Thermal conductivity and other characteristics of building materials in numbers. Comparison of the thermal conductivity of building materials - we study important indicators

Thermal conductivity table building materials necessary when designing the protection of the building from heat loss in accordance with the SNiP standards of 2003 under the number 23-02. These measures provide a reduction in the operating budget, maintaining a year-round comfortable microclimate indoors. For the convenience of users, all data are summarized in tables, parameters are given for normal operation, conditions of high humidity, since some materials sharply reduce properties with an increase in this parameter.

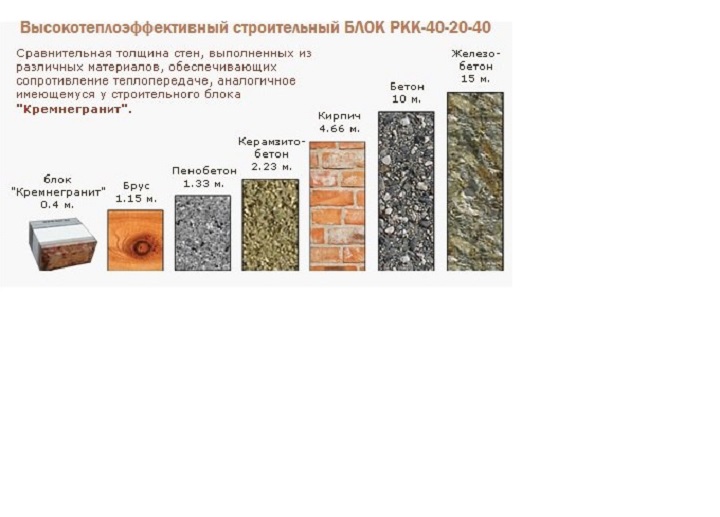

Thermal conductivity is one of the ways in which heat is lost by living quarters. This characteristic is expressed by the amount of heat that can penetrate a unit area of the material (1 m 2) per second at a standard layer thickness (1 m). Physicists explain the equalization of the temperatures of various bodies, objects through heat conduction by the natural desire for thermodynamic equilibrium of all material substances. Thus, each individual developer, heating the premises in winter, receives losses of thermal energy leaving the dwelling through the outer walls, floors, windows, and roofs. In order to reduce energy consumption for space heating, while maintaining a comfortable microclimate inside them, it is necessary to calculate the thickness of all enclosing structures at the design stage. This will reduce the construction budget. The table of thermal conductivity of building materials allows you to use accurate coefficients for wall structural materials. The SNiP standards regulate the resistance of the facades of the cottage to the transfer of heat to the cold air of the street within 3.2 units. By multiplying these values, you can get the required wall thickness to determine the amount of material. For example, when choosing cellular concrete with a coefficient of 0.12 units, laying in one block 0.4 m long is sufficient. Using cheaper blocks of the same material with a coefficient of 0.16 units, you will need to make the wall thicker - 0.52 m. pine, spruce is 0.18 units. Therefore, in order to comply with the heat transfer resistance condition of 3.2, a 57 cm beam is required, which does not exist in nature. When choosing brickwork with a coefficient of 0.81 unit, the thickness of the outer walls threatens to increase up to 2.6 m, reinforced concrete structures - up to 6.5 m. In practice, walls are made multi-layered, laying a layer of insulation inside or sheathing the outer surface with a heat insulator. These materials have a much lower thermal conductivity coefficient, which makes it possible to reduce the thickness many times over. Structural material ensures the strength of the building, heat insulator reduces heat loss to an acceptable level. Modern facing materials used on facades, internal walls also have resistance to heat loss. Therefore, all layers of future walls are taken into account in the calculations. The above calculations will be inaccurate if you do not take into account the presence of translucent structures in each wall of the cottage. The table of thermal conductivity of building materials in the SNiP standards provides easy access to the thermal conductivity coefficients of these materials.

Thermal conductivity is the process of energy transfer from the warm part of a material to the cold part of this material (i.e. molecules).

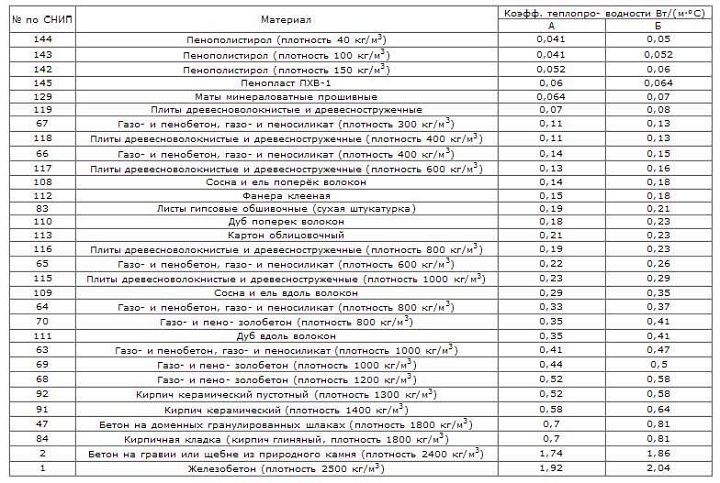

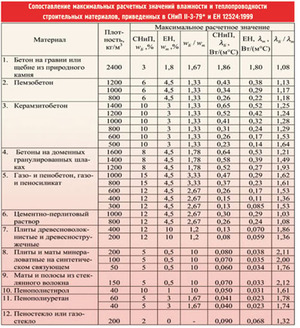

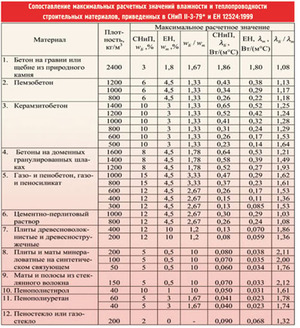

Basic values of thermal conductivity coefficients from SNiP II-3-79* (Appendix 2) and from SP 50.13330.2012 SNiP 23-02-2003.

