Diameters of chimney pipes made of stainless steel. Sandwich pipes for a chimney: their device, advantages and installation rules. Calculator for calculating the minimum diameter of a sandwich chimney for solid fuel stoves

A sandwich chimney pipe removes combustion products in a fireplace, stove or boiler, creates draft and ensures fire safety. Its installation does not take too much time and is made taking into account the characteristics of the room.

Two pipes nested one inside the other and having a heat-insulating layer in the middle are called a sandwich pipe. A special place is occupied by pipes made of heat-resistant stainless steel, they are less prone to clogging, easier to maintain. The heat insulator inside prevents condensation. In the form of insulation, non-combustible materials are used: basalt fiber or mineral wool. They are obtained from molten rocks, the low thermal conductivity of the material is achieved due to the high content of air in the mineral fibers.

Single-walled chimney elements are preferably used for the rehabilitation of chimneys. An existing brick fireplace can be repaired, with a single or transverse reduction, with stainless steel single wall chimney elements. As with a stainless steel fireplace with double wall, the single wall version is just as versatile. There are condensate pans, stainless steel pipes, chimney pipe corners, chimney caps, floor hoods and more on chimney elements.

We offer you a wide range of stainless steel single wall pipe products in various qualities. If you have any questions regarding existing chimney rehabilitation, we will be happy to assist you at any time. Call us or send us a message.

Chimney made of sandwich pipes

Advantages and disadvantages

Among the main advantages of sandwich pipes for the chimney are the following:

- light weight;

- installation speed;

- the presence of smooth inner walls (improves traction and reduces the formation of soot);

- the ability to bypass the truss system.

The main disadvantage: after 15-20 years, the heat-insulating layer wears out, and the boiler loses its original performance. Moreover, the more often the equipment is turned off, the faster the chimney from the sandwich pipes fails.

Chimney repair with stainless steel pipe

Here we offer single wall and double wall stainless steel pipes for fireplace renovation. Such rehabilitation of chimneys is generally a comprehensive reconstruction measure. In addition, the cost of restoring your chimney usually stays within a narrow range - as long as the repair is done on time and the chimney does not need to be completely rebuilt. There are three main reasons to repair your chimney, all of which can be recognized by your chimney cleaner as part of regular inspections. Then you must act quickly.

A cap is installed on top of the pipe - protection from atmospheric precipitation

Loss of tightness is a serious reason to replace the pipe. To prevent this from happening, purchase a quality product and trust the installation to professionals.

Device

The chimney is part of a looped system. It is through it that smoke is removed, due to which a rarefaction occurs in the furnace or in the fireplace and a portion of air is sucked in. The cycle then repeats over and over again.

Installation of sandwich pipes: highlights

Most of the time, a chimney requires a chimney repair due to a chimney. This is known as wetting and chimney penetration by material such as water vapour, tar and sulfuric acid. They come from condensates flue gases in the chimney - and indeed, when their temperature is constantly too low. The reasons for this may be, for example, an excessively large internal diameter chimney or too long building runs through unheated areas. Then the condensates settle on the walls of the chimney and moisten them.

A brick chimney can only be built vertically, but sometimes there are situations when, due to the characteristics of the room, it is not possible to build a strictly perpendicular structure. In this case, it is the modular system that will become best solution: with the help of transitions, elbows, tees, you can bypass a place that is inconvenient for cutting.

The inner diameter of the sandwich pipe is made of stainless steel, and the outer diameter is either made of galvanized iron or stainless steel of acid-resistant grades. Therefore, the service life of the product is long.

At an advanced stage, you can see this as brown spots on the pipe and surrounding walls. In addition, penetrating sulfuric acid gradually dissolves the building fabric, so further destruction must be eliminated by chimney repair. Even if cracking can be observed at the fireplace, it is time to repair the chimney. Otherwise, for example, flue gases can enter the interior of the premises due to a constantly growing crack and even ignite under certain circumstances. For example, cracks requiring a fireplace are caused by long-term thermal stresses that affect the building material of the fireplace, especially when you use the fireplace, for example with a stove, only sporadically.

