Heating a country house with underfloor heating. Underfloor heating system: water and electric varieties, installation diagram, prices

The use of infrared radiation for heating is beneficial from every point of view. First of all, such radiation is better perceived by the body, because we also radiate part of our heat in this range. Therefore, when using infrared waves to maintain a comfortable temperature, the thermometer usually shows 2-3 o C lower. And this leads to a reduction in heating costs. The second bonus is that you not only heat the room, but also heal. After all, infrared radiation ionizes the air, which contributes to the destruction of many viruses and bacteria, and also destroys unpleasant odors. This type of rays is used to treat many diseases, and also helps to relax and relieve nervous tension. Another positive point: electromagnetic radiation is close to zero. The only drawback of this heating option is the high price of heating materials. But installation is much easier and faster than cable systems and a water floor.

When using infrared radiation for heating, it is not the air that is heated, but the objects located in the room. First of all, the floor becomes warm, which feels very warm, even if the temperature is low. And from heated objects, by convection, the air is heated.

To date, infrared floor heating can be done using two types of heaters: film roll material and rod carbon mat. In both cases, carbon is used only in different states. Let's look at each of them in more detail.

Infrared film floor

IR film for the floor - roll material. It is a carbon fiber paste sealed in a polypropylene or polyester film. Along the edges are conductive tires (stripes) of silver and copper. Through these tires, an electric current is supplied to the carbon material (usually carbon is used). When passing electric current released through carbon a large number of heat. The strips are collected in sections of several pieces in one. They can be cut along the dividing strip between the sections, which is convenient for installation. Such a structure is also good in that if one or several strips are damaged, the rest of the tape remains operational. Since the distance between the strips is very small, even the failure of several elements in a row will not affect the sensations in any way: the floor will remain evenly warm. Roll width - from 50 cm to 100 cm, film thickness - from 0.2 mm to 2 mm.

Advantages

The film infrared floor is compatible with most floor coverings. When laying a hard surface - tiles, parquet and laminate, no additional protective layers are required. Manufacturers recommend rolling out a plastic film on top, and then you can immediately lay the tiles on a special adhesive for underfloor heating or a suitable laminate, parquet or floor board. For wood products, infrared film floors are good because they create a uniform heat flow, which is why there are no zones with different temperatures in the wood, they crack and warp less.

There is one nuance here. Some manufacturers say that the film can be hidden in a screed or under tile adhesive, others do not advise. Most practitioners say that the film is destroyed in cement. Could it be the film itself? After all, it is also different, as are the different ways of connecting it.

For laying other soft surfaces such as linoleum, carpet, etc. a solid base is required. To do this, plywood, OSB or any similar sheet material is laid on top of the same plastic film. After fixing, roll out and fix the floor covering. That's all. Easier and several times faster than with the device cable underfloor heating.

disadvantages

The first is that films are afraid of overheating. And although they have a significant margin of safety in temperature (they melt at 200 ° C and above, depending on the material of the insulating film), they can still burn out. Therefore, in those places where furniture stands or will stand, large appliances, the film is not laid. The second drawback: the high price. On average one square meter film will cost $25. The high price of the IR film is partially offset by the lack of a screed and a long service life: more than 10 years if all recommendations are followed. The third drawback is the need for painstaking and correct electrical connection of the film strips. The connection is made using terminal clamps and a set of electrical wiring, which are supplied with the film, but require proper application. It is also necessary to seal well with adhesive insulating plates those places of the contact busbars that are not used. Here, in fact, all the shortcomings.

The device and installation of an infrared floor from a film

The first good news is that no cement mortar or concrete is required when installing IR film underfloor heating. If your floor is flat, then no “wet” work. The second good news is that in one room you can make such a floor with your own hands in one day. Even without special skills.

Payment

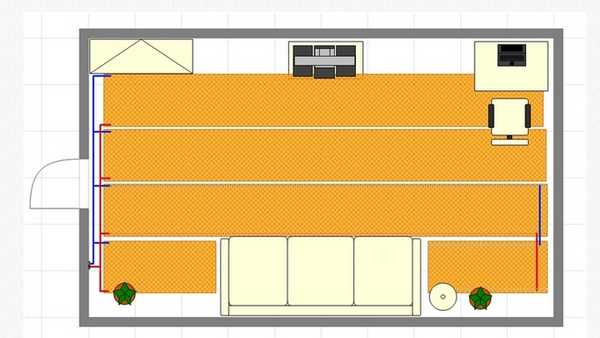

To properly make a warm floor, you need to draw a floor plan to scale. Select the areas in which the furniture / appliances will stand. Next you need. Power must be supplied to it and wires from the film heater and temperature sensor are connected to it. After that, on the area not occupied by furniture and appliances, you need to arrange the film strips so that they do not overlap each other and do not intersect, but fill the entire area as much as possible.