The thermal conductivity of some (but not all) building materials can vary significantly depending on their moisture content. The first value in the table is the dry state value. The second and third values are the thermal conductivity values for operating conditions A and B in accordance with Appendix C to SP 50.13330.2012. Operating conditions depend on the climate of the region and the humidity in the room. Simply put, A is normal “average” use, and B is wet conditions.

| Material | Coefficient of thermal conductivity, W/(m °C) |

||

| Dry | Conditions A ("normal") | Conditions B ("wet") | |

| Expanded polystyrene (EPS) | 0,036 - 0,041 | 0,038 - 0,044 | 0,044 - 0,050 |

| Expanded polystyrene extruded (EPPS, XPS) | 0,029 | 0,030 | 0,031 |

| Woolen felt | 0,045 | ||

| Cement-sand mortar (CPR) | 0,58 | 0,76 | 0,93 |

| Lime-sand mortar | 0,47 | 0,7 | 0,81 |

| Gypsum plaster plain | 0,25 | ||

| Mineral wool stone, 180 kg/m3 | 0,038 | 0,045 | 0,048 |

| Mineral wool stone, 140-175 kg/m3 | 0,037 | 0,043 | 0,046 |

| Mineral wool stone, 80-125 kg/m3 | 0,036 | 0,042 | 0,045 |

| Mineral wool stone, 40-60 kg/m3 | 0,035 | 0,041 | 0,044 |

| Mineral wool stone, 25-50 kg/m3 | 0,036 | 0,042 | 0,045 |

| Mineral wool glass, 85 kg/m3 | 0,044 | 0,046 | 0,05 |

| Mineral wool glass, 75 kg/m3 | 0,04 | 0,042 | 0,047 |

| Mineral wool glass, 60 kg/m3 | 0,038 | 0,04 | 0,045 |

| Mineral wool glass, 45 kg/m3 | 0,039 | 0,041 | 0,045 |

| Mineral wool glass, 35 kg/m3 | 0,039 | 0,041 | 0,046 |

| Mineral wool glass, 30 kg/m3 | 0,04 | 0,042 | 0,046 |

| Mineral wool glass, 20 kg/m3 | 0,04 | 0,043 | 0,048 |

| Mineral wool glass, 17 kg/m3 | 0,044 | 0,047 | 0,053 |

| Mineral wool glass, 15 kg/m3 | 0,046 | 0,049 | 0,055 |

| Foam concrete and aerated concrete on cement binder, 1000 kg/m3 | 0,29 | 0,38 | 0,43 |

| Foam concrete and aerated concrete on cement binder, 800 kg/m3 | 0,21 | 0,33 | 0,37 |

| Foam concrete and aerated concrete on cement binder, 600 kg/m3 | 0,14 | 0,22 | 0,26 |

| Foam concrete and aerated concrete on cement binder, 400 kg/m3 | 0,11 | 0,14 | 0,15 |

| Foam concrete and aerated concrete on limestone binder, 1000 kg/m3 | 0,31 | 0,48 | 0,55 |

| Foam concrete and aerated concrete on limestone binder, 800 kg/m3 | 0,23 | 0,39 | 0,45 |

| Foam concrete and aerated concrete on limestone binder, 600 kg/m3 | 0,15 | 0,28 | 0,34 |

| Foam concrete and aerated concrete on limestone binder, 400 kg/m3 | 0,13 | 0,22 | 0,28 |

| Pine, spruce across the grain | 0,09 | 0,14 | 0,18 |

| Pine, spruce along the grain | 0,18 | 0,29 | 0,35 |

| Oak across the grain | 0,10 | 0,18 | 0,23 |

| Oak along the grain | 0,23 | 0,35 | 0,41 |

| Copper | 382 - 390 | ||

| Aluminum | 202 - 236 | ||

| Brass | 97 - 111 | ||

| Iron | 92 | ||

| Tin | 67 | ||

| Steel | 47 | ||

| Window glass | 0,76 | ||

| fresh snow | 0,10 - 0,15 | ||

| liquid water | 0,56 | ||

| Air (+27 °C, 1 atm) | 0,026 | ||

| Vacuum | 0 | ||

| Argon | 0,0177 | ||

| Xenon | 0,0057 | ||

| Arbolit | 0,07 - 0,17 | ||

| Cork tree | 0,035 | ||

| Reinforced concrete with a density of 2500 kg/m3 | 1,69 | 1,92 | 2,04 |

| Concrete (on gravel or crushed stone) with a density of 2400 kg/m3 | 1,51 | 1,74 | 1,86 |

| Expanded clay concrete with a density of 1800 kg/m3 | 0,66 | 0,80 | 0,92 |

| Expanded clay concrete with a density of 1600 kg/m3 | 0,58 | 0,67 | 0,79 |

| Expanded clay concrete with a density of 1400 kg/m3 | 0,47 | 0,56 | 0,65 |

| Expanded clay concrete with a density of 1200 kg/m3 | 0,36 | 0,44 | 0,52 |

| Expanded clay concrete with a density of 1000 kg/m3 | 0,27 | 0,33 | 0,41 |

| Expanded clay concrete with a density of 800 kg/m3 | 0,21 | 0,24 | 0,31 |

| Expanded clay concrete with a density of 600 kg/m3 | 0,16 | 0,2 | 0,26 |

| Expanded clay concrete with a density of 500 kg/m3 | 0,14 | 0,17 | 0,23 |

| Large format ceramic block (warm ceramic) | 0,14 - 0,18 | ||

| Solid ceramic brick, masonry on the CPR | 0,56 | 0,7 | 0,81 |

| Silicate brick, masonry on the CPR | 0,70 | 0,76 | 0,87 |

| Hollow ceramic brick (density 1400 kg/m3 including voids), masonry on the CPR | 0,47 | 0,58 | 0,64 |

