Foam blocks for outdoor work sizes. How to choose the right foam blocks: sizes and prices per piece. General information about the foam block

Now a lot of building materials have appeared, with the help of which the structure can be erected in a fairly short time. One of them is the foam block. The high demand for foam blocks is explained by the fact that it has a lot of advantages. In particular, - . In construction, foam blocks of non-standard sizes are used when necessary. But more often, of course, you need a standard foam block size.

Among competitive wall materials, ceramics differ in that they are dry at the end of the manufacturing process.

Another key factor is the drying time of the finished wall. Dry ceramic recesses connected with a traditional mortar containing water will take up a small part of the so-called moisture. technology. But the ceramic wall is a brickwork that dries in the shortest possible time - only about 6 months to completely get rid of moisture. Thanks to this, the entire construction process can be easily closed in one season.

The foam block is widely used in private construction. Also, this material is used for the construction of agricultural and industrial facilities and many more.

True, the structures for the buildings of which the foam block was used can be no more than 12m high. However, this limitation was overcome by using wireframe technology.

This great advantage ceramics over other solutions where water accumulated in the walls can wipe out months or even years. While in summer the process is carried out naturally, in winter the energy is depleted from the heating system and the cost is for the investor.

Permanent dampness in walls is not only cumbersome and expensive, resulting in reduced thermal insulation of the wall, but can also adversely affect the health and well-being of residents. Fungal spores are usually present even in unpolluted air, and require only water to develop on wall surfaces. Most of them are not visible, but are always dangerous to health. Therefore, the level of moisture in the walls, as well as the drying time, require special attention in order to be able to enjoy the health of your home and avoid allergies.

The method of manufacturing foam blocks

Foam blocks are obtained from cellular concrete, which, in turn, is produced when a solution is obtained from cement, sand and water. A foaming agent is added to the composition, in the role of which various materials act.

To obtain a mixture of foam concrete, two methods are used:

- Barotechnology.

- With a foam generator.

First method better themes, which is very simple. However, when using a foam generator, it turns out to be higher.

Choice of foam concrete blocks: sizes and prices

How can you speed up your dream home? Application modern technologies, for example, based on the so-called. dry solution. This allows fast installation and thanks to the use of an oil-free mortar, the walls reach their parameters only 48 hours after the masonry.

With such an abbreviated investment process, the house meets all the requirements of energy-efficient, healthy and safe construction, even before the introduction of homeowners.

Hollows in this technology have special grinding surfaces, which makes them perfectly stick to each other, and the mortar is not visible in the finished masonry. Such a thin connection eliminates almost to zero the risk of creating thermal bridges in the wall through which heat passes.

A little about production technology

In order for the foam blocks to be of high quality, during their production, all components in the composition of the mixture from which they are made must be added in the correct proportions. If, for example, the amount of cement is not sufficient, the blocks will turn out to be brittle.

There is no water in the solution. Combining almost 200 years of tradition with the most advanced technologies, it has been a leader in quality and innovation on the Polish market for many years. Energy: energy-efficient building environment of the project: environmentally friendly building materials and use of renewable energy sources emotions and health: favorable climate and comfort of life: affordable construction and operation. Choice right windows It has great importance during the home building process.

This is an investment for many years, so it is important to ensure that they are strong, tight and reliable. See what types window frames ok and what parameters should be paid attention to when buying. Windows come in a variety of sizes and colors and can be made from several types of materials. Aesthetics is not everything: the technical parameters of individual products are also important. So, how to choose the best windows step by step?

An excess of this component leads to the fact that an insufficient number of bubbles form in the material, and they are unevenly distributed. This leads to a decrease in the soundproofing properties of the foam block.

Air bubbles occupy 85% of the volume of the foam block. The diameter of these bubbles is from 1 to 3 mm. Such a porous material has better heat-shielding properties than traditional brick. According to this indicator, it exceeds it by 2-3 times.

First: dimensions and material. The window size is usually set in the home project. However, it's worth checking the actual dimensions themselves - they may have changed a bit during implementation. Second: detailed technical parameters. But that is not all. The quality of window frames can be judged to a large extent based on the following parameters. Just as important as choosing a good quality window is correct installation. The fastening method must be adapted to the material of which the windows are made and to the structure of the wall.

