trading organizations, please follow the link " "

The channel is referred to the most popular type of rolled metal. It is considered an indispensable material for construction work. Due to its high strength and excellent mechanical characteristics, and a small mass, the product is able to withstand heavy loads, including transverse ones.

The advantages of the channel include a relatively low price. There is a wide range of all manufactured types of profiles. The manufacturer is ready to offer all customers a channel of various sizes and types. As a result, you can count several dozen types of this product. They are distinguished by their marking, name and conditional numbers.

The main area of application of the product is construction. No matter what the size of the building, such use is essential to increase the strength of the structures. The reason is that concrete is usually only able to withstand compressive stress, while the channel remains stable despite bending and pressure.

The following circumstance makes it possible to significantly reduce not only weight, but also strengthen the structure: metalworking and high-quality construction implies the use of this profile to reduce the load on specific stressed areas.

The product is manufactured by high-temperature rolling. The material is continuously cast or forged steel blanks. The most popular type of this material is structural high-quality steel.

Channels are usually divided into several types:

1. Products for the manufacture of which high-temperature rolling was used

2. Special

3. Bent equal-shelf

4. Bent not equal

In production, the length of the channel can not be more than 12 meters. The need to produce longer products is due to the high demand for this material in construction work.

Most often, the product is used to install floors, as well as to increase the strength of the roof and other structures. For architectural purposes, the channel is used to reinforce walls. This product is the main material of the work, where we are talking about the installation of partitions, and the reconstruction of objects. Using this rolled metal, you can significantly increase the strength of the columns.

There are also other areas of use of this type of rolled metal, in particular, heavy engineering, machine tool building. In second place are such industries, there are such areas as the automotive industry and car building.

A hot-rolled channel is a metal beam that has a section in the shape of the letter "P". If we consider it from the outside, then it has a wall with two parallel strips located on one side. All geometric dimensions are set normative documents, according to GOST. The main parameters include, as the length of the product, its width and diameter. The production of channels with a slight slope of the inner edges is provided for by GOST 535-88. The slope should not be more than 10%. GOST 8240-97 regulates the numerical assortment. The degree of slope should not be more than 10%. The channel number when marking indicates the product number, which indicates the distance between the edges from the outside. Everything is always indicated in centimeters. Other not unimportant parameters are also determined by the GOST standards.

Some varieties of hot-rolled channel bars are commonly used in the automotive industry. For the automotive industry, channels are used that are made according to the standards of GOST 19425-74; for car building, products that comply with the standards of GOST 5267-90 are more suitable.

The edges of the shelves can be located in the manufacture both at an angle and in parallel. The first type of channel will be produced with the marking "B", and the second - with "P", and is divided into several types - these are special "C", light "L", economic "E". The serial number indicates the height of the product. Its value can vary from 50 to 40 mm, the size of the shelves is usually from 3.2 to 11.5 m.

Each type of this rolled metal product has its own characteristics. 10P increases the durability of the building structure and does not require any additional heat treatment. The 12P marking channel weighs 10.4 kg. 16P is intended for installation of ceilings and installation of a temporary building structure. 20P is usually used to install complex structures that are subjected to heavy loads. 40p has a high bearing capacity, and this makes it possible to use it for the construction of bridges and high-rise buildings.

Channels are produced in the following types:

Hot-rolled steel (GOST 8240-89)

Steel bent equal-shelf ()

Steel bent unequal ()

In the manufacture of channels can be of two types - equal-shelf and unequal-shelf. According to GOST, the channel should have a length of no more than 12 meters, if necessary, the length of the profiles can be longer.

channel number | channel number | ||||||||

With prickly edges | with parallel edges |

||||||||

In most cases, the channel is used:

In construction work related to the installation of interfloor ceilings. To strengthen the roof, install solid frames. In small architecture for reinforcing walls. The channel is also used in installation work, in the construction of attics, to strengthen columns and in the construction of bridges.

In heavy engineering, the channel acts as a necessary element of those metal structures that carry heavy loads.

In machine tool building; in the automotive industry; in wagon building.

Hot-rolled steel channel

A hot-rolled steel channel is a beam with a section that looks like the letter "P". The product is made in such a way that its only wall borders on two parallel shelves located on both sides. Currently produced very a large number of types of channels. All parameters, including the size of the product, are regulated by GOST.

