Anchoring of floor slabs without mounting loops. Filling seams. Preparation for installation operations.

Comments:

- Anchoring floor slabs

- How to divide reinforced concrete floors

The question of how to carry out the installation of floor slabs becomes relevant during the construction of any room. At first glance, it may seem that installation is quite simple, but there are some nuances that need to be considered when building and erecting a building.

Floor slabs are reinforced concrete products intended for arranging floors.

To understand how to lay the slabs, you need to know the technology and rules for laying floor slabs. Divide reinforced concrete structures can be done as follows:

- round-hollow ceilings;

- tented (ribbed);

- long ribbed.

Some prefer to use monolithic iron in construction concrete plates but this option is more expensive. The most common types that are used for floors are reinforced concrete round-hollow. They have good thermal conductivity, sound insulation.

Floor slab installation technology

For installation, you must have:

- round-hollow reinforced concrete slabs;

- truck crane;

- cement mortar (cement, water, sand);

- Master OK;

- grinders or autogen;

- sledgehammers;

- level;

- scrap;

- steel brush;

- tow;

- gypsum mortar;

- lime-gypsum mortar;

- thermal insulation material;

- welding machine.

This is not to say that the installation of floor slabs is an easy process; on the contrary, it is considered quite time-consuming and risky.

Any foundation is not even and smooth, therefore, before installing reinforced concrete floor slabs, it would be correct and expedient to make the foundation even, for example, lay out a row of bricks on a concrete base. To check how even the surface is, you can use the level, level. It is possible to lay floor slabs only on the most even surface, the further service life of the entire building depends on this.

It is necessary to take care of the strength of the foundation, because due to heaving of the soil, its deformation can occur, and no matter how responsibly the builders approach the installation and how the floor slabs are laid, the building will squint over time.

The foundation can be fixed with a conventional reinforced mesh, on which concrete mortar is subsequently applied and floor slabs are installed. Cement must be at least grade 100. The height of the cement layer must be at least 20 cm.

Before installing reinforced concrete floor slabs, you need to prepare them.

If there are flaws, protrusions or chips on the surface, they must be eliminated.

To understand how to lay the slabs, before installing and installing reinforced concrete floor structures, you need to calculate the width so that they occupy the entire perimeter and do not leave uncovered parts. The calculation scheme is quite simple.

Before the installation process, a substrate of concrete mixture is laid out. Laying floor slabs is possible only with the help of a truck crane, since their weight is large enough. Having hooked reinforced concrete slabs on the hinges, they are lifted and placed in the right place. Moreover, it will not work to carry out the laying alone; for this process, a team of 3-5 people is needed. When installing, it is necessary to ensure that each plate lies flat, all elements should be as close as possible to each other. Due to the fact that the cement footboard does not harden immediately, the plates will be movable for some time, and installation inaccuracies can be corrected by correcting them with a crowbar.

It is necessary to lay floor slabs only on the main walls of the future premises. Installation of internal partitions and walls is carried out after the installation of floor slabs, and they must rest on the wall by 12 cm. Adjacent slabs must be attached to each other with mounting loops. For laying, it is better to use a cement-sand mortar, it must be liquid, the sand is carefully sifted, otherwise even if small debris gets in, it can lead to deformation of the floor and ceiling.

After the installation of the floor slabs, there are seams between them that must be sealed. Using a steel brush, all seams must be cleaned. The gaps between the elements of the reinforced concrete structure are filled with tow, pre-moistened in a gypsum solution. The tow layer must be compacted. When the gypsum mixture dries, its volume increases, so the tow will press against the walls as much as possible. After that, the gaps are covered with lime-gypsum mortar.

The ends present also need to be sealed so that the plates do not freeze during the cold season.

To do this, you can use mineral wool, concrete mortar or backing bricks.

In any construction process, force majeure situations can occur, for example, slabs can burst if unloading rules are violated or they were stored incorrectly.

But throw away so expensive construction material impractical. They can be installed on 3 main walls. Or they can carry out the installation of the attic, in this place the load is minimal.

Back to index

Laying floor slabs: important points

For the accuracy of the design, you need to draw a diagram with all sizes, so you can avoid gaps and lack of plates. If there are still large gaps, they can be filled with cinder block, and small gaps and cracks can be filled with concrete mortar.

During installation hollow core slabs overlap, you need to ensure that they are laid with the smooth side down. They should be located as close to each other as possible - even the smallest gaps should be avoided. You need to lay them, adjusting to each other along the bottom edge.

When installing floor slabs on a foundation base, it is very important to know that they should only be installed on 2 walls, and with short, not long sides. This method of installation is needed in order to prevent possible deformation and displacement if the foundation “sags”.

