The main dimensions of OSB boards of various standards and manufacturers. Properties and structure of OSB boards: their size, quantity in a pack and application

This wood-based building material was specially created for the intended use - in the construction industry. Due to the fact that OSB boards have many advantages, and there are practically no disadvantages, they are in high demand, especially in the private sector. Knowing the size and approximate cost of OSB boards, it is easy to determine the required number of samples and optimize your costs for their purchase.

OSB has many differences from other types of board and sheet materials. The structure of samples, the technology of their manufacture, the feasibility of using in a particular case and a number of other issues are separate topics. In terms of dimensions, one of the GOST requirements is more interesting. Specifications for OSB are reflected in standard No. 32567 of 2013 (table 1 - about dimensions). In particular, only the minimum values of the linear parameters are noted in it, and nothing is said about their upper limit.

All the values below are in mm, prices are in rubles / piece, in relation to the Moscow region.

OSB board dimensions

Standard (according to the GOST table):

- Length (width) - from 1,200 (with a gradation of 10 mm).

- Thickness - from 6 (gradation 1 mm).

There is also a reservation typical for GOST with specifications for other sheets and plates - the manufacturer has the right to produce OSB (as agreed by the parties) and other sizes other than standard values. That is, there are no "hard" requirements in this matter. It turns out that all tabular data is indicative. Therefore, any plate, no matter what dimensions it has, is made without violating the relevant provisions of GOST.

Before planning construction (repair) work, drawing up diagrams and calculating the required number of products, you should carefully study the OSB assortment on the local market and literally adapt to it.

Dimensions of OSB boards most often found on sale

The fact that the manufacturer has the right to determine their linear parameters does not mean that the choice is large enough. Every company focuses on last turn on demand. Proceeding from this, the release of OSB of the most "running" sizes is organized. What does the market mainly offer?

- Length - 2440, 2500, 2700, 2800.

- Width - 590, 1200, 1220, 1250.

- Thickness: 6 - 25.

When determining the feasibility of using OSB in each specific case you need to focus on the optimal combination of structural strength with its weight. This means, first of all, a competent calculation of the thickness of the plate, and not its dimensions.

- 10 - for unloaded elements, draft floors (can be used for the manufacture of I-beams).

- 12 - partitions, solid crate.

- From 15 to 25 - facing OSB, for dry screeds and the like.

Prices for oriented strand boards

The cost of OSB depends on several factors: group (for resistance to moisture), sample dimensions, thickness, manufacturer, region of sale (that is, a transport surcharge).

- The most popular plates of the category "moisture resistant" (OSB-3). The approximate price for such a sheet is 2,500 x 1,250 (9) - 602.5. An analogue with a thickness of 12 will cost 719 rubles.

- A slab 2,440 x 1,200 (9.5) costs 538. The price of the same OSB in 12 mm is about 676.

Examples for individual board manufacturers are summarized in the table.