For example, this material, during manufacture, can have a different length, which ranges from 4 to 12 meters. At the same time, the length of the channel is divided into categories - dimensional, multiple dimensional and non-dimensional. The diameter is usually between 5 and 40 mm. Also, the dimensions of the channel can be non-standard. It all depends on what requirements the customer imposes on the size of the product. The channel is produced in accordance with GOST 535-88, according to this document, the channel is made with a slope of the inner edges of the shelves and with a parallel arrangement of the edges of the shelves. In this case, the angle of the faces should not be more than 10%. GOST 8240-97 corresponds to the range of steel channel.

The hot-rolled channel number always indicates its size (that is, this is the distance between the outer edges, indicated in centimeters). Consider an example: Channel No. 10. According to this number, we can already say for sure that the distance between its faces is 10 cm. As for other parameters - the width of the shelves, wall thickness, etc. then they always comply with GOST standards. If you meet a channel marked "A", and at the end of the number is "14A", then know that this product has an internal slope of the inner edges and its shelf is at a greater distance. As a result, the weight per linear meter also increases.

Main special types hot-rolled channel:

Channel designed for use in the automotive industry. Produced in accordance with GOST 19425-74 (18C, 20C)

The channel for work in the field of car building is made in accordance with GOST 5267-90 (8V, 14V, 18V).

All edges of the channel shelves in most cases are parallel to each other. With a parallel arrangement of the facet, the product is marked "P". This type of product is usually divided into several models. The type that is marked "C" is used in the automotive industry, with the marking "L" is considered a light channel, "E" is an economic channel. A product marked "B" indicates that the edges are located at an angle.

If we consider the channel marking 24P. Then it can be given the following characteristics: it is an equal-shelf channel with a parallel arrangement of faces and a height of 240 mm.

Depending on the length, the product is divided into a channel with measured and random lengths.

When determining the serial number, the height dimension is used. The height of the channel is the place between the outer shelves, and it varies from 50 to 400 mm. The shelves have a size of 3.2 to 11.5 cm.

Any channel made by hot-rolled method is sorted into high-strength channel, index "A" and normal strength, index "B".

Due to its high strength capabilities, the channel is used in many industries.

In the construction field, the channel is most often intended for the installation of frame structures, ceilings, supports. Also goes as a material for strengthening walls.

In mechanical engineering, the channel plays an indispensable role in structures with a huge power load, as well as for those structures that have a high center of gravity in bending.

A channel made of stainless material also has a number of advantages. First of all, it is able to significantly increase strength, and is also resistant to corrosion. Such a channel is widely used for those structures that are installed in harsh environmental conditions.

Channel marked 10P is an equal-shelf product manufactured by hot-rolled method, without additional heat treatment. To make this product, steel having high weldability acts as a material for its manufacture. This type of channel is always produced in standard length, which, as noted earlier, ranges from 2 to 12 meters. According to GOST, the weight of a running meter of such a channel is 8.59 kilograms. Such a product is most often used in architectural work, to increase the stability of reconstructions and structures.

Channel marked 12 P produced by hot rolling technology, without using heat treatment. According to GOST, the weight of a linear meter of a product should be equal to 10.4 kilograms. It is made only in standard length, which ranges from 2 to 12 meters. Taking into account the fact that the channel has a large mass of up to 20%, this leads to the fact that it allows you to significantly save on the purchase of metal consumption. Channel 12P is very often used as the main material for strengthening structures, as well as for strengthening small bridges.

Channel marked 16 P manufactured using the hot rolling process. The weight according to the established GOST of the channel should be 14.2 kilograms. The product has been widely used in construction work. In particular, it is intended for the installation of ceilings and the installation of temporary structures. Often this type of channel can be seen in other industries.

Channel marked 20 P. For its manufacture, a hot-rolled method is used. The weight of the product should be equal to 18.4 kilograms. As a result, it can be safely used in heavy structures that can withstand not only heavy loads, both cyclic and dynamic. Therefore, they try to use the channel for the installation of interfloor ceilings, as well as to give strength and stability to bridges.

