Stoves for the house of long burning. This stove can be used as fuel. Advantages and disadvantages of operating furnaces with long burning

Wood stoves, as before, are widely used. They are not interchangeable for heating the cottage or country house, temporary structures or a residential building as a fallback or even a decorative addition to the chosen interior design. Unlike classic wood-burning stoves, where active combustion of fuel takes place in the furnace, wood-burning stoves are gaining popularity. long burning. This is an extensive group of designs, united by a simple principle, so that the stove will work longer on one load of firewood and at the same time give out a consistently high amount of heat.

The furnace is made of strong and heat-intensive material. It can be cast iron, thick-walled structural steel or brick.

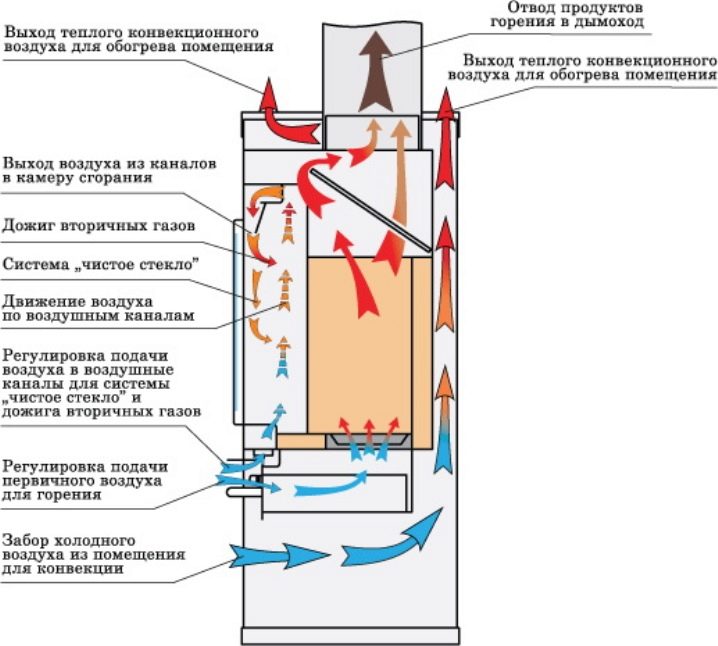

Long burning furnaces are designed to be able to adjust the air supply and provide optimal conditions to maintain smoldering. For this, the combustion chamber is made voluminous, designed for a large bookmark. The air damper is located on the side of the door. On top of the main compartment of the furnace, there is a gas ignition chamber, from which the chimney pipe already exits directly. The chambers are separated by a sheet of metal, and a window between them is formed near the inlet damper.

Most of the volume of the furnace is located outside the optimal route of air from the inlet damper to the chimney.

The inlet damper is solid, capable of completely shutting off the air supply, while the damper to the chimney necessarily has a quarter-section cutout, preventing complete shutoff.

Around the firebox, convection channels are formed, often of a circular cross section. They contribute to active convection of air to take heat from the stove and heat the room. Often these ducts are used to connect air ducts for direct heating of adjacent rooms.

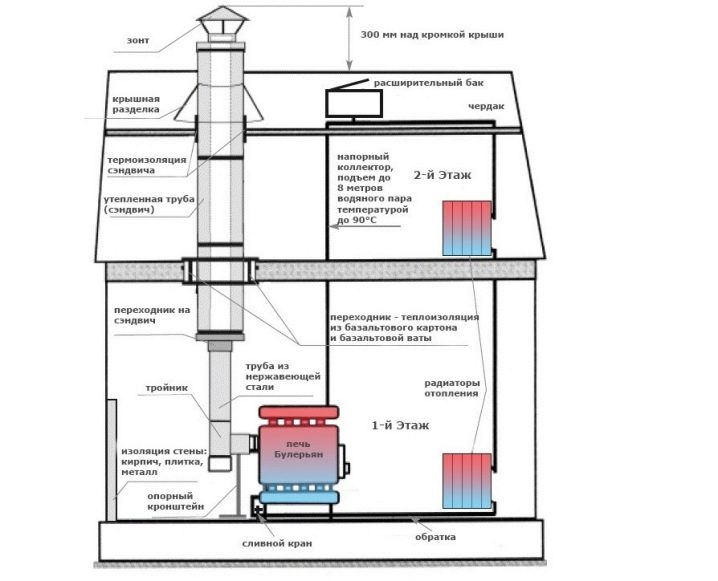

Scheme of the device of the furnace type Buleryan

The most common models of long-burning stoves for heating a private house are:

- Canadian Buleryan (Domestic analogue - Breneran).

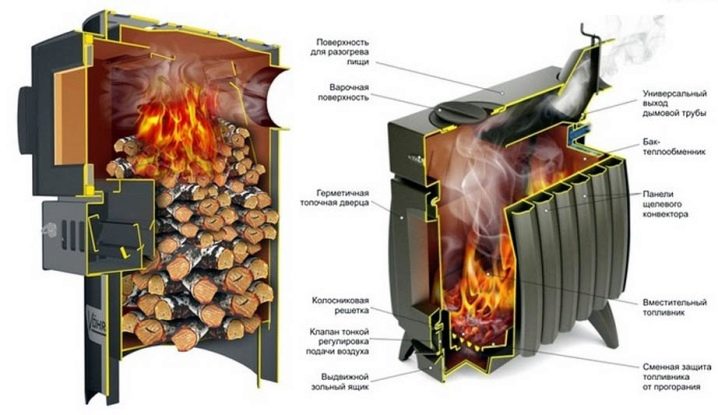

- Stoves with a hob ("Professor Butakov").