The thing is that in such cases, the entire weight of the structure moves to the third, long side, and cracks or gaps may appear on the short sides, and this cannot be allowed. Also, one should not forget that the short sides of reinforced concrete blanks should not be completely installed on the walls - by 11-15 cm. This will help reduce heat loss in the further operation of any room.

You should immediately think about where the communications will take place in order to leave gaps between the floor slabs for them.

After the installation of reinforced concrete structures, it is imperative to tie them with reinforcing bars for the strength and strength of the future premises. For this, rods with a diameter of 9-12 mm are suitable, you can use class A1 wire rod (when loads arise, it will stretch and not break). The rods are welded at one end to the loop, and the other end to the loop of the adjacent floor blank. It is impossible to connect several reinforced concrete slabs at once - only two slabs are connected to each other. From the outside, the plates are fixed with anchors.

Be sure to pay attention to the rules of transportation, unloading and storage of reinforced concrete structures and materials so that they do not undergo deformation. Between reinforced concrete slabs, wooden beams must be placed at the same distance and in the same places, otherwise they may burst under load.

In some cases, when reinforced concrete slabs are in the cold for a long time, they can freeze, then due to the moisture that will be in reinforced concrete structures, fungus and mold can form. To avoid this, you need to make small holes in each blank at a distance of 25 cm from each other and blow mounting foam into them. Thus, reinforced concrete structures will not absorb moisture.

The final operation of the zero cycle is the installation of floor slabs on the foundation, which cannot be done without lifting equipment. For most construction works TTK maps have been developed to eliminate injuries and ensure the required quality.

The layout plan of the PC takes into account interfloor technological openings, the range of reinforced concrete products of the plants in the region, the configuration of the building, the presence of ventilation ducts in the internal load-bearing walls. Separately, monolithic sections are indicated, which will have to be poured in place. Delivery of floor slabs is carried out on semi-trailers only with a length of products within 3.2 m. If non-standard panels of greater length are used, they are moved on panel carriers.

The basic rules for laying prefabricated floors are as follows:

- it is possible to lay panels only on foundations aligned in a horizontal plane;

- with a height difference of up to 5 cm, leveling with a screed is allowed, for large values only with masonry or armored belt poured into the formwork;

- support from 6 cm to reinforced concrete, from 12.5 cm to brickwork;

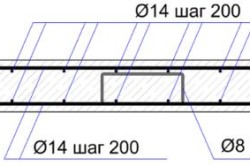

- mortar pastel thickness 15 - 20 mm with obligatory longitudinal reinforcement with a round rod 10 - 12 mm (reinforcement A240);

- adjustment of PC products should be carried out with crowbars in the first 10 minutes, always on tight lines;

- concrete plugs for voids are installed in the slab before or after laying, depending on the availability of access to the ends of the product;

- anchoring of panels to each other is mandatory, with load-bearing walls depending on the project.

Attention! It is forbidden to crush PC slabs with crushed bricks or crushed stone to level the lower planes of the basement/underground ceiling. Sand or mortar is screened before starting work in without fail.

Surface preparation

Before placing the slabs on the supporting surface, the foundation is cleaned of mortar, concrete influx, and dirt. For the installation of the first reinforced concrete product, workers need ladders, scaffolding, ladders or scaffolding in the basement. If a prefabricated floor is made on the MZLF foundation, these devices are usually not necessary.

Prior to installation, the quality of the waterproofing of the upper face of the foundation is checked. The film, roll layer must be continuous, be a continuation of the vertical waterproofing of the outer, inner walls.

At the same stage, a solution is made at the rate of 2 - 6 buckets for each floor slab, depending on its width. Or a mixture is ordered from a mortar unit of guaranteed branded strength. The mortar bed is laid for one/multiple panels depending on the following factors:

- air temperature - in the cold, the cement-sand mixture can freeze, dry out in the heat with a loss of properties;

- worker experience - professionals usually lay a bed for 3 - 4 reinforced concrete products, taking into account monolithic sections.

Attention! The working surface of the PC is the lower edge of the plate, so one specialist with a bubble level is needed from below to control the horizontal in two directions, to maintain the flatness of adjacent panels.

Installation of PC panels

Laying of floor slabs begins from the corner closest to the crane or from the wall with a ventilation duct. In any case, two installers are sufficient for slinging. Work is usually carried out from the machine that delivered the PC product to the site in order to reduce the time for unloading. To ensure design support, the length of the spans is pre-measured with a tape measure.

