Microclimatic conditions in various industrial premises. Industrial microclimate

Industrial microclimate(meteorological conditions) - the climate of the internal environment of industrial premises, is determined by the combination of temperature, humidity and air velocity acting on the human body, as well as the temperature of the surrounding surfaces.

The production microclimate depends on the climatic zone and season of the year, the nature of the technological process and the type of equipment used, the size of the premises and the number of workers, the conditions of heating and ventilation. Therefore, the production microclimate is different at different facilities. However, with all the variety of microclimatic conditions, they can be divided into four groups. The microclimate of industrial premises in which the production technology is not associated with significant heat release. The microclimate of these rooms mainly depends on the local climate, heating and ventilation. Here, only a slight overheating in summer on hot days and cooling in winter with insufficient heating is possible. The microclimate of industrial premises with significant heat emissions. Such production facilities, called hot shops, are widespread. These include boiler houses, forges, open-hearth and blast furnaces, bakeries, sugar factories, etc. In hot shops, the thermal radiation of heated and hot surfaces has a great influence on the microclimate. The microclimate of industrial premises with artificial air cooling. These include various refrigerators. The microclimate of the open atmosphere, depending on climatic and weather conditions (for example, agricultural, road and construction works).

One of the most important conditions for the normal life of a person when performing professional functions is the preservation of the body's heat balance with significant fluctuations in various parameters of the industrial microclimate, which has a significant impact on the state of heat exchange between a person and the environment.

The heat exchange functions of the body, regulated by the thermoregulatory centers and the cerebral cortex, provide the optimal ratio of the processes of heat generation and heat transfer, depending on the specific meteorological conditions. The main role in heat exchange processes in humans belongs to the physiological mechanisms of heat transfer regulation.

Under normal climatic conditions, heat transfer is carried out mainly due to radiation (heat transfer from a surface with a higher surface temperature to a surface with a lower temperature) - approximately 45% of all heat removed by the body, convection (heat transfer by substance flows, for our case - air) - 30% and evaporation - 25%.

At low ambient temperatures, increases specific gravity convection-radiation heat loss. Under conditions of elevated ambient temperature, heat loss decreases due to convection and radiation, but increases due to evaporation. When the temperature of the air and enclosures is equal to body temperature, heat transfer due to radiation and convection practically disappears, and the only way of heat transfer is sweat evaporation.

Low temperature and increased air mobility contribute to an increase in heat loss by convection and evaporation.

The role of humidity at low air temperatures is much less. At the same time, it is believed that at low ambient temperatures, increased humidity increases the heat loss of the body as a result of intensive absorption of human radiation energy by water vapor. However, a greater increase in heat loss occurs with direct wetting of the surface of the body and clothing. IN working conditions When the temperature of the air and surrounding surfaces is below the temperature of the skin, heat transfer is carried out mainly by convection and radiation. If the temperature of the air and surrounding surfaces is equal to or higher than the temperature of the skin, heat transfer occurs due to the evaporation of moisture from the surface of the body and from the upper respiratory tract, if the air is not saturated with water vapor.

Significant severity of individual factors of the microclimate at work can be the cause of physiological changes in the body of workers, and in some cases, pathological conditions and occupational diseases may occur.

Under different meteorological conditions in the human body, changes occur in the systems and organs involved in thermoregulation - in the circulatory system, nervous and sweating systems. Integral indicator thermal state the human body is body temperature. The degree of tension of the body's thermoregulatory functions and its thermal state can also be judged by changes in skin temperature and thermal balance. Indirect indicators thermal state - moisture loss and reaction of cardio-vascular system(heart rate, blood pressure level and minute volume of blood).

Violation of thermoregulation due to constant overheating or hypothermia of the human body causes a number of diseases.

