Wood boilers for steam heating. Service and maintenance. And we heat everything with firewood - the last century or cost savings?

If a loyal price for a wood-burning boiler for heating a private house is of primary importance to you, then you need to pay attention to Russian units. Today, Russian-made products are distinguished not only by their low cost, but also by their reliable operation and long service life.

Wood-fired boilers for heating a private house

Don't want to overpay? Interested in a reasonable price for wood-fired boilers with a water circuit for heating a private house in St. Petersburg? We are able to satisfy your interests, as we are the official representatives of heating equipment manufacturing companies.

Why is it worth buying wood-burning boilers for water heating? Initially, it is worth noting that this is an independent means of providing heat. Secondly, heating with firewood applies - it is also environmental safety, in which initially there are no harmful substances. Thirdly, firewood can be stored almost forever if the right conditions are created. Fourthly, a wood-fired hot water boiler does not require a lot of permits, which is necessary when using gas equipment.

Wood boilers for water heating

You can buy a wood-burning boiler for heating a private house in an online store in 1 click, spending a minimum of effort and time. Indeed, you do not need to visit different shopping centers and specialized shops in search of a suitable model. We have hundreds of units at manufacturers' prices. Characteristics, photos and price of a wood-fired boiler with a water circuit are available in the catalog of the online store, which provides all the necessary information for the buyer. Heat exchangers in which boilers can be made of both steel and cast iron. It all depends on the operating conditions and the budget of the buyer.

If you need additional information about the terms of use, technical nuances or features of installing and starting equipment, ask questions online or by phone. Our managers will easily answer all your questions.

The main disadvantage of solid fuel heating boilers is the short operating time from one tab. The fuel in the furnace burns out within 2-3 hours. Wood boilers long burning have special design, which increased the battery life to several days.

The principle of operation of a wood-fired heating boiler, long burning

Long-burning wood-burning boiler with a water circuit, uses the ability of wood to oxidize, under the influence of high temperature and limited oxygen content. The wood is charred due to the large accumulation of smoke, which restricts the access of oxygen. stands out a large number of CO.The device and principle of operation of a wood-burning boiler for long-term operation from one load is aimed at recreating such conditions in a limited space of the combustion chamber. Firewood does not burn in the full sense of the word, but smolders. The operating time increases, and the lack of heat is compensated by the afterburning of the emitted gases.

The design of long-burning boilers includes the following components:

Most long-burning boilers are equipped with an enlarged loading chamber. The internal device allows for autonomous operation for 8-12 hours. Some manufacturers offer boilers that can work from one gas station for several days.

How to choose a slow burning wood burning boiler

Heating boilers for long burning on wood are offered by several domestic and foreign manufacturers. The design of the equipment, as well as the thermal characteristics, differ significantly. When choosing a heat generator, pay attention to the following parameters:- Performance.

- Design features.

- Manufacturer country.

Power calculation

A properly selected wood-burning long-burning heating boiler can easily cope with heating a living area up to 400 - 500 m². When choosing, take into account the performance of the heat generator. The power calculation is performed as follows:- Calculate total area Houses.

- Do the calculation required power boiler using the formula 1 kW = 10 m².

- If there is a DHW circuit in the design, 15-20% of the margin is added to the result.

Design features

Types of long-burning boilers are usually classified into several groups, according to the following criteria:

Separately, it is worth highlighting boilers with a built-in storage boiler. Models of this type have one heating circuit, but are designed to heat the coolant and hot water.

Top Producers

Choosing the best wood-burning boiler for heating your home can be quite difficult, especially when you consider that products are produced by Russia, Austria, Germany, the Baltic States, the Czech Republic and Poland, and it is represented by at least a dozen various manufacturers. The cost of equipment, its thermal performance and reliability depend on the country of the manufacturer.Thanks to consumer feedback, the following rating of long-burning wood-burning boilers was compiled:

- German boilers - equipment is offered by several companies, among which models and stand out favorably. The products are fully automated and are characterized by economical fuel consumption.

