We carry gas to a private house extractor hood. Why choose metal ducts. Requirements for ventilation of a boiler room in a private house

Even with a closed firebox in a gas boiler room, an exhaust hood is required: gas leakage is possible and, as a result, poisoning of residents. In the worst case, an explosion. Therefore, an exhaust hood for a private house in accordance with SNiP is necessary: it ensures the safety of people and efficient work equipment.

The gas hood in a private house is determined by the location of the boiler room: on the basement floor, in the annex, in a separate building, in the attic, in a separate room in the house (). For liquefied gas equipment, the boiler room in the basement is not suitable. The mass of this fuel is greater than that of air.

If a leak develops, the gas will begin to accumulate at the bottom of the house and may explode.

For powerful models, a boiler room with forced ventilation for a gas boiler is mandatory).

A wall-mounted low-power unit (within 30 kW) is allowed to be placed in the kitchen if it meets the following conditions ():

- an area of at least 15 square meters;

- ceiling from 2.2 meters high;

- glazing from 3 centimeters square per cubic meter;

- the windows have transoms or vents;

- the boiler is placed 10 cm from the wall, the wall is sheathed with non-combustible material;

- There are air vents at the bottom of the door.

In accordance with 2.04.05 II-35 SNiP, ventilation for gas boilers in private homes is required. The outlet of the ventilation duct is located in the ceiling. An inspection channel is made 30 cm under the chimney for cleaning. The amount of air required for ventilation depends on the power of the unit: 8 square meters are required per 1 kilowatt. see products, if the air comes from the street, 30 sq. cm - if from the next room.

Extraction device options

Ventilation in a boiler room with a gas boiler can be natural and artificial. The first involves the creation of conditions under which the air in the boiler room will be updated by itself.

With artificial exhaust from a gas boiler in a private house, the air flow is forced by fans. Consider the features.

Natural

How to make a ventilation duct in a private house for a gas boiler: with a unit power of up to 30 kW, it is enough to make a supply air with a diameter of 15 centimeters in the lower part of the outer wall. A piece is placed in the hole plastic pipe of the corresponding section, from the outside they are closed with a grate to protect against dirt, mice, birds.

A non-return valve is placed on the inside of the pipe. Its purpose is to prevent traction on the street. Hole supply ventilation for a gas boiler in a private house, they punch in the immediate vicinity of the fuel compartment so that air passes directly into the furnace.

How to make an exhaust hood at a gas boiler in a private house: bring the ventilation duct for the gas boiler out, install a protective rain cap over the pipe. From the inside, you can also put a valve to exclude reverse thrust. The exhaust pipe in a private house for a gas boiler is located directly above it.

The natural ventilation device for a gas boiler is simple and cheap, but does not always meet the standards. Building regulations require that the air in the boiler room be completely renewed three times per hour.

This cannot be guaranteed with natural air exchange, it is uncontrollable - it depends on the season, street temperature, wind speed and direction.

Artificial

How to make ventilation in a boiler room with a gas boiler with artificial draft: the ventilation duct is equipped with a fan, the power of which is selected depending on the cross section of the channel, plus a margin of 20-30 percent. When choosing, take into account the length and geometry of the duct pipe, the number of turns. It is possible to install the fan only for the supply or only for the outlet, but it is preferable to equip both.

How to make a hood for a gas boiler in a private house: triple the volume of the room (multiply the height, width and length of the room) - you get the amount of air necessary for pumping. In accordance with this figure, one or two fans are selected.

You can increase the efficiency of air exchange using an automatic control system: the controller turns on the fans simultaneously with the boiler, turns it off when it stops ().