| Hollow ceramic brick (density 1300 kg/m3, including voids), masonry on the CPR | 0,41 | 0,52 | 0,58 |

| Hollow ceramic brick (density 1000 kg/m3, including voids), masonry on the CPR | 0,35 | 0,47 | 0,52 |

| Silicate brick, 11 voids (density 1500 kg / m3), masonry on the CPR | 0,64 | 0,7 | 0,81 |

| Silicate brick, 14 voids (density 1400 kg / m3), masonry on the CPR | 0,52 | 0,64 | 0,76 |

| Granite | 3,49 | 3,49 | 3,49 |

| Marble | 2,91 | 2,91 | 2,91 |

| Limestone, 2000 kg/m3 | 0,93 | 1,16 | 1,28 |

| Limestone, 1800 kg/m3 | 0,7 | 0,93 | 1,05 |

| Limestone, 1600 kg/m3 | 0,58 | 0,73 | 0,81 |

| Limestone, 1400 kg/m3 | 0,49 | 0,56 | 0,58 |

| Tuff, 2000 kg/m3 | 0,76 | 0,93 | 1,05 |

| Tuff, 1800 kg/m3 | 0,56 | 0,7 | 0,81 |

| Tuff, 1600 kg/m3 | 0,41 | 0,52 | 0,64 |

| Tuff, 1400 kg/m3 | 0,33 | 0,43 | 0,52 |

| Tuff, 1200 kg/m3 | 0,27 | 0,35 | 0,41 |

| Tuff, 1000 kg/m3 | 0,21 | 0,24 | 0,29 |

| Dry building sand (GOST 8736-77*), 1600 kg/m3 | 0,35 | ||

| Plywood | 0,12 | 0,15 | 0,18 |

| Chipboard, fiberboard, 1000 kg/m3 | 0,15 | 0,23 | 0,29 |

| Chipboard, fiberboard, 800 kg/m3 | 0,13 | 0,19 | 0,23 |

| Chipboard, fiberboard, 600 kg/m3 | 0,11 | 0,13 | 0,16 |

| Chipboard, fiberboard, 400 kg/m3 | 0,08 | 0,11 | 0,13 |

| Chipboard, fiberboard, 200 kg/m3 | 0,06 | 0,07 | 0,08 |

| Tow | 0,05 | 0,06 | 0,07 |

| Gypsum board (gypsum sheathing sheets), 1050 kg/m3 | 0,15 | 0,34 | 0,36 |

| Gypsum board (gypsum sheathing sheets), 800 kg/m3 | 0,15 | 0,19 | 0,21 |

| PVC linoleum on a heat-insulating substrate, 1800 kg/m3 | 0,38 | 0,38 | 0,38 |

| PVC linoleum on a heat-insulating substrate, 1600 kg/m3 | 0,33 | 0,33 | 0,33 |

| PVC linoleum on fabric backing, 1800 kg/m3 | 0,35 | 0,35 | 0,35 |

| PVC linoleum on fabric backing, 1600 kg/m3 | 0,29 | 0,29 | 0,29 |

| PVC linoleum on fabric backing, 1400 kg/m3 | 0,2 | 0,23 | 0,23 |

| Ecowool | 0,037 - 0,042 | ||

| Expanded perlite, sand, density 75 kg/m3 | 0,043 - 0,047 | ||

| Expanded perlite, sand, density 100 kg/m3 | 0,052 | ||

| Expanded perlite, sand, density 150 kg/m3 | 0,052 - 0,058 | ||

| Expanded perlite, sand, density 200 kg/m3 | 0,07 | ||

| Foam glass, bulk, density 100 - 150 kg/m3 | 0,043 - 0,06 | ||

| Foam glass, bulk, density 151 - 200 kg/m3 | 0,06 - 0,063 | ||

| Foam glass, bulk, density 201 - 250 kg/m3 | 0,066 - 0,073 | ||

| Foam glass, bulk, density 251 - 400 kg/m3 | 0,085 - 0,1 | ||

| Foam glass, blocks, density 100 - 120 kg/m3 | 0,043 - 0,045 | ||

| Foam glass, blocks, density 121 - 170 kg/m3 | 0,05 - 0,062 | ||

| Foam glass, blocks, density 171 - 220 kg/m3 | 0,057 - 0,063 | ||

| Foam glass, blocks, density 221 - 270 kg/m3 | 0,073 | ||

| Expanded clay, gravel, density 250 kg/m3 | 0,099 - 0,1 | 0,11 | 0,12 |

| Expanded clay, gravel, density 300 kg/m3 | 0,108 | 0,12 | 0,13 |

| Expanded clay, gravel, density 350 kg/m3 | 0,115 - 0,12 | 0,125 | 0,14 |

| Expanded clay, gravel, density 400 kg/m3 | 0,12 | 0,13 | 0,145 |

| Expanded clay, gravel, density 450 kg/m3 | 0,13 | 0,14 | 0,155 |

| Expanded clay, gravel, density 500 kg/m3 | 0,14 | 0,15 | 0,165 |

| Expanded clay, gravel, density 600 kg/m3 | 0,14 | 0,17 | 0,19 |

| Expanded clay, gravel, density 800 kg/m3 | 0,18 | ||

| Gypsum boards, density 1350 kg/m3 | 0,35 | 0,50 | 0,56 |

| Gypsum boards, density 1100 kg/m3 | 0,23 | 0,35 | 0,41 |

| Perlite concrete, density 1200 kg/m3 | 0,29 | 0,44 | 0,5 |

| Perlite concrete, density 1000 kg/m3 | 0,22 | 0,33 | 0,38 |

| Perlite concrete, density 800 kg/m3 | 0,16 | 0,27 | 0,33 |

| Perlite concrete, density 600 kg/m3 | 0,12 | 0,19 | 0,23 |

| Polyurethane foam (PPU), density 80 kg/m3 | 0,041 | 0,042 | 0,05 |

| Polyurethane foam (PPU), density 60 kg/m3 | 0,035 | 0,036 | 0,041 |

| Polyurethane foam (PPU), density 40 kg/m3 | 0,029 | 0,031 | 0,04 |

| Cross-linked polyethylene foam | 0,031 - 0,038 | ||