The wall thickness determines how the window is positioned in the wall. In a single-walled wall, they are mounted at half the thickness of the wall, in a two-layered one - on the outer edge, and in a three-layered one - in the heating plane. Insulation is also important. Two additional layers of insulation should be placed around the regular foam to prevent moisture from entering the room and prevent rainwater from entering from outside.

Not to mention the fact that the foam block is much lighter than brick. The standard size of the foam block is larger than that of one brick, and the weight is small. Therefore, construction using this material is carried out quickly.

Foam block houses are economical. Since in the case of building a building from this material, it almost never requires secondary insulation. As a result, less energy is required to heat the building, which saves a lot of money.

Finishing materials: wood or similar?

Assembly of the structure in its raw state usually takes 2 to 4 weeks. In addition to the foundation and floors on the ground, they do not require any wet work, so they can be installed within a year. Natural wood seems essential when you are finishing your home. It is used both indoors and on facades or in the garden. Turns out they can be replaced. wood materials which imitate very well and are more durable and easy to maintain.

Connections to the wall must be heated with polyurethane foam. The winter garden needs the right foundation, with thorough moistening and warming. It is important that the light bulb is 15 cm above ground level, then the rain spray will not be polluted. Then the wedges used will not slide out from under the beams, and the floor will not bend. The hardest part is the surface of the wooden planks. Sometimes their long edges are sunk.

If it’s a hot summer, it’s cool in the foam block house, and you don’t have to spend money on air conditioning. As for sound insulation, the effect is also noticeable here. The level of sound insulation reaches 45 dB.

Since foam blocks do not absorb moisture, they do not become damp. This material is easy to process, has high fire resistance, resists frost and putrefactive bacteria well, and is durable.

It must be made in the form of a monolithic concrete slab separated from all walls by expanding polystyrene strips or polyurethane foam strips. This allows you to freely expand the spout and prevent it from moving. To the stairs to wood flooring must be ordered from a specialized joinery. Studs are fixed on the stairs by gluing them to special anchors fixed in concrete base. The finishing edge allows the use of a metal profile to fix the surface.

Although there is a high level of confusion in online forums regarding polyurethane foam prices, since each offers different costs and scope of services, the price of the foam, along with its location, can be found on the contractor's website. We have mentioned many times that the use of roller blinds has a significant effect on reducing heat loss through windows. This is clearly shown in our table.

Laying of foam blocks in just one row (when the size of the foam block is standard) already provides the necessary properties. To obtain the same thermal insulation properties that the foam block has if the width of the wall from it is 30 m, the brick wall would have to be made 1.7 m thick.

Partially assembled frames made from profiles to size. The skeleton of the garden is connected to the foundation and walls with a stainless steel flute. Wall connections must be covered with polyurethane foam. In the walls with double walled profiles cannot be installed.

Walls on the same mortar as hollow blocks. Walls with foam inserts do not need to be filled vertically, but some manufacturers recommend injecting polyurethane foam into certain areas between blocks; This foam is supposed to provide thermal insulation continuity, therefore.

Purpose

The foam block can be a wall block or a block that serves as a heater for the walls. The thickness of the block, which is a heater, is less than that of the block, which is a building material for the walls of the house.

The standard foam block size can be - 50-500 mm. Foam blocks with dimensions of 200x300x600 mm are most often used. The strength of a block of foam concrete determines its density.

Intelligent building management. An electric drive is required for some antifreeze devices. Unlike roller blinds, they also allow full window shade, and their polyurethane foam armor fills them with sound and protects against. The joint width must be between 4 and 12 mm. This localized weakening of the section in the event of stresses is controlled.

Difficulties in the installation of non-standard foam blocks

The fittings in the outer doors are more massive than in closed doors. The base plate was insulated with polyurethane foam. We didn't pay money for quality wooden windows, knowing that large windows had to be done properly. Window sills can be installed both before and after finishing work. Know what rules to keep in mind. Most window sills can be attached to polyurethane foam; Special adhesive solutions are also available.

By the way, the construction of walls from foam concrete blocks allows you to reduce the consumption of cement mortar, since the number of joints in this case is noticeably less than in the case of brickwork. Since the density of the foam block is less than that of a brick. A building built from this material does not need a massive foundation.