Channel marked 40P. It is also produced using the hot rolling method on section rolling machines. The weight of one linear meter is 54.6 kilograms. High strength and long service life make it possible to use the channel for the construction of high-rise buildings.

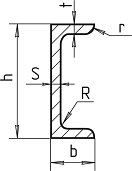

Channel with a slope of the inner edges of the shelves - U series

The slope of the inner edges of the shelves U series channels should be between 4 and 10%.

Rice. 1. Channel with a slope of the inner edges of the shelves - U series according to DSTU 3436-96 (GOST 8240-97)

Legend:

h - channel height; b - shelf width;

S - wall thickness; R is the radius of the inner curvature of the shelves;

t - shelf thickness; r - radius of curvature of the shelves.

U series channel number | Dimensions, | Weight 1m, kg | Number of meters in a ton, m |

|||||

channel 5U | ||||||||

channel 6.5U | ||||||||

channel 8U | ||||||||

channel 10U | ||||||||

channel 12U | ||||||||

channel 14U | ||||||||

channel 16U | ||||||||

channel 15аU | ||||||||

channel 18U | ||||||||

channel 18аU | ||||||||

channel 20U | ||||||||

channel 22U | ||||||||

channel 24U | ||||||||

channel 27U | ||||||||

channel 30U | ||||||||

channel 33U | ||||||||

channel 36U | ||||||||

channel 40U |

Note:

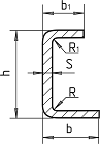

Channel with parallel flange edges - P series

Rice. 2. Channel with parallel flange edges - P series according to DSTU 3436-96 (GOST 8240-97)

Legend:

h - channel height;

b - channel flange width;

S - wall thickness;

t - shelf thickness;

r - radius of curvature of the shelves.

P series channel number | Dimensions, | Weight 1 m, kg | Number of meters in a ton, m |

|||||

channel 5P | ||||||||

channel 6,5P | ||||||||

channel 8P | ||||||||

channel 10P | ||||||||

channel 12P | ||||||||

channel 14P | ||||||||

channel 16P | ||||||||

channel 16aP | ||||||||

channel 18P | ||||||||

channel 18aP | ||||||||

channel 20P | ||||||||

channel 22P | ||||||||

channel 24P | ||||||||

channel 27P | ||||||||

channel 30P | ||||||||

channel 33P | ||||||||

channel 36P | ||||||||

channel 40P |

Note:

The mass of 1 M-channel is calculated from nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Channel economical - series E

Rice. 3. Economic channel - series E according to DSTU 3436-96 (GOST 8240-97)

Legend:

h - channel height;

b - shelf width;

S - wall thickness;

R is the radius of the inner rounding;

t - shelf thickness;

r - radius of curvature of the shelves.

E series channel number | Dimensions, mm | Weight 1 m, kg | Number of meters in a ton, m |

|||||

channel 5E | ||||||||

channel 6,5E | ||||||||

channel 8E | ||||||||

channel 10E | ||||||||

channel 12E | ||||||||

channel 14E | ||||||||

channel 16E | ||||||||

channel 18E | ||||||||

channel 20E | ||||||||

channel 22E | ||||||||

channel 24E | ||||||||

channel 27E | ||||||||

channel 30E | ||||||||

channel 33E | ||||||||

channel 36E | ||||||||

channel 40E |

Note: The mass of 1 m of the channel is calculated according to the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Lightweight channel - series L

Rice. 4. Light channel - L series according to DSTU 3436-96 (GOST 8240-97)

Legend:

h - height channel;

b - shelf width;

S - wall thickness;

R is the radius of the inner rounding;

t - shelf thickness;

r - radius of curvature of the shelves.

L series channel number | Dimensions, | Weight 1 m, kg | Number of meters in a ton, m | ||||

channel 12L | |||||||

channel 14L | |||||||

channel 16L | |||||||

channel 18L | |||||||

channel 20L | |||||||

channel 22L | |||||||

channel 24L | |||||||

channel 27L | |||||||

channel 30L |

Note: The mass of 1 m of the channel is calculated according to the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

Special channel - series C (corresponds to GOST 19425-74)

Rice. 5. Special channel - series C according to DSTU 3436-96 (GOST 8240-97)

Legend:

h - channel height;

b - shelf width;

S - wall thickness;

R is the radius of the inner rounding;

t - shelf thickness;

r - radius of curvature of the shelves.