If the material does not have values for conditions A and B in the table, then there are no corresponding values in SP 50.13330.2012 or on the manufacturers' websites, or this does not make sense for this material.

Note the increase in thermal conductivity with humidity conditions.

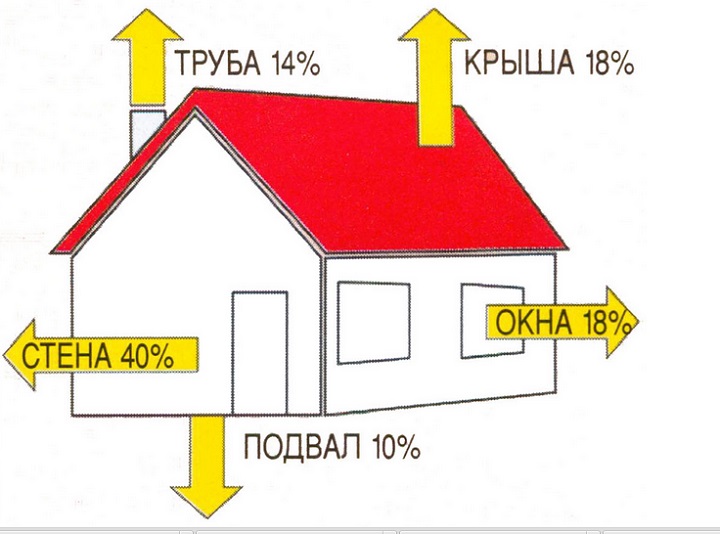

Calculation of heat loss at home

The house loses heat through the building envelope (walls, windows, roof, foundation), ventilation and sewerage. The main heat losses go through the building envelope - 60-90% of all heat losses.

The calculation of heat loss at home is needed, at a minimum, in order to choose the right boiler. You can also estimate how much money will be spent on heating in the planned house. It is also possible, thanks to calculations, to analyze the financial efficiency of insulation, i.e. understand whether the cost of installing insulation will pay off with fuel savings over the life of the insulation.

Heat loss through building envelopes

| 1) We calculate the resistance to heat transfer of the wall by dividing the thickness of the material by its coefficient of thermal conductivity. For example, if the wall is built of warm ceramics 0.5 m thick with a thermal conductivity coefficient of 0.16 W / (m × ° C), then we divide 0.5 by 0.16: 0.5 m / 0.16 W/(m×°C) = 3.125 m2×°C/W |

| 2) Calculate total area external walls. Here is a simplified example of a square house: (10 m width × 7 m height × 4 sides) - (16 windows × 2.5 m2) = 280 m2 - 40 m2 = 240 m2 |

| 3) We divide the unit by the resistance to heat transfer, thereby obtaining heat loss from one square meter walls by one degree temperature difference. 1 / 3.125 m2×°C/W = 0.32 W/m2×°C |

| 4) Calculate the heat loss of the walls. We multiply the heat loss from one square meter of the wall by the area of the walls and by the temperature difference inside the house and outside. For example, if +25°C inside and -15°C outside, then the difference is 40°C. 0.32 W / m2×°C × 240 m2 × 40 °C = 3072 W This number is the heat loss of the walls. Heat loss is measured in watts, i.e. is the heat dissipation power. |

| 5) In kilowatt-hours it is more convenient to understand the meaning of heat loss. For 1 hour through our walls with a temperature difference of 40 ° C, thermal energy is lost: 3072 W × 1 h = 3.072 kWh Energy spent in 24 hours: 3072 W × 24 h = 73.728 kWh |

It is clear that during the heating period the weather is different, i.e. temperature difference changes all the time. Therefore, in order to calculate the heat loss for the entire heating period, it is necessary in paragraph 4 to multiply by the average temperature difference for all days of the heating period.

For example, for 7 months of the heating period, the average temperature difference between the room and the street was 28 degrees, which means that the heat loss through the walls for these 7 months in kilowatt-hours:

0.32 W / m2×°C × 240 m2 × 28 °C × 7 months × 30 days × 24 h = 10838016 Wh = 10838 kWh

The number is quite "tangible". For example, if the heating was electric, then you can calculate how much money would be spent on heating by multiplying the resulting number by the cost of kWh. You can calculate how much money was spent on gas heating by calculating the cost of kWh of energy from a gas boiler. To do this, you need to know the cost of gas, the calorific value of gas and the efficiency of the boiler.

By the way, in the last calculation, instead of the average temperature difference, the number of months and days (but not hours, we leave the clock), it was possible to use the degree-day of the heating period - GSOP. You can find already calculated GSOPs for different cities of Russia and multiply the heat loss from one square meter by the wall area, by these GSOPs and for 24 hours, getting heat losses in kWh.