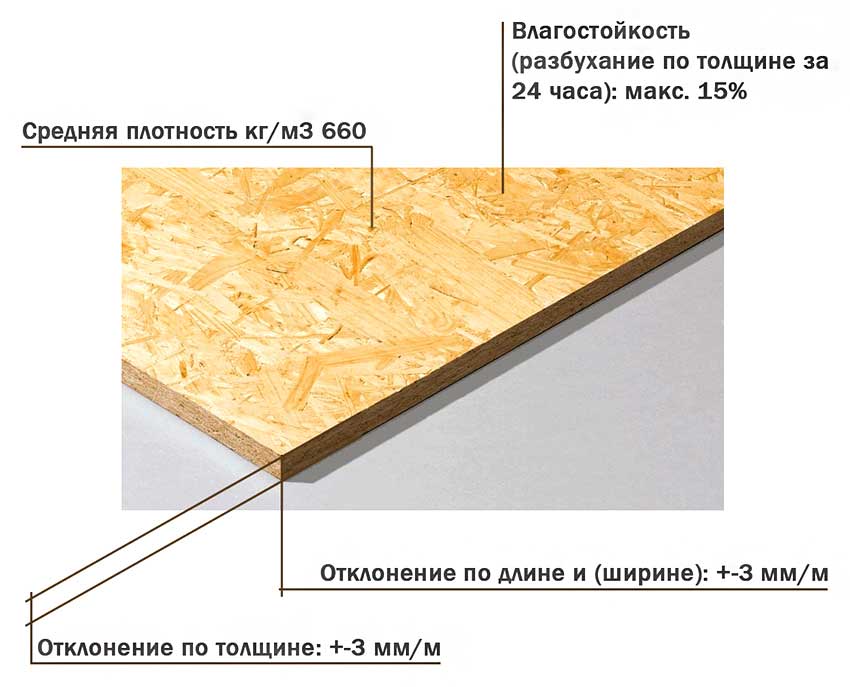

It is advisable to purchase products from well-known, reputable companies. If their interpretation (as noted above) of OSB dimensions is rather arbitrary, then the requirements for tolerances (various parameter deviations) are as "strict" as possible.

This means that the discrepancy from the declared dimensions is minimal. Consequently, during the installation of the plates there will be no problems with their joining, the formation of significant gaps, and so on. Even if such products cost a little more, then you don’t have to spend time and money (for example, on sealants or mastics).

During the period of the repair and construction boom, modern technologies and materials enjoy increased attention. So, oriented strand board (OSB) is of great interest, in the English version - OSB (oriented strand board).

It is a multi-layer sheet, which consists of more than 90% wood chips. Resins with impurities of boric acid and synthetic wax are used as glue.

OSB is an almost universal board

Yesterday and today

The first OSB board was made more than thirty years ago in Canada, and then began to be produced in the Soviet Union. A workshop was built at one of the Belarusian enterprises, which launched the serial production of oriented strand boards.

Today, the main production facilities for the production of OSB are located in Canada and the USA. Among European exporters, Austria, Germany and Latvia are considered the largest.

Plates are also produced in the Celestial Empire. However, the quality of Chinese OSB is significantly inferior to both American and European samples. The reason is that the Chinese use poplar for the production of plates, which is inferior to conifers in its characteristics.

IN last years OSB production is being established in Russia.

A special line was put into operation at the Novovyatsky Ski Plant in Kirov, where OSB boards have been produced since October 2012.

In June 2013, the first large plant in Russia for the production of OSB boards at the DOK Kalevala was officially opened. After the commissioning of the second stage, the plant's capacity increased to 600 thousand m 3 of products per year.

For numerous Russian consumers, such facts inspire optimism, since domestic products are cheaper, and in terms of quality they are practically not inferior to well-known brands.

Among those that are popular today in Russia: Georgia Pacific, Glunz, Ainsworth, LP, Kronospan and others.

Manufacturing

For the production of OSB, small-sized softwood is needed. Large chips and chips are glued together with various resins at high temperatures.

By the way, OSB is visually easy to distinguish from other building materials precisely because of the large and long chips, which are strictly oriented in different parts of the plate.

In the outer layers, it is located longitudinally, and inside the plate - transversely.

High quality such a compound provides synthetic wax, and ideal protective characteristics - salts of boric acid. There are no defects in OSB boards that are typical for wood products: voids, air pockets from knots, etc. Everything is strong and reliable here.

resins

Resins play an important role in the manufacturing process of OSB boards. The quality of the final product depends on how correctly the resin brand is selected and inscribed in the technology.

For the outer and inner layers of the slab, Various types pitches. Their concentration is from 11 to 15% of the total mass.

One of the serious problems is the high toxicity of resins. Unfortunately, they release into the atmosphere such harmful components as formaldehyde, methanol, phenol.

Popular osb sheet sizes.

As a rule, OSB board consists of three or four layers, two of which are external.