Boiler chimney device

When arranging a sandwich chimney, consider the following.

- The temperature of the incoming gases depends on the type of fuel used and the type of boiler. The higher it is, the more intense the pipe heats up.

- You can lead the outlet pipe from the stove, fireplace or boiler through the walls of the room. This option is used when a chimney system is being erected in an already built building. For each heat generating device, it is better to build its own smoke channel.

- If necessary, it is allowed to mount no more than two deviations from the vertical plane with an inclination angle of not more than 30 °.

- The horizontal section has a limit of 1 m.

- The total height of the chimney to the top of the pipe should be 5 m. This creates the necessary draft and ensures vacuum.

- The distance between a wooden (or other combustible surface) and the stove must be at least 50 cm.

- Incorrect assembly may cause a fire.

Prices for sandwich pipes for chimneys

Also, repeated cracks can be made on your fireplace. The last good reason you should aim for quick chimney restoration is to use asbestos-containing building materials during the construction of the chimney. However, asbestos fibers can be released into the lungs when inhaled and may help prevent cancer. For this reason, it is highly recommended to use a fireplace, as asbestos fibers can escape from the chimney with rising flue gas.

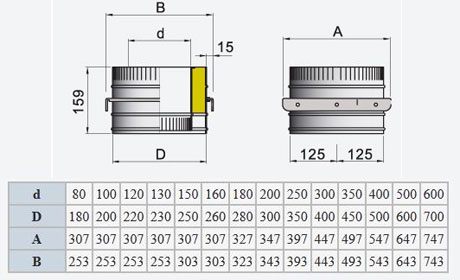

Modular Sandwich Pipe Size Chart

If the pipe passes through wooden floor, from the inner pipe of the "sandwich" to the wooden element, a distance of 38 cm must be maintained. The entire space between them must be filled with fireproof material - galvanized sheet. The chimney pipe must pass through the ceiling in its entirety, without joints. The chimney itself is mounted through a passage pipe - a metal box.

Advantages of stainless steel pipe for fireplace

The stainless steel pipes offered by us combine several advantages for your chimney repair and are therefore the optimal choice. With a stainless steel pipe, for example, the inside diameter of your fireplace can be reduced without much effort. As a result, the onset of masonry spotting can be reliably stopped. On the one hand, with smaller diameters, significantly less condensates form, and on the other hand, they no longer reach the masonry through the pipe. Stainless steel pipes are also available in various diameters.

Variants of placement and connection of chimneys are different. It depends on the conditions of the room in which you want to install. You can install a smoke exhaust system during the construction of the house and after completion construction works. They choose a place for the chimney so that when it is installed, the integrity of the house structure (logs, truss system) is not violated.

Therefore, they can be used in almost every fireplace. They are suitable for working with modern condensing boilers, which facilitate the formation of condensates from which additional heating energy can be obtained. Installing stainless steel pipes in a chimney usually involves very little work as we offer pipes different size and lengths, as well as corresponding mounting materials in a wide range. As a result, the inevitable reconnection of the chimney can be carried out within a very short time.

System installation rules

The device is assembled according to the principle of the designer. The pipe must be inserted into the pipe for a length equal to at least half of its diameter. The size of the sandwich pipe for the chimney determines its throughput.

Video: installing a chimney

Stainless steel pipe is also ideal solution in the fireplace because it is not only corrosion and rust free, but also extremely resistant to acids and chemicals. In addition, it has excellent thermal loads. After reinstalling a chimney with a stainless steel pipe from our range, you no longer need to worry about cracking. The escape of asbestos particles is also effectively prevented by venting stainless steel pipes in your chimney as part of a fireplace renovation.

For flue gases that can carry particles, can no longer come into contact with the original building structure. Last but not least, chimney reclamation with a stainless steel pipe represents an attractive price for building a fireplace.

Connection types

There are 2 ways to connect pipes: "by smoke" and by "condensate".

- "Through the Smoke"

The pipe of the lower leg enters the inside of the upper leg of the "sandwich". In this case, the smoke moves freely upwards.