The TTK maps detail how to properly lay the slabs on the foundation with minimal time:

- slinging for mounting loops - with sling hooks or special lifting devices;

- supply of the product to the installation site - the workers are at a safe distance, deploy the panel to the design position with hooks on weight;

- laying - after leveling the mortar bed, longitudinal reinforcement is sunk into it in the middle of the supporting surface (3 cm from the edge for reinforced concrete, 6 cm for masonry), the floor slab is leveled on both sides, smoothly lowered into place, the slings remain taut.

If necessary, the reinforced concrete product is adjusted with crowbars during the first 10 minutes relative to the wall axis. Then the lines are loosened completely, the bottom worker controls the horizontal in two directions.

Attention! Alignment with a mortar is carried out when the plate is lifted by all mounting loops, and not by one side. If you lift the PC by two loops, spontaneous movement is possible, squeezing out the solution from under the second edge.

When installing the first slab, the foundation cannot be used for walking by workers, regardless of the width of the tape. It is necessary to use scaffolds, ladders, scaffolding. Then the prefabricated floor is mounted according to the layout scheme, the plates are laid close to each other with long sides. Concrete (rarely polystyrene foam) plugs are usually placed in the voids at the ends after the installation of the entire prefabricated basement floor.

Binding of slabs with reinforcement

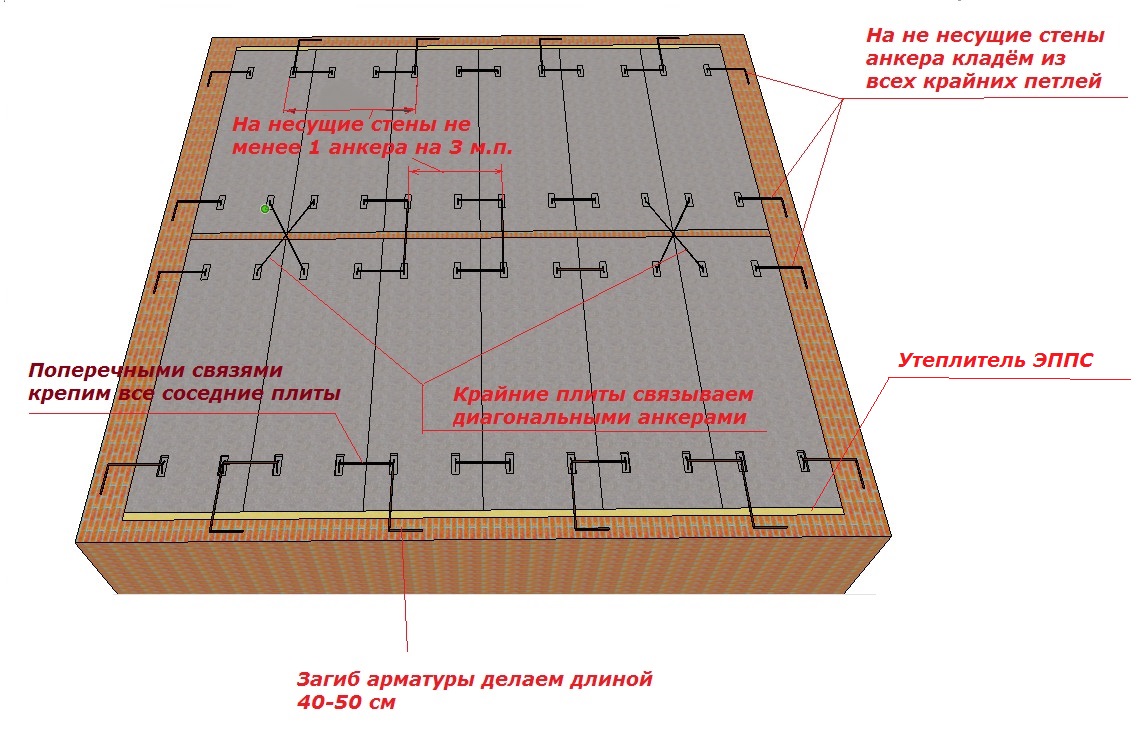

The rules for laying interfloor floors provide plate anchoring according to the following schemes:

- edge plates - diagonal tying with wire 3 - 5 mm;

- adjacent panels - U-shaped jumpers made of smooth reinforcement A240 with a diameter of 10 mm;

- plate / wall - L-shaped anchor with a bend of 30 - 40 cm;

- longitudinal connections - between the plates, based on the internal load-bearing wall, smooth reinforcement 10 mm.

Thus, the prefabricated horizontal disk of the floor receives additional spatial rigidity, connection with walls made of bricks, concrete blocks.