The role of the chimney in the ventilation process

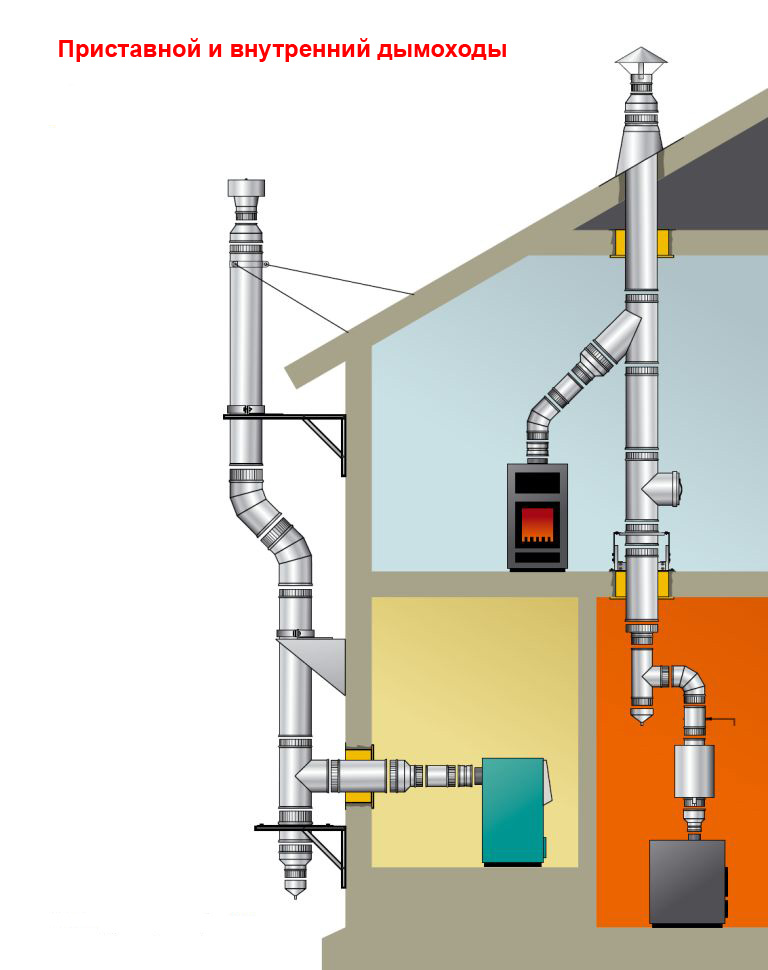

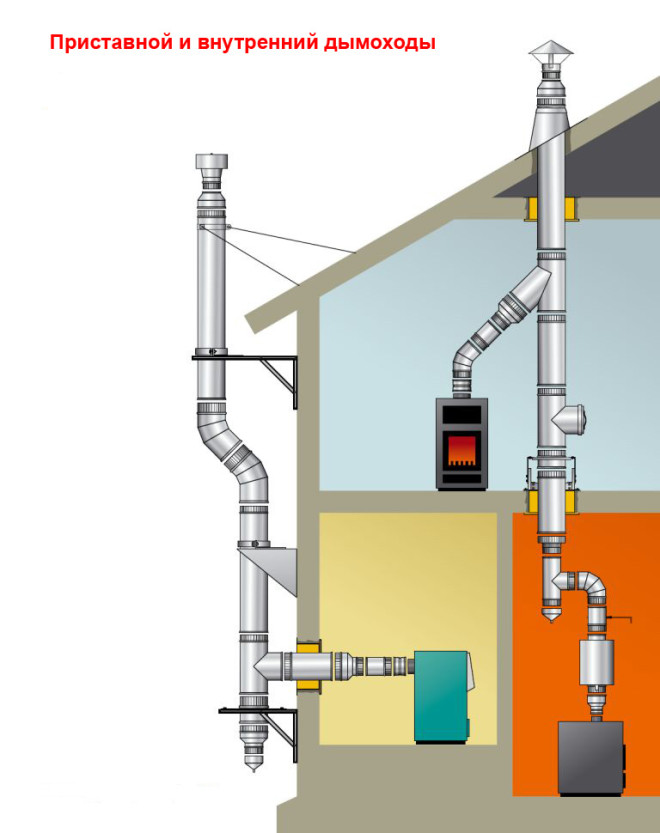

Regardless of the presence / absence of fans, the main volume of gases in both directions pumps the chimney (). Its design may be different, the choice is determined by the characteristics of the boiler itself. For example, condensing-type units require the installation of a coaxial chimney ().

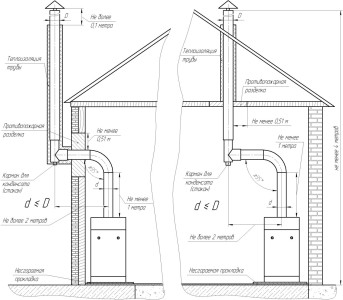

For any pipe design (coaxial, ordinary), for any orientation in space (vertical, horizontal), the cross section must correspond to the cross section of the corresponding boiler nozzle.

The instructions for the unit usually indicate the necessary parameters and type of chimney, as well as installation recommendations. Subject to these recommendations and the rules of SNiP, the hood for a gas boiler in a private house and the air supply to the burner work efficiently, combustion products do not enter the room, soot and dirt do not accumulate in the channel.