C-series channel number | Dimensions, | Shelf slope, % | Weight 1 m, kg | Number of meters per ton | |||||

channel 8C | |||||||||

channel 14C | |||||||||

channel 14Са | |||||||||

channel 16C | |||||||||

channel 16Са | |||||||||

channel 18C | |||||||||

channel 18Са | |||||||||

channel 18Sb | |||||||||

channel 20C | |||||||||

channel 20Са | |||||||||

channel 20Sb | |||||||||

channel 24С | |||||||||

channel 26C | |||||||||

channel 26Са | |||||||||

channel 30С* | |||||||||

channel 30Са | |||||||||

channel 30Sb |

Note:

1. The mass of 1 m of the channel is calculated according to the nominal dimensions at a material density of 7850 kg/m3 and is a reference value.

2. * The geometric dimensions of the channel 30C according to DSTU 3436-96 (GOST 8240-97) differ from the dimensions of the channel 30C according to GOST 19425-74

Channel range 10P - a variety of hot-rolled billets, quite extensive. All characteristics of individual samples can be found in GOST No. 8240 of 1989. There are quite a few of them - the parameters of the shelves and the wall (height, width), the radii of curvature and curvature, and a number of others. Those who are interested in more detailed information can study the indicated document on their own.

We will consider only one type of channel - No. 10, and those of its parameters that matter to a non-professional.

First of all, let's clarify what this product is. Channel 10P is one of the most used in various fields, including in individual construction (for example, as load-bearing supports). In fact, this is a metal bar with a specific profile.

Deciphering the designation

- 10 - height (in dm).

- P - a type of profile that resembles the corresponding letter of the Russian alphabet (its shelves are strictly parallel and located at right angles to the wall).

Section parameters

All linear dimensions are in "mm".

- Height (h) - 100.

- Width (b) - 46.

- Thickness: walls (s) - 4.5; shelves (t) - 7.6.

- Radii: curvature ® - 7; rounding ® - 3.0.

Sometimes you need to know the cross-sectional area. For a 10P channel, it is 10.9 cm². The length of the channel is in the range from 4 to 12 m. It can be longer if the production of such a blank is agreed with the customer.

The profile parameters are controlled at any section of the channel, but not closer than 0.5 m from its ends.

All other data, for example, errors depending on the accuracy of rental, are understandable only to specialists, so it makes no sense to give them.

Weight

For each m.p. - 8.59 kg. Provided that the density is 7.85 g / cm³. Permissible deviations from the specified mass value + 3% and -5%.

Channel 16 - this is how hot-rolled steel products of this type of shaped steel are designated. After all, as you know, bent channels are also produced, but they are not designated in this way. In addition, just like product 16, they mark a certain group (type) of U-shaped profiles, which differs from any other channels and according to appearance, and by notation.

1

The article in question 16 refers to hot-rolled channels, which cannot be confused with any other type of channel steel products, both in designation and in appearance. This view has only some external resemblance to bent steel profiles. However, one has only to take a closer look at these products, as significant differences in shape and even cross-sectional dimensions immediately become visible. In detail, all the differences, including production technologies, between bent and hot-rolled channel profiles are set out.

Hot rolled channel profiles

Only hot-rolled channels are marked with a number, and one that not only corresponds to some standard size, but is also equivalent to the profile height (the width of the wall, which is measured between the outer edges of the shelves) - 10 times less than it. That is, according to the designation of the channel, you can calculate its height. For example, if, then 240 mm, and for profile No. 16 - 160 mm.

All other channels are designated differently. Information about the product must be sought in the corresponding GOST according to their long, several-digit number, or, but this is only for bent profiles, all main dimensions are already given in the marking (for example,).

2

Channel 16 is made only according to the 8240 standard. This GOST applies to steel hot-rolled channel products of special and general purpose, which, depending on the profile number, have a height in the range of 50–400 mm and a shelf width of 32–115 mm.