Similarly to walls, you need to calculate the heat loss values for windows, front door, roofs, foundations. Then sum everything up and get the value of heat loss through all enclosing structures. For windows, by the way, it will not be necessary to find out the thickness and thermal conductivity, usually there is already a ready-made heat transfer resistance of a double-glazed window calculated by the manufacturer. For the floor (in the case of a slab foundation), the temperature difference will not be too large, the ground under the house is not as cold as the outside air.

Heat loss through ventilation

The approximate volume of air available in the house (volume internal walls(Does not include furniture)

10 m x 10 m x 7 m = 700 m3

Air density at +20°C 1.2047 kg/m3. The specific heat capacity of air is 1.005 kJ/(kg×°C). Air mass in the house:

700 m3 × 1.2047 kg/m3 = 843.29 kg

Let's say all the air in the house is changed 5 times a day (this is an approximate number). With an average difference between internal and outdoor temperature 28 °C for the entire heating period, on average, heat energy will be spent per day to heat the incoming cold air:

5 × 28 °C × 843.29 kg × 1.005 kJ/(kg×°C) = 118650.903 kJ

118650.903 kJ = 32.96 kWh (1 kWh = 3600 kJ)

Those. during the heating period, with five replacements of air, the house will lose an average of 32.96 kWh of heat energy per day through ventilation. For 7 months of the heating period, energy losses will be:

7 × 30 × 32.96 kWh = 6921.6 kWh

Heat loss through the sewer

During the heating period, the water entering the house is quite cold, for example, it has average temperature+7°C. Water heating is required when residents wash dishes, take baths. Also, the water from the ambient air in the toilet bowl is partially heated. All the heat received by the water is washed off by the residents into the sewer.

Let's say that a family in a house consumes 15 m3 of water per month. The specific heat capacity of water is 4.183 kJ/(kg×°C). The density of water is 1000 kg/m3. Let us assume that on average the water entering the house is heated up to +30°C, i.e. temperature difference 23°C.

Accordingly, per month, heat loss through the sewer will be:

1000 kg/m3 × 15 m3 × 23°C × 4.183 kJ/(kg×°C) = 1443135 kJ

1443135 kJ = 400.87 kWh

For 7 months of the heating period, residents pour into the sewer:

7 × 400.87 kWh = 2806.09 kWh

Conclusion

At the end, you need to add up the received numbers of heat losses through the building envelope, ventilation and sewerage. Get an approximate total number home heat loss.

I must say that heat losses through ventilation and sewerage are quite stable, it is difficult to reduce them. You will not shower less often or poorly ventilate the house. Although partially heat loss through ventilation can be reduced with the help of a heat exchanger.

Calculation of heat loss at home can also be done using SP 50.13330.2012 (updated version of SNiP 23-02-2003). There is an appendix G “Calculation of the specific characteristic of the consumption of thermal energy for heating and ventilation of residential and public buildings”, the calculation itself will be much more complicated, more factors and coefficients are used there.

Today, the issue of rational use of fuel and energy resources is very acute. Ways to save heat and energy are being continuously worked out in order to ensure the energy security of the development of the economy of both the country and each individual family.

The creation of efficient power plants and thermal insulation systems (equipment that provides the greatest heat exchange (for example, steam boilers) and, conversely, from which it is undesirable (melting furnaces)) is impossible without knowledge of the principles of heat transfer.

Approaches to the thermal protection of buildings have changed, the requirements for building materials have increased. Every house needs insulation and heating system.. Therefore, in the heat engineering calculation of enclosing structures, it is important to calculate the thermal conductivity index.

The concept of thermal conductivity

Thermal conductivity - it's like that physical property material, in which the thermal energy inside the body passes from the hottest part of it to the colder one. The value of the thermal conductivity index shows the degree of heat loss by residential premises. Depends on the following factors:

It is possible to quantify the property of objects to pass thermal energy through the coefficient of thermal conductivity. It is very important to make a competent choice of building materials, insulation to achieve the greatest resistance to heat transfer. Miscalculations or unreasonable savings in the future can lead to a deterioration in the indoor climate, dampness in the building, wet walls, stuffy rooms. And most importantly - to high heating costs.

For comparison, below is a table of thermal conductivity of materials and substances.

Table 1

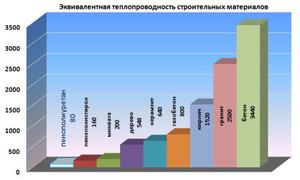

Metals have the highest values, heat-insulating objects have the lowest.

Classification of building materials and their thermal conductivity

Thermal conductivity of reinforced concrete, brickwork, expanded clay concrete blocks, commonly used for the construction of enclosing structures, has the highest standard indicators. In the construction industry wooden structures are used much less frequently.

Thermal conductivity of reinforced concrete, brickwork, expanded clay concrete blocks, commonly used for the construction of enclosing structures, has the highest standard indicators. In the construction industry wooden structures are used much less frequently.

Depending on the thermal conductivity values, building materials are divided into classes:

- structural and heat-insulating (from 0.210);

- heat-insulating (up to 0.082 - A, from 0.082 to 0.116 - B, etc.).