In conditions of excess thermal energy, restriction or even complete exclusion of individual heat transfer pathways can lead to a violation of thermoregulation, as a result of which overheating of the body is possible, i.e., an increase in body temperature, increased heart rate, profuse sweating, and with a strong degree of overheating - heat stroke - disorder coordination of movements, weakness, drop in blood pressure, loss of consciousness.

Due to a violation of the water-salt balance, a convulsive illness can develop, which manifests itself in the form of tonic convulsions of the limbs, weakness, headaches, etc.

When working outdoors during intense direct irradiation of the head, sunstroke may occur, accompanied by headache, visual disturbances, vomiting, convulsions, but body temperature remains normal.

The impact of infrared radiation on the human body causes both general and local reactions. The local reaction is stronger when irradiated with long-wave radiation, therefore, at the same radiation intensity, the tolerance time is shorter than with short-wave radiation. Due to the large depth of penetration into the tissues of the body, the short-wavelength part of the infrared radiation spectrum has a more pronounced overall effect on the human body.

Under the influence of infrared study, biochemical shifts and changes in the functional state of the central nervous system occur in the human body, the secretory activity of the stomach, pancreas and salivary glands increases.

Cold discomfort (convection and radiation) causes thermoregulatory shifts in the human body, aimed at limiting heat loss and increasing heat generation. Reducing body heat loss occurs due to vasoconstriction in peripheral tissues.

Under the influence of low and low air temperatures, chills (swelling, itching and burning of the skin), frostbite, myositis, neuritis, radiculitis, etc. can develop. Prolonged cooling contributes to the development of diseases of the peripheral nervous, muscular systems, joints: radiculitis, neuritis, myositis, rheumatoid diseases . With frequent and severe cooling of the extremities, neurotrophic changes in tissues may occur.

Rationing of the production microclimate and prevention of its adverse effects

Sanitary standards the microclimate of industrial premises No. 4088-86 regulate the norms of the industrial microclimate. They determine the air temperature, relative humidity, air speed, optimal and permissible values of the intensity of thermal radiation for the working area, taking into account the season and severity labor activity.

IN industrial premises where, due to technological requirements for the production process, the technical unattainability of their provision or economically justified inexpediency, it is impossible to establish permissible standard microclimate values, it is necessary to provide for measures to protect workers from possible overheating and cooling

The main way to improve working conditions in hot shops is to change the technological process, aimed at limiting heat sources and reducing the time of contact of workers with a heating microclimate, as well as using effective ventilation, rationalizing the work and rest regime, drinking regime, workwear.

Most effective tool improvement of meteorological conditions is the automation and mechanization of all processes associated with the heating of products.

Thermal insulation and shielding significantly reduce heat radiation and the flow of radiant and convective heat into the working area. Reflective screens and water curtains effectively protect against radiant heat.

In industrial premises, where sources of convection radiant heat are significant, one of the important measures to normalize meteorological conditions is natural ventilation- aeration, as well as mechanical ventilation with the obligatory use of local air showers.

A significant factor in improving the efficiency of workers in hot shops is the observance of a reasonable work and rest regime, a reduced working day, additional breaks, rest rooms, etc.

For the rest of workers in hot shops, special cabins or rooms with radiation cooling are used.

Favorable effect after thermal loads is provided by hydroprocedures - half-souls, installed near the place of work.

For personal prevention of overheating, rational drinking regimen. With large moisture losses (more than 3.5 kg per shift) and a significant time of exposure to infrared radiation - 50% or more - chilled, salted (0.3% NaCl) carbonated water is used with the addition of potassium salts and vitamins. With less moisture loss, the consumption of salts is replenished with food. In the southern regions of the country, in hot shops, a protein-vitamin drink, green long leaf tea with the addition of vitamins, etc. are used.

In the prevention of overheating, personal protective equipment (overalls made of cotton, woolen and staple fabrics, fiber, duralumin helmets, felt hats, etc.) play an important role.