- Austrian boilers - produced models, are almost identical in quality to German units. A distinctive feature of Austrian boilers is the maximum automation and the presence of a multi-level security system. Products are offered by concerns, Wirbel, etc.

- Czech boilers - brands and ATMOS are considered the most popular. Universal stations operating both on wood and on other types of fuel remain in demand. Judging by the number of sales, boilers with cast-iron heat exchangers are in special demand among domestic consumers.

- Baltic boilers - the Russian consumer was able to evaluate the quality and thermal efficiency of the Latvian ones, the main advantage of which is a long operating time from one fuel tab. In offline mode, the boiler is able to work for more than 2 days. The design of the unit is so simple that local "craftsmen" offer device diagrams for self-assembly.

- Russian boilers - the first models of long-burning boilers, were not entirely successful, had many design flaws. In modern models, errors have been corrected, which has increased the popularity of heating technology. At the moment, the products are offered by Teplodar, Trayan and others. Low price for wood boilers heating of long burning, unpretentiousness to fuel quality - all this explains the high popularity of products of domestic manufacturers.

- Polish boilers - products of manufacturers are presented on the market:, Defro, Wichlacz. Boilers are practically analogues of German and Austrian companies, but at a more affordable cost. The popularity of models is somewhat limited by the difficulties with the supply of components and somewhat grown in Lately unit price.

Features of the operation of wood boilers with long burning

The burning time of one bookmark of firewood is from 8 to 24 hours. The battery life depends on several factors:- Boiler type.

- Fuel quality.

- Proper operation.

How to achieve long burning wood

The consumption of firewood, subject to the use of the long burning mode, is less than in conventional boilers, by 30-40%. The efficiency reaches 92%. Not all consumers manage to get the boiler to work in the long burning mode the first time. Some complain about the copious release of resin during the burning of wood.You can achieve long-term burning of firewood by carefully following the manufacturer's recommendations:

- Firewood is kindled with a fully open damper.

- In the mode of long burning, the boiler is transferred only after reaching a temperature of 600 ° C.

- The humidity of firewood should not exceed 20%. Heating with coniferous wood is not recommended.

Violations of the rules of operation leads to the fact that tar is formed from firewood in the boiler. Most often, the following conditions are not met:

- The minimum outlet temperature of the coolant must not fall below 65°C.

- It is correct to heat the boiler with hard wood: aspen, beech, acacia, oak, etc.

- The high humidity of firewood leads to an abundant release of resin.

How to properly load firewood

Stacking firewood in the boiler is carried out in accordance with the following rules:- The logs are split into large pieces.

- Stacking firewood in the firebox is carried out as tightly as possible. It is important to avoid voids between logs.

- The length of the logs should be less than the size of the loading chamber, at least 5 cm.

Ignition is carried out exclusively with dry splinters. It is forbidden to use gasoline or kerosene to kindle firewood. From time to time, it is recommended to use special chemical briquettes that remove tar deposits on the walls.

How much firewood do you need for the winter season

The device of a long-burning boiler allows you to save on fuel, approximately 15-30%, depending on the model chosen. The approximate consumption of firewood is calculated as follows:- It is generally accepted that for heating every 100 m², 3 Gcal / month will be required.

- When burning a kilogram of firewood, 3200 kcal is released.

- To get 1 Gcal, long-burning boilers burn 312 kg of firewood.

- To obtain 3 Gcal, approximately a ton of wood is required.