Attention: The standard support of PC slabs is 6 - 12.5 cm. In the event of seismic activity, the anchors will ensure the evacuation of people from the building, preventing individual slabs from collapsing.

For normal connection of the PC with internal load-bearing walls, it is enough to put 3 longitudinal anchors for each linear meter of length. All elements are joined with mounting loops by welding in accordance with SP 70.13330 for enclosing and load-bearing structures.

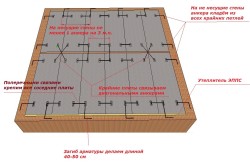

Thermal insulation of joints

After laying the slab, the perimeter of the foundation is leveled brickwork. This material is by default a cold bridge, so it is necessary to lay bars of extruded polystyrene foam or mineral wool between it and the floor slab. Only in this case, heat loss through the floor will be minimal.

Scheme of insulation of the ends of floor slabs.

It is allowed to use solid strips along the entire length of the wall, prefabricated from pieces of insulation. If there are gaps, it is necessary to fill them with mounting foam, the characteristics of which are almost similar to the specified heat insulator.

Sealing joints

The above thermal insulation is required exclusively along the outer perimeter of the floor slabs. However, reinforced concrete products have tapered longitudinal edges, so there are seams between them. In addition, the width of the internal load-bearing walls is usually greater than the supporting surfaces of two adjacent slabs. In the first case, it is enough to fill the longitudinal joints of the floor slabs with M100 mortar. In the second option, it is necessary to monolith the site, linking the slabs and the foundation together. To do this, you can use ready-mixed concrete of class B12.5 and higher.

Attention! In areas of internal load-bearing walls, the strip foundation may contain ventilation ducts coming from the underground level. Before laying the mixture on this monolithic section, it is necessary to first perform masonry to continue the channels to the next floor.

This technology makes it possible to lay PC slabs on the foundation with minimal time without reducing the strength of the horizontal floor disk. At the same time, a rigid connection with the load-bearing walls is provided, the safety of residents during natural disasters is guaranteed.

Advice! If you need contractors, there is a very convenient service for their selection. Just send in the form below detailed description work that needs to be done and offers with prices from construction teams and firms will come to your mail. You can see reviews of each of them and photos with examples of work. It's FREE and there's no obligation.

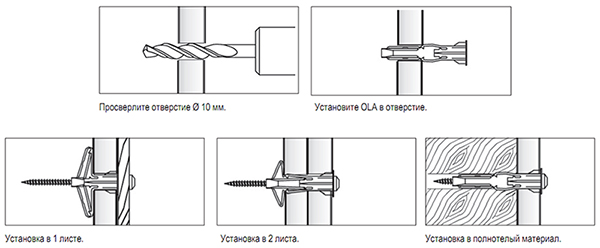

Anchor is a metal fastener designed to connect building structures by screwing or embedding into brick, concrete or masonry. It is used for the construction of any objects: baths, garages, multi-storey and private houses, factories and other things. Anchoring of floor slabs is carried out in brick, reinforced concrete, foam, aerated concrete buildings, it allows you to make them more reliable and prevent premature destruction.

Foundation bolt - a strong fastening in the form of a rod with a threaded end. It is intended for ordinary buildings, for the construction of dams, nuclear power plants.

Moth bolt - a screw for fixing bases with a low bearing capacity.

anchor device

The fastening connection is held in the structure in 3 ways:

1. With the help of friction created due to the presence of a spacer in the form of a metal collet or plastic dowel.

2. Using the stop. Being in different planes, the refracted anchor experiences compensation loads. This is how foundation bolts work.

3. By gluing. The rod immersed in the monolith is easily held in the structure, thus, the floor panels are anchored to each other.

In construction, a combination of all of the above options is most often used.

Peculiarities

The fastening of walls with plates and with each other is carried out with the help of rods, brackets and special metal plates. Anchors are made of stainless or galvanized steel. First, a box with floor slabs is installed, then they begin to strengthen. Stainless steel is used for outdoor work and in areas of high humidity.

Anchoring of each floor of the floor, including the basement and attic, should be done so that the building can last longer.

Strengthening the anchoring of reinforced concrete floor slabs in walls made of foam concrete or aerated concrete allows increasing their bearing capacity.

In the event of a collapse of such a building during an explosion, an earthquake, the people in it will have more chances of salvation, since the floors will not be able to quickly stack on top of each other.

Fixing walls to slabs

To connect building elements you will need:

- Anchors of a suitable size;

— equipment for drilling holes;

- tools that allow you to bend steel elements to give them the desired shape;

cement mortar.