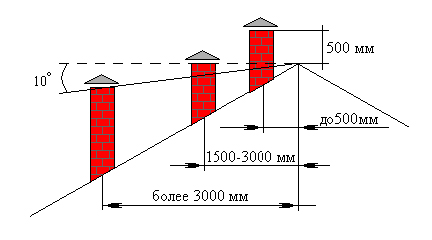

If the chimney is vertical, the pipe should rise above the ridge by at least 0.5 meters, by flat roofs- per meter. The number of knees is minimal (no more than three). The chimney is equipped with an inspection window for cleaning, a condensate trap, and a protective visor from rain.

Video on how to make a ventilation duct in the house.

When installing equipment that runs on any type of fuel - gas, coal, wood, diesel - oxygen is consumed, and combustion products are released that are dangerous to life and health. Therefore, for the safe use of the equipment, ventilation is required for the boiler, regardless of its type of furnace (open, closed). The article will answer the most basic questions related to ventilation.

Requirements for ventilation of rooms with heating equipment

The requirements for ventilation of rooms where gas equipment is installed are almost the same for both the boiler room and the kitchen with a gas stove. Gas stakes with a closed combustion chamber are equipped with a ventilation duct, through which oxygen enters the burner and smoke is removed. You can also purchase a smoke extractor separately.

You can install ventilation to the heating boiler with your own hands, most importantly, observe the following requirements:

- no more than two heating devices are connected to ventilation;

- the wall on which the column or boiler is installed must be protected, and the equipment should not hang tightly;

- the gases obtained during the combustion process must enter at a distance of at least 50 centimeters per different levels; if the level is one, then a cut is installed in the chimney at a level of 50 centimeters or more;

- ventilation or a smoke exhauster must be installed absolutely tightly, the seams must be treated with sealant.

Where heating equipment is installed may vary depending on the type of boiler and its power. According to established standards, there general rules for installing chimneys. The pipe must be at least two meters, the diameter of the pipe must not be less than the inlet to the boiler.

For proper operation of ventilation, it is necessary to make a diagram and calculations, it is important to know the parameters of the room and heating equipment. For safety, the air supply must be three times the consumption.

How to choose a ventilation system

A boiler room and a ventilation scheme are being designed at the stage of construction of a private house. There are three types of air exchange systems:

- natural ventilation, but for the home it can work intermittently, especially if PVC windows are installed or in the summer, when there is no temperature difference;

- flow ventilation, suitable for a house up to 300 square meters;

- supply and exhaust, used for large houses.

Natural ventilation can be done by hand with a minimum set of tools. To do this, a hole with a diameter of about 20 centimeters is made in the wall. , gate valve and grid. Also, the room must have a window and a window. This system can be made in addition to the main one, as an additional one.

Supply ventilation is brought to the roof of the house, above the place where the equipment is installed. Two pipes are installed, the first for the inflow of fresh air, the second for the removal of combustion products and gases. The first pipe can be additionally equipped with . The ventilation scheme of the supply type can be seen in the photo.

Supply ventilation is brought to the roof of the house, above the place where the equipment is installed. Two pipes are installed, the first for the inflow of fresh air, the second for the removal of combustion products and gases. The first pipe can be additionally equipped with . The ventilation scheme of the supply type can be seen in the photo.

Ventilation for a gas boiler in the house can be installed by yourself, following the instructions or by appropriate specialists. In the latter case, it is necessary to conclude an agreement and check the admission of specialists.

For mounting exhaust ventilation you will need a grate - to prevent dirt from entering, a fan with a check valve so that gas does not enter the house, and an air duct. The pipe must match the diameter of the fan. Installation is quite simple, the chimney is led through the roof and connected to the boiler.

Ventilation for a gas boiler with a closed combustion chamber is different from the ventilation system for a boiler with an open combustion chamber.

Boilers with an open combustion chamber must be installed only in a well-ventilated and ventilated room. Basically, boiler rooms are used to install such heating equipment. Mandatory conditions for the installation of boilers with an open combustion chamber are windows, vents and a door with openings.

Boilers with a closed combustion chamber use a chimney with air intake from the street and from neighboring rooms. Thus, boilers with a closed chamber can be installed in any room. Now it is allowed to install units with a closed chamber in basements and basements, the requirements for the installation of such equipment have been simplified.

Features of the chimney of a closed combustion chamber

Most units that use natural gas as fuel have a closed combustion chamber and a coaxial chimney. It differs in design and has a number of advantages.