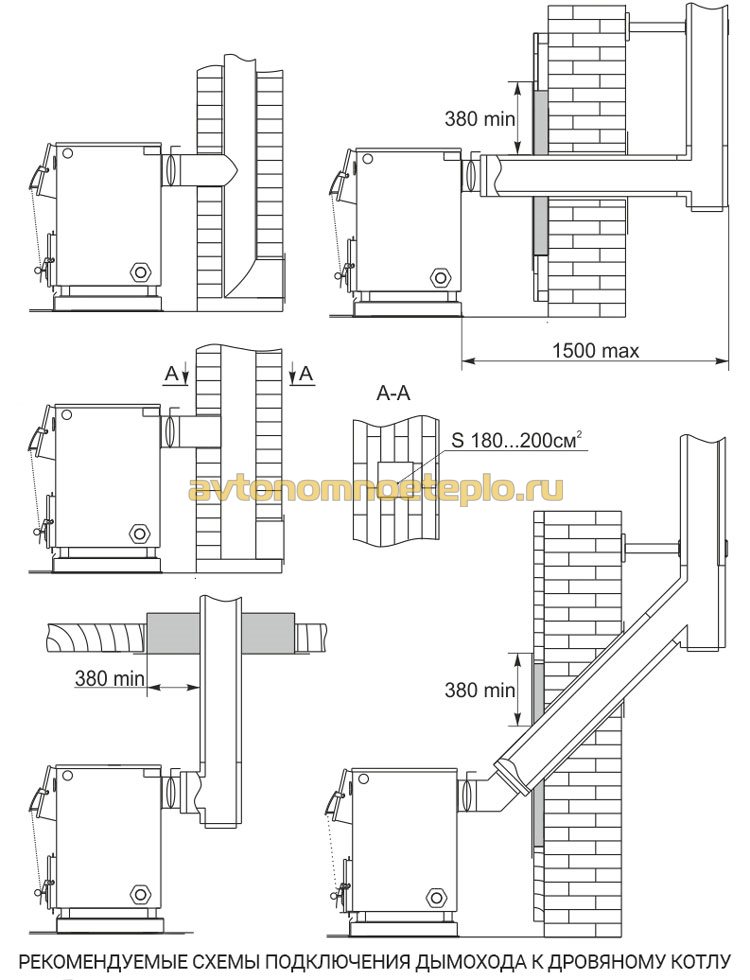

Rules and regulations for the installation of a long-burning wood-burning boiler

The installation of a long-burning boiler is carried out in compliance with the standards applicable to all wood-fired boilers. During installation work, the existing requirements of PPB and SNiP are taken into account:

In the room used for the boiler room, it is necessary to have supply and exhaust ventilation and natural lighting. If necessary, it is allowed to place the boiler in the basement. Content

- Firewood as a type of fuel

- Advantages and disadvantages of wood heating

From time immemorial, people have used firewood to heat their homes. With the advent of alternative fuels such as gas, diesel and electricity, they began to fade into the background, but are still one of the main types of fuel in our country. In this article, we will consider a wood-fired heating boiler, the advantages and disadvantages of using firewood as a type of fuel, as well as the installation features of heating devices of this type.

Before moving on to the consideration of wood-fired boilers with a water circuit, let's first take a closer look at this type of fuel. What is the secret of their special popularity in Russia and what are the disadvantages of their use in heating system your private house or cottage.

The top leaders have already emerged on the Russian market, among the models working on pellets. It is to them that this review is dedicated. So let's get started.

Firewood as a type of fuel

As you know, firewood is a part of a tree trunk intended for burning in order to obtain heat and light. This type of fuel is widely used in our country not by chance, because. most of it is covered with forests of various species.

Photo 1: Pine wood for a solid fuel boiler

Coniferous and hardwood firewood have different calorific value. The former give less heat and burn out much faster. In addition, they take up more space due to their low density. Hardwoods, on the other hand, burn hot and for a long time. That is why, the owners of country houses, if possible, try to harvest hardwood firewood.

Unlike oil and gas, firewood is a renewable source of energy. This is their feature, among others, and brought them such popularity. One cubic meter of wood in terms of calorific value is equal to 200 liters of oil and 200 cubic meters of gas. Another significant advantage is their low ash content in the region of 1-2%.

The disadvantages of firewood include their low calorific value compared to the same gas or coal. Another disadvantage is high humidity. The process of water evaporation steals some of the useful heat, while reducing the overall calorific value.