- Heating boilers with long burning chamber.

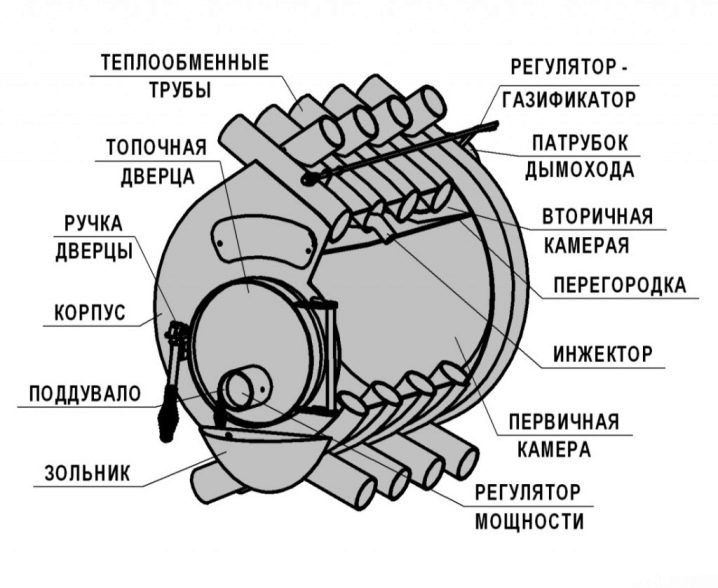

Buleryans attract attention with their rounded shape and the presence of pronounced convection pipes. They are intended for quick heating of any type of premises in which there is a chimney. The design is extremely simple. It is based on a metal cylinder, divided by a horizontal partition into two chambers, the main lower one for laying firewood and the smaller upper one for burning gas. Pipes are welded on the sides with arcs, providing fast heating of the air due to increased convection.

| WID 00 | WID 02 | Novaslav Montreal 02 | Klondike NV-100 | Klondike NV-400 | |

| power, kWt | 6 | 18 | 18 | 6.2 | 19,5 |

| 100 | 400 | 400 | 100 | 400 | |

| Efficiency, % | 75 | 75 | 75 | 80 | 80 |

| Weight, kg | 70 | 130 | 127 | 52 | 120 |

| Furnace volume, dm3 | 48 | 142 | 100 | 25 | 100 |

| 4 | 8 | >8 | 8 | 10 | |

| Chimney height, m | 5 | 7 | 7 | 6 | 6 |

Cooktop stoves, as well as decorated stoves for residential installations, have the more familiar rectangular or diamond shape. Structurally, there are no differences. It is possible to include a grate in the combustion chamber. Often the chimney outlet is carried out vertically without the organization of a separate condensate collector. The condensate flows into the upper chamber and burns out. Some models are supplied with transparent tempered glass doors. In addition to aesthetics, this makes it much easier to set up a long burning mode by observing the process in the furnace.

| Ermak-Thermo 100C | Ermak-Thermo 300 | Termofor Student | Termofor Professor | Termofor Fire-Battery 9 |

|

| power, kWt | 6 | 18 | 9 | 40 | 13 |

| Heated room volume, m3 | 100 | 300 | 150 | 1000 | 200 |

| Efficiency, % | 80 | 80 | 85 | 85 | 85 |

| Weight, kg | 45 | 80 | 77 | 235 | 62 |

| Firebox depth, mm | 500 | 675 | |||

| Furnace volume, l | 70 | 400 | 62 | ||

| Operating time on one load, h | 12 | 10-12 | 10 | 10 | 10 |

| Chimney height, m | 5 | 7 | 5 | 7 | 7 |

| Door | Glass | Metal | Glass | Glass | Glass |

Heating boilers are distinguished only by the presence of a storage tank with water, formed around the main chamber, and a gas combustion chamber. The difficulty in the execution of such boilers lies in the selection of the optimal mode of operation, because when heated, the water takes a lot of heat, which knocks down the long burning mode. In fact, you have to adjust the dampers each time for different temperature conditions.

Principle of operation

Furnaces for long-term burning of firewood are otherwise called gas generators. The combustion process is divided into two main stages: kindling with active combustion of fuel and the main mode with limited oxygen access, smoldering firewood, generation and combustion of gas.

If warmed up to high temperature firewood or special fuel briquettes from pressed sawdust, but do not allow them to burn actively, limiting the access of oxygen, then there will be no active flame in the furnace. The wood begins to smolder slowly, and ideally not in its entirety. Under the influence of high temperature, the release of combustible gas begins, which, when burned, gives the main part of the heat.

At the first stage, a small amount of firewood is placed in the stove and the inlet damper opens for direct access to oxygen-rich air, and the outlet damper to maintain an active flame. At this time, the furnace warms up and the total temperature in the furnace is set.