The chimney consists of two pipes of different diameters and inserted into each other. Smoke and gas are removed through a pipe of a smaller diameter, and the air flow is provided by a pipe with a larger diameter. This design ensures safety and prevents overheating of a smaller diameter pipe.

For a closed combustion chamber, it is not necessary to ventilate the room, but if the draft is bad, then it is necessary to install a smoke exhauster, but in this case the system will be volatile.

But in any case, for a home in the private sector a gas boiler with a closed firebox will be more economical, especially with a coaxial chimney.

What is a smoke exhauster for?

For any heating unit, draft is important, then the efficiency of the boiler decreases, combustion products enter the room; to prevent this from happening, a smoke exhauster is used. It can be installed on almost any ventilation system.

Smoke exhausters are divided into three types:

- a flowing smoke exhauster is installed on the inlet pipe of the boiler, it is turned on as needed manually or automatically;

- centrifugal traction machine;

- natural draft booster, equipped with an axial fan and installed at the end of the pipe.

The smoke exhauster is preferable for solid fuel direct combustion boilers He does his job well. For electric or pyrolysis boilers, the meaning of installing a smoke exhauster practically loses its meaning.

Add to bookmarks

Chimney system installation

For successful and full-fledged operation of the system using gas boilers, it is necessary to calculate and correctly install exhaust pipes for gas boilers. Compliance with all safety requirements and correct installation will protect the life and health of family members and extend the life of the gas boiler.

An example of a piping system for a gas boiler in a private house. The type of gas boiler depends on its installation and placement of chimneys.

Types of boilers and ventilation systems

There are not many varieties of gas boilers, but the installation of the chimney will directly depend on the type of installation. According to the type of installation, boilers can be divided into:

- wall;

- floor.

The wall-mounted boiler can be installed in any room or space.

wall gas boilers are small in size, and the installation takes place on a wall or partition in the room. At the same time, wall-mounted boilers are divided according to the type of exhaust gases: forced and natural ventilation. A prerequisite for a forced system is a separate horizontal exhaust pipe that goes outside and through which gas combustion products are discharged. For natural ventilation, a chimney is needed, through which, due to natural draft, combustion products are removed. Special conditions apply to the internal arrangement of such chimneys.

Floor boilers are more voluminous, and they are installed directly on the floor. For them, vertical or horizontal exhaust pipes are provided, and the choice of chimney option depends on the room where the boiler is installed. It can be a brick chimney with a stainless sleeve inside. It prevents the destruction of bricks from exposure to aggressive environments and temperature extremes during the operation of gas boilers.

According to the type of burner, boilers are available with an open and closed combustion chamber.

With an open system, it is necessary to independently ignite the boiler.

The safety requirements for installing this type of boiler are the presence of forced ventilation necessary to maintain gas combustion, and a natural chimney system to remove combustion products.

In a closed combustion chamber, the necessary air is supplied and exhaust gases are removed using a coaxial chimney. This is the principle of "one in one", which allows through one exhaust system under the action of the built-in fan, remove exhaust gases, and through the other - saturate the gas combustion chamber with oxygen.

How to choose a chimney for a gas boiler

The chimney device includes several stages:

- Design and calculation of boiler power. Such calculations should be carried out by specialists, since an incorrect design will entail an error when the structure is installed. Correcting defects will cost much more than initially making design documentation for the exhaust system.

- Choice of chimneys. If the project of a house or apartment does not provide for a special design for a chimney, then it is chosen depending on the type of gas boiler.

- The choice of materials for the chimney. These are pipes, adapters, nozzles, umbrella, sealant and other components.

- Chimney installation. The ideal option is to install the hood by a specialist. But in some cases it is possible to mount ventilation system and with their own hands, while observing all the technical conditions and safety precautions.

There are many factors to consider when choosing a chimney system for a gas boiler.

- open or closed combustion chamber of a gas boiler;

- the material from which the parts are made;

- the diameter and size of the smoke structure, including the umbrella itself;

- chimney installation.

The choice of pipes for the chimney

If the type of boiler combustion chamber is determined immediately upon purchase, then the choice of pipes for the chimney can be difficult for those who have not encountered this problem before. The right choice for the device of the exhaust system is very important, since not only the operation of the gas boiler, but sometimes the health of people living in the room depends on their operation, service life and reliability. Not every material is suitable for the manufacture of exhaust elements specifically for gas fuel operation. The most suitable products for these purposes can serve as products:

- Made of stainless steel grade 310S, 316L, 316, 304. They can be used both for interior finishing of the chimney and as an independent exhaust system. During installation, it is necessary to accurately calculate the diameter of the smoke structure.