- "By Condensation"

The inner top tube is inserted into the bottom tube. And for the outer pipe, on the contrary: the lower one is placed in the upper one. The condensate moves freely downwards. This option is usually used in modern boilers running on gas. In metal, cast iron, the smoke temperature is about 300 °. Steam begins to condense at temperatures below 100°C. During the kindling, the steam turns into drops of water, which rolls down into the condensate trap.

Act now - start with chimney restoration now!

To prevent further chipping, cracking, or loosening of the asbestos from your fireplace, do not place the fireplace on a long bench. Now take action and restore your fireplace with our high quality stainless steel pipe. This not only improves the operational safety of your chimney, but also contributes to the protection of the building structure and, finally, not to last turn your health. We will be happy to help you select the right high quality stainless steel components for your chimney upgrade.

The second method of assembly "by condensate" is more acceptable. The passage through the roof is done in the same way as the passage through the ceiling. The gap between the rafters and the pipe must be maintained at least 150 mm.

Roof cutting makes the pipe outlet airtight

Fire safety

Subject to the norms of SNiP, you can be sure of the safety of the structure under construction.

Necessary tools and materials

The chimney pipe helps to get rid of the smoke coming from the stove or fireplace. The pipe must be designed correctly to be as efficient as possible. Screwdrivers Screwdrivers Knuckles or elbows Stainless steel lining Stainless steel screws Silicone caulk. Slide the wooden slab off the wall.

Installation of a chimney from a sandwich pipe through the roof

At least 8 inches, but even that depends on the manufacturer's instructions. Approach the path you need to move from the stove to the exhaust fan. This must be done before purchasing any pipe. Make your way down from the exhaust pipe. Place some caulk in the hole and press the primary tube into the exhaust. Build your way down using straight tubes and bend. Make sure there are as few bends in the chimney pipe as possible. Acquire a joint and many elbow tubes if necessary.

- If the chimney is installed in wooden house, use cuttings - enclosing elements made of non-combustible materials. The dimensions of the cuts are as follows: 38 cm - to the parts protected from fire, and 50 cm - to the non-protected ones.

- The building is protected with a layer of plaster of 25 mm on a metal sheet or mesh with fireproof materials (silica mats, basalt wool).

- Between wooden beams and chimneys located with them in the same wall must maintain an interval of 50 cm (if the beam is not insulated) and 38 cm (if the beam is protected by thermal insulation).

- The chimney should protrude 50 cm or more above the top of the roof.

- The scheme of the chimney from the sandwich pipes is drawn up at the design stage of the house.

Backdraft and fire are the consequences of a rash choice of a smoke exhaust system. But a modern chimney is not only durable and safe. It must withstand condensate containing acids and withstand high flue gas temperatures. Only in this case the design will last a long time.

Place the vacuum cleaner in the outlet after applying some seal. Thus, the solution will have a seal with a chimney. Use stainless steel screws and secure the silicone to seal the gaskets and make sure they are installed on the bottom of the flue shaft. The pipe must be at least 5 feet long to stand out on top of the chimney inside the chimney. Make sure the pipe is at least 2-3 meters above the roof.

After you're done, call your local fire department and have them inspect the system. This must be done because the chimney pipe must comply with safety regulations and standards in order to avoid any problems. Stainless steel fixed chimney sandwich system, designed to extract flue gases from appliances to gaseous fuels under vacuum, is the ideal solution for building new indoor and outdoor chimneys and using heat-insulated chimneys.

Any heating appliance, be it a fireplace, a boiler or a stove in a bath, requires the installation of a chimney. A lot depends on how well this element is made. This is both safety and good reliable traction in any weather and practicality with a beautiful appearance. To date, the most optimal and advanced solution for the removal of combustion products will be a sandwich pipe for a chimney. But what the sandwich pipe is made of and how the installation of chimneys of this type is carried out, we will consider below ...