Modern technologies allow the manufacture of slabs of almost any size, but in practice the following standards are mainly applied:

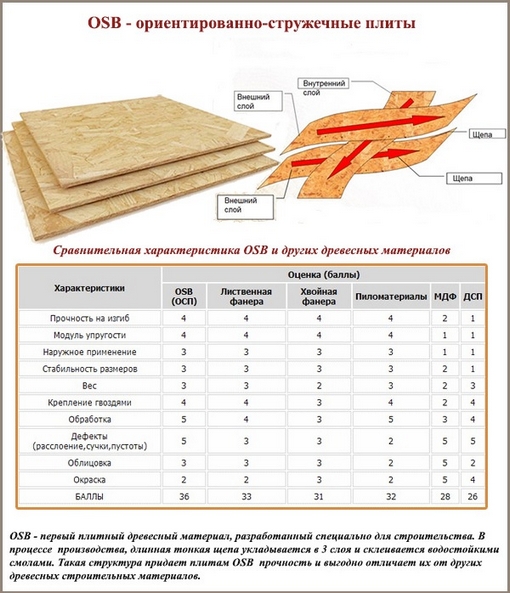

OSB VS Chipboard

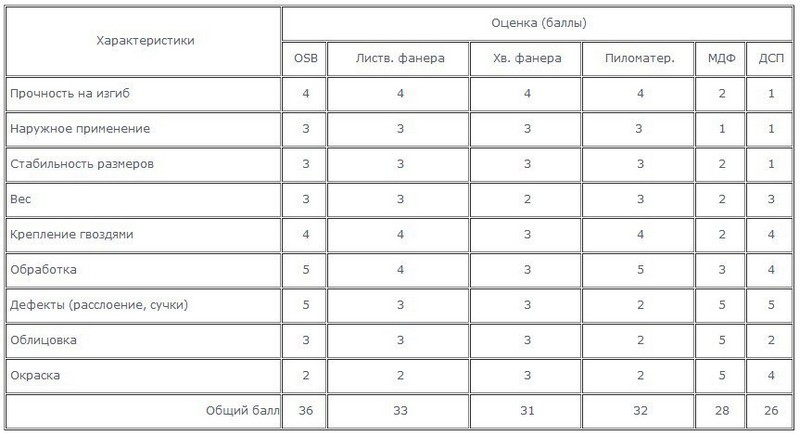

OSB boards were created primarily to compete with chipboard (chipboard) as a more modern and high-quality product. And this was achieved. OSB has physical and mechanical characteristics almost three times higher than those of chipboard structures.

Table of evaluation characteristics of wood-based panels:

Among others positive properties of OSB relate:

The uniformity of the structure and its high strength.

Moisture resistance, due to which the oriented strand board does not lose its properties, even being in water for a day.

OSB boards are very easy to process, glue and paint.

They hold screws and nails securely.

Various defects (voids, delaminations, knots) practically do not occur.

OSB boards cannot be spoiled by insects.

The undoubted advantages of this material include low price, attractive appearance"under the tree", a relatively small weight of the plate.

This is especially important when working at height: you can do without cranes, blocks and scaffolding.

Disadvantages of OSB boards not much, although there is one weighty one that has already been mentioned - the high content of formaldehyde and other toxic materials in some brands of products.

For this reason, the Ministry of Health of the USSR at one time banned the production of plates on the territory of the state. But this is already a fact of history.

Table specifications(OSB 3):

Application

Due to their universal properties, OSB boards are widely used in construction.

1. Wall cladding. OSB can be successfully combined with other facing materials, creating beautiful compositions.

2. Removable formwork when concreting. The strength of the plate allows it to be used repeatedly even in draft construction work.

3. Full roof sheathing. OSB is often used as a basis for roofing materials (tiles, slates, etc.). Here important factors are the high sound insulation of the slab, its rigidity, the ability to withstand high natural loads: wind, rain, snow, sudden changes in temperature.

4. Draft floor - as the main flooring and log.

5. Single-layer floor in lightweight building structures.

6. I-beams. IN wooden houses they serve as a support between floors and walls.

7. SIP panels are made from OSB boards, which consist of two outer layers of oriented strand board and an inner layer of expanded polystyrene.