Photo 2: Installing a hot water boiler in a boiler room country house

Photo 2: Installing a hot water boiler in a boiler room country house

Harvesting firewood for the entire heating season is not an easy task. A forest of a suitable species is felled, knots are cut off and then the tree trunk is sawn into short pieces called "chocks". Subsequently, the chocks are stabbed with a special ax called a “cleaver” into individual logs, which are then stacked in woodpile in a specially equipped place under a canopy.

In cold winters, firewood is used to heat stoves in the house and bathhouse, and is also used in central heating boilers. Let's look at what it is, what its device and design features are.

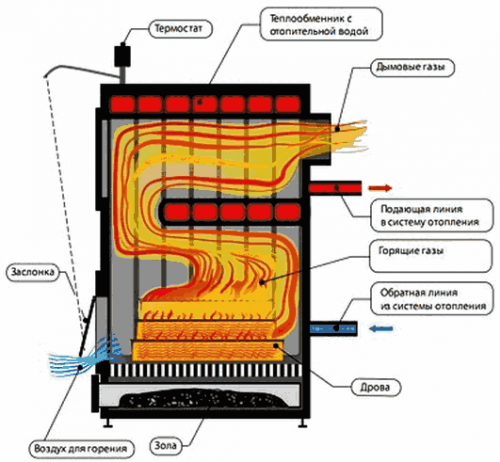

Back to indexWater heating boiler device

Water heating boilers are cast iron or steel devices, by burning in which solid fuel, the coolant is heated in a special reservoir, which in turn circulates through a closed heating system and heats the room.

Photo 3: The principle of operation of a wood-fired boiler with a water circuit

Photo 3: The principle of operation of a wood-fired boiler with a water circuit Wood-fired boilers are the simplest and cheapest devices that can only be bought from solid fuel heat generators. Structurally, they consist of the following units and assemblies:

loading chamber

The loading chamber or firebox, as it is also called, is a compartment with a door in which the firewood is placed. A feature of a wood-fired boiler, unlike coal or pellet boilers, is the presence of a larger firebox that allows you to accommodate fairly large logs.

Ash pan

The ash pan (blower) is located in the lower part of the heating boiler, directly under the furnace, and serves to collect the combustion products of solid fuel in the form of ash. To ensure cleaning, the blower is equipped with a door.

grate

The grate is a grate made of steel or cast iron that separates the firebox and the ash pan. Through the holes in the grate, the ash formed as a result of combustion is poured into the ash pan. Also, through these holes, air is supplied to the combustion chamber, improving traction and fueling combustion.

heat exchanger

Structurally, a heat exchanger is a container of complex shape, inside of which there is a coolant, most often water. The complexity of its shape is due to the fact that to ensure maximum heat removal inside the boiler. The variety of its designs is quite large. Each manufacturer tries to bring his own innovation that can increase the efficiency of the boiler. The most common type of heat exchanger is the water jacket.

Chimney

In the process of burning wood in a heating device, volatile products are released, which must be discharged into the atmosphere. For these purposes, the chimney in a solid fuel boiler serves. Having given maximum energy to the coolant, volatile gases rush along chimney out. Correct is extremely important, because. The combustion products of firewood contain toxic compounds and their entry into a dwelling can lead to sad consequences.

As you can see, the heater is simple. Additionally, in modern TT boilers, various additional devices are used to increase the efficiency of their work, such as: draft regulators, smoke exhausters, etc. There are also both single-circuit and double-circuit modifications, with the possibility of hot water supply.

Photo 4: Boiler chamber for loading firewood

Photo 4: Boiler chamber for loading firewood The principle of operation of water heating boilers is as follows. The boiler is installed indoors, filled with coolant and connected to the supply and return lines of the heating system. A portion of firewood is loaded into the firebox and set on fire. Burning, firewood heats the coolant, which moves through pipes to radiators in various parts of the house. Having given heat to the premises, it returns back to the boiler, where it is heated and the process is repeated. The ash accumulates in the ash pan, from where it is then removed during the cleaning of the boiler. Flue gases are discharged outside through the chimney.