System installation rules

A wide range of nominal sizes from 130 mm to 300 mm, a wide range of components and accessories, including anchor elements and their low weight, allow building chimneys of any size and height. Individual components are longitudinally welded on plasma machines and have a 60mm high top neck to ensure easy, secure and strong connections. For reinforcement and static fastening, each connection is fixed with an external coupling. Our stainless steel chimney systems can be combined.

Sandwich pipe device, their dimensions and diameters

Installation of a chimney from a sandwich pipe

From the name itself it is clear that "fashionable" chimneys consist of several layers, like a sandwich pie. There is an inner diameter of the pipe and an outer one. Between them is a mineral fiber. As a rule, this is basalt wool or other non-combustible mineral insulation.

Multilayer stainless steel fixed chimney system designed to extract flue gases from appliances into gaseous, liquid and solid fuel under vacuum, is the ideal solution for the construction of new indoor and outdoor chimneys and the creation of thermal insulation chimneys. A wide range of nominal sizes from a diameter of 110 mm to a diameter of 500 mm, a wide range of components and accessories, including anchor elements and their light weight, allow building chimneys of any size and height.

Preparing for installation

The individual components are longitudinally welded on plasma machines and have a 100mm high top neck to ensure easy, secure and strong connections. The multi-layer stainless steel fixed chimney system, designed to extract flue gases from appliances to gaseous fuels in pressurized operation, is the ideal solution for the construction of new indoor and outdoor chimneys and the implementation of thermal insulation chimneys. A wide range of nominal sizes from 80 mm to 300 mm, a wide range of components and accessories, including anchor elements and their light weight, allow building chimneys of any size and height.

External and internal sleeves of pipes are made of stainless or galvanized steel. The thickness of the metal in this case can be 0.5 or 1 mm. This, of course, affects the price of the pipe and its durability. Stainless steel in all its characteristics is much superior to galvanization, so draw your own conclusions.

IN Lately enameled sandwich chimneys became popular. Special enamel not only gives a certain aesthetic appearance, but also perfectly protects the metal from high temperatures, condensation and soot.

Sandwich pipes for chimneys - a luxury or a panacea?

The individual components are longitudinally welded on plasma machines and have a 60 mm high neck with a special seal that ensures easy, reliable, tight and strong connections. Ceramic profiled insert with full ceramic neck.

Moisture resistant, no gaps. For all types of objects, including low energy. This is a rear-vented 3-piece smoke system, unlike the original design, however it uses a new thin-walled isostatically molded ceramic insert. It is suitable for extracting flue gases from conventional appliances into solid, liquid and gaseous fuels.

Modern design solutions can be quite exclusive. Today we are moving away from those stereotypes that have been around for centuries. Now you can position and remove the chimney almost anywhere: vertically, horizontally, on a slope.

One of the options for mounting a sandwich pipe

For ease of installation of such systems, the following components may be included in the package for sandwich pipes: head umbrellas, support consoles, wall mounts, various clamps, rings and ties, corners and turns, gates (latches) and tees, ceiling and roofing cuttings, starting adapters and plugs. You can list for a long time, in a word - this is a "constructor for adults" ...

Depending on the power of the installed boiler or furnace, the sizes of the sandwich pipes are different. Here we can distinguish the following standard diameters of the inner and outer pipes, respectively: 310, 300/380. All dimensions are naturally in millimeters. The usual length of one pipe element is 1 meter.

Advantages and disadvantages of sandwich chimneys

Like any design, sandwich pipes have their advantages and disadvantages. Of course, there are much more pluses and this is due to the original and practical device. As they say, everything ingenious is simple. Here are some advantages of sandwich pipes:

- Due to its design feature, sandwich chimneys have high fire safety

- Lightweight and compact design of the entire chimney. This does not require the organization of an additional foundation and, as a result, unnecessary financial costs.

- Versatile mounting options: really make any bold design decisions. Turns, bends, rounding various obstacles, this is a common thing

- Ability to lead the chimney through the ceiling or through the wall

- Due to the double circuit and insulation, little condensate forms in the pipe. The absence of moisture inside the chimney contributes to insignificant deposits of soot on the inner walls of the pipe

- Due to the smooth surface of the metal, good traction is formed in the sandwich pipe

- Simple and easy installation of chimneys

- Sandwich chimneys are virtually maintenance free. They are not subject to corrosion, have good smoke impermeability and excellent resistance to high temperatures, aggressive environments, etc.