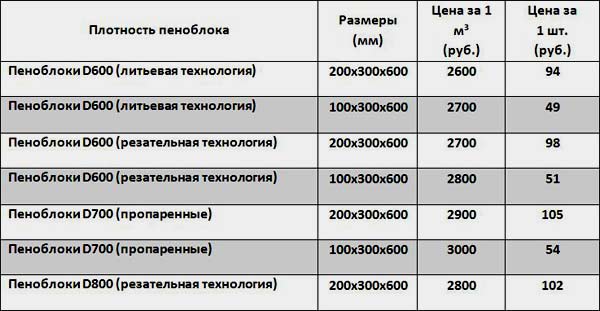

Price for foam concrete blocks varies within certain limits, but the order is naturally the same. Foam blocks for the construction of partitions are cheaper than foam blocks, from which the walls of the building are erected.

For installation of partitions

You will not need to build ventilation ducts, as their functions will be used in the supply and exhaust ducts. In both insulated and non-insulated versions, it is only possible to install insulation in the hinged door. As a heating material, manufacturers usually use polyurethane foam or extruded polystyrene. Standard gates are common, so usually.

The problem of warming up the body during swimming is the most relevant subject in Polish climatic conditions. Unfortunately, the weather does not spoil, and the wind is most often found in combination with adverse atmospheric conditions. Effective Ways warming our bodies are already described in the article. This time we want to focus on the foam.

The density of the material also affects the cost. The higher the density of the foam block, the more expensive it is. The density of the foam block is indicated by the letter "D".

The use of foam concrete blocks rather than bricks in the construction of a private house helps to reduce the time for carrying out construction works. Save a solution of cement or adhesive that holds blocks of other materials together.

Foam, what are the characteristics and what are the properties? Most of us have already faced this dilemma: “which foam to choose for yourself?”. There are many products on the market, so how to find the right foam? The answer is based on the next steps. Unfortunately, you must understand that you cannot make a stump float in all conditions. Foams can be "roughly" divided into 2 types.

Warm fabrics are made of neoprene sheets, the thickness of which reaches 5 mm. Obviously, not all cutouts are of the same thickness so as not to restrict or impede movement. The thickest parts of the chest are the most susceptible to cooling. Foam designed for use at extremely low temperatures should be good, but good things don't always mean cheap. High-quality winter foam is a semi-dry foam with a tight lock or special inserts under the lock from the inside, which minimizes the amount of poured cold water.

The size of the foam block is standard or not standard - not the only point in which these products differ. The surface of the foam block may also be different. It is either smooth or rough. This is influenced by the method of manufacturing foam concrete blocks.

Some manufacturers produce foam that has no blockage at all. Featured products are also equipped with additional neck seals, special sleeves and leg cuffs - all to prevent cold water between the foam and the skin. Foam so-called. warm, thick two-piece material: neoprene covered with stretch and neoprene covered with soft rubber. Rubber foams are considered warmer due to less wind chill effects. However, the superiority of triceps foams lies in the incredible feeling of lightness and freedom of movement that they provide with their great flexibility.

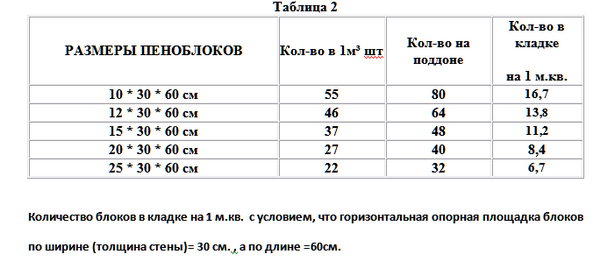

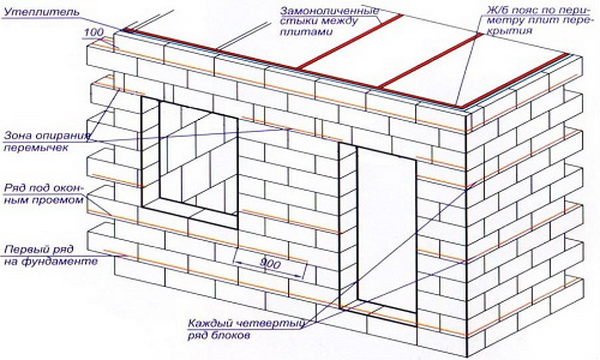

Then it’s time to ask the question: “How much of this material will be needed for construction?” To begin with, it is worth deciding what area of \u200b\u200bthe room you need, whether you will make extensions to the house and internal partitions, as well as load-bearing walls made of foam blocks. To do this, you need to calculate the area of \u200b\u200ball the walls and pre-calculate the dimensions of window and door openings and subtract them from the total area. In carrying out such calculations for building a house, they play an important role. It is from them that you can find out the amount of material.