Further, a large portion of firewood or briquettes is immediately laid in the oven, and the damper closes, almost completely blocking the air supply. In the stove, the air flow is supplied not from below, but from the side or even from above, so as not to allow the entire load of firewood to ignite at the same time. Oxygen should be enough only for slow smoldering.

Firewood warms up, and the release of combustible gas begins, which subsequently burns out in the upper chamber before exiting into the chimney. In order for the gas to completely burn out, cover the damper on the chimney.

One bookmark in a long-burning furnace should be enough for 6-10 hours of continuous heat generation. This is her main advantage. As a consequence, the target use of heat is also increased.

Furnace Disadvantages

Setting the optimal mode of smoldering and gas formation is quite complicated and painstaking. It is necessary to fill your hand with a specific furnace and type of fuel in order to be able to quickly move to the second stage of slow smoldering without consequences.

Incorrect setting is fraught with burnout of the entire bookmark of firewood in excess allowable temperature, as well as a complete shutdown of oxygen, from which the gas will not burn through and will go uselessly through the chimney, increasing the risk of a sudden fire.

During operation, the stove produces a lot of ash and smoke, from which the chimney quickly becomes clogged. It is best to provide a collapsible type chimney and regularly check its condition and clean it from dirt. The stove in normal operation creates a weak draft, so the condition of the chimney is a key safety point.

The oven must not be operated without constant supervision. Changing weather conditions, incorrect combustion settings and coking of the chimney can cause draft collapse, as a result of which carbon monoxide will quickly fill the room, and combustible gas will provoke an explosion or uncontrolled fire.

With water circuit

The ability of a long-burning stove to maintain a constant temperature in the firebox is ideal for incorporating a water circuit into one of the firebox chambers. In another version, the pipes of the water circuit are located around the entire furnace, occupying part of the convection heat exchangers on the outside.

Ermak-Thermo 350-AKVA with a water circuit

A long-burning heating boiler will provide continuous heating of the coolant for a long time without the need to regularly add firewood. Due to the precise regulation of the process of smoldering and combustion of gases, the efficiency of the furnace reaches 85% and it is possible to smoothly adjust the temperature in the boiler.

However, installing a water circuit in a long-term storage oven, which is not directly intended for this, is fraught with a violation of its operation. The water circuit takes away heat from the gas combustion chamber, and it does not burn out completely.

with hob

Models of long-burning stoves, designed primarily for heating residential premises, are equipped with a hob. A flat sheet metal surface on top of a stove used for heating and cooking.

There is no adjustment as such on the hob. The temperature depends on the intensity of combustion of gases in the upper chamber of the stove. In some models, an additional damper reduces the temperature of the hob, fencing off the gas from the combustion chamber.

Cast iron

Furnaces for stationary installation are made of cast iron. Due to the resistance of the material and its durability, the furnace will last up to 50 years without breakdowns and burnout of the walls. Cast iron, in addition to this, is a heat-intensive material and keeps the set temperature in the furnace for a long time, which stabilizes the combustion mode.

The natural disadvantage of cast iron stoves is their huge weight. They are installed permanently and always on a prepared base in the form of a concrete foundation. To protect surrounding structures, the distances recommended by the manufacturer must be adhered to.

The distance to a wooden wall must be at least 1.2 meters, to walls made of non-combustible materials at least 35 cm.

from brick

The principle of laying a brick long-burning furnace is the same as that of a conventional, fast-burning furnace. The furnace is being built with a larger volume, and a gas combustion chamber is added on top. In many furnaces, there is already a coil leading to the chimney to improve heat transfer, which is enough to slightly modify and prepare for gas combustion.

Laying a long-burning stove out of brick is considered not best idea. The abundance of ash and resins, the rapid coking of brick walls due to their roughness require frequent cleaning. Metal walls in this case are more reliable, they are mostly self-cleaning by pyrolysis. Brick under the same conditions due to the porosity of the surface is covered with a layer of soot, which is almost impossible to remove without the use of hard abrasives.

The problem of heating a country house excites many, and there are more than enough options. There are various recommendations, but they mainly concern the nuances of choosing the type of fuel used. Everything else - power, design and the like - these are details.

In principle, for a private house, choose suitable model not so difficult, given the huge range of heat generators. But is all the advice of "experienced and knowledgeable people" useful to summer residents, given some points?

Information about long-burning stoves for summer cottages is, unfortunately, quite rare. But in relation to a light country house building, this improved version of the legendary "potbelly stove" fits perfectly.

Features of work

The furnace furnace is qualitatively sealed, and by regulating the flow of air into it, it is possible to slow down the combustion process. In this case, the fuel (and this is wood) breaks down into components such as gas (pyrolysis) and coke. Hence the other name of such furnaces - gas-generating. The firebox itself is made in 2 “steps”. Slow combustion takes place in the lower chamber, and afterburning of the decay products occurs in the upper chamber. Accordingly, the efficiency of such furnaces is very high, and the burning time of one "bookmark" of fuel is significant.

Pros and cons

It will suffice to point out that great advantage long-burning furnaces in that you do not need to constantly puzzle over where to get fuel. At each site, something is certainly installed for burning grass and branches - a home-made "potbelly stove" or a metal barrel, although someone can do without them. But the fact that everyone has to burn this country garbage is a fact, since regularly after arriving at the site, summer residents are forced to clean up the territory. In addition, the design of some models makes them suitable for cooking (a kind of "wood-burning hob").