8. You can use the plate as a rigid base for the manufacture of thermal panels.

9. OSB- lovely material for high-quality packaging: containers, boxes, boxes and other containers.

It is important to know that plates OSB are classified:.

OSB-1 is used in conditions of low humidity (non-moisture resistant boards), OSB-2 has increased mechanical strength and low moisture resistance. OSB-3 has high mechanical strength and moisture resistance. And OSB-4 is good for making structures that carry significant mechanical loads.

Therefore, when buying, consult with experts.

Did you know that some quality building materials are made from waste? For example, for the manufacture of OSB (oriented strand board), various waste products from the production of woodworking are used. And then the raw materials are widely used for the construction of buildings for various purposes. OSB is also used for the installation of various partitions, walls and battens. Interestingly, in terms of technical parameters, the material is superior to chipboard. When choosing an OSB board, dimensions and prices are important. The presented review will help you to study the characteristics and capabilities of this raw material, as well as to choose best option for construction work.

Panels are used for room dividers

In order to successfully use such materials in construction, you need to find out what OSB boards are and what they consist of. Sheets are made from pieces of wood. This is a large-sized chip of different breeds. Particles are connected using a special resin, wax and under the influence of pressure and high temperature. The slab is a multilayer structure, with individual layers located in different directions. All components of the OSB sheet are environmentally friendly and safe.

This option has a lot in common with chipboard, from which it differs in the location of the chips in different layers. OSB is also a related material with, but differs in characteristics and cost.

Are you wondering why a recycled wood product is so popular? It's all about the extraordinary advantages of this raw material compared to the rest:

- the ability to choose products by strength and thickness;

- sheets are strong for bending when wet, which allows for sheathing various curved surfaces;

- OSB - a plate with a homogeneous structure and strong fixation of individual elements, which eliminates delamination;

- easy to process;

- special impregnation protects against the growth of pathogenic microflora;

- the material has high rates of sound insulation and thermal insulation;

- the sheathed surface is resistant to moisture, so it can be wet cleaned.

Note! Since the OSB is lightweight, installation on wood devices is carried out without additional reinforcement.

Classification of OSB boards and methods of their production

When choosing OSB boards s, sizes and prices matter, but so do the varieties. There are four groups:

- OSB1 is a light weight board used in the furniture industry or as a packaging material. Operated in conditions with low humidity;

- OSB 2 is a denser sheet with more layers. Can be used in dry rooms as a cladding;

- OSB3 is used in rooms with a high level of humidity. The plate is able to withstand moderate mechanical stress. Used for partition walls load-bearing structures and various walls;

- OSB 4 has additional reinforcement and increased moisture resistance. Used as a building material. Sheets are able to withstand significant loads.

The first stage of production involves the selection of suitable wood. Logs of thin trees are sawn and then crushed to shavings. Then the material is dried and transferred to a special machine, where large and small chips are separated. Then binder solutions are added to the chips, giving the sheet strength and resistance to moisture. The resulting mixture is mixed with resins and paraffin in a special drum. Then a slab is formed. In this case, the chips are laid in layers in different directions.

Interesting information! The most popular option is OSB 3 sheets, which have universal characteristics. They are used in the construction of low-rise houses.

Characteristics of OSB sheet: standard sizes

OSB board is not harmful to health. It is worth considering that the material is so in demand due to its characteristics:

- Convenient and reliable sizes of plates;

- workable and easy to cut. In this case, there are no cracks and chips;

- ease of finishing. After installation, the sheets can simply be painted or any facing materials can be applied;

- is tested for fire resistance;

- boards are durable, as they can withstand loads up to 650 kg / m3;

- light weight, which does not cause problems when transporting materials;

- OSB sheets are able to withstand loads. This is a rigid composition in which any fasteners are mounted.

When choosing the sizes and prices of OSB boards, you can focus on certain data. For example, the size of the plates in length and width does not have a single standard. Most often, cutting according to individual requests is offered.