What is a foam block and why is it better?

Few people do not know that foam blocks are made from foam concrete, which is a type of cellular concrete. Foam concrete blocks are porous lightweight concrete, consisting of a mixture of water, sand and cement. During its manufacture, specialized foam is added, which makes the block porous, giving it some important properties. In each of the blocks there are air bubbles with a diameter of 1-3 millimeters, and their volume reaches up to 85% of the total volume of the entire foam block.

Foam concrete blocks have a number of important advantages over similar building materials. Houses built from foam blocks do not require, due to which you can significantly save on heating, which means that energy costs will be less. In such a house in the summer it is always cool.

What are the dimensions of the foam block?

The dimensions of the foam blocks for building a house are quite decent, because the walls are 30 centimeters thick. Interestingly, without additional insulation, the thickness of such a wall will have the same properties as a brick wall, the thickness of which is 1.7 meters.

The parameters of each block are stable (height, thickness, length in centimeters):

- for walls - 20x30x60,

- for partitions - 10x30x60.

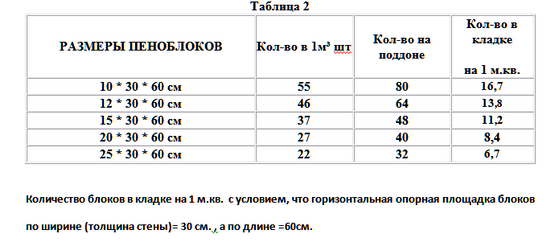

As a rule, the sizes of foam blocks for building a house can be different. Therefore, when buying, this must be taken into account, because depending on this, the number of blocks can be either more or less. It is worth noting that there are foam concrete blocks used in construction only for, which means they will not endure bearing load because they are quite thin.

It should be noted that changes in the size of the block are reflected only in the width and thickness of the blocks, and they are usually standard in length - 60 cm.

The thickness of the blocks ranges from 5 cm to 50. They are made in such a way that 2.5 centimeters are added to the thickness each time, that is, there is a pattern - 5; 7.5; 10; 12.5…..etc. up to 50 cm.

Naturally, the greater the thickness of the blocks, the stronger and load bearing capacity, respectively, higher. But not always and not in any city you can pick up any size of foam blocks for building a house. Most often they can be found in large cities, where there is a great demand for them, or not far from the enterprises that produce them.

If the city is located far from the enterprises, then the sellers are not too puzzled, and bring standard sizes blocks, which are considered the most optimal and are used in most construction projects.

How to calculate the number of foam blocks?

So, if you have one layer, then, as mentioned earlier, you need to calculate the area of \u200b\u200bthe walls minus openings for doors and windows, and then divide by the side section of the block, which, as a rule, is 300x600 mm or 200x600 mm.

As you can see, there is nothing complicated, and all because with such construction there is almost no waste. If the blocks need to be cut, then this can be done using a conventional hacksaw. Scraps do not need to be thrown away, they will come in handy. You can also make a block out of them, which can also be used for laying a wall.

Please note that the seams between the blocks do not need to be taken into account, because when the blocks are properly laid using a specialized glue, the so-called mastic, they are almost imperceptible.

Even if you use the usual cement mortar when laying, taking into account the size of the blocks, the seams will also be small.

It should be noted that when buying blocks, do not forget that some blocks may be damaged during delivery, just like during the construction process, so you should take a few blocks in reserve. Usually, about 2-3% of the total number of foam blocks is taken for stock.

![]()

-

Sip panels are used in the construction of buildings with a small number of floors and premises for household, public and residential purposes. For example, most often SIP panels are built ... -

The foam block is a large brick obtained from a concrete mixture mixed with special foaming compounds. It is this foaming composition that forms pores in concrete, thanks to which the blocks ... -

When building a house, it is important to choose good material. It must be durable, reliable, heat-saving. One of these options is foam concrete, which is convenient to use in the form of ready-made ... -

A long time ago wooden houses shelter people from bad weather, heat and frost. It will probably continue to be so. The popularity of wooden houses is easily explained, because such houses have... -

The beam is cut by specialists immediately under finished project structures where all the bars are fitted one to the other. The timber house construction calculator allows you to accurately calculate how much timber ...