To prevent cold air from entering the production premises, it is necessary to equip air curtains or airlocks at the entrance. If heating of the building is not possible, air and radiant heating is used. When working outdoors in cold climatic zones, they arrange breaks for heating in specially equipped warm rooms. An important role is also played by overalls, footwear, mittens (made of wool, fur, artificial fabrics with heat-shielding properties, heated clothing, etc.). Termination of work in the open air at low temperatures is carried out on the basis of a decree of local executive authorities.

1 Industrial microclimate and its impact on the human body ...... 3

2 The main parameters of the microclimate ………………...……………………….5

3 Creation of the required microclimate parameters……………………………….9

3.1 Ventilation systems……………………………………………………………9

3.2 Air conditioning……………………………………………….11

Vegetable crops in the mountains of western Cameroon. Coffee and socio-economic changes in the highlands of Western Cameroon. The Bankruptcy of the Coffee Farm as an Engine of Local Development in Western Cameroon: Lessons to Learn from Three Decades of Cooperative Observation of the Rural World.

Faculty of Sciences, University of Antananarivo, Madagascar. After coffee, gardening? Is kitchen bathroom paint really the best paint for these rooms? Painting is one of the last finishing tasks. It can be identified by simply spreading the paint against the wall with a roller or brush. But it is not so. Even with such seemingly simple actions, mistakes can be made that will reduce the durability of the painting and the subsequent discomfort and problems with the use of the premises.

3.3 Heating systems……………………………………………………………11

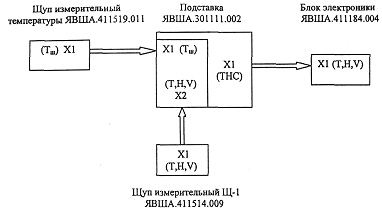

3.4 Instrumentation……………………………………...11

List of used literature…………………………………………..13

1 Industrial microclimate and its impact on the human body

The microclimate of industrial premises is the climate of the internal environment of these premises, which is determined by the combinations of temperature, humidity and air velocity acting on the human body, as well as the temperature of the surrounding surfaces.

Wet rooms include places where, during normal daily use, water is occasionally splashed onto the floor and walls can be splashed with water or water vapor condensation. In residential buildings these will include: kitchens, bathrooms, bathrooms, laundries, dryers and in industrial buildings: various laboratories, some premises of the food industry, such as butchers, breweries, fruit and vegetable processing plants.

Walls and ceilings are usually made of ceramic building materials: hollow blocks, concrete blocks, bricks. Then they are leveled with cement-lime plaster or gypsum plaster and smoothed with smooth plaster or acrylic plaster. Walls and ceilings can also be made of gypsum boards, which are elements of the so-called. Dry building interior. At the very end, the surfaces of the walls and ceilings are painted with emulsion paints. Despite so many layers, the wall retains its porosity, which is why we say it "can breathe".

Figure 1 shows the classification of the industrial microclimate.

Figure 1 - Types of industrial microclimate

The meteorological conditions of the working environment (microclimate) affect the process of heat transfer and the nature of the work. The microclimate is characterized by air temperature, its humidity and speed of movement, as well as the intensity of thermal radiation. Prolonged exposure of a person to unfavorable meteorological conditions sharply worsens his state of health, reduces labor productivity and leads to diseases.

In practice, this means that it is possible to exchange water vapor and air "in" and "out" of the wall. The wall behaves like a sponge - on wet and cold days it collects water vapor, and when it is dry and hot it returns to the room. This creates a microclimate for every room. Unfortunately, when the room is more humid than dry, the wall can accumulate more and more steam. Over time, it can also sink - in places like water drops can be seen - then we say "the wall is sweating". If there is heat in the room, the combination of these factors can lead to mold eruptions and mold.

High air temperature contributes to rapid fatigue of the worker, can lead to overheating of the body, heat stroke. Low air temperature can cause local or general cooling of the body, cause colds or frostbite.