The “minus” is very relative - a small heating area. For a country house, this is irrelevant.

There are several types of long burning stoves. But it is hardly advisable to install most of them in a country house because of the size and price of the product. For small, light buildings, a cheap, modest-sized stove is quite enough, which will heat the house for the duration of the owners' stay in it. Of course, those who live on the site all year round, in an impressive building, in several rooms (or even floors), they may not be suitable, but then you already need to talk about heating a private house. And this is a slightly different topic. Therefore, we restrict ourselves to just a short description of small-sized and relatively inexpensive stoves for summer cottages.

Stoves Professor Butakov

Stoves Professor Butakov

Model overview

It makes no sense to dwell on foreign-made products, if only because they will have to pay 39,000 or more rubles for them. It is unlikely that they will be of interest to the "ordinary" summer resident. Therefore, it will be enough just to list some types of units found on our market - Enbra, EdilKamin and a number of others.

But domestic-made stoves (for example, the "" series of stoves) are quite affordable and are great for small suburban buildings, which are most of our summer cottages.

"Matrix"

The cheapest model from this series is the "hundredth" (Matrix-100). The numerical symbol indicates what “squaring” of the room it is able to effectively heat on one tab for 7-8 hours. The chimney pipe is displayed depending on the location - either back or up.

The cheapest model from this series is the "hundredth" (Matrix-100). The numerical symbol indicates what “squaring” of the room it is able to effectively heat on one tab for 7-8 hours. The chimney pipe is displayed depending on the location - either back or up.

On top is a panel used for cooking. On the door there is a glass insert that allows you to observe and control the combustion process. In principle, for a small cottage, this is quite enough.

Price - from 5 360 rubles.

"Top Model"

Series 140 - 300 different modifications. The characteristics are about the same. The peculiarity is that there are convection holes on the upper surface of the casing. They provide the flow of heated air into the room. If you additionally purchase a heat sink, then such a stove will also heat the adjacent room.

Series 140 - 300 different modifications. The characteristics are about the same. The peculiarity is that there are convection holes on the upper surface of the casing. They provide the flow of heated air into the room. If you additionally purchase a heat sink, then such a stove will also heat the adjacent room.

Price (depending on the series) - from 9,850 to 18,840 rubles.

There are still quite a few equally successful domestic models - Ermak (from 4,640 rubles), Normal (from 6,890 rubles) and a number of others.

For a country house, our Russian stoves are the most acceptable option. Both in terms of their capabilities and cost.

- One of the cheapest models is quite suitable for giving, since the issue of external design of the case is usually not on the agenda. And if later you want to improve the design, then it is easy to do it yourself. How to "sheathe" the oven, a good owner will always have it.

- Crude fuel should not be placed in such furnaces, since their efficiency is sharply reduced.

The device of a small hearth with a live flame is a prerequisite for creating an atmosphere of comfort in the country. For such needs, units of appropriate sizes with a reliable design and a functional combustion chamber should be selected. At the same time, it should be a visually attractive object that fits into the overall style of the room. Such requirements are met by long burning, which brings both an aesthetic effect and fills the house with warmth. Compared to classic designs, this option has several differences that should be considered when buying. In most cases, such units fully justify use in summer cottages, but there are also unpleasant exceptions.

Features of long burning furnaces

Models of this kind do not have a classic ash pan, since there are practically no combustion products left during operation. But a hole is provided through which air is supplied to give long-term combustion. This is a kind of supply pipe, supplemented by a regulator. Another similar element is installed in the afterburning zone and serves as an air intake. In technological terms, the main feature of the design of units with long-term combustion is the need to provide a sufficient supply of air to maintain a stable combustion process.

Due to the absence of a blower passing from the ash pan, manufacturers have the opportunity to develop small designs. In a typical design, a wood-burning stove for long-term burning may not exceed the dimensions of a washing machine, although there are also non-standard modifications.

Principle of operation

A feature of the concept of long-term combustion involves the intensification of gas formation processes. In this case, stoves are considered, the furnace of which is fueled with wood, but models that run on coal, pellets and other types of fuel are also common. The main thing remains one thing - the support of slow smoldering, during which the decay of fuel elements occurs. As a result, large volumes of gas are formed and, most importantly, heat is released steadily. In the process, wood burning emit fireproof ash and gaseous mixtures. And here it is necessary to emphasize another feature of such models - this is the implementation of secondary afterburning. All components released during combustion rise to the upper chamber and undergo re-combustion. Just to stimulate the secondary afterburning, an active supply of oxygen to the chamber through the nozzles is provided. Compared to traditional stoves, which are designed to work intensively, long-burning models emit more gases and heat.

Varieties of the unit

The main methods of separating this design by type include taking into account such features as the material of manufacture and the shape of the body. Most manufacturers use metal to create fireplace stoves of this type, but there are also alternative solutions. The most popular are cast iron and stainless steel structures. Ceramic models are less common. It would seem that such materials do not have the proper margin of fire resistance, but the developers provide for the implementation of a lining that increases the heat resistance of surfaces. As for the shape, on the market you can find not only the usual rounded and rectangular ones, but also wood-burning ones with different dimensions for giving. This form factor allows you to save space in the room, which is especially beneficial when installing the unit in a modest summer cottage.