An important parameter is the thickness of the sheet, which is in the range of 2-26 mm:

- 2-16 mm - thin plates with low weight and low strength. Used for covering surfaces with light loads. These can be furniture elements, ceilings or the base of the roof;

- 17-32 mm - plates with high bending strength and moisture resistance. Sheets are used to create and finish surfaces with high loads.

Helpful information! Finished products are cut using a dimensional grid. At the same time, even edges remain, and the sections are grooved.

Where OSB boards are used

OSB plates are used everywhere in many types of construction work. It is also necessary in the manufacture of furniture, for finishing inside various vehicles and for packaging.

You can purchase the product for the following purposes:

- roof lathing device;

- installation of floor coverings on a draft;

- sheathing of internal types of walls;

- flooring device;

- installation supporting structures for finishing materials;

- boxes, pallets and other types of packaging;

- V furniture production as supporting elements;

- sandwich panels for frame buildings;

- I-beams of special strength.

The most popular OSB 3 board is used for roofing, furniture production, floors and ceilings.

How to choose the right OSB board: sizes and prices

Depending on the purpose of using the plates, the dimensions of the materials are selected. It is also worth considering that the price of different manufacturers will be different. OSB sheet size 9 mm can be purchased at an average cost of 550-750 rubles per piece.

If you do not have experience in construction, then purchase plates of standard parameters. If the dimensions are the same and standard, then it is easier to calculate required amount. Choose the material according to the appropriate size and thickness. If necessary, the sheets can be further cut.

The cost depends on many factors. One of them is the country of origin. European and American materials are more expensive than alternatives. Also, the price is influenced by the thickness of the plates and the brand.

In the table you can see the prices for materials of individual manufacturers and their characteristics.

Table 1. Average cost of OSB boards

| Image | Products | Dimensions, mm | price, rub. |

|---|---|---|---|

| Kronospan | 2240*1220*12 | 450 |

| Arbec Norbord | 2240*1220*6,3 | 430 |

| Glunz | 2500*1250*9 | 710 |

| Kalevala | 2800*1250*12 | 780 |

| Kronospan | 2240*1220*22 | 990 |

For a good purchase, you must analyze the parameters and performance of OSB boards: dimensions and prices, as well as technological parameters. When choosing sheets for laying floor covering you should use the following tips:

- it is better to choose materials from Canadian and European manufacturers;

- flooring is made on a concrete screed or on logs;

- OSB 3 sheets are more suitable for flooring;

- when planning the location of the plates, it is worth choosing the option that leaves less waste.

Helpful information! If necessary, the plate is cut with a saw. It is better not to use a jigsaw, as it will not provide a flat surface.

High-quality OSB boards will help create strong and durable structures. And the plates of what dimensions and manufacturers to choose are up to you.

Video: why Canadians chose OSB instead of plywood

OSB flooring is now very popular. It has many advantages and makes it possible to reduce the repair time. OSB is a highly compressed board, which consists of several layers. The raw material for the production of this material is long chips (6-9 cm each) obtained from coniferous tree species (pines, sometimes aspens). The strength of the OSB is provided by the different orientation of the chips. For example, in the middle it is placed perpendicularly, and in the extreme layers - along the length. Pressing is carried out under the influence of high temperature and pressure. At the same time, the material is impregnated with resins and waxes, which ensure its moisture resistance.

OSB has the following advantages:

- and processing.

- During sawing or drilling, the sheet does not begin to crumble.

- No warping during operation.

- Homogeneous structure.

- Very high sheet strength, which can replace even wood materials. Keep in mind that the material can withstand enormous loads if they are distributed correctly.

- No knots.

- High degree of moisture resistance.

- Long service life - about 20 years.

As you can see, OSB is an excellent material for arranging both a rough and a finished floor.

Production of OSB boards and application for flooring on logs

Production of OSB boards and application for flooring on logs Material types

Before you start working with sheets, you need to understand what they are:

- OSB - 1. This is the least durable and thinnest plate. It can only be used in rooms where there is never an increase in humidity.

- OSB - 2. Such sheets can be used for arranging load-bearing structures only in dry rooms.