Let us dwell on the GOSTs, which are also used in the manufacture of channels of the 8240 standard. These GOSTs provide requirements for the quality of the manufacture of metal products and their technical characteristics, namely: strength and other properties, as well as classification by them; a list of steel grades used for the production, indicating their chemical composition; other parameters of the finished product. Depending on the conditions of use, as well as the purpose of the metal products (in this case, the channel), they are guided by one of the following standards:

- GOST 19281-89 - applies to all types of rolled metal products made from steel alloys with increased strength (low-alloy steels are implied);

- GOST 535-2005 - for sectional and shaped products, both for general and special purposes, made of carbon steels of ordinary quality;

- GOST R 52927-2015 - applies to rolled products made from alloys of increased, high and normal strength and is intended for the construction of berths, pontoons, ships (river and sea), oil and gas platforms and other welded structures;

- GOST 27772-88 - applies to various metal products made of carbon and low-alloy alloys intended for steel building structures with welded and other joints;

- GOST R 55374-2012 - for some types of hot-rolled steel, including shaped, intended for use in bridge building and made of alloyed structural alloys.

According to the 8240 standard, all products manufactured according to it are divided into several types. The first, but not the main division is in the shape of the shelves. The latter at the channel can be:

- With an inclined edge on the inner side of the channel.

- With parallel edges.

Channel with inclined edge

The main division - according to the shape and geometric dimensions of the cross section - into a series of hot-rolled channel profiles:

- U - products with shelves of the 1st type;

- P - channels with shelves of 2 types;

- E - economical profiles with shelves of 2 types;

- L - light series channels with shelves of 2 types;

- C - special profiles with shelves of the 1st type.

In addition, channel 16, like a number of other products (other sizes) of the 8240 standard, in the U, P and C series is represented not by one, but by several types. It means that there are profiles of the main size and additional ones. The last ones from the same series, with the same wall height, are designated in the same way. But they differ from the main standard size in greater massiveness. That is, they have thicker walls, wider shelves and may have larger radii of curvature at the edges of the latter. Channels of these additional sizes are reinforced. Letter indices are added to their marking: "a" - for the first additional size and "b" - for the second, more powerful one.

Channel No. 16 has only one (first) additional size in the U, P and S series. Thus, in accordance with GOST 8240, the assortment of this product consists of 8 items. These are profiles: 16U, 16aU, 16P, 16aP, 16E, 16L, 16C and 16Ca.

3

All rolled products of the 8240 standard are equal-shouldered (they often say about channels - equal-shouldered). It means that the shelves of the profile are of the same width. It, like other dimensions, depends on the series of the product, as well as on whether the main standard size is a channel or is it a reinforced modification. Therefore, different types channel products, designated by the same number, differ in shape and cross-sectional area, and as a result, they also have different: specific gravity(weight 1 meter); moments of resistance, inertia and static half-sections; radii of inertia; the distance between the axes and the outer surface of the wall. This is reflected in technical specifications profile.

Only one parameter does not depend on the series and type of standard size of the channel - this is the height of the product. As already explained above, for rolled products No. 16, its value is 160 mm.

All other dimensions of the cross section of channel No. 16 by series are indicated in the table:

|

Channel series №16 |

Section dimensions (excluding height), mm |

||||

|

Shelf width |

Shelf thickness |

Wall thickness |

Curve radius between wall and shelves on the inside |

Corner radius at the edge of the shelf |

|

Note. In the standards and other technical documentation on the sectional drawings of the channel profile, the dimensions are indicated as follows:

- height - h;

- wall thickness - s;

- dimensions of the channel shelves: thickness - t, and width - b;

- rounding radii: on inner surface profile - R, and on the edge of its shelf - r.

The thickness of the shelves of the first type (with an inclined edge on the inside of the product) is indicated and the average is measured. That is, in the middle between the edge of the shelf and the wall of the profile. The location of this point is calculated by the formula: (b - s) / 2.

The cross-sectional area values \u200b\u200b(taken from GOST 8240) by series (cm 2): for channels 16U and 16P - 18.1, 16aU and 16aP - 19.5, economical 16E - 17.85, light 16L - 9.04, and for special 16С - 21.95 and 16Са - 25.15.

Sectional area of the channel16U

Weight of one meter for profiles No. 16 series:

- 14.2 kg - for 16U and 16P;

- 15.3 kg - 16aU and 16aP;

- 14.01 kg - 16E;

- 7.1 kg - 16L;

- 17.53 kg - 16C;

- 19.74 kg - 16Ca.