Despite widespread gasification, wood-fired boilers continue to be widely used in country houses. It is quite possible to equip a heating system based on a solid fuel boiler on your own. It is enough to understand the principle of operation of the equipment, follow the manufacturing technology and adhere to all fire safety standards.

Wood heating: advantages and disadvantages

Solid fuel boilers are a popular way to provide autonomous heating private house, cottage, garage, warehouses and industrial facilities. Wood-burning boilers have a number of significant advantages compared to devices that run on special fuels:

- The material used for the firebox has an acceptable cost and reduces energy costs.

- Firewood is an environmentally friendly fuel that does not cause allergic reactions and other diseases.

- The wood burning boiler is easy to operate.

- High speed of heating the room - after turning on the boiler, the thermal effect occurs within a few minutes.

- Solid fuel boilers for wood are independent. Their operation does not require connection to the gas system / electrical industrial system.

- Firewood firewood is aesthetically pleasing, therefore such boilers are often installed both in small country houses and elite cottages.

- In addition to heating, wood-burning stoves/boilers can provide a home hot water without additional costs. The boiler will heat the water boiler, which will simultaneously play the role of a water heating radiator.

Homemade wood-burning boiler: photo

The disadvantages of such devices include:

- The susceptibility of the metal body of the boiler to corrosive processes.

- The need for regular cleaning of equipment from fuel combustion products (ash).

- The short period of burning and heating from one loading.

Types of wood-fired boilers

Wood-fired boilers for the home, depending on the method of supply, are divided into two types: automatic and manual. The first type includes boilers on pellets. The fuel is placed in special bunkers and from there it is supplied for combustion. The device can operate in automatic mode for a long time.

Electrical equipment can be connected to a wood-burning boiler - this will reduce the frequency of human participation in the heating process. The devices work in parallel, and the electric boiler maintains the minimum temperature of the water.

An alternative way to reduce human involvement is to use a battery tank. The system operates in automatic mode - heat accumulates in the tank during the day, and energy is consumed at night.

Wood burning boilers with manual loading can be divided into three types:

- traditional boilers. The device has a standard design - the furnace chamber is located below. Such boilers are laborious to maintain.

- pyrolysis boilers. The equipment operates on the principle of separating fuel into solid and gaseous components. Advantages of pyrolysis devices: high efficiency, low ash and soot formation. However, such boilers require the use of dry wood with a moisture content of not more than 20%.

- In long-burning wood-fired boilers, the top layer of fuel burns out, and the rest slowly smolders. Distinctive feature boilers - a high level of efficiency and the ability to control power consumption. The device can be serviced once a day.

Wood boiler device

The wood-fired boiler is made of heat-resistant material that is resistant to high temperatures. The main elements of the boiler are:

- combustion chamber;

- ash chamber;

- chimney - pipes for venting air to the outside, passing through a container with water / steam.

The ash chamber and the combustion chamber are separated by grates. Both chambers are closed with special barriers and doors.

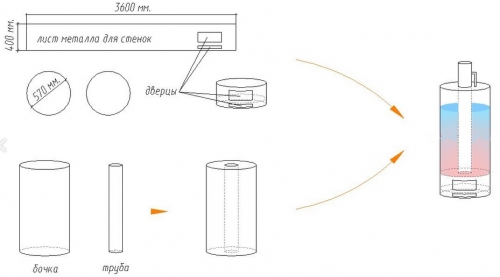

Do-it-yourself wood-burning boiler

Wood-fired boiler drawing

A simple wood-burning boiler can be made independently without the use of complex technological equipment. The main essence of the technology is the transformation of the process of burning firewood into the process of smoldering.

Scheme of a wood-fired boiler

Between the two casings (internal and external) there is a layer of air. Cold air enters from below, heats up from the walls of the inner casing and moves up through the hole in the outer casing. Hot air warms the room.