- Covered with special protective enamels (enamelled). These parts can be made in the form of sandwiches, that is, with internal insulation. Such products are the most durable. When purchasing structures with a heat-insulating layer, it is necessary to take into account the diameter of the inlet of the gas boiler and the diameter of the exhaust system.

- Aluminum hood. They are also applied when interior decoration. and as separate exhaust parts of the ventilation system.

An essential condition when choosing chimney pipes is the diameter and dimensions. These parameters must be accurately calculated by a specialist. In this case, the diameter of the inlet of the duct system must be less than the diameter of the structure included in it. Options are possible when the products are connected to each other by adapters or branch pipes.

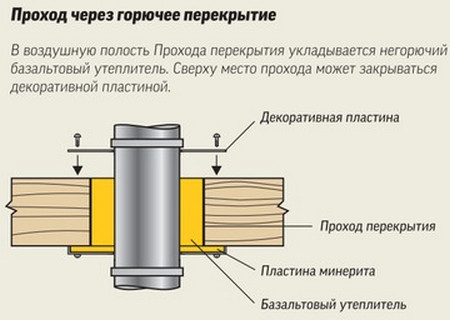

The internal system must be protected by a thermal insulation layer around the entire perimeter. At the same time, the installation chimney requires separate sealing of all joints with special heat-resistant sealants. This will prevent leakage of exhaust gases and dust into the room. Products with thermal insulation are fastened together with self-tapping screws. And the installation is carried out in the following order: the pipe, the diameter of which is smaller, must enter the upper one with a larger diameter.

Installation of the chimney system

Installing a chimney requires certain knowledge. If the project provides for a brick chimney, then it must be protected inside by a metal capsule. Brickwork does not allow exhaust gases to be completely hermetically sealed. At the same time, a brick under the influence of an acidic environment, condensate and thermal temperature extremes can quickly collapse. For gas boilers, the use of galvanized metal pipes as protection is not allowed.

If a gas boiler with an open combustion chamber is installed, then the chimney must be installed vertically. Natural ventilation should have good draft. Therefore, when calculating such a system, both the height of the smoke structure, and the umbrella that protects the system from foreign objects getting inside, and the condensate collection system should be taken into account. Particular attention must be paid to the diameter of the flue system. It must fully comply with the standards for the removal of exhaust gases to a certain height of the room. This is especially true for individual buildings.

An hood for the hood and various deflectors are also provided for the sandwich part. Umbrella and accessories are also the final elements of chimneys. They are made from galvanized steel and copper. There are two types:

- umbrella for pipes without insulation;

- umbrella for sandwich tube.

But for the chimney of a gas boiler, such systems are prohibited. The umbrella reduces the possibility of exhaust gases being released into the open space and promotes the mixing of carbon monoxide and air, which allows this mixture to enter back into the system to support the combustion process. This, in turn, creates dangerous situations. Therefore, an umbrella is strictly prohibited.

The choice of a suitable chimney system and proper installation, taking into account all norms and operating requirements, will allow you to use a reliable system for many years. That is why for any work with chimneys and chimneys, it is necessary to use the services of qualified specialists.

One of the characteristic signs of our time has been the construction of new or the conversion of old country houses for permanent residence. Choosing a solution for organizing the heating of their own homes, many owners stop at installing gas boilers, as the most economical and productive types of heating units.

For reliable and safe operation of such a system, it is necessary to install the correct chimney, which can ensure the entry into the furnace required amount air and the removal of combustion products into the atmosphere.What material should the chimney for a gas boiler be made of?

At first glance, it seems that the answer to this question is obvious: the chimney system must be brick. In fact, everything is not so simple at all. Indeed, just a few decades ago, the installation of almost any chimney consisted of laying a brick pipe to a height just above the ridge of the house. However, we should not forget that in those days houses were heated mainly with the help of stoves and fireplaces, and brick was one of the most affordable materials.

At present, the installation of brick chimneys for gas systems heating is not recommended for the following reasons:

- The design of modern boilers assumes a fairly high efficiency of the fuel combustion process. Therefore, the temperature flue gases in the place where the outlet pipe is connected is quite low (somewhere around 100°C). When moving up, these gases quickly cool and turn into condensate (dew point temperature for gas combustion products 40-60 ° C), which settles on the walls of the chimney;

- Similar processes can also be observed in the chimneys of conventional furnaces, however, the products of combustion of fuel from gas boilers, in addition to water and carbon dioxide contain sulfur impurities. It is they who, settling on the walls of the chimney, cause the greatest harm to it;

- There is an opinion that a brick chimney will be the cheapest option. But if we take into account the complexity and time that will have to be spent on its installation, the savings will turn out to be rather doubtful.

For the same reasons, asbestos-cement and galvanized steel pipes should not be used to remove exhaust gases from the boiler.

The most popular chimney material today is stainless steel. Stainless steel hoods have an optimal round shape, are resistant to aggressive influences, provide easy connection and fire safety.

Modernization of old chimneys

Quite often, owners of private houses have the problem of converting an existing chimney into a heating system based on a gas boiler. For example, a house was built a long time ago, it was heated with a brick stove and was used only during warm periods, but now I want to insulate it and start living permanently.

In order not to rebuild the entire chimney, it is sleeved, that is, pipes are inserted into the brick base, which are not afraid of the resulting condensate.

There are two different types of sleeves:

- Installation of stainless steel pipes. The diameter of the pipe must correspond to the outlet head of the boiler, and its height must correspond to the height of the brick chimney. The annular space is covered with a non-combustible heat insulator (expanded clay, perlite, foam glass). Such a solution will ensure the insulation of the chimney and a significant reduction in the amount of condensate formed.

- The introduction of an elastic liner made of a special polymer material. This technology is called Furan-Flex and consists in the fact that the flexible filler expands under the action of steam, which is injected from below with the help of a special generator, and takes the form of an outlet channel. The diameter of the chimney remains practically unchanged. The method is quite promising, it provides a simple installation of a protective coating, but it is much more expensive than the option with metal pipes.

Choice of constructive solution

As we said earlier, the exhaust pipe for a gas boiler is most often made of stainless steel. Depending on the location of the boiler and the possibilities of structural changes in the house, various types of chimney devices are possible:

- indoors. Installation of such a system is quite complicated and is usually carried out simultaneously with the construction of the house. It is necessary to strictly comply with fire safety requirements and carefully protect the places where interfloor ceilings and roofs pass. But you need to insulate only the uppermost part of the pipe.

- Outside (attached chimney). The easiest option for wall-mounted boilers. The pipe is led outside through a hole in the side wall. The diameter of the hole must ensure the possibility of laying the pipe and the thermal insulation layer. Insulation must be carried out along the entire length of the gas outlet line.

Features of laying a chimney through the roof

If the installation is carried out inside an already built room, work must begin with cutting holes in the ceiling and roof. IN interfloor ceilings install special through pipes, which have the shape of a cube with an internal hole. Its diameter is chosen in such a way that the main structure fits snugly into it.

Collect the chimney from the bottom up, starting from the boiler head. At the very beginning and every 3-4 meters, brackets are installed for rigidly attaching pipes to the wall.

When passing through the roof, a flexible metal sheet is laid and the junction is treated with non-combustible insulation and heat-resistant sealant.

The internal chimney system is equally well suited for both wall-mounted and floor-standing boilers. Its main advantage is that almost the entire exhaust pipe is located indoors and does not require serious insulation. The main thing is to ensure fire safety and tightness of all joints.

The internal chimney system is equally well suited for both wall-mounted and floor-standing boilers. Its main advantage is that almost the entire exhaust pipe is located indoors and does not require serious insulation. The main thing is to ensure fire safety and tightness of all joints.

Attached chimneys

The installation of an exhaust system outside the premises is much simpler, especially if the house has already been built and the owners constantly live in it. It is only necessary to correctly calculate the diameter of the hole in the wall and carefully cut it out. After that, installation is carried out as follows:

- A pipe segment is led out into the wall opening at a distance of at least 25 cm (if the wall is treated with non-combustible materials, then this distance according to SNIP can be reduced to 5-10 cm);

- By means of a rotary knee gathers vertical section. The joints are sealed with a refractory mixture, then they can be further protected and strengthened with clamps with a threaded tie;

- Every 1-2 meters, the structure is fixed with wall brackets;

- After assembly, the chimney is treated with an anti-corrosion coating and insulated with non-combustible materials (most often mineral wool).

An attached chimney is best made from two-layer pipes. They provide better air flow to the furnace part of the gas boiler, are easier to insulate and safer. In addition, in a significant part of modern boilers, a closed combustion chamber is implemented, which necessarily requires connection to chimneys from two coaxial pipes.

Chimney installation rules

The device of the chimney must obey the main rule - ensuring fire safety. For the exhaust system of gas boilers, this is especially important - in the cold season it works constantly:

- When processing surfaces near which the chimney passes, it is necessary to use only refractory materials;

- The installation of all joints, interfloor and under-roof connections must ensure absolute tightness.

In no case should you arrange a joint between pipes inside the ceilings;

- It is very important to correctly size all holes. They must be chosen, taking into account not only the diameter of the pipe, but also the thickness of the layer of insulation and thermal insulation.

In the process of designing and assembling the system for removing combustion products from a gas boiler, the following design requirements must be taken into account:

Removal of combustion products from several boilers

The operating rules for heating systems indicate that when using several gas boilers, each of them must be connected to a separate chimney. However, if such boilers are installed in already built houses, a more flexible approach is allowed: several floor or wall units can use a collective exhaust system, provided that a distance of 75 cm in height between the points of entry of combustion products is observed. In this case, the cross-sectional area of the chimney must not be less than the area of the widest outlet pipe of all connected boilers.

Installing a chimney for a gas boiler is no less important than choosing the heating unit itself or calculating and designing the heating system route. Subject to all the rules given in the article, you will receive an efficient and safe exhaust gas system that will provide comfort and coziness in your home, no matter how cold it is outside the window.

An air duct for a gas boiler in a private house is often confused with a chimney. They are actually two different systems. In the case of a chimney, perfect tightness is required - a small leak of combustion products can be fatal. It is better if a special channel is arranged under it, but in certain cases it is possible to install one ventilation shaft. At the same time, the entry of harmful substances into the ventilation shaft from different devices should be carried out not at the same level, but from different points. In this case, one should rely on SNiP 2.04.14-88.

Natural and forced ventilation

A ventilation duct and a chimney are not the same

It is desirable that in a private house a special room be allocated for a gas boiler. This room is called the boiler room. In some houses, the boiler is mounted in the kitchen. In the first and in the second case, it is necessary to take care of ventilation. The circulation of air flows can be carried out in a natural and forced way.

Natural ventilation is allowed if the boiler output is 30 kW. The principle of operation is based on the difference in pressure inside and outside the house. Air can enter through vents or doors. Such ventilation is called unorganized. In the case of natural ventilation with organized stimulation, supply and exhaust ducts with adjustable dampers are mounted. For better traction, the ventilation system can be equipped with a deflector.

Important! In a room with a gas boiler, the ventilation system allows not only to provide the house with fresh air, but also helps to remove excess heat from the pipes and the gas boiler.

With natural ventilation in the boiler room, care must be taken to install supply and exhaust ventilation ducts. To do this, a hole with a section diameter of 100, 150 mm is cut out in the wall, an air duct is inserted into it - part of a plastic pipe. All cracks are carefully filled with foam. The ventilation pipe is equipped with a mesh or grate that does not allow pests or dust to enter the house.

The check valve will help to secure the room from the return of air. The exhaust pipe is mounted above the boiler, as the combustion products tend to rise up. The supply ventilation duct for a gas boiler in a private house is mounted at the bottom of the boiler room so that the supply air enters directly into the combustion chamber.

Forced ventilation

Forced ventilation is installed when it is not possible to make natural ventilation. This option allows you to mechanically regulate the inflow and outflow of air. Fans are used for forced ventilation. Most often, channel devices are mounted. They are selected depending on the diameter of the duct section.

Forced exhaust ventilation - a safer option in the boiler room

If the boiler room is equipped with a floor gas boiler, mechanical devices are selected with a margin of 30% of their maximum load. The performance of the equipment depends on the length of the ventilation ducts and their bends, as well as the diameter of the pipe section. To do this more accurately, you must at least use the formula for calculating air exchange:

L - the maximum productivity of the equipment is expressed in m3 / 1 hour

V is the volume of the ventilated room. It can be found by multiplying the area by the height (V = S x h).

K is a value that indicates the rate of air exchange individually for each room. Knowing all these indicators, you can easily choose a fan with required power. There is also a simpler option for performing calculations - on our website.

The supply air can be heated or cooled as desired. There are options for arranging boiler rooms with an air conditioning system. It is better to mount fans in metal cases in air ducts.

The forced ventilation system can be equipped with automation. For example, when the boiler is turned on, the fans will turn on at the same time. It is important to remember that according to the norms of SNiP, a complete renewal of the air in the boiler room should be carried out 3 times in 1 hour. Based on these requirements, you need to take care of how to make a ventilation duct in a private house for a gas boiler correctly.

Important! A reasonable option would be a combination of natural and forced ventilation. In the event of a power outage, air circulation can be carried out naturally.

Calculation of ventilation in the boiler room

To do this, you need to know the volume of the boiler room, the dependence of the ceiling height on the coefficient of increase in the air exchange rate. The supply air velocity must be at least 1 m/s. Knowing these characteristics, it is possible to calculate the required dimensions of the air duct, select the diameter of the ventilation duct section for the removal and inflow of air flow.

Duct parameters

| Diameter, mm | Air flow in m3/h at speed in m/s | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 m/s | 2 m/s | 3 m/s | 4 m/s | 5 m/s | 6 m/s | 7 m/s | 8 m/s | |

| 100 | 28.3 | 56.5 | 84.8 | 113 | 141 | 170 | 198 | 226 |

| 125 | 44.2 | 88.3 | 132 | 177 | 221 | 265 | 309 | 353 |

| 140 | 55.4 | 111 | 166 | 222 | 277 | 332 | 388 | 443 |

| 160 | 72.3 | 145 | 217 | 289 | 362 | 434 | 506 | 579 |

| 180 | 91.6 | 183 | 275 | 366 | 458 | 549 | 641 | 732 |

| 200 | 113 | 226 | 339 | 452 | 565 | 678 | 791 | 904 |

| 225 | 143 | 286 | 429 | 572 | 715 | 858 | 1001 | 1145 |

| 250 | 177 | 353 | 530 | 707 | 883 | 1060 | 1236 | 1413 |

| 280 | 222 | 443 | 665 | 886 | 1108 | 1329 | 1551 | 1772 |

| 315 | 280 | 561 | 841 | 1122 | 1402 | 1682 | 1963 | 2243 |

| 355 | 356 | 712 | 1068 | 1425 | 1781 | 2137 | 2493 | 2849 |

| 400 | 452 | 904 | 1356 | 1809 | 2261 | 2713 | 3165 | 3617 |

| 450 | 572 | 1145 | 1717 | 2289 | 2861 | 3434 | 4006 | 4578 |

| 500 | 707 | 1413 | 2120 | 2826 | 3533 | 4239 | 5946 | 5652 |

Why choose metal ducts

It is necessary to determine not only the diameter of the section, but also the material of which it consists ventilation tube. Air ducts are:

- metal;

- metal-plastic;

- non-metallic.

For ventilation of the boiler room, it is better to use metal ventilation ducts. They meet all fire safety requirements. Such pipes are aluminum, steel or galvanized. The main requirement for such ventilation ducts is corrosion resistance.

Air ducts made of metal can withstand both static and shock loads. Therefore, the risk of destruction of the ventilation structure is minimal. Some pipes are flexible, so you can bend them with your own hands at any angle. High structural strength - allows you to withstand maximum internal pressure.

The only disadvantage of metal pipes is that they do not withstand the effects of condensate and become rusty over time. Only 2 types of metal are unconditionally resistant to moisture - aluminum and stainless steel. When installing such pipes, you need to take care of the fasteners. Pick one that can handle the load. Therefore, the installation process may be delayed. The price of such pipes is also higher than for air ducts made of other materials.

Checking the operation of the ventilation system

You can check the operation of ventilation yourself. To do this, just bring a piece of notebook paper or a napkin to the ventilation duct. If there is traction, then the sheet will be fixed at the grate. If this does not happen, then perhaps there were errors in the calculation or the requirements were not observed during the installation of air exchange systems. Although the cause may be clogging of the air ducts.

If the boiler is in the kitchen with interior door without a special slot at the bottom, and the ventilation ducts for the inflow and outflow of air are mounted in different rooms, then with closed doors there will be no traction. To avoid stagnation of air in practice, plastic door ventilation grilles are used. They can be round or rectangular. Depending on the material, the purchase price may be different.

The safe operation of the heater depends on ventilation. Therefore, it is worth taking seriously the design and choice of the type of ventilation. Do correct calculations and installation. If knowledge and experience is not enough, then it is better to resort to the services of specialists. It is important that the area of \u200b\u200bthe room corresponds to the installed equipment. The floor in the boiler room must be made of non-combustible materials. It is best to use a cement screed.