Each material has its own characteristics and therefore the installation of fasteners is carried out in different ways. So anchoring the walls to the slabs in brick house made using steel L-shaped elements at a distance of 3 m from each other. After that, the metal is carefully sealed with a solution 40 mm wide to prevent corrosion.

For the arrangement of openings for communications, it is allowed to rest the plates on adjacent panels. In this case, curved rods are used class A-P with a diameter of at least 12 mm. Composite anchors require welding.

For fastening hollow slabs to blocks of foam concrete or sand-lime bricks, an MKT anchor made of carbon steel with an internal thread is used, which is screwed into the base material. The rigidity of the nodes is provided by friction. The distance between them must be at least 6 m. To ensure strength, when laying on porous materials, it is advisable to use an anchor belt.

- All plates must be in the same plane, the check is carried out by level. The surface difference should not exceed 20 mm.

- It is necessary to lay the blocks so that there is enough space for insulation to the outer edge.

- Only after all the plates are laid, they are anchored.

- The panels are connected to each other either with the help of an armored belt, or by tying or welding the reinforcement protruding from them.

- During rain or snow, work must be suspended.

- When drilling holes in the slabs, make sure that the reinforcement is not damaged.

- A defective product that cannot be repaired cannot be used, it is better to replace it.

- Bandaging of floor slabs without eyelets (without using holes) is allowed in case of creating an armored belt.

When using an anchor, it is necessary to take into account the bearing capacity of the structure, that is, the ability of the fastener to carry loads; worth paying attention to specifications materials, the strength of concrete, otherwise premature wear or deformation of the fasteners is possible.

| Articles |

Construction work on the construction of a house includes many nuances that are unknown to inexperienced craftsmen. One such point is flooring, which is an important technology that will affect the life of a building. This forces us to deal with this issue especially carefully. It is worth starting with familiarization with the possible consequences of mistakes at this stage.

The place of support of floor slabs on a brick wall is the area of intersection of perpendicular planes. When building an individual house, people make this knot in different ways. The choice of connection method is far from always correct and reliable. Not to face the terrible consequences (expensive repairs or reconstruction) of wrong decisions is possible only through painstaking study of this issue in advance.

Materials used as flooring

Reinforced concrete slab- the most reliable building material that is used for the purpose of creating floors. There are certain differences in the process of their manufacture, which are associated with their structure:

- Cellular concrete.

- Prefabricated-monolithic (the most common).

- From heavy concrete (it can be attributed to other categories, because this component is also found in other products).

- Multi-hollow.

The listed structures of floors of brick buildings are used in specific conditions, depending on the project of the house, the design load and the width of the span.

They can be grouped into two categories:

- Ceilings between floors in a brick house, which are used for buildings with several levels. Installed in the opening of the bearing wall on a special lining to ensure good fastening. Particular importance should be given to the width of the overlap of floor slabs on the wall.

- The attic type is not designed for heavy loads, therefore it is installed in the wall opening without lining.

For craftsmen who plan to build a house of several floors on their own, it is recommended to opt for a precast concrete floor. They have the highest strength and load-bearing capacity, as well as simplified installation.

The ceiling also has the function of heat and sound insulation. In this case, it is necessary to apply thermal insulation from the side of the attic and at the junction with the wall. But this is the case when there are heat losses through the roof.

Slab support unit

In order to make a ceiling capable of carrying a large load, it is not enough to choose a durable slab. We need a delicate approach to this knot. It is necessary to correctly carry out calculations, taking into account the fact that partitions cannot serve as a support.

Any building material has a marking indicating the parameters of the product (earthquake resistance, bearing capacity, etc.). This applies not only to reinforced concrete slabs. Bricks used for construction must also meet your requirements. A small example: a multi-storey building should not be built from double silicate bricks with the M150 brand.

Be sure to check the project and the materials used for compliance with the requirements of GOST 956-91. If a discrepancy is found, there may be problems with permits.

It should be clearly understood for yourself that the overlap node - important element from design to completion of construction. In addition to this, it is worth paying attention to another important point,  connected with the overlap - the place of support brick wall to the foundation:

connected with the overlap - the place of support brick wall to the foundation:

- It must be reliable and designed for high pressure. It is worth avoiding weak points in which the foundation of the house can settle significantly. This can cause the cover to warp.

- The foundation must be wider than the brickwork. Otherwise, a change in the shape of the bearing walls will follow due to the weakening of the masonry mortar.

- The thickness of the floor slab and the brick wall must match. This only works in the case of high-quality bricks made in accordance with GOST.