The values of the weight of one meter and the cross-sectional area are theoretical, because they were calculated by formulas, moreover, for profiles with nominal dimensions. Calculating the mass of one meter, the density of the steel alloy was taken equal to 7850 kg / m 3 (by the way, the equivalent value of 7.85 g / cm 3 is indicated in the standard).

GOST 8240 rolled products are produced in lengths of 2–12 m. The standard allows the production of profiles longer than 12 m. This should be agreed between the customer and the manufacturer. Channels are produced in batches, in which the profiles have one of the lengths:

- measured - some specific, specified in the purchase order;

- multiple dimensional;

- unmeasured - within the range regulated by the standard or not less than that specified in the order;

- limited within the boundaries of unmeasured;

- measured with non-dimensional products, the number of which does not exceed 5% of the total mass of the supplied lot;

- multiple of measured with non-dimensional products, the number of which does not exceed 5% of the total mass of the supplied lot.

4

Of all the requirements of this standard for products manufactured according to it, we will focus on the main ones. We are talking about the maximum deviations from the nominal values of the cross-sectional dimensions, length and weight regulated by the standard. Channel No. 16 has the following deviations allowed by GOST for values (mm):

- height - ±2;

- flange widths: for profiles 16U, 16aU, 16P, 16aP, 16E, 16S and 16Ca - ± 2, and 16L - ± 1.5;

- shelf thickness - -0.5;

- wall thickness: for products 16U, 16aU, 16P and 16aP - not controlled, 16E and 16L - ± 0.5, and 16C and 16Ca - ± 0.7;

- wall deflection ƒ: for products 16U, 16aU, 16P, 16aP, 16E, 16S and 16Ca - no more than 1, and 16L - no more than 0.51;

- shelf skew ∆ - no more than 1.

Channel No. 16 values

Limit deviations in length are not regulated for all profiles. They are provided by GOST 8240 only for rolled products of measured and multiple lengths. The maximum values of these tolerances are as follows:

- for profiles 2–8 m long - +40 mm;

- for profiles longer than 8 m - + mm, but not higher than 100 mm (L - profile length in meters).

The maximum weight deviations allowed by the standard for a single single profile are ± 6%, and for a delivered batch of products - ± 4%. This deviation is calculated by subtracting from the actual weight of the supplied batch the value obtained by calculations according to the tables of the standard 8240. That is, the tabular specific gravity (given above) is multiplied by the total footage of the batch of profiles. At the same time, if the theoretical mass of the purchased profiles with a measured or multiple length is calculated, then in this case 1/2 of the sum of the deviations allowed by the standard along the length of the metal products in the batch should be added to the total footage.

Surface area of 1 ton of rolled steel.

Click on the position you are interested in.

| Profile name, number and thickness section, mm | Surface area 1 ton profile, m 2 | Profile name, number and thickness section, mm | Surface area 1 ton profile, m 2 |

|---|---|---|---|

| 1. Sheet steel and bent open profiles. The surface is given total on both sides. | |||

| Sheet thickness | Square | Sheet thickness | Square |

| 2,0 | 127,6 | 12,0 | 21,5 |

| 2,2 | 115,9 | 14,0 | 18,4 |

| 2,5 | 102,3 | 16,0 | 16,2 |

| 2,8 | 91,2 | 18,0 | 14,4 |

| 3,0 | 85,0 | 20,0 | 13,0 |

| 3,2 | 79,9 | 22,0 | 11,8 |

| 3,5 | 73,0 | 25,0 | 10,4 |

| 4,0 | 63,9 | 28,0 | 9,4 |

| 5,0 | 51,1 | 30,0 | 8,7 |

| 6,0 | 42,7 | 32,0 | 8,2 |

| 7,0 | 36,6 | 36,0 | 7,3 |

| 8,0 | 32,1 | 40,0 | 6,6 |

| 9,0 | 28,5 | 45,0 | 5,9 |

| 10,0 | 23,4 | 50,0 | 5,4 |

| 11,0 | 21,5 | 55,0 | 4,9 |

| 2. Profiles bent closed square, rectangular and pipes. The surface is given on the outside. |