Now about the shortcomings that still exist:

- Relatively high cost. A chimney of this type, especially with various "bells and whistles", will fly into a tidy sum

- Relatively long service life: 10-15 years. When compared with brickwork, then the sandwich pipe serves much less

- Over time, thermal expansion and contraction can cause slight depressurization of the flue duct.

Installation of sandwich pipes: highlights

All work on the installation of sandwich chimneys begins with marking and sawing out all the necessary technological holes. This refers to the ceiling or wall, as well as the roof itself. It should be borne in mind that the distance from the pipe to unprotected wooden structures should not be less than 40-45 cm. For fire safety purposes, let it be more than less. Otherwise, the use of protective screens is a must!

Installation of the "designer-chimney" begins to be carried out from the bottom up. First of all, a single-circuit pipe is installed on the furnace. Due to the absence of insulation, heat transfer is significantly increased. For example, a single-circuit sandwich pipe for a bath can be equipped with a hanging water tank. It is possible to use a cylindrical metal mesh for stones, which greatly increases the efficiency of the stove. The use of special economizers-convectors on the first segment of the chimney also enhances the heat transfer coefficient.

On the installed “single-circuit sleeve”, the so-called starter adapter is mounted. It is needed in order to reliably and beautifully connect a single-walled pipe with a sandwich. Then a gate is mounted to adjust the draft level or a double-circuit chimney immediately goes.

Such a nuance should be clarified: the assembly of sandwich pipes can be carried out in two ways (“by smoke” and “by condensate”). “Smoke” is when the top tube is inserted into the bottom one. The smoke does not encounter any obstacles. "According to condensate" - the opposite is true: the upper segment is mounted on the lower one. For an optimal result, we put on the outer sleeves of the pipes “by smoke”, and the inner ones - “by condensate”. For a better sealing effect, it is advisable to use a special heat-resistant sealant and crimp clamps.

Calculate the height of the chimney to the ceiling in such a way as to exclude the junction of the segments in the overlap area. This will increase the degree of fire safety. And now the most important moment. Many consider sandwich chimneys to be the absolute standard of safety and do not install a passage box in the ceiling passage, relying only on the thermal insulation of the pipes themselves.

The result is often very deplorable. Passage ceiling box must be used. He will protect wooden structures from heat and fire. It can be covered with expanded clay, foam glass, but not with sand. It is possible to use mineral wool as a heat insulator.

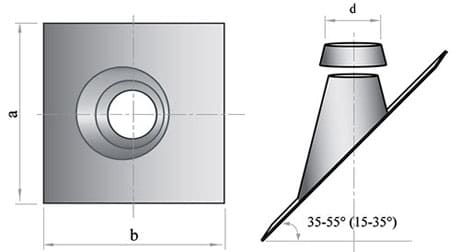

When conducting a chimney through the roof, it is wise to use an element such as a flash master. This is a special sealant for roof passages, which is commonly called a "flash drive". The element is necessary and practical, you can’t do without it. A metal roof cutting element is also used here, which ensures a reliable and stable position of the chimney.

Depending on the design of the chimney, a "revision" is sometimes installed in the lower part. This sandwich pipe element is usually installed on an attached chimney that has a horizontal section. There is a small door for cleaning the smoke channel. Very convenient and right moment.

On the upper part of the chimney, spark arresters, deflectors-umbrellas are installed. Purpose: to extinguish sparks and protect the pipe from precipitation and debris.

When installing a sandwich pipe for a chimney, it is necessary to exclude their contact with various communications (electrical wiring, gas pipeline, plumbing and sewer pipes, ventilation ducts). Following the manufacturer's instructions for assembling such a "constructor", you can easily install a chimney from sandwich pipes with your own hands. This will not be difficult, although you still have to “wiggle your brains” and work with your hands.

Chimney from sandwich pipes