Hollow core slab

The ceiling is a system of slabs and the floor that is on them. Factory-made multi-hollow slabs have a length of 240 to 720 cm and a width of 100 to 180 cm. The thickness is 22 cm. The transverse shape of the voids can be different: a circle, an oval or a polyhedron. The most common are round ones.

The laying of the slabs is carried out as follows: they must rest on both sides on the load-bearing walls through a layer of cement mortar. They should rest on a brick wall to a depth of 9 to 12 cm.

Warming

The ceiling of prefabricated reinforced concrete slabs needs to be insulated when it is basement or attic. First fill the connecting seams and other irregularities. They arise due to the alignment of the plates along the lower plane, which will serve as the ceiling. Works are carried out with a solution of cement and sand.

When the cement dries, the slabs are covered with a vapor barrier with the necessary overlap, in which all joints are glued. The selected insulation is laid on the film. The layer thickness must be determined in the heat engineering calculation.

Vapor barrier film should be used only in the case of mineral heaters. If a polymer insulation is used, such as extruded polystyrene foam, then vapor and waterproofing are dispensed with. This ability is due to a special structure resembling closed cells. The cost of this type of insulation is higher than mineral, but this disadvantage is partly offset by the fact that there is no need to purchase and install films.

Vapor barrier film should be used only in the case of mineral heaters. If a polymer insulation is used, such as extruded polystyrene foam, then vapor and waterproofing are dispensed with. This ability is due to a special structure resembling closed cells. The cost of this type of insulation is higher than mineral, but this disadvantage is partly offset by the fact that there is no need to purchase and install films.

When the thickness of the insulation boards is not enough, they are laid in two layers. The seams are located in different places. On the insulation, the floor screed is performed with a cement-sand mortar. It is reinforced with a mesh with a mesh of 100 × 100 mm. Any floor covering is already mounted on top of the screed.

You can use special heaters: polyurethane foam and cellulose insulation. They are sprayed onto the surface under pressure, which allows you to fill all the bumps without seams.

Floor fasteners

Floor slab anchoring is used to strengthen the structure, make it stronger and reduce the risk of warping. This step is difficult to do on your own and you may need the help of specialists. The cost of work may seem overpriced, but this is not something worth saving on.

There is one trick in this matter - the distance between the anchors can be increased by placing them through the slab, but not more than three meters. The plates are fastened with anchors to each other. Anchoring is one of the most critical stages in the installation of ceilings. Anchoring, coupled with cement-filled joints, form stiffeners for the building.

conclusions

In addition to a well-designed project and high-quality materials, the consistency and conscientiousness of the work is also important. This will affect the result of construction. It is not enough to lay the overlap clearly and correctly. It is necessary to erect a building wisely from the very beginning:

- Pour the foundation correctly.

- Wait for the concrete to dry.

- Brickwork should be carried out with a minimum seam, according to the instructions.

It's really do-it-yourself. But if you have doubts about your abilities, then you can entrust this to the masters of the construction business.

Ceiling structures must meet the requirements for strength, fire resistance, sound insulation and thermal insulation. All these characteristics are possessed by reinforced concrete slab type. They are used in the construction of industrial, multi-apartment and individual buildings.

They serve as intermediate floors, where their lower surface acts as a ceiling, and the upper floor of the upper room. Also, the slabs are laid on garages, sheds and other buildings for household purposes, thus forming a roof. Often they are used as a foundation.

Types of floor slabs

There are 2 types: monolithic slabs ceilings and voids. The first are distinguished by a large margin of safety and bearing capacity. Among the serious drawbacks are their weight, high thermal conductivity and low soundproofing properties. Such products are often used for the construction of public and industrial buildings.

Floor slabs photo

- Hollow concrete products are used in the construction of private houses due to their cheaper cost and light weight compared to monolithic counterparts. This factor, of course, does not allow one to do without special equipment for PC delivery to the site and installation, but, nevertheless, it makes it possible to significantly reduce the load on load-bearing walls and foundations. And as a result, reduce the cost of their arrangement, using a smaller amount of building material.

- The voids that run along the entire length of the concrete product can be round, oval and polygonal in shape. They can be used when laying communications using cable channels, plastic boxes or corrugated pipes.

Hollow core slabs guarantee:

- good heat and sound insulation qualities;

- fire resistance;

- load distribution on load-bearing walls;

- high mechanical strength;

- durability.

Thanks to the smooth surfaces of the slabs, all further finishing work will take place with not only a minimum investment in leveling the ceiling (floor), but also with less labor costs.

floor slab dimensions

- Floor slabs are produced in lengths from 1880 to 6280 mm in increments of 100 mm.