|||

| Wall thickness | Square | Wall thickness | Square |

| 2,0 | 65,2 | 12,0 | 10,8 |

| 2,5 | 52,1 | 4,0 | 9,3 |

| 3,0 | 43,5 | 16,0 | 8,1 |

| 3,5 | 37,3 | 7,0 | 7,6 |

| 4,0 | 32,9 | 18,0 | 7,5 |

| 5,0 | 26,5 | 20,0 | 6,7 |

| 6,0 | 22,0 | 22,0 | 6,1 |

| 7,0 | 19,0 | 25,0 | 5,5 |

| 8,0 | 16,6 | 28,0 | 5,0 |

| 9,0 | 14,5 | 30,0 | 4,7 |

| 10,0 | 13,1 | 32,0 | 4,4 |

| 11,0 | 11,8 | 40,0 | 3,5 |

| 3. Steel is angular, equal-shelf. The surface is given total from all sides. | |||

| Shelf thickness | Square | Shelf thickness | Square |

| 3 | 86,5 | 14 | 19,0 |

| 4 | 65,0 | 16 | 16,6 |

| 5 | 52,0 | 18 | 14,9 |

| 6 | 44,0 | 20 | 13,3 |

| 7 | 37,0 | 22 | 12,0 |

| 8 | 33,0 | 25 | 10,6 |

| 9 | 29,5 | 28 | 9,6 |

| 10 | 26,3 | 30 | 9,0 |

| 12 | 22,0 | ||

| 4. Hot-rolled channels. The surface is given from all sides. | |||

| profile number | Square | profile number | Square |

| 5 | 47,1 | 20 | 38,3 |

| 6,5 | 46,4 | 20A | 36,4 |

| 8 | 45,4 | 22 | 36,6 |

| 10 | 44,7 | 22A | 34,9 |

| 12 | 43,1 | 24 | 35,0 |

| 14 | 41,6 | 24A | 33,3 |

| 14A | 39,7 | 27 | 33,2 |

| 16 | 40,5 | 30 | 31,4 |

| 16A | 38,7 | 33 | 29,6 |

| 18 | 39,3 | 36 | 27,7 |

| 18A | 37,7 | 40 | 26,1 |

| 5. I-beams. The surface is given total from all sides. | |||

| profile number | Square | profile number | Square |

| 10 | 44,4 | 27 | 33,0 |

| 12 | 43,1 | 30 | 31,2 |

| 14 | 41,8 | 36 | 26,7 |

| 16 | 40,5 | 40 | 24,9 |

| 18 | 39,1 | 45 | 23,2 |

| 20 | 38,1 | 50 | 21,4 |

| 22 | 36,7 | 55 | 19,7 |

| 24 | 34,4 | 60 | 18,1 |

| 7. Beams with parallel flange faces. The surface is given total from all sides. | |||