Design Options

There are two types of furnace structures that implement the principle of long-term combustion. The first group includes ready-to-use factory models, the installation of which is limited only to the supply of a chimney and the organization of a flat surface. The second group is more massive furnace structures, which can be made of stone, brick or tile materials. For comparison, if wood-fired ones are capable of providing heat transfer with a power of 4-10 kW, then in the case of furnace fireplace structures, this value reaches 15 kW. With individual orders of the unit, this level can also be increased, allowing heating houses up to 250 m 2 in area. Another question is whether it is advisable to use large fireboxes in the country? But it depends on the parameters of the structure. By the way, one of the key features of brick fireboxes is their integration into the wall, so not every dacha will be able to allow such an installation.

Models with water circuit

If you want to focus on the heating function of the fireplace stove, then it makes sense to turn to models with a water circuit. These are units, which include a heat exchanger, pipes and a storage tank. Depending on the requirements for heating, the user selects the configuration and scheme according to which the system will be installed. At the same time, wood-burning can be performed in different versions relative to the internal structure. The difference between the models lies in the way those contours are located. In the standard version, they are placed longitudinally in the combustion chamber and strictly in the center. There are also modifications in which the principle of "water jacket" is implemented. This means that the walls have, in a sense, a double structure, in which water circuits are enclosed. The coolant circulates in them, which can be adjusted to specific heating needs.

A question of price

The range of prices for units with long burning is quite wide. This segment also includes models for 15-20 thousand rubles, and versions for 50 thousand or more. But it is important to consider that a fireplace stove, the price of which does not exceed 30 thousand, is unlikely to be able to provide more than 10 kW of power. These are usually compact cast iron units that may look attractive, but their heating function leaves much to be desired.

Models with a water circuit can be found in the lines of manufacturers Hark, Schmid and Supra. There is also a distinction between classes, but in the middle segment price tags of 30-40 thousand dominate. However, you can find more affordable, but high-quality wood-burning stoves. Inexpensive options for 20 thousand, in particular, are offered by domestic manufacturers Ecofireplace and Ermak.

Positive feedback about stoves

Devices of this type demonstrate an example when the optimization of the principle of operation of the furnace brings a tangible effect during operation. According to the users of such furnaces, with small volumes of solid fuel supply, high productivity of the equipment can be achieved even against the background of traditional analogues. For example, once loading a fireplace, you can count on a 10-hour support for a certain temperature in the room. With such results, a wood-burning stove for giving a long burning time allows you to save cash and at the same time receive sufficient amounts of thermal energy. This is also noted by the owners of small summer cottages with small stoves, and the owners of households that use powerful models of 15-20 kW.

Negative Feedback

Still, ensuring high performance results with saving fuel reserves is given at the expense of other characteristics. For example, it takes a long time to switch to the same long burning mode. But many owners of cottages, just for the purpose of quick heating, acquire a fireplace stove. Reviews note that for such needs, models with intense combustion should be preferred, as they enter the acquisition phase faster. optimal temperature. There is also criticism of the design of units with long burning furnaces. The fact is that the output of secondary combustion products occurs at low temperatures, which contributes to the excessive formation of condensate. Therefore, the manufacturers themselves recommend considering the location of the chimneys in such a way that a minimum number of transitional sections is formed.

Conclusion

Using the long smoldering mode provides many advantages, which are expressed in the form of efficient heating and fuel economy. Especially for large buildings, it makes sense to purchase just such a fireplace stove. The price of 25-30 thousand for a unit with average power characteristics, of course, does not add to the attractiveness of this solution, but with long-term operation, the economical consumption of firewood will pay for itself. On the other hand, if the purchase of a furnace is considered precisely as a heating system, then you can turn to full-fledged boilers, which will cost even more in terms of energy efficiency. Still, the fireplace stove wins due to the combination of heating function, decorative qualities and ease of use. The principle of long burning does not contradict the first two conditions, but from the point of view of ergonomics, such units are not the best option even in their segment.

Long-burning wood-burning stoves are used to fill the room with heat without constant regulation of the combustion process and practically without ash and soot waste. Therefore, in most of them there is no blower-ashpit, as in the usual heating systems. The installation of such a fireplace is the best way create a cozy homely atmosphere with visible fire with minimal maintenance and little firewood.

Long-burning stoves can be chosen for the home, for a bath, with simple heating of the room or with additional functions of the hob, with a water or air circuit for heating neighboring rooms. It is worth considering in more detail the most common types of such structures and their features.

Kinds

Prefabricated fireplace stoves

According to the installation method, stoves can be prefabricated options and more complex models that need to be built into the interior. If you do not want to carry out complex construction works, that is, the opportunity to buy a factory model, the body of which is made of cast iron and equipped with transparent doors. In the kit of such furnaces there are often chimneys, which are fixed vertically above the firebox. These devices on legs are easy to carry, and it is possible to install them in a new place if necessary.

Embedded

For a small room of 20-30 sq. m. a compact model of a built-in fireplace-stove on long-burning wood is quite suitable. The facade can be lined with bricks or natural stone, and inside there is a factory-made cast-iron firebox with a transparent damper. The advantages of such a project are that you can implement any fireplace design to your liking and organize additional functions: stoves, countertops, heating circuits.