- The thickness of the floor slab is 220 mm. The standard product width is 990, 1190 or 1490 mm, although you can find plates with other sizes.

- The weight of the floor slab is determined by its dimensions, approximately this indicator varies from 500 to 1500 kg. Concerning bearing capacity units of the product, then on average it is 800 kg per 1 sq.m.

What you need to know before buying a PC

- The presence of traces of rust and grease on the surfaces of the product is not allowed.

- The maximum allowable cracks are 0.1 mm, but their complete absence is better.

- All edges of the plates should have the most even surfaces, without bulges and depressions.

- Permissible deviation from the nominal value in length - 10 mm, thickness - 5 mm, width - 5 mm.

- The product must have the appropriate quality certificates.

Before you start laying floor slabs, you need to know that:

- the rough side of the plate should be facing up, and the smooth side down;

- fitting of products is carried out on their lower sides;

- Reinforced concrete products should rest on 2 short sides, the long side is not recommended to be placed on the wall;

- you will need components for a sand-cement mortar;

- laying of plates is carried out close to each other without gaps;

- crane services are hourly, so everything necessary is prepared for his arrival so that the work goes without a hitch;

- slabs should rest only on load-bearing walls, the rest of the internal partitions (walls) are erected after the installation of the ceiling;

- for a well-coordinated installation to help the crane, you will need at least 2, and preferably 3 people;

- before rough finishing, the voids of the slabs are filled with crushed stone or expanded clay.

Preparing walls before installing floor slabs

- Bearing walls are leveled. They should be as even as possible in height, the allowable difference is a maximum of 10 mm. You can identify the difference in heights by means of a long beam, which is placed on two opposite walls. A building level is placed on top of the beam, and the longer it is, the more accurate the result.

- Thus, all supports under the floor slabs are checked. It is important to take measurements as often as possible. To do this, a beam or bar is installed in the corners of the building, then moves every 1-1.5 m. The relevant data can be written on the walls with chalk or a marker.

- Next, the highest and lowest point is located and the concrete mixture is laid out using a cellular metal mesh. Supports erected from foam concrete, slag, gas silicate blocks are necessarily reinforced. This can be done by means of a reinforcing belt with a height of at least 15 cm.

- Armopoyas evenly distributes the load, prevents deformation of the walls and protects the floor slabs from breaking.

- The formwork is assembled from the most even boards in accordance with the values obtained, that is, the edges can have different heights. You can use a special U-shaped profile. The structure is arranged around the entire perimeter of the house box, including non-load-bearing walls, especially if the building is made of lightweight block materials.

- To knead the sand-cement mortar, 1 bucket of cement (M500) and 3 buckets of sand are taken, so much water is needed so that the mixture is neither liquid nor thick. Sand must be sifted to remove pebbles, which will contribute to the destruction of the layer under the weight of the slab.

- After pouring, the solution is pierced with a trowel or piece of reinforcement to prevent the formation of air gaps. Rammer should be given increased attention.

- Before laying floor slabs, voids must be sealed to prevent freezing. If the concrete products have been stored at the construction site for a long time, then it is recommended to drill one or two holes in the areas where the voids pass, through which excess moisture will escape. It should be noted that the holes are sealed with concrete mortar, and during installation, the slab should be facing down.

- Factory voids are filled with expanded clay or large pieces of one and a half bricks are simply inserted, and the remaining gaps are closed with cement mortar. Although in Lately factories produce slabs already with closed voids.

- The mixture in the formwork should dry well, gain strength, this will take at least 3 weeks.

Crane platform

- The soil where the lifting equipment will stand must be compacted. It is impossible to install a crane near a house under construction in the presence of a basement. The supporting "leg" of the special equipment creates a very significant load on the ground, which can lead to the collapse of the basement wall.

- For loose or bulk soils, it is recommended to order a crane with a longer boom. If the work is carried out in spring or autumn, when the soil is saturated with moisture, the platform for the truck crane is laid out with road slabs (used products can be used). Because technology can get bogged down in slush under its own weight.

Slab lining

- It is not recommended to cover two spans with one slab. Such a load under certain circumstances can lead to its cracking. If just such a laying scheme was chosen, then in this case it is recommended to make an incision with a grinder with a diamond disk (to its depth) exactly in the center of the middle wall.

- If a crack nevertheless occurs, then it will go exactly in the direction of the notch, which is quite acceptable.

- Unfortunately, it is not always possible to complete the overlap with whole slabs. Sometimes they have to be lined both in width and in length. Here you need a sledgehammer, a grinder with a diamond disc, a crowbar and muscle strength.