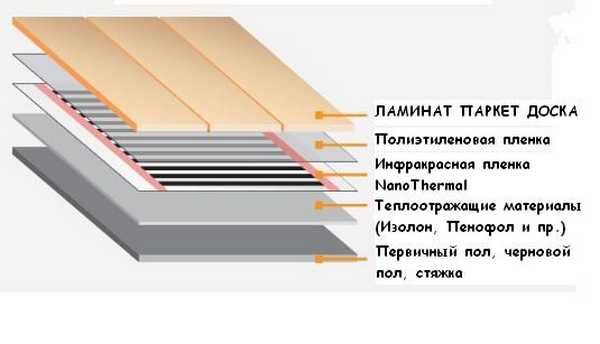

What does one of the options for the “pie” of infrared floor heating using carbon film look like?

The choice of heating intensity depends, firstly, on whether the warm floor is the main type of heating or additional. If floor heating is only a matter of comfort, and the main heating of the room is carried out by other systems, you can choose from low-power models from 150 W / m 2. If the room is heated only from the floor, choose products with a power above 250 W / m 2 (the maximum for today is 400 W / m 2).

The second factor that affects the choice of power is the type of flooring. Under the same operating conditions and the same requirements, it is necessary to lay a film of greater thickness under the tiles than under other types of flooring: it absorbs heat very intensively and at the same temperature it feels cold to the feet.

Mounting infrared film

The first thing to do is to reduce heat loss through the floor and adjacent walls. To prevent leakage through the walls, tape insulation or a strip of polystyrene foam 10 mm thick and about 10 cm high is laid around the perimeter. Then, a layer of heat insulator is laid on a flat and clean subfloor (on the entire surface of the floor, and not just under the foam). In order for the heating to be efficient, it is advisable to use a foil or metallized material: it reflects the heat directed downward. Since cement mortars are used very rarely here, the foil will also serve properly for many years (it quickly collapses in the screed). The use of such material increases the heating efficiency and reduces heating costs. The heat insulator can be rolled or in the form of mats and plates. Fasten the thermal insulation to the floor with glue, double-sided tape or staples from a mounting gun.

Then, on top of the plan, roll out the infrared thermal film with the copper strip down (matte surface on top, not shiny). Make sure that air does not accumulate under it. Where necessary, cut the roll according to the marked markings (dashed line and scissors image). It is more convenient if all heating elements are deployed with contacts to the wall where the thermostat will be installed. The distance between adjacent strips is a few centimeters. If you are planning an infrared floor under linoleum, it is better to lay the strips more densely so that the distance between the tires is 1 cm. But the tires should not touch and overlap under any circumstances.

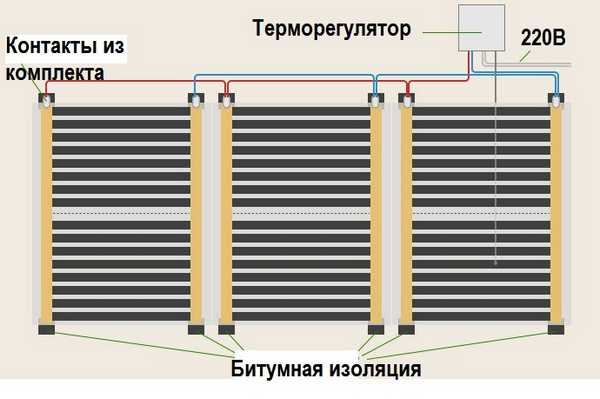

IR floor connection

Now you need to connect all the strips with an electric cable, which is usually included. Make contact on a current-carrying copper strip. One part of it is located under the residential, the other - on top. Now crimp the contact with pliers. So install contacts on all tires deployed towards the thermostat. On the far side of the thermostat, open sections of the copper conductor must be covered with insulating tape (included).

When installing a piece of insulation, cover the entire width of the busbar, including the silver mesh if present (see illustration). Having installed all the contacts and insulators, attach the IR film to the heat insulator with adhesive tape, and fasten the strips together with it.

A thermostat is installed on the wall. Lead to it wires from the heating strips. Under one of them, you need to make a recess in the heat-insulating material for the floor temperature sensor and wires to it. After laying and securing the sensor, run the wires from it to the thermostat as well.