For a bath

Features of fireplace stoves for a bath in their increased moisture resistance and compactness for a small room. Bath models on long-burning wood come in ready-made options, which are easily installed in the steam room. Cases are made of high-strength stainless steel, transparent doors from the tempered glass. Most designs provide for regulation of the heat supply, and the dimensions of such products do not exceed 1000 x 800 x 700 mm, which allows them to be easily transported and installed in any corner of the bath.

The most popular and high-quality domestic models of long-burning sauna stoves-fireplaces are Teplodar, Termofor and Ermak, and imported ones are Finnish Harvia and Kastor.

with hob

It is very convenient to combine two functions of stove-fireplaces with a hob. It is optimal to install them in the kitchen for heating it, with which it is convenient to cook dishes on an open natural fire. An example is the Okhta model with a solid black steel body, a cast-iron firebox and a framed single-leaf tempered glass door. On a single-burner ceramic hob, you can boil a kettle, heat soup or cook dinner in a short time. Due to its small dimensions, this stove is suitable even for a small country kitchen, and its appearance with burning firewood is very attractive.

With water or air circuit

Factory models of fireplace stoves with a water or air circuit allow not only to heat the room in which they are located, but also to supply other rooms in the house with heating and warm water. They can be connected to a complex system of pipes several tens of meters long, through which heated water enters radiator batteries in neighboring rooms or is discharged to a tap in a bathroom or bath. The average power of such systems is 9-11 kW, which is quite enough for heating one-story building with 2-3 rooms even in severe frosts. Of the most common fireplace stoves with a water circuit, Angara-Akva and Pechora-Akva can be noted.

The air circuit fireplace stove uses hot air for the local heating system in the house. Through pipes divorced from the heating device, it penetrates into other rooms. The advantages of this method are greater reliability, unlike water systems, less pressure acts on the air pipes, and they do not run the risk of suddenly breaking through. Among the shortcomings, it is worth noting that the air system is not suitable for rooms with ventilation: kitchen, bathroom, toilet.

Constructions

The design of cast-iron or steel stoves for long-burning wood consists of the following elements:

- metal case on legs or a heat-insulating base to protect the floor;

- firebox;

- damper made of transparent heat-resistant glass;

- ash pan for collecting soot;

- cast iron grate;

- branch pipe for the output of combustion products;

- air channels to ensure a stable combustion process.

The operation of such a heating device is based on the long-term combustion of fuel due to enhanced gas formation processes. That is, in the furnace there is not intense burning, but a slow smoldering of firewood. This releases a large amount of gas. Due to it and the access of additional oxygen through the nozzles, the gaseous combustion products pass through the stage of secondary afterburning. The result is a minimum of waste, and the efficiency of the stove increases.

Another common design of long-burning stoves is based on the gradual advancement of the flame in the stacked firewood from top to bottom. Such a process greatly increases the time until the fuel is completely consumed, and no less heat is released. As an example, consider a burning match - if its head is directed upwards, then the flame will move down very slowly, if you tilt the head down, then the match will burn out in a very short time.

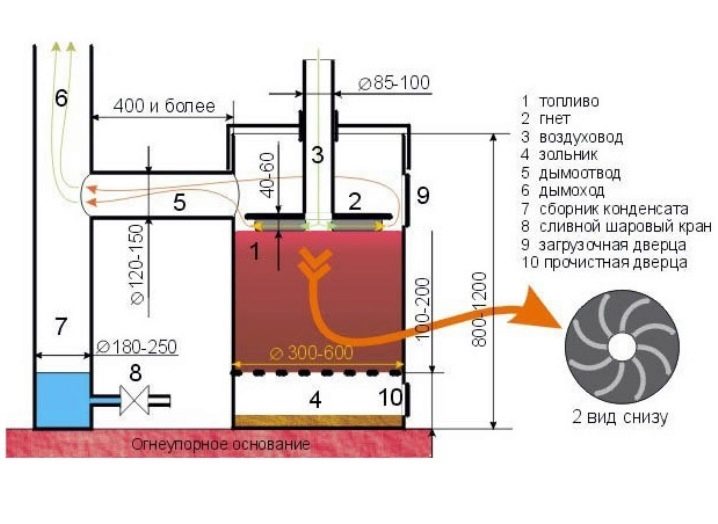

The design of a long-burning heating device with a vertical downward movement of the flame is called the Bubuafonya furnace by the name of its developer. In its firebox there is a movable disk, which plays the role of a piston, which descends as the top layer of firewood burns. There are gaps between the disk and the walls of the furnace boiler through which the resulting smoke rises and exits through the chimney. From above, the furnace is equipped with an air duct for the oxygen necessary for combustion to enter inside, the horizontal chimney from the furnace is connected to the chimney leading to the street. In addition, this design provides a container for collecting condensate.

Not only wood is used as fuel, there are varieties of long-burning stoves on coal and peat briquettes. They have a higher specific heat of combustion, but wood firewood is better suited for creating a cozy atmosphere, a pleasant smell of a fire and an aesthetic appearance in the firebox of such a fireplace.

Fireplace stoves with a water circuit consist of almost the same elements as the usual type, which is used to heat one room. But around the firebox they have a heat exchanger in the form of a radiator or spiral. It consists of metal pipes through which water circulates. When heated, the liquid enters the heating systems distributed throughout the house.