Air humidity has a significant impact on the thermoregulation of the human body. High relative humidity (the ratio of water vapor content in 1 m3 of air to their maximum possible content in the same volume) at high air temperature contributes to overheating of the body, while at low temperature it increases heat transfer from the skin surface, which leads to hypothermia of the body. Low humidity causes the mucous membranes of the worker's pathways to dry out.

"Regular" emulsion paint under the conditions described above can be a good substrate for mold and mildew to grow. Addition to emulsion lime, which is strongly alkaline, inhibits the growth of any organisms under such unfavorable conditions. Unfortunately, even a small addition of lime to emulsion paint impairs its strength properties, and its appearance- lime paint can be used for painting rooms with less aesthetic requirements, such as basements, garages.

To prevent such situations, the walls should be painted with another suitable paint. Firstly, it must have high mechanical strength - the paintwork must be resistant to long-term exposure to water. Only interior paints comply with the Polish Standard to meet this condition.

Air mobility effectively contributes to the heat transfer of the human body and is positively manifested when high temperatures, but negatively low.

Subjective sensations of a person change depending on the change in microclimate parameters (Table 1).

| Air temperature, ºС | Relative air humidity, % | Subjective feeling |

| The most pleasant state. Not related to the problem of painting, but a very important problem is properly designed and working ventilation. Often in old buildings, after replacing the windows with new, very dense ones, made of wood or plastic, it covers the walls first with mold and then with fungi. This applies especially to the aforementioned wet areas, i.e. the kitchen and bathrooms, but often other rooms as well. In most cases, the cause is the lack or insufficient ventilation, which is responsible for the depletion of moisture coming from the daily use of the apartment. Good, calm condition. Fatigue, depression. No discomfort. Unpleasant sensations. Need for rest. No discomfort. Normal performance. Inability to do hard work. Increase in body temperature. Health hazard. For example, during normal daily use of an apartment, the following amounts of water vapor are emitted. Adult. All this moisture must be drained through the ventilation ducts - otherwise it remains in the apartment and accumulates, among other things. In walls and ceilings, which can lead to mold. Ventilation ducts must be throttled, which is not so obvious, for example, in old buildings. If there is a problem with the so-called. You can use mechanical installation support with various types fans. The fan can be controlled using a humidity sensor - it turns on automatically, for example, during a shower in the shower and turns off after the water vapor is drained when the humidity drops to normal. Free fresh air must be provided to ensure proper ventilation. This can be done, for example, through windows that are not completely airtight or current inlets. If the windows are new and airtight, and there is no natural supply air, install special diffusers, for example, under or above the windows. |

Table 1 - Dependence of a person's subjective sensations on the parameters of the working environment

To create normal working conditions in industrial premises, standard values of microclimate parameters are provided: air temperature, its relative humidity and speed of movement, as well as the intensity of thermal radiation.

Direct diffusers require manual control, but there are more advanced so-called ones. diffusers are flexible. In such a diffuser, a special element is installed that reacts to changes in humidity. It is connected to a control lever valve that closes off the inlet. The size of this opening, and therefore the amount of fresh air entering the room, depends on the humidity in the room.

Pigs love to rest in the straw. They also tend to get out

“The level of production largely depends on the conditions in which the animals are kept,” says the drug. Veterinary. In this case, we can say with confidence that the microclimate in the pig farm determines the profitability of production. Disclosure the best performance animal origin will only occur if the conditions for proper maintenance and nutrition are met.

2 Basic microclimate parameters

In the process of labor in a production facility, a person is under the influence of certain conditions, or microclimate - the climate of the internal environment of these premises. The main normalized indicators of the air microclimate of the working area include temperature, relative humidity, and air velocity. The intensity of thermal radiation of various heated surfaces, the temperature of which exceeds the temperature in the production room, also has a significant impact on the parameters of the microclimate and the state of the human body.

Microclimatic conditions can be improved by. Cleaning of windows and walls - frequent bleaching, washing, disinfection and disinfestation, regular check of the ventilation system functionality, correct use of handles, limiting the use of dust feed.