- OSB - 3. This material is well suited for arranging load-bearing structures in those rooms where the humidity level is often high. This type of product is used in construction most often.

- OSB - 4. Such sheets must be laid in those rooms where a very strong mechanical load is expected on the floor. The thickness of such a plate is maximum. In addition, the material is carefully processed with wax and resins, so it is not at all afraid of moisture.

Comparison of OSB with other wood-based materials

Comparison of OSB with other wood-based materials

Specifications

Before buying an OSB, you need to consider its technical parameters:

- Moisture resistance: depending on the type of coating, this parameter ranges from 12-25%. The most resistant to moisture is the plate with the smallest indicator.

- Mechanical strength. The most reliable can be considered plates of the 3rd and 4th class. In general, the strength of the product along the transverse axis ranges from 1200-1800 N / triple, as in black2, and along the longitudinal axis - 2500-4800 N / mm2.

- Product weight. One plate can weigh from 12 to 43 kg.

Table of characteristics of OSB-3 with different board thicknesses

Table of characteristics of OSB-3 with different board thicknesses - Material thickness: 0.6-2.2 cm.

- Environmental friendliness: according to laboratory studies of various organizations, the content of harmful components in the composition of the product does not exceed the permissible limits.

The cost of the plate depends on its technical parameters and is 420-780 rubles. a piece.

How to choose the right product?

Before laying the OSB, it is necessary to determine the following parameters:

- Foundation type. This depends on the thickness of the material.

- Product size.

- Required qualities (for example, if you lay OSB in a dry room, then you may not need such a quality as moisture resistance).

- Manufacturer. It is best to give preference to European, Canadian and North American manufacturers. Their products are certified by international organizations.

The use of OSB for fine and rough flooring

The use of OSB for fine and rough flooring For the arrangement of floors, OSB - 3 is most often used.

How should the material be processed for different types of flooring?

OSB floors can be rough and finished. In the second case, the surface is simply sanded and varnished. Naturally, the gaps between the sheets should be invisible. If you decide to lay another facing material on top of OSB, then the base must be pre-prepared depending on which coating you will use:

- . The base must be even, especially at the junction of the plates.

- or . In this case, it is better to use thin plates, which will make the transition between them smooth and almost imperceptible. Additionally, it is treated with a sealant. Please note that if one sheet of OSB is laid on the floor, then the expansion gap is arranged from the side of the walls.

- . When choosing such a facing material, it must be borne in mind that the base for its laying should be as strong and even as possible. Sheets should be fixed so that they are motionless. If you lay OSB on logs, then in this case they should be mounted at a small distance from each other.

Features of the installation of the draft base

So, if you decide to use OSB boards for subfloor equipment, you need to decide on what you will lay them on: concrete or wooden logs. In any case, OSB - 3 will be the most acceptable material. If the base for installation is a concrete screed, then the sheet thickness may not exceed 1 cm. In the case of laying on wooden logs, this parameter can reach a maximum of 2.5 cm. The material is attached to concrete when the help of dowels. You can fix it on the tree with self-tapping screws. Please note that the caps of the fasteners must be recessed into the slab. Thus, you will achieve perfect evenness of the surface. If you need to achieve maximum strength of the base, then the sheets should be laid in 2 layers. In this case, the seams in the lower and upper layers should not match.

During installation, pay attention to the quality of the joints. They need to be aligned and smoothed as much as possible. For this, an elastic sealant is used. Arrangement of the subfloor is done as follows:

- To begin with, logs are mounted on the floor.

- Now you can screw additional bars to them (at the bottom). Their cross section should be 5x5 cm.

- The side that will be in contact with concrete or facing the ground must be additionally treated with an antiseptic or bituminous mastic (one layer is enough).

- Plate fastening. This can be done using special nails, screws or glue.

- . It can be foam or mineral wool. Expanded clay can also be poured between the slab and the ground.

- Laying an additional OSB board, which will serve as the basis for subsequent cladding.