In addition to buying factory models with a water or air circuit, you can create a project and build fireplaces according to your taste and needs, for example, brick, stone, monolithic. This method is unique in that it is possible to create a fireplace portal with a firebox of any size, and, accordingly, of any power - for large buildings with several floors.

If a ready-made cast-iron or steel fireplace stove with a heating circuit is purchased, then the operating power is indicated in its technical data sheet. Based on this value, a model is selected depending on the area of \u200b\u200bthe building:

- 60-200 sq. m. - up to 25 kW;

- 200-300 sq. m. - 25-35 kW;

- 300-600 sq. m. - 35-60 kW;

- 600-1200 sq. m. - 60-100 kW.

DIY

It is easiest to create a long-burning stove for a country house by purchasing a finished cast-iron firebox. There are several varieties of them:

- wall-mounted - designed for mounting in a fireplace near the wall, they will be closed with masonry on three sides, and on the front side there is a transparent damper;

- corner fireboxes - installed in the corner type of fireplace;

- double-sided models have transparent dampers on opposite sides and are suitable for simultaneous heating of two adjacent rooms;

- with a heat exchanger for output to the heating circuit.

After the firebox is purchased, you need to create a fireplace project with facade cladding around it. Here you need to consider whether the metal heating cabinet has legs from below or protection against high temperatures. If it is not there, then it is necessary to build a heat-resistant base of concrete, brick or ceramics in the floor.

Facing the facade of the fireplace with a finished firebox is best done with refractory ceramic or clay bricks in one layer. After the masonry is completed, one should not immediately take on a full kindling. It is necessary that the solution is completely dry and the walls shrink. This will take 2 to 4 weeks. During this time, it is worth drying the fireplace. To do this, it is necessary to heat it daily with a small amount of dry firewood, no more than 2 kg.

Manufacturers of heating equipment today offer such a huge range that each consumer can easily choose for himself something specific, exactly suited to the requirements of the conditions of the organization. heating system. Among the proposals, their worthy place is occupied by long-burning stoves. If we talk about the heating system of a summer house or a small cottage, then the best option hardly to be found today. Of course, provided that in the holiday village there is neither central heating nor a gas main.

It is not even worth comparing traditional wood-burning stoves with a long-burning stove. Just note that they have completely different efficiency. For the former, it does not exceed 60%, for the latter it reaches 95%. Here is the difference, here is the reason for choosing the second design. What is the reason for this effect?

- It's all about the design of the unit, which consists of two combustion chambers. In the first, firewood or another type of solid fuel burns. Here the combustion process takes place with a low concentration of oxygen. In the second furnace, gases are burned that are released during the combustion of fuel.

- In the first firebox, combustion actually takes place, which is called low-calorie. That is, not a very large amount of heat is released, but at the same time the temperature is sufficient to heat the room where the long-burning stove is installed. By the way, in the combustion zone the temperature reaches +1100C.

So, let's take a closer look at how a long-burning stove works. In fact, it has already been described above in what sequence heat is transferred. But we are now interested in the process taking place in the first combustion chamber. So experts call it differently: pyrolysis, hydrolysis, gas generation. In a simple way, it will be “smoldering”, which, in principle, is what happens, because burning solid fuel at a low concentration of oxygen simply can not. The only thing left is to smolder.

Let's look at how the process of heating a cold house takes place. Solid fuel is placed in the long-burning stove and ignited. In this case, the blower damper opens completely. It is important here that the fuel immediately ignites and begins to produce the maximum value of thermal energy. The house is cold, and our task is to quickly heat it up to the required temperature. By the way, with the help of this stove you can heat a small house in half an hour.

So, the house has warmed up, you can proceed to the low-calorie process. That is, the blower damper practically closes, thereby blocking access to the combustion chamber of fresh air, which is what we need. The best option If the furnace is filled with a new batch of fuel, then it can be expected that the duration of its burning will be as long as possible.

I would like to add that manufacturers today offer a fairly wide the lineup long burning stoves. And each consumer can choose a model both in terms of power, and in terms of the frequency of fueling, and according to external data.

Advantages and disadvantages

Like any heating device, these long-burning units have their pros and cons. Therefore, choosing one or another model, each of us must come to terms with the shortcomings that will be present in the heater you have chosen.

Advantages

Homemade construction

- Huge fuel savings. This is the biggest advantage of long-burning stoves. And no matter what adherents of other models say, you can’t argue with this factor. The savings are clear and so great that the choice leaves no alternatives.

- Efficiency. This has already been discussed above, just mark it as a given.

- Choice of dimensions. Currently, manufacturers offer small models and presentable appearance stoves that will fit into any interior of a house or cottage. In any case, they will not be ashamed of themselves.

- Ease of maintenance. Long-burning stoves make it possible to carry out the laying of fuel with a large frequency. By the way, this figure varies in a fairly wide range from 5 hours to 2 days.

- Ability to use a wide range of combustible materials as fuel. There are not only solid fuels, but also liquid ones. By the way, combined long-burning boilers have already appeared on the market today.

Flaws

Device "Sapphire"

- High requirements for the design of the chimney. For example, the inability to use a multi-pipe. In some designs, a horizontal chimney is provided, for example, in Strapuva long-burning stoves.