Many diseases of the respiratory system of pigs are caused by excessive dust in the pig farm, too little slurry selection. Ammonia, combined with excessive heat and humidity, irritates mucous membranes, causes inflammation and a number of other conditions, says the veterinarian. The microclimate of a pig farm influences animal health, reproductive parameters and feed intake.

Relative humidity is the ratio of the actual amount of water vapor in the air at a given temperature to the amount of water vapor that saturates the air at that temperature.

If there are various heat sources in the production room, the temperature of which exceeds the temperature human body, then the heat from them spontaneously passes to a less heated body, i.e. to a person. There are three ways of heat propagation: conduction, convection and thermal radiation.

The main microclimatic factors include. Temperature and humidity, concentration of toxic gases in the air, air movement, lighting. Construction of the building, quality of construction materials, location of the pig farm, use of auxiliary equipment - feeding equipment, removal of faeces, temperature and humidity control. The correct parameters of the microclimate in the pig farm. . Piglets are most sensitive to too cold temperatures, especially in the first days of life. Therefore, it is necessary to use an additional heater in the piglet handle.

Thermal conductivity is the transfer of heat due to the random (thermal) movement of microparticles (atoms, molecules) that are in direct contact with each other. Convection is the transfer of heat due to the movement and mixing of macroscopic volumes of gas or liquid. Thermal radiation is the process of propagation of electromagnetic oscillations with different wavelengths, due to the thermal motion of atoms or molecules of a radiating body.

Temperatures that are too low in fattening and pigeons for sows or boars can increase feed intake, which will reduce the profitability of rearing, since energy feeds will be used to warm the body of the animal instead of building muscle tissue.

Proper lighting in the piglets' pen also affects the microclimate of the piglets. Maintaining proper air humidity is very important for health. Too much humidity contributes to the development of pneumonia, fungal infections and rheumatic diseases. On the other hand, too low humidity affects the respiratory tract by irritating the mucous membranes. Floating dust, dust and germs in the air have an easier way to enter the body. The optimum humidity for all groups in the same room is 70%.

In real conditions, heat is transferred not by any one of the above methods, but by a combined one.

The heat entering the production room from various sources affects the air temperature in it. The amount of heat transferred to the ambient air by convection (Qk, W) during a continuous heat transfer process can be calculated according to Newton's heat transfer law, which for a continuous heat transfer process is written as:

The most sensitive to excess moisture in the environment are small piglets and piglets, the body cools down faster, reduces immunity and, most likely, gets sick. Many diseases of the respiratory system of pigs are caused by excessive dust in the pig farm, too little manure selection.

Replacing forced or gravity air is also very important in a poultry farm. Properly ventilated ventilation is designed to bring fresh air into a building and remove toxic gases, dust, and excess heat and moisture. Harmful substances such as ammonia, hydrogen sulfide, carbon dioxide and excess dust and dust have bad influence for the welfare of the pigs. By damaging the mucous membranes in the respiratory system, they allow microbes to enter the body. An excess of these substances with inefficient ventilation can lead to reduced feed intake, reduced daily growth and a number of respiratory and reproductive diseases.

![]() ,

,

where α is the convection coefficient, ;

S - heat transfer area, m2

t is the source temperature, ºС;

tv is the ambient air temperature, ºС.

The amount of heat transferred by radiation (Qi, J) from a more heated solid to a less heated body is determined by:

This is just as important as other microclimatic factors. This significantly affects the welfare of the herd. Light influences the time of feeding, the contact of the animals in the group and the orientation in the pens. The quality, intensity and duration of light during the day affect reproductive and hormonal factors.