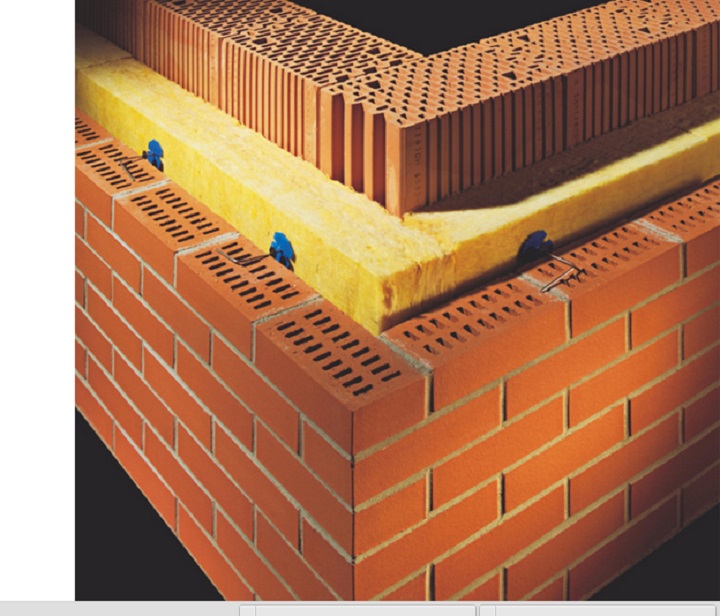

Efficiency of sandwich structures

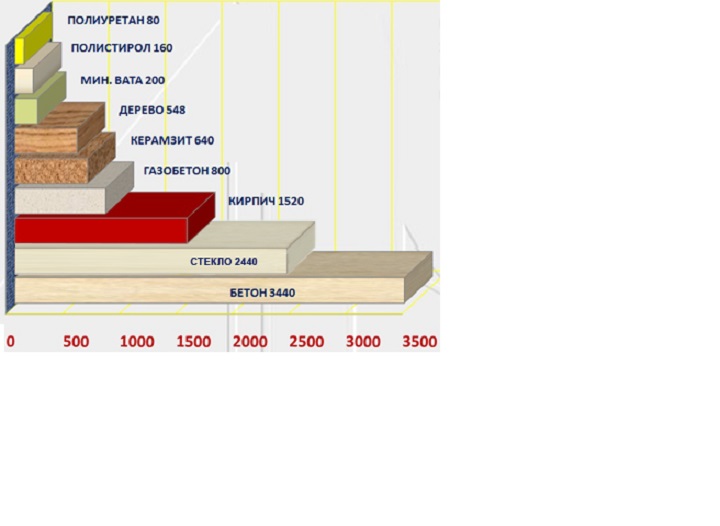

Density and thermal conductivity

Currently, there is no such building material, high load bearing capacity which would be combined with low thermal conductivity. The construction of buildings based on the principle of multilayer structures allows:

Combination structural material and thermal insulation allows to ensure strength and reduce the loss of thermal energy to an optimal level. Therefore, when designing walls, each layer of the future enclosing structure is taken into account in the calculations.

It is also important to take into account the density when building a house and when it is insulated.

The density of a substance is a factor that affects its thermal conductivity, the ability to retain the main heat insulator - air.

Calculation of wall thickness and insulation

The calculation of the wall thickness depends on the following indicators:

- density;

- calculated thermal conductivity;

- heat transfer resistance coefficient.

According to the established norms, the value of the heat transfer resistance index of the outer walls must be at least 3.2λ W/m °C.

Calculation thickness of walls made of reinforced concrete and other structural materials is presented in table 2. Such building materials are characterized by high load-bearing characteristics, they are durable, but they are ineffective as thermal protection and require irrational wall thickness.

table 2

Structural- thermal insulation materials capable of being subjected to sufficiently high loads, while significantly increasing the thermal and acoustic properties of buildings in wall enclosing structures (tables 3.1, 3.2).

Table 3.1

Table 3.2

Heat-insulating building materials can significantly increase the thermal protection of buildings and structures. Table 4 shows that the lowest values of the thermal conductivity coefficient have polymers, mineral wool, plates from natural organic and inorganic materials.

Table 4

The values of the tables of thermal conductivity of building materials are used in the calculations:

The task of choosing the optimal materials for construction, of course, implies a more integrated approach. However, even such simple calculations already at the first stages of design make it possible to determine the most suitable materials and their quantity.

What is thermal conductivity? Knowing about this value is necessary not only for professional builders, but also for ordinary people who decide to build a house on their own.

What is thermal conductivity? Knowing about this value is necessary not only for professional builders, but also for ordinary people who decide to build a house on their own.

Each material used in construction has its own indicator of this value. Its lowest value is for heaters, the highest for metals. Therefore, it is necessary to know the formula that will help calculate the thickness of both the walls being built and the thermal insulation in order to end up with a cozy home.

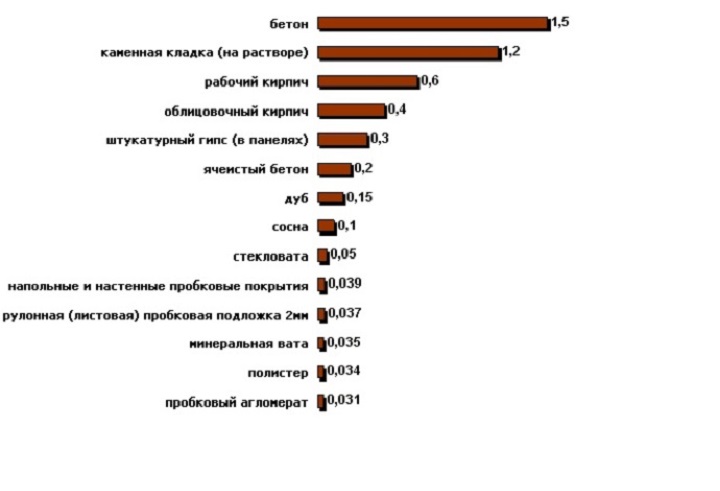

Comparison of heat conductivity in the most common heaters

To understand the conduction of heat different materials intended for insulation, you need to compare their coefficients (W / m * K), given in the following table:

As can be seen from the above data, the heat conductivity index of building materials such as thermal insulation varies from a minimum (0.019) to a maximum (0.5). All thermal insulation materials have a certain variation in readings. SNiPs describe each of them in several forms - in dry, normal and wet. The minimum coefficient of heat conductivity corresponds to a dry state, the maximum - to a wet one.