| profile number | Square | profile number | Square |

| 20B | 49,1 | 50B2 | 22,8 |

| 20B1 | 39,4 | 50B3 | 20,9 |

| 20B2 | 36,7 | 55B | 26,7 |

| 20B3 | 33,6 | 55B1 | 22,6 |

| 23B | 45,9 | 55B2 | 20,8 |

| 23B1 | 38,0 | 55B3 | 19,1 |

| 23B2 | 35,3 | 60B | 24,4 |

| 23B3 | 32,0 | 60B1 | 20,5 |

| 26B | 43,2 | 60B2 | 18,6 |

| 26B1 | 35,9 | 60B3 | 17,2 |

| 26B2 | 33,3 | 70B | 21,0 |

| 26B3 | 30,4 | 70B1 | 19,1 |

| 30B | 40,7 | 70B2 | 17,4 |

| 30B1 | 35,4 | 70B3 | 15,9 |

| 30B2 | 33,0 | 70B4 | 14,6 |

| 30B3 | 30,1 | 80B | 19,3 |

| 35B | 37,8 | 80B1 | 17,2 |

| 35B1 | 34,4 | 80B2 | 15,5 |

| 35B2 | 31,1 | 80B3 | 14,2 |

| 35B3 | 28,4 | 80B4 | 13,1 |

| 40B | 34,9 | 90B | 17,8 |

| 40B1 | 30,8 | 90B1 | 15,7 |

| 40B2 | 27,8 | 90B2 | 14,5 |

| 40B3 | 25,5 | 90B3 | 13,2 |

| 45B | 32,3 | 90B4 | 12,0 |

| 45B1 | 27,5 | 100B | 16,7 |

| 45B2 | 24,9 | 100B1 | 14,4 |

| 45B3 | 22,8 | 100B2 | 13,0 |

| 50B | 29,3 | 100B3 | 11,7 |

| 50B1 | 24,8 | 100B4 | 10,6 |

| 8. I-beams wide-beams. The surface is given total from all sides. | |||

| profile number | Square | profile number | Square |

| 20SH | 38,9 | 50SH4 | 14,2 |

| 20SH1 | 33,8 | 50SH5 | 12,9 |

| 20SH2 | 31,2 | 60SH | 21,4 |

| 23SH | 37,9 | 60SH1 | 17,4 |

| 23SH1 | 30,9 | 60SH2 | 16,0 |

| 23SH2 | 27,8 | 60SH3 | 14,6 |

| 26SH | 33,2 | 60SH4 | 13,1 |

| 26Sh1 | 28,6 | 60SH5 | 11,8 |

| 26Sh2 | 25,9 | 60SH6 | 10,7 |

| 30SH | 30,1 | 70SH1 | 15,8 |

| 30SH1 | 26,0 | 70SH2 | 14,4 |

| 30SH2 | 23,4 | 70SH3 | 13,1 |

| 30SH3 | 21,1 | 70SH4 | 12,0 |

| 30SH4 | 19,4 | 70SH5 | 11,0 |

| 35SH | 26,8 | 70SH6 | 10,3 |

| 35SH1 | 22,7 | 70SH7 | 9,5 |

| 35SH2 | 20,8 | 70SH8 | 8,8 |

| 35SH3 | 19,1 | 80SH | 17,4 |

| 40SH | 23,2 | 80SH1 | 14,4 |

| 40SH1 | 20,4 | 80SH2 | 13,2 |

| 40SH2 | 18,9 | 80SH3 | 12,1 |

| 40SH3 | 17,9 | 90SH | 15,7 |

| 40SH4 | 16,2 | 90Sh1 | 13,1 |

| 50SH | 22,6 | 90SH2 | 12,1 |

| 50SH1 | 19,4 | 90SH3 | 11,1 |

| 50SH2 | 17,4 | 100SH | 14,2 |

| 50SH3 | 15,7 | 100SH1 | 12,3 |

| 9. Column I-beams. The surface is given total from all sides. | |||

| profile number | Square | profile number | Square |

| 20K | 32,3 | 35K1 | 19,3 |

| 20K1 | 29,3 | 35K2 | 17,3 |

| 20K2 | 26,1 | 35K3 | 15,6 |

| 20K3 | 23,7 | 35K4 | 14,2 |

| 20K4 | 21,7 | 35K5 | 13,0 |

| 23K | 31,6 | 35K6 | 11,9 |

| 23K1 | 27,5 | 35K7 | 10,9 |

| 23K2 | 25,7 | 35K8 | 10,0 |

| 23K3 | 23,2 | 40K | 19,9 |

| 23K4 | 21,2 | 40K1 | 17,5 |

| 26K1 | 26,1 | 40K2 | 16,0 |

| 26K2 | 23,3 | 40K3 | 14,5 |

| 26K3 | 20,9 | 40K4 | 13,1 |

| 26K4 | 19,2 | 40K5 | 11,8 |

| 26K5 | 17,6 | 40K6 | 10,8 |

| 30K1 | 21,4 | 40K7 | 9,8 |

| 30K2 | 19,9 | 40K8 | 9,0 |

| 30K3 | 18,3 | 40K9 | 8,2 |

| 30K4 | 16,7 | 40K10 | 7,8 |

| 30K5 | 15,2 | 40K11 | 6,2 |

| 30K6 | 14,1 | 40K12 | 5,2 |

| 30K7 | 12,8 | 40K13 | 4,4 |

| 30K8 | 11,7 | 40K14 | 3,7 |

Profile name,

number and thickness

section, mm Surface area

1 ton profile, m 2