The connection diagram of the infrared floor is shown in the figure. Now wires are connected to the contacts: they remove the insulation from small area, the bare conductor (conductors) is inserted into the contact connector, crimped with pliers. Check the strength of the connection and insulate with a piece of bituminous insulation that comes with the kit (two pieces, one on top, the other on the bottom, pressing them tightly against each other). Lead all the wires to the thermostat, connect according to the diagram that is on its reverse side.

The electrical connection to the thermostat must be carried out by a qualified person. After the power is on, you can test the system: set the temperature to 30 ° C, after a few minutes check whether the strips heat up well and whether the connections spark. If everything is OK, you can lay a hard floor finish or a base under soft materials.

Finishing coating of IR floor

If tiles, parquet or laminate are laid on the infrared film floor, all that is needed is to roll out a protective (polyethylene or special) film. It will prevent water from entering the current-carrying parts during operation and will protect against damage during installation. If you use a laminate, you can use a substrate instead of a film (or together with a film). There is, by the way, a special infrared film for tiles.

Under the tile, you need to lay a layer of glue 1-2 cm, and after it dries, proceed to the finishing work (glue and grout for joints are special - for a warm floor). You can immediately lay the tiles on the glue, but the thickness of the glue and tiles must be at least 2 cm.

If a soft floor covering is to be used, it is necessary to make a solid base for it. It can be plywood sheets (10mm) or OSB, other similar material. It is attached to the floor with ordinary screws or dowels. Only when fixing a solid substrate, care must be taken not to get into the conductive strips (copper and silver). It is also desirable to destroy as few carbon strips as possible. Having completed the manufacture of a rigid base, you can lay the floor covering - linoleum, carpet, carpet, etc. The main thing is that the temperature sensor and thermostat work, which will protect the film from overheating.

This is the whole setup. You can turn on the infrared floor and warm up. By the way, the film does not have to be laid on the floor. You can make yourself an infrared wall or even a ceiling. There are even special IR films that are installed under suspended or stretch ceilings.

Mobile warm floor

One of the main advantages of the IR film is its elasticity and sufficiently high strength. We decided to use these qualities to the fullest and made a mobile warm floor. This is a small piece of heating material with a thermostat and an electrical plug that can be moved from place to place. It can be twisted and folded. You can put the rug anywhere and turn it on. A mobile warm floor can be made on the basis of an infrared carbon film, or on the basis of a cable mat or a resistive film. Naturally, IR mats are more expensive than resistive ones, but in addition to heating, they also have a healing effect.

Mobile infrared floor - mat with thermostat

If you have a piece left from the installation, you can make such a rug yourself by connecting a piece of IR film to the wires, carefully insulating the contacts. Then connect the wires to the standard plug. Get a portable infrared heater. You can put this rug under your feet, on a chair, etc. Such a mobile film warm floor will help out if the heating suddenly fails, or it simply cannot cope with abnormal cold. It takes a few minutes to connect. The only thing - you need to ensure that there is no overheating. There is no thermostat in the homemade version, although you can connect it in conjunction with the sensor, but then the rug will be too expensive.

Rod infrared warm floor

This infrared floor is called a rod floor because of the shape of the heating elements. Inside the insulating rod is a composite material, which includes carbon, silver and graphite. This combination of materials added a very good bonus to the advantages of IR radiation: the system is self-regulating. That is, she herself can reduce / increase the amount of heat generated in each area.

Rod infrared floor looks like this

IR rods are connected with insulated copper wires. The heating elements are connected in parallel, which means that if one or more elements are damaged, the rest of the system will work. But this applies to rods. If you interrupt the connecting wire located on the side, the performance will be lost.

Parallel connected carbon rods are rolled into rolls. Their width is 07-1.5 m, length is up to 25 meters. Rated power 110-250W/rm. At maximum power, the heater operates for several minutes until the screed is heated, then the amount of heat and power consumption are significantly reduced. Therefore, such floors are much more economical in operation than analogues of another design.

Installation of an infrared floor from rods

This electric underfloor heating system is easy to install. The subfloor must be level. The maximum allowable height difference is 1 cm per 1 m 2. As with film heaters, it is important to provide a good level of thermal insulation. Therefore, along the walls and on the floor we lay thermal insulation. As with other underfloor heating, the best option is metallized material, which is attached to the base with double-sided tape, glue or staples.