As can be seen from the above data, the heat conductivity index of building materials such as thermal insulation varies from a minimum (0.019) to a maximum (0.5). All thermal insulation materials have a certain variation in readings. SNiPs describe each of them in several forms - in dry, normal and wet. The minimum coefficient of heat conductivity corresponds to a dry state, the maximum - to a wet one.

If individual construction is planned

When building a house, it is important to consider specifications all components (material for walls, masonry mortar, future insulation, waterproofing and vapor vent films, finishing).

To understand which walls the best way will retain heat, it is necessary to analyze the thermal conductivity of not only the material for the walls, but also the mortar, as can be seen from the table below:

| Item number | Wall material, mortar | Thermal conductivity coefficient according to SNiP |

| 1. | Brick | 0,35 – 0,87 |

| 2. | adobe blocks | 0,1 – 0,44 |

| 3. | Concrete | 1,51 – 1,86 |

| 4. | Foam concrete and aerated concrete based on cement | 0,11 – 0,43 |

| 5. | Foam concrete and aerated concrete based on lime | 0,13 – 0,55 |

| 6. | Cellular concrete | 0,08 – 0,26 |

| 7. | ceramic blocks | 0,14 – 0,18 |

| 8. | Cement-sand mortar | 0,58 – 0,93 |

| 9. | Mortar with lime | 0,47 – 0,81 |

Important . From the data given in the table, it can be seen that each building material has a rather large spread in terms of the thermal conductivity coefficient.

This is due to several reasons:

This is due to several reasons:

- Density. All heaters are produced or stacked (penoizol, ecowool) of various densities. The lower the density (more air is present in the thermal insulation structure), the lower the heat conductivity. Conversely, for very dense insulation, this coefficient is higher.

- The substance from which they are made (base). For example, brick is silicate, ceramic, clay. The coefficient of thermal conductivity also depends on this.

- The number of voids. This applies to bricks (hollow and solid) and thermal insulation. Air is the worst conductor of heat. Its thermal conductivity coefficient is 0.026. The more voids, the lower this figure.

The mortar conducts heat well, so it is recommended to insulate any walls.

If you explain on the fingers

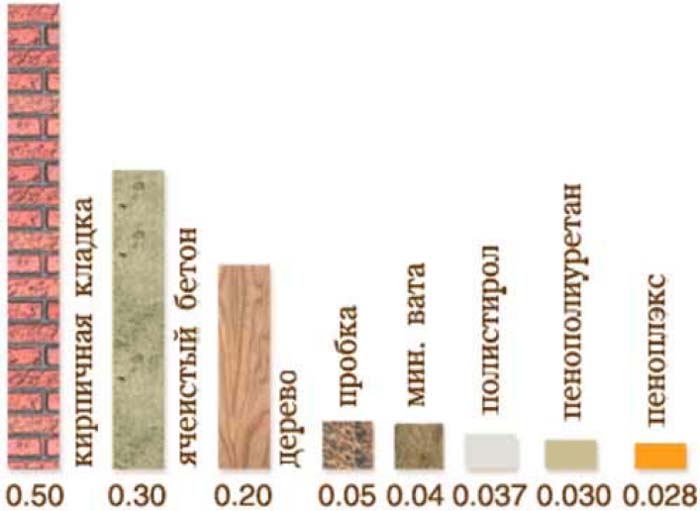

For clarity and understanding of what thermal conductivity is, you can compare a brick wall with a thickness of 2 m 10 cm with other materials. Thus, 2.1 meters of bricks laid into a wall on a conventional cement-sand mortar are equal to:

- a wall 0.9 m thick made of expanded clay concrete;

- timber, with a diameter of 0.53 m;

- wall, 0.44 m thick from aerated concrete.

When it comes to such common heaters as mineral wool and polystyrene foam, then only 0.18 m of the first thermal insulation or 0.12 m of the second is required so that the thermal conductivity of a huge brick wall turns out to be equal to a thin layer of thermal insulation.

A comparative characteristic of the thermal conductivity of insulating, building and finishing materials, which can be produced by studying SNiPs, allows you to analyze and correctly compose an insulating cake (base, insulation, finish). The lower the thermal conductivity, the higher the price. A striking example is the walls of a house made of ceramic blocks or ordinary high-quality bricks. The former have a thermal conductivity of only 0.14 - 0.18 and are much more expensive than any of the best bricks.

different materials have different thermal conductivity, and the lower it is, the less heat exchange between the internal environment and the external one. This means that in winter in such a house it remains warm, and in summer it is cool.

Thermal conductivity is a quantitative characteristic of the ability of bodies to conduct heat. In order to be able to compare, as well as accurate calculations during construction, we present the numbers in the table of thermal conductivity, as well as strength, vapor permeability of most building materials.

There are the following types of heat exchange processes:

- thermal conductivity;

- convection;

- thermal radiation.

Thermal conductivity- this is the transfer at the molecular level of heat between bodies or particles of the same body that have different temperatures, when there is a fairly active exchange of motive energy of molecules, atoms and free electrons, i.e., the smallest particles of the body.

This process is carried out by structural particles of bodies moving in a chaotic order (meaning molecules, atoms, etc.). A similar heat exchange occurs in any physical body that has a non-uniform temperature distribution. The heat transfer mechanism itself in one way or another depends on the state of aggregation of the substance at the current moment.

thermal radiation- the transfer of energy from one body to another body, occurring through electromagnetic waves.

All methods of heat transfer are often implemented jointly. So, convection is accompanied by thermal conductivity, because in this case particles with different temperatures inevitably come into contact.