Excessive compaction can adversely affect the microclimate in keeping pigs and animals. Pigs love to rest in straw. If it is possible to paddock in the paddock and use more garbage, then you should do it. The satisfaction of the animals will increase because they will be able to behave naturally, bury themselves in heat-resistant bedding, roll in the mud and enjoy nature. The ability to exhibit natural behavior has a significant impact on animal welfare.

where S is the radiation surface, m2;

τ is time, s;

C1-2 is the coefficient of mutual radiation, ;

Θ is the average slope.

A person in the process of labor is constantly in a state of thermal interaction with the environment. For the normal course of physiological processes in the human body, it is necessary to maintain an almost constant temperature (36.6 ºС). The ability of the human body to maintain a constant temperature is called thermoregulation. Thermoregulation is achieved by the removal of heat released by the body in the process of life into the surrounding space.

The microclimate in the pig farm is very an important factor welfare. Welfare affects high production results and, in turn, the profitability of production. Improving the microclimate and thus animal welfare will benefit the breeder's pocket by increasing slaughter productivity, improving breeding rates, reducing pig mortality and reducing the number of sick animals requiring veterinary intervention.

Our designers will help you choose The best decision! We have experience in the design of microclimate support systems in various applications in archives, storage facilities, medical shops and optical laboratories. There are also individual and large recreational pools, ventilation systems, ice arenas for ventilation and moisture collection, accurate air humidity in the museum, maintenance of normal normal dust, and other precise control of ventilation systems.

Heat transfer from the body to environment occurs as a result of: heat conduction through clothing (Qt); body convection (Qk); radiation to surrounding surfaces (Qi), evaporation of moisture from the skin surface (Qsp); heating of exhaled air (Qv), i.e.:

Qtotal \u003d Qt + Qk + Qi + Qsp + Qv

This equation is called the heat balance equation. The contribution of the heat transfer routes listed above is not constant and depends on the parameters of the microclimate in the production room, as well as on the temperature of the surfaces surrounding the person (walls, ceiling, equipment). If the temperature of these surfaces is lower than the temperature of the human body, then heat exchange by radiation goes from the human body to cold surfaces. Otherwise, heat transfer is carried out in the opposite direction: from heated surfaces to a person. Heat transfer by convection depends on the temperature of the air in the room and the speed of its movement of evaporation - on the relative humidity and the speed of air movement. The main share in the process of removing heat from the human body (about 90% of the total amount of heat) is contributed by radiation, convection and evaporation.

The normal thermal well-being of a person when performing work of any category of severity is achieved subject to the thermal balance. Let us consider how the main parameters of the microclimate affect the heat transfer from the human body to the environment.

Effect of ambient temperature on human body associated primarily with the narrowing or expansion of blood vessels in the skin. Under the influence of low air temperatures, the blood vessels of the skin narrow, as a result of which the flow of blood to the surface of the body slows down and heat transfer from the surface of the body decreases due to convection and radiation. At high ambient temperatures, the reverse picture is observed: due to the expansion of the blood vessels of the skin and an increase in blood flow, heat transfer increases significantly.

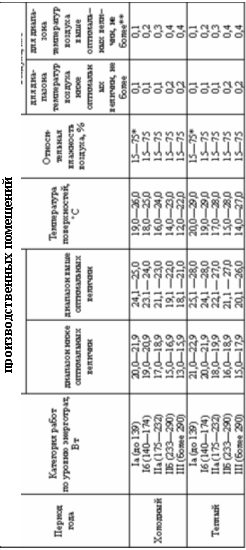

IN normative documents the concepts of optimal and permissible microclimate parameters are introduced.

Optimal microclimatic conditions are such combinations of quantitative parameters of the microclimate that, with prolonged and systematic exposure to humans, ensure the preservation of the normal functional and thermal state of the body without straining the mechanisms of thermoregulation.

Permissible conditions provide such a combination of quantitative parameters of the microclimate, which, with prolonged and systematic exposure to a person, can cause transient and rapidly normalizing changes in the functional and thermal state of the body, accompanied by a tension in the mechanisms of thermoregulation that does not go beyond the limits of physiologically adapted capabilities.