- To facilitate the process, use a beam or board of the appropriate length. Lumber is placed under the slab strictly along the line of the future cut. At some point, the concrete product will break under its own weight.

- First, a grinder is cut on the upper surface of the plate along the marked line. Further, by means of a sledgehammer, blows are applied along the entire length of the concrete goods. Hits should be applied as often as possible. If the cut falls on a hollow hole, then the plate will break pretty quickly.

- When cutting the slab in width, considerable effort will have to be applied. The rebar that comes across is cut off welding machine or cutter. It is not recommended to use a grinder, as the disc may “bite”. But if only this tool is available, then do not cut the metal rod to the end - leave 2-3 mm. Perform the final break with a crowbar or sledgehammer.

Carrying out the cutting of the slab, all possible consequences fall on your shoulders! No manufacturer will give official permission to carry out these works.

- If there are not enough whole slabs for a complete overlap, and the remaining space is small, then the laborious cutting process can be avoided by using the following two methods:

- The last or first slab does not adjoin the wall in length. The formed void between the slab and the supporting wall is laid with bricks or blocks. A cement screed, performed upon completion of construction, will reliably unite and fasten the masonry to the slab.

- This method is good if the existing concrete panels are laid butt-to-butt, and the remaining distance is distributed between the two supporting walls and filled in as described.

- It should be remembered that if the empty opening is more than 30 cm, then when pouring the screed, reinforcement is performed in this area.

- The plates are mounted close to the walls, and the empty gap remains between the plates themselves. Thick moisture-resistant plywood is attached to the lower surfaces of the reinforced concrete products, reinforcement must be laid with a call to the upper surfaces of the plates.

- Thus, something will turn out in the form of a formwork, which is poured with concrete mortar. After complete drying, the plywood is dismantled, and a general screed is made over the boards.

Installation of floor slabs

- For work you will need a crane and at least 4 people (crane operator, slinger and 2 assistants). A prepared concrete solution with a thickness of not more than 20 mm is laid out on the bearing supports with a reinforcing belt. The plate rises in a horizontal position at the desired height. All actions, namely the movement and direction of the load, are carried out under the guidance of the slinger.

Installers accept the floor slab, adjust the optimal location. Before the slings are removed by means of crowbars, the concrete panel is guided to the installation site with maximum accuracy:

- from the slab to the wall along the long side, a minimum distance of 50 mm is left;

- there should be no gap between the plates;

- the width of the support on each short side of the boards must be at least 150 mm.

Inspection of concrete floor slabs

- After installation of the ceiling, the evenness of the surfaces of adjacent plates is checked by level. If the height difference is more than 4 mm, then the plates are reinstalled. The concrete products are lifted again by a crane, and, in accordance with the situation, the solution is removed or added.

- It is impossible to dilute the seized concrete layer with water, the solidified mixture is completely removed, and a freshly mixed one is applied in its place. As soon as the leveling is completed, they proceed to fixing the plates between themselves and to the load-bearing walls.

Anchoring of reinforced concrete floor slabs

Upon completion of the installation work and after the leveling of the plates has been carried out, they are anchored. If there is a project, then a special scheme should be present in the documents. Otherwise, anchoring is done as follows:

- anchor loops are mounted to the load-bearing walls and go onto the floor slabs by about 40-50 cm. As a rule, two fasteners are enough for the entire length of the panel (they are located a meter from the edge of the slabs). In the same way, one anchor is set in width;

- if the docking of the plates occurs along their short side, then these sections are fixed diagonally using working holes with reinforcement located in them. In their absence, you can use special fasteners with L- and U-shaped forms;

- between themselves, concrete slabs are fastened at the points of the mounting holes. Metal rods must be stretched as much as possible and fixed by welding, at least at three points.

- After that, the eyes and seams between the slabs are filled with fine crushed stone, and then sealed with sand-cement mortar. It is not worth delaying with these works, as construction debris can get into the holes.

Features of the technology of installation of floor slabs

- Hollow core slabs are widely used in the construction of low-rise and individual buildings. Although they are smaller and lighter than their monolithic counterparts, they nevertheless require thickened walls and reinforced foundations. In addition, they will not be able to block buildings that are complex in architecture.

- But, despite these shortcomings, the plates provide a reliable overlap, characterized by a long service life. Their use is justified in cases where the plates become the basis for the flooring of the roofing material, that is, they act as a flat roof.

Floor slabs video

When preparing and installing floor slabs, it is important to take into account many technical issues, which means that you need to have certain knowledge and skills. If you are unsure of the calculations, contact a specialized organization where they will draw up a project in accordance with all the requirements of SNiP.