Preparation of tools and materials

Wood boiler can be made from the following materials:

Tools to get the job done:

- welding machine;

- drill;

- Bulgarian;

- electrodes;

- hammer and chisel.

Assembly guide

We will analyze step by step how to make a wood-fired boiler:

Installation and commissioning

For sufficient air circulation, the boiler must be installed 20-30 cm above the floor level. “Legs” made of steel elements must be welded to the boiler base. It is desirable to lay a refractory foundation under the boiler.

Work on connecting the boiler to the heating system takes place in two stages:

- Cut the supply and return pipes of the heating system into the boiler body using special nozzles.

- Insert a flue pipe into the water tank.

Before connecting the boiler, it is necessary to take care of the safety conditions. Around the boiler, erect a brick screen about 1 m high - the wall will increase the heating efficiency and protect against careless touches of hot metal. There should be a distance of about 30 cm between the heating installation and the brick screen.

The order of the water boiler in operation:

- Remove the cover and heat dissipating disc from the unit.

- Open the air damper on the air supply pipe.

- Place the firewood tightly in the firebox no higher than the level of the chimney. Pour some small chips on top of the firewood.

- Pour firewood with a small amount of ignition fluid. Fire up the oven.

- Cover the boiler with a heat dissipating disc and close the lid.

- When the fuel flares up, the damper can be closed.

Homemade wood-burning boiler: video

Despite the active gasification in many regions and districts of the Russian Federation, they are still relevant for heating a private house. They are appropriate where there is no gas boiler or gas supply costs are too high. On the other hand, a wood-burning heating option is much better than a massive brick oven.

To decide whether you generally need this device in the house or not, get to know it better. Solving the issue of heating a house does not require fuss and hasty decisions. You need to understand all the nuances.

Device

- firewood is loaded into the furnace;

- through a heat exchanger made of steel or cast iron, heat is transferred to the coolant (the boiler is connected to a water circuit for heating the house). As a result, the entire room is heated;

- The principle on which the boiler is based wood heating, is pretty simple:

Manufacturers continually invent new solutions. Follow the latest market news, each modification has its own nuances.

- different wood-fired boilers differ primarily in the size of the combustion chamber - the larger it is, the higher the power of the unit.

heat exchanger

When choosing a heating furnace, the question often arises: which heat exchanger should be preferred?

Heat exchangers also differ from each other:

- steel heats up quickly. But it also cools down faster, although it is important for a water circuit oven that the water heats up as soon as possible. Service life on average 10 years;

The main disadvantage of a steel heater is its vulnerability to corrosion. Therefore, a water circuit filled with distilled water is sometimes used, although this implies some expense.

- the cast-iron element heats up longer and gives off heat for a longer time. It has an impressive service life (will last at least 20 years).

With frequent and sharp temperature changes, the cast-iron heat exchanger is prone to fairly rapid destruction. Be careful when operating.

Varieties

The consumer has a choice among several solutions, each of which has its pros and cons. In any case, the heating systems of a residential building must be reliable, and also meet the requirements for thermal power (living area, intensity of operation, length of the cold season in the region, etc.).

Boiler classic

This design is the simplest and most understandable of all that exist on the market today.

Peculiarities:

- similar to an ordinary stove - equipped with a firebox, a chimney and an ash pan;

- operation does not require complex knowledge;

- runs on fuel with low efficiency;

- consumes a lot of wood.

According to user reviews, such stoves are relatively effective in heating small rooms where there is no need to supply the boiler with a water circuit (that is, such devices are not suitable for heating a private house).

If installation of carrier wiring is planned at your facility, classic boilers will not suit you.

Pyrolysis boiler

The efficiency of such heating is much higher than in the previous case.

The efficiency of such heating is much higher than in the previous case.