GOST 12.1.005-88 “Working area air. General sanitary and hygienic requirements” presents the optimal and valid parameters microclimate in the production room, depending on the severity of the work performed, the amount of excess heat in the room and the season (season).

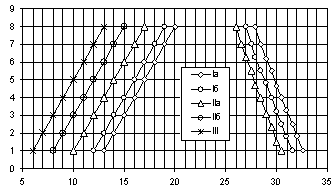

In accordance with this GOST, there are cold and cold periods of the year (with an average daily outdoor temperature below +10 ºС), as well as a warm season (with a temperature of +10 ºС and above). All categories of work performed are divided into: light (energy costs up to 172 W), moderate (energy costs up to 172–293 W) and heavy (energy costs over 293 W). According to the amount of excess heat, industrial premises are divided into rooms with insignificant excesses of sensible heat (Qi.t. ≤ 23.2 J/m3∙s) and premises with significant excesses of sensible heat (Qi.t. > 23.2 J/m3∙s ). Industrial premises with a slight excess of sensible heat are referred to as "cold shops", and with significant - to "hot".

To maintain normal microclimate parameters in working area apply: mechanization and automation of technological processes, protection from sources of thermal radiation, installation of ventilation, air conditioning and heating systems. An important place is also given to the proper organization of work and rest for workers performing labor-intensive work in hot shops.

The mechanization and automation of the production process makes it possible to drastically reduce the labor load on workers (the mass of cargo lifted and moved manually, the distance of cargo movement, to reduce transitions due to the technological process), to completely remove a person from production environment, shifting his labor functions to automated machines and equipment. To protect against thermal radiation, various heat-insulating materials are used, heat shields and special ventilation systems (air showering) are arranged. Thermal protective equipment should ensure thermal exposure at workplaces of not more than 350 W/m2 and equipment surface temperature not higher than 35 ºС at temperatures inside the heat source up to 100 ºС and not higher than 45 ºС - at temperatures inside the heat source above 100 ºС.

The main indicator characterizing the effectiveness thermal insulation materials, - low coefficient of thermal conductivity, which for most of them is 0.025-0.2 W / m∙K.

Used for thermal insulation various materials, for example, asbestos cloth and cardboard, special concrete and brick, mineral and slag wool, fiberglass, etc. As heat-insulating materials for steam pipelines and hot water, as well as for refrigeration pipelines used in washed refrigerators, mineral wool materials can be used.

Heat shields are used to localize sources of thermal radiation, reduce exposure at workplaces, and also to reduce surface temperatures.

To quantify the protective effect of the screen, the following indicators are used: the heat flux attenuation factor (m); screen efficiency (ηe). These characteristics are expressed by the following dependencies:

where E1 and E2 are the intensity of thermal exposure at the workplace, respectively, before and after the installation of screens, W/m2.

There are heat-reflecting, heat-absorbing and heat-removing screens. Heat-reflecting screens are made of aluminum or steel, as well as foil or mesh based on them. Heat-absorbing screens are structures made of refractory bricks, asbestos cardboard or glass. Heat shields are hollow structures cooled from the inside with water.

A kind of heat-removing transparent screen is the so-called water curtain, which is arranged at the technological openings of industrial furnaces and through which tools, processed materials, workpieces, etc. are introduced into the furnaces.

Beyond physiological adaptive capacity. At the same time, there are no violations in the state of health, there are no uncomfortable heat sensations that worsen well-being and a decrease in working capacity. The optimal parameters of the microclimate in industrial premises are provided by air conditioning systems, and the permissible parameters are provided by conventional ventilation and heating systems. ...

Dependencies of the form v=Q/H Since the upper limit of the air flow velocity at the workplace in some cases is less than 0.1 m/s, not all of the listed anemometers are suitable for certification of this microclimate parameter. The simplest device for measuring airflow velocity is a catathermometer, the principle of operation of which is based on the intensity of heat removal from the working part ...