Having laid the thermal insulation and gluing its joints with adhesive tape, roll out the mat from above without reaching the opposite wall 15-20 cm. At the turning point, cut one of the side connecting cables in the middle between the rods and turn the roll in the desired direction. Repeat this operation until you finish laying. When rolling out the roll, make sure that the wires do not touch or intersect. Attach the rods and conductors to the thermal insulation with adhesive tape and fasten them together. So far, the process has been the same as when laying IR film flooring. Next, the differences begin.

Now we cut out windows between the rods in the heat insulator in some places. They will "tie" the screed laid on the core IR floor with the subfloor. They are arranged in a checkerboard pattern. The total area of "holes" is 20-25% of the area of thermal insulation. It is better to cut a lot of small pieces - so the heat loss through them will be less. Now it's the turn of the electrical part.

Rod connection

Using the wire and terminal clamps included in the kit, you need to connect the cut power wires to one system. We remove the insulation from the wire by about 1 cm in the place where it was cut when turning the mat. We take a clamp / contact and put it on a bare conductor, crimp it with tongs or pliers. We put a piece of heat shrink tubing of a slightly larger diameter on the wire from the kit. We insert the stripped end of this wire on the other side into contact. We squeeze it too. After checking the strength of the connection (twitch) with the help of a building hair dryer, we achieve shrinkage of the tube on the contact. We got a well insulated contact. In some firms, bitumen is used instead of heat-shrinkable pipes for insulation. Strips of this material adhere very well to any surface and do not conduct current. In this case, they take a piece of bituminous insulation and, having laid the contact, crimp it well. So we connect all the contacts. The connection diagram is shown in the figure.

Having collected everything, we connect it to the thermostat installed on the wall. We also connect a temperature sensor to it, which we place in the middle between the rods (you can fix it with tape). After completing the connection, turn on the system, set 30 ° C and carefully observe. If there is no spark, no strange smell, all the strips are heated, then everything was done correctly and you can proceed to the final stage of installation.

Laying the flooring on the IR rod floor

This option is an ideal choice for underfloor heating under tiles. In this case, the installation is very simple. Just take tile adhesive and tile and lay. The only condition is that the thickness of the adhesive + tile must be more than 2 cm for uniform heating and a normal level of heat transfer. This is the best underfloor heating for tiles or porcelain tiles.

Under all other types of coating, a screed is required. Its thickness is at least 2 cm. Laying the floor covering only after the composition has completely dried. And keep in mind that you can’t categorically turn on the underfloor heating system to speed up drying: cracks will appear, and they lead to a decrease in heating efficiency.

Infrared radiation is not the only way to organize electric floor heating. Can be laid or made

Results

The device of infrared heat-insulated floors is several times simpler than similar cable systems. Their undoubted advantage is useful and pleasant radiation, high heating rate and lower energy consumption (carbon infrared floors are especially beneficial from this point of view). Disadvantage: high price and rather troublesome and painstaking electrical assembly.

The realities of modern life are such that more and more often residents have to solve communal problems on their own, including issues of heating their homes. Maintaining a normal temperature in an apartment often becomes a real disaster, since batteries are of little use, and heaters do not so much raise the temperature in the home as increase monthly electricity consumption. That is why more and more people are interested in electric floor heating, which is perhaps the most reliable option today to maintain an adequate temperature in the apartment.

A thin warm floor can not only save you and your loved ones from constant hypothermia forever, but also change the microclimate of the entire room. The eternal companion of all heaters is dry and stale air, which causes migraines, general fatigue, and contributes to the rapid development of acute respiratory diseases. This happens because the heated layers of air rise to the ceiling, and the owners of the apartment, suffocating from stuffiness, continue to wrap their feet in warm blankets. Such a heating system is especially dangerous for the elderly and children.

Electric underfloor heating, unlike traditional heating systems, creates indoor optimal conditions for work and leisure. Installing a thin warm floor will ensure that the air is warmed up only at the surface of the floor covering. Thanks to this, the normal level of humidity in the room is maintained, the people in it feel quite comfortable. Using a floor heating system can significantly save energy, which is an important factor in our difficult time.

Proper installation and operation of floor heating systems guarantee a quiet life for their owners: warm floors do not take up extra space in the house, but at the same time they heat the room faster and better than any other heater. They are easy to use, safe for life and health. In addition, the floor heating construction system is so simple and reliable that it can serve for decades, maintaining not only the temperature in the room, but also keeping the warmth of the hearth.

Of course, not all familiar floor coverings can fully "get along" with electric floor heating: some materials have too low a level of thermal conductivity. The ideal covering for your new underfloor heating can be porcelain stoneware or ceramic tile, an order of magnitude worse, such heating systems are combined with linoleum, which is the most popular flooring in modern apartments. But the real problems arise if the owner wants to combine underfloor heating and parquet (or other wood flooring).

When fulfilling such a whim of the client, specialists have to calculate not only the degree of humidity and the type of wood, but also take into account many other factors in order to ensure the full functioning of the underfloor heating system. In this case, contractors can offer a worthy alternative - floor heating by laying pipes with water connected to the central heating system.

Water floor heating was known to the ancient Romans. Since then, its design has changed little, which proves the practicality of such a heating system, proven over the centuries. An important factor when choosing floors with water heating, the quality of pipe materials is the main indicators of which should be reliability and a long period of guaranteed operation. The pipeline for heating, as a rule, is made of a metal-polymer, the cost of which will significantly hit your pocket.

However, it is better not to save on equipment: repairs will cost more. For long-term and full-fledged functioning of water floor heating, it is necessary to purchase pipes only from trusted suppliers who have long conquered the world market with the quality of their equipment.

Underfloor heating system based on pipes with hot water, as mentioned earlier, is very simple in its design. Installation of a warm floor of this type is carried out as follows: on a previously prepared base, layers of hydro and thermal insulation are laid, over which a pipeline is laid. Pipe laying resembles the design of the original pattern, since the performance of the future heating system will depend on the complexity of the contour and the number of bends. After reaching the desired density of laying the pipeline, the entire structure is poured with concrete.

Water floor heating impresses many buyers with its absolute safety and environmental friendliness. However, it will not be easy to regulate the temperature differences of such a heating system, especially if the pipes are connected to common system heating. It is worth noting that a warm floor based on water heating is far from the most the best option for residents of high-rise buildings.

Judge for yourself: obtaining permission to install such a heating system will be very difficult, since typical utilities are not too interested in installing additional sources of heating. And it’s unlikely that you will be able to experience all the delights of such a warm floor, because the slightest excess of the “fence” of hot water from the central heating system will cause a sharp drop in temperature in the neighbors’ apartments, who simply won’t let such “hooliganism” go down. Therefore, a prerequisite for installing a water-based underfloor heating should be the installation of a heating boiler, which will save you from such problems once and for all.

Significant competition to water heating systems is underfloor heating with electric heating, which exists thanks to the invention of the heating cable. A warm floor with electric heating is more sensitive than water, it quickly heats up the room, which is a considerable advantage in the harsh Russian winters. Another advantage of electric underfloor heating is the possibility of remote control, which makes it possible to save energy without sacrificing your own comfort.

The main source of heat in floor coverings is a low-temperature heating cable, which can be resistive or self-regulating. A more profitable option is a self-regulating cable: it is insensitive to overheating, therefore it is more reliable and safe. Another disadvantage of a resistive cable is a strictly standardized length, the violation of which leads to overheating or insufficient thermal conductivity. That is why the cost self-regulating cable justifiably high.

The disadvantage of underfloor heating based on electric heating is the magnetic field that is formed in the room due to the functioning of the heating cable. But experts are sure that the normal shielding of the cable allows you to create an electromagnetic field that does not exceed the natural background of the earth.

Viewed: 491

At the beginning of the new heating season and during the next stage of increasing energy prices, the topic of heating a house is of particular relevance. How to save on coolants in winter but not freeze? The question in our time is more than burning.

Yielding to new trends, many consumers prefer the installation of underfloor heating, instead of or along with traditional heating radiators. But is it the right choice? Let's look at the advantages and disadvantages of this method of heating a home.

From the article you will learn:

Underfloor heating - heating features

The "warm floor" system, as the name implies, is an option for heating a house precisely by heating the floor. Since school physics lessons, we know that warm air tends to rise from the bottom up. Have you noticed that on the second floor of a private house in winter it is always warmer than on the first floor? (This does not apply to the attic.) And in anatomy lessons we were told that a person begins to freeze if his feet are cold. “Keep your feet warm and your head cold,” remember?

Why this elementary knowledge was not taken into account earlier in the construction of both private and multi-storey housing, we will not understand. It so happened that the radiator heating system, which significantly loses in terms of comfort warm floor, today it is mounted in most houses of the post-Soviet space. Most likely, the level of technological development simply did not allow the introduction of heating of this type of housing earlier.

If speak about country house, then at the construction stage, the owner himself chooses the method of heating his home. Yes, and replacing standard radiators in a private house with underfloor heating is not a problem, there would be money. If desired, apartment owners also have the opportunity to install underfloor heating as an additional or main source of heat when the batteries are turned off.

Types of warm floors

Any "warm floor" system is a combination of heating elements located under the floor covering and providing uniform heating of its entire surface. To date, there are two options for the implementation of such a project: electric floor heating and water floor heating. The difference in heat sources and heating elements:

In the first case, heat comes from heating special conductors during the passage of electric current. In the second, heated water circulating in a pipe system, metal or plastic, acts as a heat carrier.

However, due to the peculiarities of installation and operation of a warm water floor, its installation in apartment buildings while technically impossible. But it has a number of advantages over electric when installed in country estates. Electric underfloor heating can be successfully installed both in an apartment and in a private house, for example, on a closed veranda or balcony, if there is any need for this.

Types of electric underfloor heating differ in the type of heating elements. On the modern market, there are systems "warm floor" cable, film (infrared), thermomats. They differ from each other in terms of styling and the level of energy consumption, which manufacturers are constantly striving to reduce.

Water heated floors also have their subspecies, which differ mainly in installation technology:

- Concrete technology (heating elements are mounted under a monolithic concrete screed).

- Laying technology (performed by laying several layers of materials of different types).

Underfloor heating - system advantages

The advantages of both electric and water heated floors include the fact that heating of this type:

In addition, if we talk about the features of a specifically electric underfloor heating, it is advisable to install it because:

- Installation of an electric underfloor heating is a guarantee of the well-being of the owners during the heating season. At the level of the legs, the system maintains a temperature of 24 degrees Celsius. In the area of the body - 20, and the head - 16 degrees. According to scientists, this is the optimal temperature regime for a person to feel comfortable.

- This temperature can be maintained automatically during the entire operation time. This allows the rooms to be heated evenly. Modern electrical systems"warm floor" are equipped with special control sensors that allow you to "adjust" the temperature regime to the individual characteristics and life schedule of the owners. When you plan to return home, the system will raise the temperature in the room according to a given schedule; when you are not at home, it will work with less heat output.

- In addition, the thermostat allows you to heat individual rooms more or less. That is, individually set the temperature regime for each room. Old radiator heating systems do not allow this in principle.

- High reliability. According to the manufacturers, electric underfloor heating without overhaul can be used as much as the house itself.

- Electric underfloor heating is easy to install under most modern floor coverings. Given the fact that there are several types of system on the market, it can be installed in any housing.

Water heated floor also has its advantages:

- Its temperature regime is quite low - no more than 50 degrees Celsius. This significantly reduces heating costs, saving up to 40% compared to standard batteries.

- Warm floor water - best option in terms of environmental safety and sanitary and hygienic standards. Access to its heating elements is hidden and children will not be able to contact them, which makes it optimal for installation in a nursery.

- In rooms with high ceilings, savings in thermal energy when using a water-heated floor can reach more than 50%.

- Compared with electric underfloor heating, water - 5-7 times more economical in operation.

- Due to the design, a water-heated floor interacts perfectly with almost all floor coverings (linoleum, carpet, laminate, tile), as long as they have good thermal conductivity.

Disadvantages of underfloor heating

Not without a fly in the ointment here. Depending on the type of system, each type of underfloor heating has its own disadvantages. The disadvantages of the electric floor are that:

- With its use, the cost of electricity increases significantly. The average figures are 110-150 W per 1 m 2, although this does not take into account the savings on lowering the heating temperature during the absence of the owners and other operating factors. With the right approach modern systems heating of this type can save up to 40% of energy. Particularly good in this regard are electric heated floors of the infrared type, during the operation of which the average indicators are reduced to 50%.

- Electric networks in old houses may not withstand the load, which will increase considerably during such space heating. Consider this fact before deciding to install an electric underfloor heating system.

- With the use of an electric floor, the level of electromagnetic radiation increases. Some believe that it negatively affects human health, although only unbiased scientists can answer this question for sure. By the way, manufacturers of infrared floors claim that the film floor reduces electromagnetic radiation to zero.

- The main disadvantage of an electric underfloor heating, in our opinion, is that in winter, in the event of a sudden or planned (and this happens to us) power outage, you can freeze in your own house. Of course, if such a system is the only source of heating.

The disadvantages of a water heated floor are:

- Long and serious installation. At the stage of building a new house, this disadvantage, as such, can not be considered. But installing a warm water floor in a house that is already in operation is a serious hassle.

- The need to reinforce pipes or a whole screed, the use of several layers of waterproofing. All this significantly increases the cost of installation, compared with classical heating systems and, especially, electric underfloor heating.

- Water, passing through the contours of the pipes, gradually cools and heats the following rooms somewhat less. This must also be taken into account;

- Compared to an electric floor, the reliability of a water floor is much less. This is due to the possibility of pipe leaks. By the way, it is precisely because of this that water heated floors are not allowed to be installed in apartments.

A common disadvantage of all underfloor heating systems is that when using such heating, floor coverings still need to be chosen with care. The fact is that under the influence of temperatures, some, for example, wooden floor coverings can collapse. Based on this, consult the seller of the floor covering whether it is suitable for laying on a warm floor. Also take an interest in its thermal conductivity: some types of wood will reduce the effect of heating from a warm floor to nothing. But for the "warm floor" system, all types of ceramic and stone tiles, exotic woods are ideal, laminate works well.

Underfloor heating: pros and cons for human health

Manufacturers claim that this heating system is only good for the human body. However, there are skeptics who fundamentally disagree with this. Opponents of the system argue that a warm floor, in particular an electric one, emits a harmful electromagnetic field that adversely affects the human cardiovascular system. Another argument against warm floors is the fear of some doctors that constant heating can have a bad effect on the health of the feet.

Proponents of all these arguments consider myths and stupid horror stories. Repeated studies show that the electromagnetic radiation from the electric floor is so small that it looks negligible against the background of other electrical appliances. Regarding the heating of the feet, the temperature of the heated floor is not so high as to cause any harm to health.

Despite all the assurances and assurances of experts in safety, there are no winners in the dispute about whether a warm floor can harm the health. Everyone has their own opinion. Given the fact that there is some competition in the production of heating systems, talk about the potential threat of the "warm floor" system will appear in the media space from time to time. It remains for us to analyze the information and draw conclusions based on both data and common sense.

Underfloor heating: we incite all the pros and cons

Weighing the above information on the scales of rationality, we note the following:

- The "warm floor" system is a very comfortable way for a person to heat a room.

- This is definitely the best, compared to traditional radiators, option for heating a private house. But, if you do not have your own autonomous power plant, you should choose a water floor. It is reasonable to use electric - only as an additional source of heat, for example, in the bathroom, in the kitchen or in a room where small children often play on the floor.

- Installing a water floor requires hassle and money. But its operation several times reduces the cost of heating the house in winter. So over the next few years, the money for installing a water floor will pay off, but the savings will remain.

- Electric underfloor heating is the best solution for residents with central heating. The system, as a rule, is not installed in all rooms, but, for example, in a bedroom or bathroom. There you can bask until the local authorities decide whether to turn on the heat in the house or not.

Useful video: the pros and cons of the "warm floor" system

You will also be interested in:

Electric underfloor heating is represented by various types of systems: thin heating mat, heating cable, carbon rod mat, infrared film, each of which has its own range of characteristics and applications.

Literate selection and calculation of underfloor heating ensures the most efficient functioning of the heating system with the lowest energy costs.

To independently make an accurate choice and calculation of a warm floor, use the formulas described below or contact the specialists of the Warm Floor chain of stores in your city.

The choice of a warm floor is carried out on the basis of the following data:

- Required degree of heating in a room or building. Electric underfloor heating can be used as a comfortable heating of the floor surface, as well as the only source of heat in the apartment.

- Type of flooring used indoors. Each coating has different thermal conductivity and thermal sensitivity, which must be compatible with the heating system.

- Mounting type- cement screed (at the stage of overhaul); underfloor heating for tiles or dry installation for laminate (for cosmetic repairs).

- Total floor area, in which a warm floor will be installed, and an area unoccupied by furniture.

First step to create optimal temperature using the "warm floor" system - determining the required degree of heating: whether it will be enough for you to comfortably heat the floor surface (the so-called “additional heating”) or is it necessary to compensate for the lack of central heating due to the warm floor (main heating). The answer to this question will determine the level of power that the underfloor heating system should have. For comfortable heating - this is 100-150 W / m 2; for the main heating - 160-200 W / m 2; for cold unheated rooms (balconies and loggias) - 200-250 W / m 2.

It is important that required power was compatible with the selected floor covering, whose manufacturers usually specify rapids allowable temperatures . So, for laminate and linoleum, the optimal power is 100-130 W / m 2, the temperature of the floor surface should be in the range of 26-28 ° C. Therefore, these coatings are recommended to be used with underfloor heating only for additional heating. In most cases, CALEO infrared film is used for such coatings. Alternative options are Devidry thermomat (manufacturer DEVI) and TVK-130 LP (THERMO).

For our customers, the service of choosing and calculating a warm floor is free!

The cost of CALEO LINE film underfloor heating analogs is about 325-350 rubles. per running meter. This is 650-700 rubles. per square meter.

At the same time, the thermal film itself is only heating elements, and not a “warm floor” system ready for installation.

In addition to the heating film, it is necessary to purchase accessories for installation - terminals or eyelets, bituminous insulation, electrical wires.

Tiles and porcelain stoneware are suitable for both primary and secondary heating, i.e. compatible with high power - 150-220 W / m 2. Manufacturers DEVI, THERMO, WARMSTAD and IQWATT have heating mats that are widely used as underfloor heating under tiles and porcelain tiles.

When choosing a warm floor, it is important to consider base surface state on which the system will be mounted:

- For overhaul recommended for installation cable systems(Warmstad WSS model from WARMSTAD (Russia); Deviflex 18T from the manufacturer DEVI (Denmark); SVK-20 heating cable from THERMO (Sweden)), mounted under a cement screed 3-5 cm high. Such a warm floor is compatible with absolutely any floor covering . The system is turned on after the screed has dried, after 30 days.

- When, when the screed is already equipped, heating mats are suitable, such as, for example, the IQ floor mat from IQWATT or the UNIMAT infrared rod warm floor. Thin mats are mounted in a thin layer of leveling soil (1-1.5 cm thick), and UNIMAT thermomats are placed under tile adhesive (2-3 cm).

- Another option for an equipped screed - dry installation, which allows you to save the height of the room. For this purpose, the CALEO infrared film is designed, which can be turned on immediately after installation.

Pay attention to the location of the object in which the underfloor heating will be installed. It is worth considering factors such as the presence of heated rooms below and above or a cold foundation (soil). In case of high heat losses, heat-insulating material must be placed under the heating system.

Most underfloor heating systems are installed in that part of the room where there are no large objects or equipment (bed, wardrobe, refrigerator), that is, in a free area. This is necessary in order to avoid "locking" the system and its further overheating. If there is no certainty that the furniture will always be in the same place, then it is necessary to opt for a warm field with self-regulation function– core mat UNIMAT. This property allows the system to adapt itself to environment, reducing or increasing the power level as needed and thereby saving energy.

The calculation of the warm floor is carried out in three different ways, depending on the type of heating system.

1. Calculation of heating mats and infrared film

When choosing the required set of heating mat, infrared film (CALEO), the following formula is applied:

S total - S zan. =S;

where:

S total - the area of the room;

S - the area occupied (locked) by furniture;

S is the area of the required set.

Calculation example:

The area of the children's room is 12 m 2, of which 5 m 2 are occupied by furniture. According to the formula:

12 m 2 - 5 m 2 \u003d 7 m 2

To heat this room, you should choose a warm floor with an area of \u200b\u200b7 m 2.

In the case of a thermomat, its shortening and extension is prohibited, therefore the area of the installed warm floor is rounded down. CALEO thermal film can be cut, which makes it possible to connect individual strips of underfloor heating and combine various sets of this brand. For example, an infrared film of 5 and 4 m 2 or 4, 3 and 2 m 2 can be installed on 9 m 2 . And also one large set can be used in several rooms. It all depends on the configuration of the room and the desired scheme for laying the warm floor.

2. Calculation of the heating cable

To determine the required power of the heating cable, the formula is applicable:

R required * S free = P;

where:

R required - the required power in space heating (comfort heating: 100-150 W / m 2; main heating: 160-200 W / m 2; for cold unheated rooms - 200-250 W / m 2);

S free - free area from furniture (calculated by the formula: S general - S zan.);

P is the power of the heating cable.

Calculation example:

For kitchen heating with total area 10 m 2, of which 4 m 2 are occupied by furniture, as a rule, a power of 160 watts is required. Thus, the required power of the thermal cable will be:

160 W * (10 m 2 - 4 m 2) = 960 W

The power of the heating cable should be as close as possible (upwards) to the required one. Therefore, for this kitchen, a 1020 W heating cable (heating cable SVK-20) is recommended, if we talk about the THERMO model line. Installation of a warm floor will be carried out with the calculation of the area of \u200b\u200bthe room and the laying step.

3. Calculation of the UNIMAT rod mat

The UNIMAT infrared rod mat has self-regulation function, so not afraid of locking furniture and the area of the set should be equal to the area of the room.