- To switch to the pyrolysis fuel combustion mode, you must first heat the house itself to a certain temperature. This consumes a large amount of fuel, because the furnace will operate in the traditional full combustion mode.

Choosing an oven

Turning to the choice of a long-burning stove, it is necessary to decide what area it will heat. Currently, manufacturers offer models with which it will be possible to maintain the required temperature in suburban private houses with an area of 80-250 m². Let's face it, a very good range, which makes it possible to use these heating units for many suburban residents. This is the first.

Boiler in the interior

The second is the duration of fuel smoldering in the first combustion chamber. Here, the long-burning stove is divided into three groups:

- Minimum time: 5 to 8 hours.

- With an average: from 8 to 10 hours.

- With a maximum: over 10 hours.

Production material

An equally important component of the choice is the material from which the furnace will be made. Currently, three main materials are used: steel, cast iron and brick. And when the question arises, is it possible to make a long-burning stove with your own hands, life has already answered for everything. No problem, it's possible and even easy.

What to choose? If there is a question of making a stove with your own hands, then you should not mess with cast iron, and it will not work. The technology of casting the necessary units, parts and parts is too complicated. Therefore, brick and steel remain.

circuit diagram

What can you say about a brick oven? This is a traditional option that justifies itself in all cases of life. The only negative is that it will take too long to heat the room in order to achieve the required temperature regime. The brick has great inertia, so it will not be easy and long to warm up the masonry even in one element. And that takes a lot of fuel.

Therefore, only a long-burning stove remains, which you can do with your own hands. For example, from a barrel. Let's look at this model, which has its own name - Bubafonya. By the way, wood-burning stoves from a barrel have always been popular. They did not require large material costs, their design is simple, making it with your own hands is not a problem. The only thing I would like to note is the need to have the skills to work with electric welding, a grinder, a measuring tool.

Do-it-yourself oven

What else is needed besides a metal barrel?

- Sheets of iron 4-5 mm thick.

- Pipe with a diameter of 100 mm.

- A grate, better finished, although it can be made with your own hands, for example, from a corner and wire.

- Asbestos cord.

barrel construction

Now the sequence of assembly work:

- A lid is cut out at the barrel with an allowance of 40-50 mm. In it, a hole is made in the center a little more than a pipe diameter of 100 mm.

- At the bottom of the barrel, a rectangular hole is cut out for the firebox. Fuel will be laid through it.

- A little lower, a smaller rectangular hole is made for the blower.

- From the inside of the barrel, wire guides are welded between the firebox and the blower, on which the grate will be laid.

- In the upper part, a hole for the chimney is cut out on the side. A pipe with a diameter of 100 mm and a length of 20-40 cm is immediately welded to it.

- Now a pancake with a diameter slightly less than the diameter of the barrel is cut out of the metal sheet.

- A hole is made in the pancake in the center and a pipe with a diameter of 100 mm is welded to it. The length of the pipe should be 20-50 cm more than the height of the barrel.

- Rectangles 50-80 mm wide are cut from the same sheet, but their length should be equal to the distance from the edge of the pancake to the edge of the through hole in the center. These pieces are evenly welded in a circle with a rib on the reverse side of the welded pipe. This node is called a press. With its help, the fuel will be pressed down so as not to create a large space for the combustion zone.

- Now we need to carry out a partial assembly. That is, a grate is installed, a press is lowered from above. A lid is put on it so that the press tube enters the hole in the lid.

- Now the cover is welded to the body of the stove around the entire perimeter. Here it is important to weld the seam very tightly. An asbestos cord must be laid in the gap between the protruding pipe and the opening of the cover; it will become a barrier to smoke and carbon monoxide.

- The door is hung on the opening of the firebox.

- The gate is installed on the blower.

Everything is ready, it remains only to install the stove at the destination and attach the chimney to it. Under such a unit, a strong and refractory base must be poured, this is important.

Bookmark fuel

hole cutting

Now to the question, how to bookmark the fuel? To do this, you will definitely need an assistant. He will lift the press by the protruding pipe. It is necessary to lift it as high as possible in order to fully open the combustion chamber. The fuel is packed tightly with minimal space between its parts. The less air inside the furnace, the longer the pyrolysis process takes.

Not everyone, probably, understood why a pipe is needed, which is welded to the press. This is a special channel through which fresh air will be supplied to the fuel combustion zone. And the ribs welded on the bottom will create the necessary space for air to enter, plus they add extra weight to the press.

Types of Buleryan

This is one of the models of long-burning stoves that you can make with your own hands from a two-hundred-liter metal barrel. Let's face it, the option is not the most difficult, but not the most beautiful. No one will install a barrel in a residential area, therefore such furnaces are most often installed in utility rooms for official purposes. For example, in garages, workshops, greenhouses and so on. Although some summer residents install them inside the main building, ennobling the structure with additional elements. For example, you can install a decorative screen in front of the stove, or line it with bricks. Whoever wants, he will find options to make the stove beautiful.

Conclusion on the topic

So, long-burning stoves are becoming more and more popular today. And the reasons are their advantages over traditional models. I would not like to repeat myself, but we note only two advantages: high efficiency and low fuel consumption.