Subfloor cake from OSB boards

Subfloor cake from OSB boards Before laying the first layer of sheets, it is necessary to waterproof the floor.

You can lay the material on a dry screed. The filling must first be aligned with the beacons. Next, it is necessary to mount an OSB layer, on top of which the same sheets are laid, only with offset seams. You can fix them with self-tapping screws, the step between which is 15 cm. Please note that the fasteners must be screwed along the edge of the second layer.

The dimensions of the OSB sheet can be useful to those who decide to start redevelopment of their home. This type of wood chip material has many properties that have made it so popular among builders. It is used not only in construction, but also in the furniture industry. Why should it be used?

Material characteristics

OSB or oriented strand board is becoming increasingly popular all over the world. In some countries it is used as the main building material for frames of prefabricated buildings. The construction of such facilities saves a lot of time and money. So what are the features of OSB boards?

At first glance, it can be confused with chipboard, but both materials have different characteristics. In addition, their production technology also has differences. OSB is created by the hot press method, but at the same time, layers of chips and chips are laid strictly in the direction of technology. The structure obtained after pressing has increased strength and rigidity. In addition, the directional chip sheet has other advantages:

- it is light;

- has a high degree of moisture resistance;

- is an excellent sound insulator;

- burns badly;

- is an absolutely pure material, harmless to human health;

- simply processed with a regular hacksaw.

It is thanks to all these characteristics that this material has become widespread. It is used to create partitions, erect temporary structures, insulate and create a layer of sound insulation.

In the main construction work, OSB boards are used, the dimensions of which correspond to 2440x1200 or 2500x1250 mm. They can be used as wall cladding, subfloor, bedding or additional protective layer. The thickness of the sheet in this case can vary from 8 to 40 mm. Specially to order, non-standard products can be produced, the dimensions of which differ markedly from factory standards.

Another advantage of OSB can be called ease of processing. You do not need to have special equipment to give the workpiece the required shape and size.

Varieties of OSB

In total, there are about four main types of OSB chipboards:

- The first class is thin sheets that are used as wall cladding. They have the smallest thickness and rather low insulation and stability characteristics.

- The second class is blanks with a thickness of 11 mm or more. They have compacted walls, but do not differ much from the previous type. Can be used as a heater or sound insulator. Able to withstand short-term exposure to a humid environment without consequences.

- The middle class - three, is the most popular material. Corresponds to the economic equation price = quality. The thickness of the boards from 15 mm allows the use of class 3 OSB to create partitions, floor coverings and as a protective material for walls. Has the increased resistance to influence of the damp environment.

- Reinforced panels of class 4 with a thickness of 20 mm or more are used in the frame construction of buildings and for the creation of reinforced partitions. High moisture resistance and rather high mechanical characteristics of the material are used to protect vulnerable structural elements. Sheets of the 4th grade are an excellent option for creating a fine floor covering. High quality workmanship requires additional costs, so the price of the latter type is quite high and can sometimes differ by almost two times from the 3rd class.

The most popular materials are grades 3-4. They are able to replace several layers of protective elements, while they are much easier and faster to mount.

Large sheet sizes allow you to cover a huge working area using just one piece of material. This means that for one room you need only two blanks and a little glue. The use of OSB is cost-effective. The only inconvenience when working with it is the delivery and transportation of huge sheets.

It is worth noting that there are various sheet sizes on sale from world manufacturers from different countries.

For example, Belgian standard size sheet - 2700x1200 mm, and in Austria 2800x1250. That is, you can find various blanks, and this helps a lot when you need to close a certain area with a solid monolithic canvas.

Conclusion on the topic

Thanks to the ability to choose the required dimensions of the OSB slab, it is possible to plan an economical redevelopment of a part of the housing. Large sheets are convenient to use for quick finishing of floors, as well as wall coverings. Sealed partitions in the apartment are very easy to perform with just two OSB boards, which are mounted within a few hours. It will take no more than two days to apply a decorative layer. As a result, you can get an almost full-fledged wall with high insulating characteristics, made in 3-4 days.

More articles on this topic: