Construction of a monolithic house. Innovations and technologies in modern monolithic construction

Progress in the construction field is slow. Proven and effective technologies have been used for decades. However, significant competition leads to the search for new solutions that allow buildings to be built faster, cheaper and with greater strength.

Much of the innovation comes from Western countries and is brought in by international construction companies. In the Russian Federation, modern technologies are fully used for the construction of the largest or non-standard facilities of great social importance. After mastering the technology, it finds application in typical buildings. Thus, innovative methods become publicly available.

Construction of the Moscow-City complex as a celebration of high technologies

An excellent example of modern is the complex of buildings "Moscow-City", located in the capital. It would be impossible to carry out such a grandiose project without innovative techniques. One of the most famous objects of this complex is the Mercury Tower, which, at a height of 338.8 m, is the tallest skyscraper in Europe. To achieve such a height, it was necessary to use a number of new solutions, including concrete prestressing technology.

The prestressing of concrete makes it possible to reduce the weight of the structure and increase its strength properties.

This technology allows you to increase the step supporting columns 2 times or more, reduce the thickness floors by 20%. Reducing the consumption of concrete is achieved up to 25%.

The technology of concrete prestressing has been known for a long time, but it was used to create separate blocks. AT monolithic construction it has only recently come into use. Its essence lies in the fact that steel reinforcement with high strength is stretched with the help of hydraulic and screw jacks. After that, concrete is poured. When it seizes, the tension is loosened. The rebar tries to return to its original length and exerts a compressive force on the material. During operation of the resulting product, these compressive loads reduce tensile deformations, which are a common cause of failure of concrete structures.

high-rise complex "Moscow City" - monolithic construction

high-rise complex "Moscow City" - monolithic construction

Higher strength indicators for monolithic elements with stressed reinforcement make it possible to build concrete structures with long spans without intermediate supports. This reduces the overall weight of the building. This method was proposed earlier by the Soviet scientist Viktor Mikhailov, but his ideas remained unclaimed. And the successful experience of building according to the method of an engineer from France, Eugene Freycinet, began to be widely used first in Europe, and then in Russia.

Another innovation was used in the construction of the Rossiya multi-storey tower. It has a considerable number of underground floors that go into the ground at 56 m. Work with this building was carried out by the Satori construction company. Up&Down technology was used, which proved to be excellent when performing operations with deep pits. It involves the gradual removal of the soil, as the ceilings are erected in the underground tiers. This approach makes it possible to quickly build both above-ground and underground part building.

Experts believe that there is currently no alternative to Up&Down technology in urban construction. It allows you to significantly reduce the construction time of the building, since construction is carried out simultaneously up and down relative to ground level. Unlike traditional construction methods, there is no need to wait until the ground floor is completely completed. This technology is now increasingly used not only at non-standard facilities, which is the Moscow City complex, but also in conventional construction in many large cities of the Russian Federation. Often this method is the only way out when sealing building is carried out.

While doing construction works within the city, and especially in its center, it is required to reduce the use of heavy equipment to a minimum. The height of truck cranes is much less than modern high-rise buildings, and they do not allow you to deliver concrete to the top, which is used to fill the floors. In this regard, at the construction site of the Moscow City complex, such a technical innovation as was used.

SANY concrete pumps were used to supply mortar to the enormous heights of the towers. At the same time, concrete grade B90, which is characterized by very low fluidity. The choice of concrete brand was made by the general contractor, based on the safety of the building. Buildings were built all year round even when the temperature dropped to -20°C. For this, the technique was adapted in a special way. It was equipped with a starting system that provides operation at low temperatures, heating hydraulic drive and a thick layer of thermal insulation.

According to the engineers, the concrete pump has become a necessary installation on the construction site. Without its use, the terms of work would have increased significantly, and time in such construction plays a decisive role. With the help of the application, up to 60 cubic meters of concrete per hour can be applied to the upper floors. During the construction of a residential neighborhood or several objects around the city, a concrete pump becomes a mandatory installation, without which the work goes much more slowly.

Quarter in Khamovniki in the English style

In the construction of residential, and especially luxury real estate, considerable attention is paid to giving buildings individuality from an architectural point of view. One such example is the Knightsbridge residential complex, in which the developer tried to convey the spirit of old London, in which there were quite intricate architectural forms. Despite complex façades and layouts, the deadlines for completion of such complexes are tight, and the busy schedule requires builders to look for new solutions that can reduce the turnaround time.

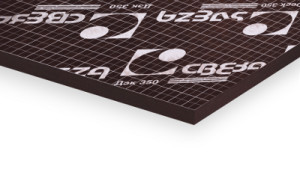

When creating Knightsbridge Private park, considerable attention was paid to the assembly of formwork. As is often the case, the result was a simple improvement in the process - the use of laminated plywood for concreting floors, on which a template grid was applied in advance. This greatly simplifies the marking and cutting of concrete formwork slabs at the construction site.

The use of plywood sheets makes it easier for the daily work that builders need to do - measuring and marking. When using laminated plywood with a marked grid, workers can easily measure the required distances. This mesh reduces the time it takes to lay the reinforcing bars. Lines running at intervals of 25 and 50 mm can serve as guides and with their help it is easy to maintain a step when laying reinforcement. The laminated plywood itself has an acrylic-based coating that protects the material from moisture.

Kazan-Arena and Otkritie Arena - platforms for new records

The opening of the International Universiade, held in Kazan, took place on July 6, 2013. The main venue for it was the new Kazan Arena stadium. Its construction was completed almost twice as fast as that of similar facilities, due to the use of modern methods of formwork.

If you take an interest in the duration of different stages of construction work at a monolithic construction site, you can see that the installation and dismantling of the formwork requires the most time. These processes are quite labor-intensive, and they largely determine the pace of construction. Significant savings in the time spent on the construction of the Kazan Arena made it possible to achieve the creation, connected by "quick locks".

The assembly of the system using this technology can be started immediately, when the formwork is brought to the construction site. Conventional formwork is assembled on site, which requires a lot of time. When moving to the next floor with a different layout, such formwork must be completely disassembled and redrawn, doing all the work, in fact, from scratch. And the formwork system, which consists of standard components, is much easier to install - the “quick locks” are disconnected, the elements are transferred to a new location and reconnected. Such a system has great durability.

During the construction of the Kazan Arena, PSK-CUP formwork of a beam-frame structure was used. It combined the advantages of both panel and beam-and-beam formwork systems, at the same time also acting as scaffolding. Such an innovative design made it possible to save the funds needed for the rental of scaffolding, their installation and dismantling.

construction of Otkritie Arena

The Spartak Stadium, also called the Otkritie Arena, located on the territory of the old Tushino airfield, is due to open in mid-2014. The final project was agreed only in 2010, which required the builders to speed up the work on pouring concrete. At the same time, they had to be carried out in the winter period, and the low temperature should not have a negative impact on the strength of concrete.

To ensure normal hardening, the concrete was heated using heat guns with electric heating elements. About 60% of the concrete work at the Otkritie Arena stadium was completed in the winter of 2011-2012. Great importance the formwork of the beam-frame structure PSK-CUP played. It provided resistance to high loads and temperature extremes.

During the construction of the Otkritie Arena, another new technology was used - connecting fittings using couplings. The use of such elements instead of welding rods and their knitting made it possible to significantly speed up the installation of reinforcement, since this operation required no more than 10 minutes.

Compared to bypass tying, sleeve connections reduce the consumption of reinforcing bars. Also, the advantage of this method is that it allows you to create a connection with equal strength along the entire length of the reinforcing cage. This ensures that the loads are evenly distributed across all the bars. A welded joint has an important drawback - the difficulty of controlling the quality of the seam. This requires bulky equipment that cannot be used in the field. Couplings provide high quality joint through the use of tapered threads.

Concrete prestressing, powerful mix pumps, laminated plywood with mesh, couplings and other new technologies make it easier for builders. Such technologies give companies an advantage over competitors and freedom of decision in the construction of complex buildings.

A monolithic multi-storey building is a serious object in which the heating, water supply, ventilation, power supply and sewerage systems are connected into a single whole.

The construction process is divided into several stages, which ultimately affects the time. Despite this, multi-storey buildings are increasingly being built precisely according to monolithic technology.

The main stages of the construction of multi-storey buildings using monolithic technology

Any construction high-rise building using monolithic technology - the procedure is long and painstaking. Moreover, this applies not only to the construction work itself, but also to the approval of the project and other paper documentation.

Consider the main stages of the construction of a monolithic high-rise building:

- 1. Perhaps the most difficult stage is connected just not with construction. To get started, you need obtain a building permit and select a suitable site. Then comes a difficult period of coordinating controversial issues with the local administration (given the complexity of the urban construction sector, this stage will take a huge amount of time and nerves).

- 2. On the allocated plot of land geological and topological exploration . It is necessary to correctly determine the type of soil and its composition, the depth of occurrence ground water, the level of soil freezing and other important indicators.

Pit for the construction of a residential building

Pit for the construction of a residential building  pile field under monolithic house

pile field under monolithic house  Removable formwork

Removable formwork  Removable wall formwork

Removable wall formwork

- 3. The most important step is development of a multi-storey building project . It includes all the necessary construction documentation: material calculation, engineering systems, sections, floor plans, final estimate. The project is the last paper document and after it the stages of construction work begin.

- 4. The site is being laid out and preparatory work is underway to prepare the foundation. Necessary dig a pit and drive piles under the foundation. After that, the installation of the frame from the reinforcement begins (use a rod of rectangular or round section). During the construction of a multi-storey building using monolithic technology, the frame plays an important role - it gives the structure the necessary rigidity.

- 5. Performed installation of removable formwork from wooden shields, polystyrene foam or plastic. You can use ready-made formwork. At the end of assembly, produce pouring concrete mortar with further tamping (use deep vibrators). Now it remains to wait for the complete drying and hardening of the mixture, after which the formwork is dismantled. Various additives can be used to speed up the process. According to this principle, they build floor by floor.

- 6. Insulation and facade finishing produced after the complete drying of the last layer of concrete. It takes at least 28 days, and even more in wet and cold weather.

- 7. At the final stage, the house connected to all necessary communications . After that, the territory adjacent to the house is ennobled.

Fixed formwork (example)

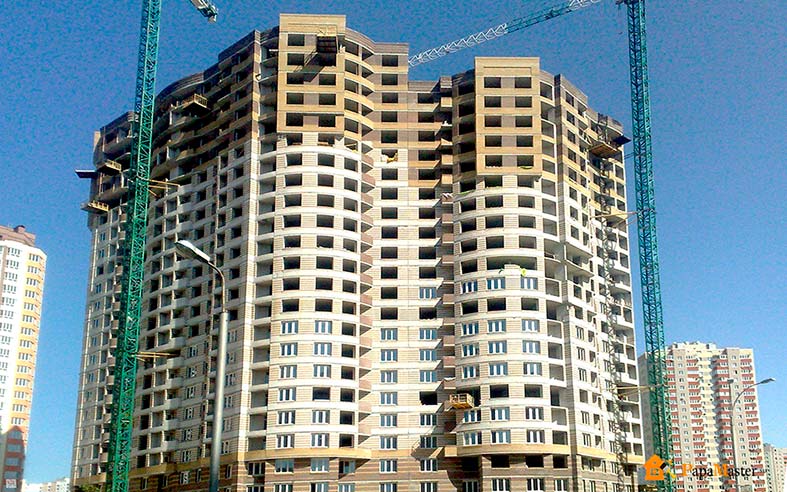

Fixed formwork (example)  Construction high-rise building by monolithic technology

Construction high-rise building by monolithic technology

Advantages of monolithic multi-storey buildings

Monolithic high-rise buildings have obvious advantages over brick and panel counterparts.

- First of all, it is worth highlighting their reliability and compactness.

- An important component is external attractiveness.

- An insulated and plastered monolithic high-rise building looks much better than a panel or brick one.

- In addition, very often, when building a multi-storey building using monolithic technology, additional architectural techniques and elements are used: ledges, bay windows, curved walls, window openings with original geometry.

- One of the key benefits is durability. Thanks to a special construction technology, monolithic construction has fewer joints, which can significantly increase the service life. Such buildings can be built in seismically active areas.

- Monolithic high-rise buildings are ideal as objects with a developed infrastructure. In the basement and first floors there is the possibility of arranging retail outlets, sports facilities, parking lots and other establishments.

Disadvantages of monolithic skyscrapers

The disadvantages include reasons that are not related to the operational characteristics of buildings. The main negative point is the likelihood of shifting the deadlines for the completion of the object. This happens due to an incorrect calculation or when the weather conditions worsen. This includes the complexity of the work, because not every company can master monolithic structure.

Issue price

It may seem that, taking into account the above characteristics, the cost of such a house is several times higher than the budget of similar buildings made of panels and bricks. In fact, their cost is approximately equal, and with a well-designed project, it can be even lower. An analysis of the real estate market shows that housing prices in monolithic high-rise buildings are 10-15% lower. Thus, this property can be considered an excellent investment.

Technologies of monolithic housing construction

Similar abstracts:

Short story development and improvement of building technologies. Construction of the National Library of Belarus with the help of high technologies. Role modern technologies in the construction of wooden cottages and cottage settlements.

Analysis of modern construction technologies. Features of the Royal Building System method - building structures intended for pouring concrete. Construction principle monolithic building. frame houses(Canadian technology for the construction of wooden houses)

Bifunctional residential buildings. Metal structures of buildings of complex delivery. Progressive types of insulation for the walls of buildings. Implementation of external insulation systems. mansard roof and ventilation. Types of roofing cake for insulated attics.

Social demands for housing. Demography of the population and the structure of the housing stock. Urban planning factors, number of storeys of designed buildings. Compositional and artistic features. Space-planning structure of a residential building, building materials.

Determination of the specifics of the typology of housing construction. Types of houses: sectional, corridor, gallery. Ordinary, rotary and face sections. Social features of housing design. Architectural and aesthetic requirements for the organization of the apartment.

Advantages of the construction of volume-block buildings, the feasibility of using the method. Technology of mounting elements, its sequence; assembly mechanisms. Technological sequence of works, sealing of joints of external panels.

Types of architectural solutions one-story house: one-, two-, four- and eight-apartment apartments. Characteristics of blocked houses: cross-blocked, on relief, special types. Varieties of designs of one-story houses, requirements for their reliability.

The advantages of frame houses in comparison with other structures, their cost, manufacturability, thermal properties. Features of construction: types and manufacture of frames, external and internal cladding, cladding, partitions, used heaters.

Structural solutions of the building and its engineering characteristics. Calculation of volumes of materials. Construction equipment and mechanisms. Technological operations for the construction of the facility. Normative labor costs. Estimated cost of construction.

Design of an 18-storey residential building from monolithic reinforced concrete, a residential building with a hidden crossbar and a 2-storey residential building. Engineering and technical equipment of the building. Foundations, walls and partitions, overlapping and covering, stairs, roofing.

Foundations of low-rise buildings and the main reasons for their high cost. Strip foundations for residential and public buildings with basement. Kinds building materials for low-rise construction. Types of building construction. Comparison of economic efficiency.

The study of the properties of stone materials, the use of artificial stone in constructive solutions for building walls. Types of artificial materials and their differences from natural stone material. The use of porcelain stoneware in the installation of ventilation facades.

The layout of large-sized shields and blocks. Preparation of labor and cost estimates concrete works. Ways of supply, laying concrete mix. Choice of erection crane for supplying formwork, reinforcement and installation of structures, concrete-laying equipment.

Residential houses from volume-spatial blocks. Buildings from prefabricated blocks, rooms and apartments. Advantages of building houses using block-room technology, equipment and design support. Classification of the sizes of spatial elements.

Development of a project for the construction of the above-ground part of the building with load-bearing structures from monolithic reinforced concrete: the choice of the method of production of work, the calculation of labor costs, quality control of production, assessment of the need for inventory and tools.

North America as a leader in the construction of skyscrapers. The design of Canadian houses. Material and technological support of construction. Architectural expressiveness of the house. Internal communications: water supply, sewerage, heating system wiring.

Individual residential building. Blocked houses. Space-planning solutions for blocked houses. Flexible layout of apartments. Stair and lift units used in multi-storey buildings. Structural solutions for multi-storey residential buildings.

Trends in the development of housing construction. Factors influencing the choice of optimal design solutions. The structure of the state and cooperative construction of residential buildings. Economic efficiency of reducing the materials of the outer walls of residential buildings.