Design features:

- relative novelty on the market (therefore, reviews are still few and it is premature to draw global conclusions);

- it is possible to develop a high efficiency;

- with high efficiency, significant savings in fuel consumption are achieved;

- exhaust gases during the combustion process move into the pipe;

- from the pipe, pyrolysis gases transfer their temperature to the heat exchanger;

- Judging by the foregoing, I would like to call this design ideal. However, it has a significant drawback - a strict selection of fuel.

Long burning boilers

According to experts, for heating a private house, it is preferable to

According to experts, for heating a private house, it is preferable to

Peculiarities:

- such boilers with a water circuit are able to work for long hours on one wood-burning bookmark (the figure of 3-5 days speaks for itself, and the good reviews of grateful users only enhance the reputation of these products);

- such long-burning furnaces can operate on different types fuel (and are easily rebuilt from one to another).

Alas, to buy one for little money is simply unrealistic. Comfortable pleasure costs a lot of money and, as they say, will cost a pretty penny.

Safety requirements

It should be remembered that boilers with a water circuit require attention from a safety point of view. This is not only about ignition risks, but also about full-fledged air-gas circulation.

Fire hazard.

- The most important are the following points:

- availability of free space for storing fuel - firewood cannot be stored directly at the stove, since the risk of ignition increases;

- it is necessary to provide exhaust ventilation indoors, especially if you purchased a boiler to heat your house high power;

Without sufficient ventilation, the unit will not cope with the amount of gases emitted during combustion. But among them there is carbon monoxide.

- it is strictly necessary to ensure the remoteness of the boiler from the walls and from the ceiling at a distance of at least 1 m;

- the size of the room must be at least 8 square meters. meters;

- the base must be non-flammable. For this purpose, the site is concreted. Another option is to cover the existing pedestal with tiles or iron, if it is, for example, wooden.

Chimney

The safety of the whole house and residents also depends on:

- flue material - stainless steel. Only this material will protect the structure from the deposition of greasy soot and resinous substances. Stainless steel has a high slip coefficient, that is, microparticles repel rather than “stick”;

Simple iron pipes are very difficult to clean due to the abundance of tar and soot deposits.

- make sure that the chimney passes through the wall of the house at a certain angle, and ideally, you need to make a hole in the roof. This measure will ensure the full release of combustion products to the outside;

- Be sure to place the upper edge of the pipe about 1 m above the roof ridge. Otherwise, there will not be sufficient traction.

Buy or DIY

Is it possible to make a wood-fired boiler yourself? Of course, Russian craftsmen are capable of much. However, the end result will be significantly lower compared to purchased designs. And if it is more or less simple to build a stove for low-power heating of a house, then it is hardly possible to create a powerful long-burning unit.

Is it possible to make a wood-fired boiler yourself? Of course, Russian craftsmen are capable of much. However, the end result will be significantly lower compared to purchased designs. And if it is more or less simple to build a stove for low-power heating of a house, then it is hardly possible to create a powerful long-burning unit.

As a result, your costs will be significant (search for materials, time, worries, damage in case of an unsuccessful experiment), and you will not be able to get sufficient heating. It is advisable to spend money once on solid equipment, and enjoy everyday comfort for many years.

The most expensive are long-burning modifications, all the same, the costs pay off handsomely. The myth that prices are too high can be easily dispelled by starting to use a modern unit in practice.

Do-it-yourself home-made wood-burning boilers and stoves will not give the high power and high user safety that factory products are capable of.

Disadvantages and risks in the operation of homemade boilers:

- short service life;

- the inability to ensure long-term combustion;

- low efficiency;

- overheating of the case (hence - burns with accidental touches).

Almost all user reviews suggest that it is better to find several tens of thousands of rubles for a quality product than to try to build an engineering masterpiece and still not achieve the desired goal.

How much do wood-fired boilers and wood-burning stoves with water heating cost? Focus on the order of prices in the region of 58-65 thousand rubles. at a power of 20-24 kW. The most positive reviews are addressed to such models as Protherm DLO 30, Dakon DOR F 24, Buderus Logano G221 and a number of others. Note that prices are always slightly higher.