The process of convection is carried out when moving in space unevenly heated sections of the medium. In this case, the transfer of heat is inextricably linked with the transfer of this same medium.

To achieve the same warmth in a brick house as a wooden frame gives, the thickness brick walls must exceed three times the thickness of the walls of a wooden building

The process of joint heat transfer by convection and heat conduction is called convective heat transfer. Heat transfer is essentially a convective heat exchange between a moving medium and a fixed (solid) wall. Heat transfer is often accompanied by thermal radiation. Heat transfer in this case is carried out jointly through processes such as thermal conductivity, convection and thermal radiation.

There is a transfer of matter, the so-called mass transfer, manifested in the equilibrium concentration of the substance.

The joint simultaneous flow of heat transfer and mass transfer processes is called heat and mass transfer.

Thermal conductivity is expressed in the thermal movement of the smallest particles of bodies. The phenomenon of thermal conductivity can be observed in solids, and in stationary gases, and in liquids, provided that convective currents do not arise in them. When erecting various kinds of structures, including residential buildings, knowledge is needed about the thermal conductivity of building materials, including such as expanded polystyrene, polyurethane foam, etc.

Coefficient of thermal conductivity

An indicator of the thermal conductivity of materials is the coefficient of thermal conductivity

Speaking of thermal conductivity, they also mean the quantitative characteristics of the ability of bodies to conduct heat. The ability of a substance to conduct heat is different. It is measured in such a unit as the coefficient of thermal conductivity, which means specific thermal conductivity. In numerical terms, this characteristic is equal to the amount of heat passing through a material with a thickness of 1 m and an area of 1 sq. m / s at a single temperature range.

Previously, it was assumed that thermal energy is transferred depending on the flow of caloric from one body to another. However, later experiments refuted the very concept of caloric as an independent type of matter. In our time, it is believed that the phenomenon of thermal conductivity is due to the natural tendency of objects to a state as close as possible to thermodynamic equilibrium, which is manifested by the equalization of their temperatures.

Vacuum thermal conductivity

It is interesting to consider the coefficient of thermal conductivity of vacuum from this point of view. It is close to zero - and the deeper the vacuum is, the closer its thermal conductivity is to zero. Why? The fact is that in vacuum there is an extremely low concentration of material particles that are able to transfer heat. But heat is still transferred in a vacuum - by radiation. So, for example, in order to minimize heat loss, a thermos is made with double walled pumping air between them. They also make silver. The properties of materials such as foil foam and other similar insulating materials are based on the same quality that the mirror surface reflects radiation better.

Below we watch educational videos for a more complete presentation of such a physical concept as thermal conductivity, using specific examples.

Thermal conductivity table

| Material | Density, kg/m3 | Thermal conductivity, W / (m * C) | vapor permeability, Mg/(m*h*Pa) |

Equivalent1 (with heat transfer resistance = 4.2m2*C/W) thickness, m | Equivalent2 (when vapor permeation resistance =1.6m2*h*Pa/mg) thickness, m |

| Reinforced concrete | 2500 | 1.69 | 0.03 | 7.10 | 0.048 |

| Concrete | 2400 | 1.51 | 0.03 | 6.34 | 0.048 |

| Expanded clay concrete | 1800 | 0.66 | 0.09 | 2.77 | 0.144 |

| Expanded clay concrete | 500 | 0.14 | 0.30 | 0.59 | 0.48 |

| Red clay brick | 1800 | 0.56 | 0.11 | 2.35 | 0.176 |

| Brick, silicate | 1800 | 0.70 | 0.11 | 2.94 | 0.176 |

| Brick ceramic hollow (gross 1400) | 1600 | 0.41 | 0.14 | 1.72 | 0.224 |

| Hollow ceramic brick (gross 1000) | 1200 | 0.35 | 0.17 | 1.47 | 0.272 |

| foam concrete | 1000 | 0.29 | 0.11 | 1.22 | 0.176 |

| foam concrete | 300 | 0.08 | 0.26 | 0.34 | 0.416 |

| Granite | 2800 | 3.49 | 0.008 | 14.6 | 0.013 |

| Marble | 2800 | 2.91 | 0.008 | 12.2 | 0.013 |

| Pine, spruce across the fiber | 500 | 0.09 | 0.06 | 0.38 | 0.096 |

| Oak across the grain | 700 | 0.10 | 0.05 | 0.42 | 0.08 |

| Pine, spruce along the fiber | 500 | 0.18 | 0.32 | 0.75 | 0.512 |

| Oak along the grain | 700 | 0.23 | 0.30 | 0.96 | 0.48 |

| Plywood | 600 | 0.12 | 0.02 | 0.50 | 0.032 |

| Chipboard | 1000 | 0.15 | 0.12 | 0.63 | 0.192 |

| Tow | 150 | 0.05 | 0.49 | 0.21 | 0.784 |

| Drywall | 800 | 0.15 | 0.075 | 0.63 | 0.12 |

| Facing cardboard | 1000 | 0.18 | 0.06 | 0.75 | 0.096 |

| mineral wool | 200 | 0.070 | 0.49 | 0.30 | 0.784 |

| mineral wool | 100 | 0.056 | 0.56 | 0.23 | 0.896 |

| mineral wool | 50 | 0.048 | 0.60 | 0.20 | 0.96 |

| 33 | 0.031 | 0.013 | 0.13 | 0.021 | |

| Expanded polystyrene extruded | 45 | 0.036 | 0.013 | 0.13 | 0.021 |

| Styrofoam | 150 | 0.05 | 0.05 | 0.21 | 0.08 |

| Styrofoam | 100 | 0.041 | 0.05 | 0.17 | 0.08 |

| Styrofoam | 40 | 0.038 | 0.05 | 0.16 | 0.08 |